Escolar Documentos

Profissional Documentos

Cultura Documentos

Supercritical Fluid Extraction of Vegetable Matrices

Enviado por

AlexRiveraDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Supercritical Fluid Extraction of Vegetable Matrices

Enviado por

AlexRiveraDireitos autorais:

Formatos disponíveis

J.

of Supercritical Fluids 92 (2014) 115176

Contents lists available at ScienceDirect

The Journal of Supercritical Fluids

j our nal homepage: www. el sevi er . com/ l ocat e/ supf l u

Review

Supercritical uid extraction of vegetable matrices: Applications,

trends and future perspectives of a convincing green technology

M.M.R. de Melo, A.J.D. Silvestre, C.M. Silva

CICECO, Department of Chemistry, University of Aveiro, Aveiro 3810-193, Portugal

a r t i c l e i n f o

Article history:

Received 20 January 2014

Received in revised form31 March 2014

Accepted 1 April 2014

Available online 24 April 2014

Keywords:

Supercritical uid extraction

Optimization

Modeling

Scale-up

Economic analysis

Biomass

Trends

a b s t r a c t

Along more than a decade, R&D on supercritical uid extraction (SFE) of vegetable matrices has been

increasingly reported in the literature. Aiming at portraying the current state of this eld and its evo-

lution in terms of raw materials, products, modes of operation, optimization, modeling techniques, and

closeness to industrial application, a large compilation of almost 600 essays from 2000 to 2013 has

been deeply analyzed in order to unveil those indicators and their trends. Furthermore, strengths and

weaknesses are identied, and some remarks that may drive upcoming research are provided.

Globally, more than 300 species are reported in the literature, with prevalence of the extraction of seeds

(28% of works) and leaves (17%). The main families of extracted compounds, cosolvents and operating

conditions adopted are critically examined, being possible to conclude that researchers investigate many

times working regions far from the optimum due to practical limitations or absence of experimental

optimization. Current phenomenological, statistical and semi-empirical approaches are reviewed, along

with scale-up studies, and economic analysis. In the whole, the most comprehensive picture over SFE of

vegetable matrices is provided in this review, highlighting pertinent aspects and opportunities that may

further consolidate the convincing route of this technology for the next years.

2014 Elsevier B.V. All rights reserved.

Contents

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

2. Biomass matrices and naturally occurring molecules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

3. Focuses of SFE works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

4. Operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

4.1. Pressure and temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

4.2. Solvent power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

4.3. Cosolvent addition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

4.4. Flow rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

5. Modeling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

5.1. Subsidiary relations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

5.2. Extraction models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

5.3. Statistical models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

6. Scale-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

7. Economic analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

8. Final remarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Acknowledgements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Corresponding author. Tel.: +351 234 401549; fax: +351 234 370084.

E-mail address: carlos.manuel@ua.pt (C.M. Silva).

http://dx.doi.org/10.1016/j.supu.2014.04.007

0896-8446/ 2014 Elsevier B.V. All rights reserved.

116 M.M.R. de Melo et al. / J. of Supercritical Fluids 92 (2014) 115176

1. Introduction

In the last 13 years (20002013), the extracts of more than 300

plant species have been studied using supercritical uid extraction

(SFE) technology. It is worth noting the major share of SFE research

covers vegetable biomass [1,2]. While many extracts andpure com-

ponents of these species are already in use for human nutrition

and health purposes, others represent potentially newapplications

involving plants whose knowledge, in most of the cases, has been

empirically established or still lacks scientic coverage.

The remarkable interest of scientic community on this tech-

nology has been driven by the great versatility of carbon dioxide,

the most used solvent in supercritical state, whose properties can

be tuned in order to provide extracts with desirable compositions

(selectivity enhancements), while at the same time it ensures an

innocuous separation process both to human health and to the

environment. Other solvents (e.g. ethane, propane) have also been

object of research but their use is not as widespread as carbon

dioxide, and for this reason the emphasis of this reviewis on super-

critical carbon dioxide (SC-CO

2

).

Among the vast group of species that have been studied under

the scope of SFE, some have appeared in great number in liter-

ature since 2000. It is the case of grape (Vitis vinifera L.) [325]

tomato (SolanumlycopersicumL.) [2635], thyme (Thymus vulgaris

L.) [3644], eucalypt (Eucalyptus spp.) [4553], coffee (Coffea spp.)

[5462], sunower (Heliantus annuus L.) [6369], ax (Linum usi-

tatissimum) [7075], rosemary (Rosmarinus ofcinalis L.) [7683],

red pepper (Capsicum anuum L.) [8490], and rice (Oryza variety)

[9197].

In what concerns food related species, the great expansion

of nutraceuticals market in recent years, as an emerging sector

comprising the use of dietary substances for prevention of dis-

eases [98], has been attracting the attention of researchers and

food industry. In this context, SFE is advantageously positioned

as a sustainable and safe extraction option for the preparation

of plant extracts for supplements and nutrient enriched products

in which, as Perrut anticipated in 2000 [99], the natural charac-

ter of the preparation mode has a high marketing value. Besides

those requisites, when SFE is applied to eatable raw materials

as a pretreatment for removal of compounds (e.g. cleaning of

rice), other advantages are also observed, such as the enhance-

ment of product shelf life and, eventually, the shortening of the

cooking time [1]. In addition, research on this eld has also

explored the valorization of residues from main stream processes

[100,101].

As aresult, asubstantial number of dairyplant products has been

object of SFE technology, such as, among others, apricot (Prunus

armeniaca L.) [102106], carrot (Daucus carota L.) [107110],

cashew (Anacardium occidentale L.) [111114], cocoa (Theobroma

cacao) [115117], garlic (Allium sativum L.) [118121], ginger

(Zingiber ofcinale) [122126], ginseng (Panax spp.) [127130],

laurel (Laurus nobilis L.) [131135], orange (Citrus sinensis L.)

[136140], oregano (Origanum spp.) [141145], pumpkin (Cucur-

bita spp.) [146150], soybean [151156], turmeric (Curcuma longa

L.) [157161], and wheat germ(Triticumspp.) [162167].

Following a major trend of western pharmaceutical industry

of integrating oriental folk medicine species that have been used

for centuries in natural formulations for a myriad of health prob-

lems, extracts of a signicant number of species used in those

contexts have been prepared using SFE. Although many species

are still to be recognized for their health/nutrition benets by

health authorities such as World Health Organization, others have

seen their bioactivity conrmed, such as on the cases of Acorus

calamus [168], Andrographis paniculata [169], Azadirachta indica

[170173], Curcuma longa [157161], Cyperus rotundus [174], Oci-

mum gratissimum [175,178,179], Panax ginseng [127,129], Taxus

baccata L. [180]. Its application has been directed by the inter-

est to isolate and quantify phytopharmaceuticals existing in those

extracts so that further pharmacological studies canthenbe carried

out in order to conrm the respective bioactivities. An elucidat-

ing perspective on this research path was recently published for

the case of triterpenoid compounds, either with respect to their

extraction with SC-CO

2

[181], either in terms of the correspond-

ing bioactivity studies that support their therapeutic potential

[182].

This review intends to document and systematize the pro-

gresses of supercritical CO

2

extraction research upon natural

extracts, with emphasis on raw materials, products, modes of

operation, optimization, modeling techniques, and closeness to

industrial application. A large compilation of almost 600 essays

from 2000 to 2013 has been deeply analyzed in order to unveil

indicators and trends. It is expected that this compilation and dis-

cussion provide hints and suggestions to researchers with respect

to the different aspects that contribute to the nal viability of SFE

technologies and, thus, to its widespread implementation at com-

mercial level.

The review is structured in the following way: Section 2 is

devoted to the presentation of biomass matrices and naturally

occurring molecules, followed, in Section 3, by the focuses of SFE

research. In Section 4, aspects related to the operation of SFE units,

the impact and optimization of process variables are covered. Mod-

eling is introducedinSection5, anddiscussedinterms of empirical,

simplied, comprehensive andstatistical approaches. The next two

sections highlight the scale-up (Section 6) and economic analysis

(Section 7). Final remarks conclude the reviewin Section 8.

2. Biomass matrices and naturally occurring molecules

When overviewing the eld of vegetable matrices extracts for a

period larger than a decade, a vast group of species arises as issue of

SFE research, hence revealing the strong interest and attention that

supercritical uids have conquered. A wide-ranging compilation

of works in this eld is presented in Table 1, sorted by the scien-

tic names of plant species substrates. Information regarding the

vegetable species, target molecules andoperating conditions (pres-

sure, temperature, solvent ow rate, and cosolvent content) are

provided for each SFE publication, as well as the respective analyt-

ical techniques employed and complementary features about each

work.

Considering the representative number of works covered in this

review, it is possible to depict some structural tendencies regard-

ing the directions research has followed in this eld, such as the

characteristics of the biomass matrices that have been most stud-

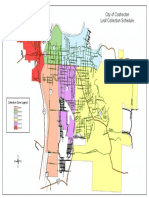

ied. Accordingly, Fig. 1 presents a statistical distribution of the

vegetables matrices types mostly found on SFE publications. It

becomes clear that supercritical uids have been mainly applied

to the extraction of seeds and leaves. Together, they represent 45%

of the plant fractions of all the works considered, being seeds the

biggest fraction (28%), and leaves (17%). They are followed by fruits

(10%), roots (7%), owers (5%), rhizomes (3%) and bark (2%). On the

other hand, parts such as stems, branches, and woods seem not

to justify individual studies of SFE, being instead included only in

cases where matrices comprise mixtures of components, such as

aerial parts, which account for 9% of the researched matrices. In

addition, processed vegetables like pomace or husks represent 5%

of the 544 SFE publications considered.

In view of the vast diversity of molecules found in natural

matrices, vegetables are typically matter of research for more

than one application. Depending on the species and plant com-

ponent studied, SFE processes can be devoted to many naturally

occurring compounds. Furthermore, SFE extracts obtained from

vegetable matrices are typically mixtures of the following family

M

.

M

.

R

.

d

e

M

e

l

o

e

t

a

l

.

/

J

.

o

f

S

u

p

e

r

c

r

i

t

i

c

a

l

F

l

u

i

d

s

9

2

(

2

0

1

4

)

1

1

5

1

7

6

1

1

7

Table 1

Publications comprising SFE vegetable rawmaterials from2000 to 2013, and their respective features.

Scientic name Common name Plant part Target Extraction

yield (wt%)

P (bar) T (

C) CO

2

& co-solvent Analytical technique Other Features Ref.

Berries Fruit Phenolic 1.45.20 80300 60 EtOH GCMS Antioxidant activity [242]

Tea Seed 730 300400 6080 1020 L

CO2

kg

1

sample

015% EtOH

Gravimetric Soxhlet extraction

Sonication

ANOVA

[243]

Cuphea Seed 28.1 270 50 15 kg

CO2

kg

1

sample

GC Acid value

Gardner color

FAME

[244]

Abutilon hybridum

Malvaviscus drummondii,

Pavonia hastata,

Pavonia. lasiopetala

Sida spinoza

Hibiscus Seed 11.4 534 80 20 L

CO2

kg

1

sample

FAME

GC-FID

Soxhlet extraction [245]

Achyrocline satureioides Macela Flower 8796 200300 3035 416 kg

CO2

kg

1

sample

GCMS Modeling [246]

Acori graminei Rhizome -Asarone 2.53.0 80140 3555 960 L

CO2

kg

1

sample

GCMS Hydrodistillation [247]

Agrimonia eupatoria

Agrimonia procera

Leaf 04.3 150350 3542 1% EtOH HPLC [248]

Alkanna tinctoria Alkannin 50300 3080 30 kg

CO2

kg

1

sample

HPLC RSM

DoE

[249]

Allium cepa L. Onion Bulb Sulphur 0.62.5 100300 4565 2941 kg

CO2

kg

1

sample

GCMS Pilot scale

Two-step decompression

system

Steam distillation

Soxhlet extraction

[250]

Allium cepa L. Onion Bulb 0.0050.025 103287 30950 200800 L

CO2

kg

1

sample

Gravimetric Analysis

GCMS

Adsorbent bed [251]

Allium cepa L. Onion Bulb 0.2954.68 160240 3545 66220 L

CO2

kg

1

sample

GCMS RSM

DoE

[252]

Allium sativum L. Garlic Bulb 3-Vinyl-4H-1,2-dithiin 0.81 100 4555 3L

CO2

kg

1

sample

GC

GCMS

DoE

RSM

[119]

Allium sativum L. Garlic Flake Allicin 0.42.3 150450 3565 97 kg

CO2

kg

1

sample

HPLC Modeling [121]

Allium sativum L. Garlic Flake 0.61.0 140400 3560 1.8 kg

CO2

kg

1

sample

HPLC [120]

Allium sativum L. Garlic Clove Allicin 240 35 HPLC [118]

Alnus glutinosa (L.) Gaertn Bark Betulin,

betulinic acid,

lupeol

1.53.8 300450 4060 010% EtOH

545kg

CO2

kg

1

sample

TLC

GCMS

LCMS

RP-HPLC

Soxhlet extraction [253]

Aloe barbadensis Miller Aloe vera Leaf 0.131.5 350450 3250 020% (v/w) MeOH Gravimetric analysis DoE

Antioxidant activity

[254]

Alpinia oxyphylla Seed 1.362.80 2040 4565 RSM

DoE

[255]

Amaranthus caudatus Amaranth Seed Tocopherols, fatty acids,

sterols

3.48.3 200400 40 5600 L

CO2

kg

1

sample

HPLC

GC

GCMS

Ultrasound extractions [222]

Amaranthus caudatus Amaranth Seed 46 200400 40 5.6 L

CO2

kg

1

sample

HPLC

GC-FID

Organic solvent extraction

Ultrasound extraction

[256]

Amaranthus caudatus Amaranth Seed Squalene 06 150250 4070 4000 L

CO2

kg

1

sample

HPLC Particle size effect [198]

Amaranthus cruentus Amaranthus Bract 0.54.8 100300 4070 100 kg

CO2

kg

1

sample

Gravimetric analysis Soxhlet extraction

Solubility

Flowrate effect

Modeling

[257]

Amaranthus paniculatus Amaranth Seed Squalene 110280 60100 1200600 L

CO2

kg

1

sample

HPTLC Modeling

DoE

[199]

Ammi majus Seed Furocoumarins 250550 4080 10% EtOH

20160kg

CO2

kg

1

sample

1

H NMR SC chromatography [232]

Anacardium occidentale L. Cashew Anacardic acid 060 300 4060 HPLC Modeling [111]

Anacardium occidentale L. Cashew Fruit Cardanol 225300 50 845 kg

CO2

kg

1

sample

GCMS Cost optimization [113]

Anacardium occidentale L. Cashew Fruit 123 200300 4060 GCMS Modeling

Flow rates effect

Thermal method comparison

[112]

1

1

8

M

.

M

.

R

.

d

e

M

e

l

o

e

t

a

l

.

/

J

.

o

f

S

u

p

e

r

c

r

i

t

i

c

a

l

F

l

u

i

d

s

9

2

(

2

0

1

4

)

1

1

5

1

7

6

Table 1 (Continued)

Scientic name Common name Plant part Target Extraction

yield (wt%)

P (bar) T (

C) CO

2

& co-solvent Analytical technique Other Features Ref.

Anacardium occidentale L. Cashew Shell 1.14.0 147294 4060 411 L

CO2

kg

1

sample

Gravimetric analysis Fractionation [114]

Andrographis paniculata Hempedu bumi Leaf Andrographolide 80240 4070 015% EtOH

015% H

2

O

015% Acetic acid

X-ray diffraction

HPLC

Purication objective

SEM

[169]

Andrographis paniculata Hempedu Bumi Leaf Andrographolide 100 40 HPLC

TLC

Modeling

Particle sizes effect

[258]

Anemopsis californica Yerba mansa Leaf 56 355 100 28 L

CO2

kg

1

sample

GCMS Steam distillation [259]

Angelica archangelica L. Angelica Root 90120 4060 GCMS Hydrodistillation [260]

Angelica dahurica 24 250350 4450 21,81843,636 L

CO2

kg

1

sample

(75% EtOH/25% H

2

O)

GCMS DoE [261]

Angelica gigas Nakai

Angelica sinensis

Angelica acutiloba

Angelica Rhizome 0.48 296 80 60 L

CO2

kg

1

sample

GCMS Solid-phase microextraction [262]

Angelica sinensis (Oliv.) Diels

(Umbelliferae)

Root Ferulic acid 0.84.0 300500 4565 040 kg

CO2

kg

1

sample

EtOH

HPLC Particle sizes effect [263]

Anoectochilus roxburghii Herb Phytosterols

-Sitosterol, stigmasterol

250 45 50 L

CO2

kg

1

sample

H

2

O

HPLC

APCI

MS

Soxhlet extraction

DoE

[221]

Apium graveolens L. Celery Seed 023 100200 45 10150 kg

CO2

kg

1

sample

Modeling [264]

Arbutus unedo L. Strawberry Fruit Phenols

150300

4080 30 kg

CO2

kg

1

sample

020% (w/w) EtOH

RSM

DoE

Antioxidant activity

[265]

Arrabidaea chica (Humb.

Bonpl.)

Leaf Anthocyanins 03.6 300 40 020% EtOH

0140 kg

CO2

kg

1

sample

HPLC Fractionation

Organic solvent extraction

[266]

Artemisia absinthium L. Wormwood Leaf + ower 0.753.66 90180 4050 88447 kg

CO2

kg

1

sample

EtOH

[267]

Artemisia annua L. Wormwood Leaf Artemisinin 07 75400 3050 0400 kg

CO2

kg

1

sample

GC-FID DoE

Hydrodistillation

Soxhlet extraction

Modeling

[196]

Artemisia arborescens L.

Helichrysum splendidum

(Thunb.) Less

Leaf 0.10.4 90 50 14 kg

CO2

kg

1

sample

GCMS Hydrodistillation [268]

Artemisia capillaris T. Whole plant Capillarisin 173 50 7.5 (wt)% ethyl-acetate Bioactivity test

DoE

RSM

[269]

Artemisia sieberi Wormwood Aerial parts Camphor 1.714.9 101304 3565 1.84.2 L

CO2

kg

1

sample

GC

GCMS

Hydrodistillation

DoE

[211]

Atractylode lancea Root 2.310.3 150250 4060 2262 L

CO2

kg

1

sample

GCMS DoE [270]

Atractylodis macrocephalae Baizhu Rhizome 3.676.76 150450 4060 54 L

CO2

kg

1

sample

[271]

Azadirachta indica A. Juss Neem Seed 585 100260 3055 4.726 L

CO2

kg

1

sample

010% MeOH

HPLC dp, Q effects [171]

Azadirachta indica A. Juss Neem Seed 570 100260 3560 02.7 L

CO2

kg

1

sample

Gravimetric dp effect

Modeling

Q effects

[173]

Azadirachta indica A. Juss Neem Seed 085 100260 3560 2186 L

CO2

kg

1

sample

Gravimetric analysis Modeling

Effect of particle size

[172]

Azadirachta indica A. Juss Neem Seed Nimbin 00.02 100260 3560 1253 kg

CO2

kg

1

sample

HPLC [170]

Baccharis dracunculifolia Baccharis Leaf DHCA, PHCA, p-coumaric

acid, kaempferide

2.44.7 200400 4060 85 kg

CO2

kg

1

sample

HPLC Soxhlet extraction [272]

Baccharis dracunculifolia, Baccharis Branch and leaf (E)-nerolidol; spathulenol 0.38 90120 4060 340 L

CO2

kg

1

sample

GC

GCMS

ODS trap (n-hexane)

Hydrodistillation

[273]

Baccharis trimera Baccharis Branch and leaf 1.72.3 90 4070 80 L

CO2

kg

1

sample

GC

GCMS

Modeling [274]

Baccharis trimera Baccharis Stem and leaf 0.32.0 100300 3040 GCMS Modeling

Solvent extraction

[275]

Betula pendula Roth Birch Leaf Amino acids 100400 35100 MeOHH

2

Oacetonitrile HPLC-FLD Soxhlet extraction [276]

Bixa orelana L. Annatto Seed Carotenoid bixin 145 200300 5060 100 kg

CO2

kg

1

sample

5% EtOH

Gravimetric analysis Modeling

Flow rates effect

Particle sizes effect

[277]

Bixa orelana L. Annatto Seed Bixin 100350 3050 GC-FID Modeling [278]

Bixa orelana L. Annatto Seed Bixin 1.43.5 200400 4060 35482 kg

CO2

kg

1

sample

UVvis

spectrophotometer

HPLC

Economic analysis

Scale-up

Modeling

[279]

M

.

M

.

R

.

d

e

M

e

l

o

e

t

a

l

.

/

J

.

o

f

S

u

p

e

r

c

r

i

t

i

c

a

l

F

l

u

i

d

s

9

2

(

2

0

1

4

)

1

1

5

1

7

6

1

1

9

Borage ofcinalis L. Borage Seed -Linolenic acid 00.18 0350 3060 375015,000 L

CO2

kg

1

sample

GC Soxhlet extraction [280]

Borage ofcinalis L. Borage Seed Fatty acids 030 200300 4060 0130 kg

CO2

kg

1

sample

GC Modeling

Soxhlet extraction

[185]

Borago ofcinalis L. Borage Seed Caprylic acid methyl ester 0.124.3 100350 40 120 kg

CO2

kg

1

sample

02% EtOH

GC [281]

Borago ofcinalis L. Borage Seed 030 200300 55 060 kg

CO2

kg

1

sample

Bed length effect

Flowrate effect

SEM

[691]

Borago ofcinalis L. Borage Seed 957 150250 3060 1000 L

CO2

kg

1

sample

HPLC

GCMS

Soxhlet extraction [282]

Brassica napus L. Rapeseed Seed 512 300 40 10130 kg

CO2

kg

1

sample

Gravimetric analysis Modeling [283]

Brassica napus L. Rapeseed Seed 7.728.1 200300 4060 626 kg

CO2

kg

1

sample

GCMS RSM

Modeling

Soxhlet extraction

[284]

Brassica napus L. Rapeseed Seed 1847 517 100 Gravimetric analysis Solvent extraction

Vortex extraction

[156]

Brassica napus L. Canola Press cake Phenolics 2.110.3 300500 4060 10% EtOH

61kg

CO2

kg

1

sample

HPLC [285]

Brassica oleracea Broccoli Leaf Amino acids 1 100250 5080 2035% (v/v) MeOH GCMS Solvent extraction [286]

Bunium persicum Boiss.

Mespilus germanica L.

Black cumim

Medlar

Seed

Seed

Benzaldehyde

-Terpinene

200 45 2 L

CO2

kg

1

sample

GCMS Hydrodistillation [287]

Bupleurum falcatum Root Saikosaponins 918 300400 4050 2400 L

CO2

kg

1

sample

9% (v/v) EtOH

HPLC DoE [288]

Cajanus cajan Pigeonpea Leaf Cajaninstilbene acid

pinostrobin

0.21.3 200400 4070 EtOH HPLC Antioxidant activity

DoE

SEM

RSM

[289]

Calendula ofcinalis L. Marigold Flower Faradiol 5 500 50 105 kg

CO2

kg

1

sample

LPLC

HPLC

Preparative HPLC [290]

Calendula ofcinalis L. Marigold Flower 02.6 120200 2040 030 kg

CO2

kg

1

sample

Gravimetric analysis Modeling [291]

Calendula ofcinalis L.

Matricaria recutita

Marigold

Chamomile

Flower 01.8 90100 4050 035 kg

CO2

kg

1

sample

Soxhlet extraction

Hydrodistillation

Modeling

SEM

Particle sizes effect

[292]

Calendula ofcinalis L. Marigold Flower 3.8 100200 2040 50 kg

CO2

kg

1

sample

GC

GCMS

Modeling

Solvent extraction

[293]

Calendulae os

Crataegus ssp.

Matricaria recutita L.

Marigold

Hawthorn

Chamomile

Flower Phenolic 0.55.5 300689 50 016 L

CO2

kg

1

sample

0.520% (v/v) EtOH

HPLC

HPLC-PAD-MS

GC

[294]

Camellia sinensis L. Tea (green) Seed 14.829% 5090 3545 4001800 L

CO2

kg

1

sample

HPLC RSM

DoE

Antioxidant activity

[295]

Camellia sinensis L. Tea (green) Leaf Caffeine 150300 4560 62.5625 L

CO2

kg

1

sample

HPLC Ultrasonic assisted

Moisture effect

DoE

[296]

Camellia sinensis L. Tea (green) Leaf Epigallocatechin gallate 100300 4060 30240 L

CO2

kg

1

sample

HPLC Modeling

Soxhlet extraction

[297]

Cannabis sativa L. Hemp Seed 17.322.1 300400 4080 3060 kg

CO2

kg

1

sample

GCMS Soxhlet [298]

Cannabis sativa L. Hemp Seed 1021 250350 4060 19kg

CO2

kg

1

sample

GC-FID RSM

DoE

Particle sizes effect

[299]

Capsicum annuum L. Red pepper Seed, fruit, stem Vitamin A and E 200300 45100 100133 L

CO2

kg

1

sample

EtOH (13% v/v)

Microencapsulation [86]

Capsicum annuum L. Paprika Fruit Carotenoid 8185 300500 6080 270 kg

CO2

kg

1

sample

Spectrophotometry Fractionation [88]

Capsicum annuum L. Paprika Fruit 450 50 1547 kg

CO2

kg

1

sample

Soxhlet extraction

Particle sizes study

Modeling

[85]

1

2

0

M

.

M

.

R

.

d

e

M

e

l

o

e

t

a

l

.

/

J

.

o

f

S

u

p

e

r

c

r

i

t

i

c

a

l

F

l

u

i

d

s

9

2

(

2

0

1

4

)

1

1

5

1

7

6

Table 1 (Continued)

Scientic name Common name Plant part Target Extraction

yield (wt%)

P (bar) T (

C) CO

2

& co-solvent Analytical technique Other Features Ref.

Capsicum annuum L. Paprika Seed 010 200400 40 GCMS

HPLC

Solvent extraction

Soxhlet extraction

[89]

Capsicum annuum L. Jalape no Flake 00.11 120320 40 HPLC Modeling [84]

Capsicum annuum L. Red pepper Flake 155 320540 40 0160 kg

CO2

kg

1

sample

HPLC Soxhlet extraction

Micrograph

Fractal analysis

Pelletization

Modeling

[87]

Capsicum annuum L. Red pepper Fruit 0.72.2 100500 4060 0370 kg

CO2

kg

1

sample

GCMS

GC-FID

SEM

Use of biotic elicitor

[90]

Capsicum frutescens L. Red pepper Fruit 16 162230 40 Gravimetric analysis DoE

RSM

Rancimat test

DSC

Velocity effect

[300]

Capsicum frutescens L. Red pepper Seed Capsaicinoids 1590 162218 40 7168 kg

CO2

kg

1

sample

HPLC Soxhlet extraction

DoE

RSM

[301]

Capsicum spp.

Piper nigrum

Zingiber ofcinale

Chili

Black Pepper

Ginger

Piperine 4.112.0 300 40 030 kg

CO2

kg

1

sample

1

H NMR spectroscopy Soxhlet extraction [124]

Carthamus tinctorius Safower Seed 1040 220280 3540 7243 kg

CO2

kg

1

sample

GC-FID Particle size effect

Modeling

Pilot scale

[302]

Carum carvi L. Caraway Fruit Limonene

carvone

19 70400 80 03% MeOH

03% EtOH

03% Acetone

03% Acetonitrile

03% Hexane

03% Dichloromethane

03% Chloroform

03% Toluene

GCMS

GC-FID

HPLC

Harvest time effect

Particle sizes effect

[207]

Carum carvi L. Caraway Seed Carvone

limonene

5080 2860 FT-IR

GC-FID

Analytical technique study [303]

Carum carvi L. Caraway Seed 90 50 GCMS Hydrodistillation [304]

Carum copticum Carum Seed 1.05.8 101304 3555 13.5 L

CO2

kg

1

sample

GC

GCMS

Hydrodistillation

ANOVA

[305]

Cassia tora Juemingzi Seed 0.27 250 45 GC-FID

GCMS

[306]

Catharanthus roseus Leaf Terpenoid indole alkaloids

(Vindoline, catharanthine)

200400 4080 0.30.9 L

CO2

kg

1

sample

MeOH 2.26.6% v/v

HPLC DoE

Soxhlet extraction

Ultrasonic solidliquid

extraction

Water extraction

[307]

Ceratonia siliqua L. Carob tree 00.45 (%) 150220 4160 HPLC Antioxidant activity

DoE

[308]

Chamomilla recutita L. Chamomile Flower 0.54.3 100200 3040 3 kg

CO2

kg

1

sample

GCMS

GC

Modeling [309]

Chamomilla recutita L.

Rauschert

Chamomile Flower 1.9 90 40 92 kg

CO2

kg

1

sample

HPLC

GC

In-line inclusion [310]

Chrysobalanus icaco Abajeru Leaf Lupenol 0.95 105200 4080 58148 L

CO2

kg

1

sample

GC-DIC

GCMS

Soxhlet extraction

Hydrodistillation

[311]

Cinnamomum zeylanicum Cinnamon Bark Tyrosinase

melanin

90120 4050 GCMS Soxhlet extraction

Hydrodistillation

[312]

Cistus ladanifer L. Roc Rose Leaf Labdanum 0.10.5 80100 3070 28 kg

CO2

kg

1

sample

GC Two-step decompression

system

[216]

Citrullus lanatus Watermelon Fruit Lycopene 0.0010.004 207414 7090 90 L

CO2

kg

1

sample

1015% EtOH

HPLC [205]

Citrullus lanatus

Hibiscus sabdarriffa Lin

Kalahari melon

Roselle

Seed Tocopherols 200400 4080 HPLC RSM

DoE

[224]

Citrullus lanatus Kalahari melon Seed Phytosterol 59.578.5 200400 4080 72 L

CO2

kg

1

sample

GC-FID RSM

DoE

[313]

M

.

M

.

R

.

d

e

M

e

l

o

e

t

a

l

.

/

J

.

o

f

S

u

p

e

r

c

r

i

t

i

c

a

l

F

l

u

i

d

s

9

2

(

2

0

1

4

)

1

1

5

1

7

6

1

2

1

Citrus depressa Fruit Nobiletin, tangeretin 0.41.6 200400 4080 32L

CO2

kg

1

sample

EtOH

HPLC Particle size effect [314]

Citrus grandis L. Osbeck Pomelo Fruit Flavonoids 1.72.4 280420 6080 515 L

CO2

kg

1

sample

Gravimetric Analysis Antioxidant activity

RSM

DoE

Conventional solvent

extraction

[241]

Citrus junos Yuzu Seed 1028 200500 4070 GC-FID Soxhlet extraction [315]

Citrus latifolia

Tanaka

Lime Fruit Limonene 1.63.6 90110 4060 60320 L

CO2

kg

1

sample

GC

GCMS

Hydrodistillation [316]

Citrus maxima Merr Peel 276345 4050 3600 L

CO2

kg

1

sample

HPLC [317]

Citrus paradisi L. (variety Ruby

Red)

Citrus plants Peel Naringin 78108 4095 515% EtOH HPLC Maceration extraction

Reux extraction

[318]

Citrus paradisi Macf. Grapefruit Seed Limonoids

naringin

0.10.6 345483 4060 1030% EtOH

8.6L

CO2

kg

1

sample

HPLC DoE

RSM

Multistep extraction

[319]

Citrus sinensis Korean orange Peel Perillyl alcohol 00.9 150200 3060 GC [137]

Citrus sinensis Korean orange Peel Perillyl alcohol 04.4 200 50 84kg

CO2

kg

1

sample

GC Pilot plant [136]

Citrus sinensis Orange Fruit 613 200 40 20100 kg

CO2

kg

1

sample

Gravimetric analysis Modeling

Diatomaceous earth

Scale-up

[138]

Citrus sinensis,

C.limon

C. reticulata

Cytrus Seed 02.41 85490 40 GC-FID

GC-EM

Organic solvent extraction

Extractors effect

Fractionation

[140]

Citrus sinensis. L. Osbeck Orange Pomace L-limonene

palmitic and oleic acids

n-Butyl benzenesulfonamide

-sitosterol

0.853 100300 4050 0340 kg

CO2

kg

1

sample

28% (wt.) EtOH

GCMS Antioxidant capacity

Ultrasound

Soxhlet extraction

[139]

Citrus unshiu Press cake Carotenoids 172448 70 020% EtOH RSM

DoE

[320]

Cocos nucifera L. Coconut Kernel 9.864.7 517 120 410 L

CO2

kg

1

sample

Soxhlet extraction

Diatomaceous earth

[321]

Coffea arabica Coffee Husk/spent 0.59.7 100300 4060 101189 kg

CO2

kg

1

sample

415% (wt.) EtOH

HPLC Modeling

Soxhlet extraction

Antioxidant activity

[54]

Coffea arabica

Coffea robusta

Coffee Residue Kahweol

cafestol

16-O-methylcafestol

012 140190 4070 91kg

CO2

kg

1

sample

GC-FID DoE

RSM

Soxhlet extraction

[62]

Coffea arabica

Coffea robusta

Coffee Residue 15 190 4055 85kg

CO2

kg

1

sample

Gravimetric analysis Economic analysis

Tryacylglicerides prole

[61]

Coffea arabica Coffee Bean Cafestol, kahweol 235380 6090 62.5 L

CO2

kg

1

sample

HPLC Soxhlet extraction

DoE

[55]

Coffea arabica Coffee Bean Caffeine 017 152352 5070 0200 kg

CO2

kg

1

sample

HPLC [58]

Coffea arabica Coffee Bean 250300 5090 RSM

DoE

[59]

Coffea arabica variety Mundo

Novo

Coffee Bean 152352 5060 05% (wt.) EtOH

05% (wt.) isopropyl alcohol

HPLC [56]

Coffea canephora var. Robusta Robusta coffee Husks Caffeine 2459 200300 60100 35197 kg

CO2

kg

1

sample

HPLC [60]

Coffea spp. Coffee Seed 4.219.4 150350 4060 90 kg

CO2

kg

1

sample

HRGC Soxhlet extraction

Modeling

[57]

Coix lachrymal-jobi Adlay Seed 8097 100300 3055 7.5200 L

CO2

kg

1

sample

Gravimetric analysis Ultrasound assisted SFE

Flowrate effect

[322]

Coix lachrymal-jobi L. var.

Adlay

Adlay Seed 11.682.6 100250 3550 180 L

CO2

kg

1

sample

GCMS Ultrassound assisted SFE

Particle size effect

[323]

Colchicum autumnale L. Seed Colchicine 247 2540 07% MeOH HPLC Organic solvent extraction

Soxhlet extraction

Sonication

[324]

Commiphora myrrha

Acorus calamus

Commiphora

Acorus

Exudates

rhizomes

Furanogermacranes 3.23.5 90 4550 GCMS Hydrodistillation

Steam distillation

[168]

Coptis chinensis Coptis chinensis Rhizome Berberine 0.157.53 200600 60 EtOH

MeOH

1,2-Propanediol

HPLC Soxhlet [325]

1

2

2

M

.

M

.

R

.

d

e

M

e

l

o

e

t

a

l

.

/

J

.

o

f

S

u

p

e

r

c

r

i

t

i

c

a

l

F

l

u

i

d

s

9

2

(

2

0

1

4

)

1

1

5

1

7

6

Table 1 (Continued)

Scientic name Common name Plant part Target Extraction

yield (wt%)

P (bar) T (

C) CO

2

& co-solvent Analytical technique Other Features Ref.

Cordia verbenacea D.C. Leaf -Caryophyllene 34 80300 60 177 kg

CO2

kg

1

sample

GCMS Fractionation

Soxhlet extraction

Hydrodistillation

Modeling

[326]

Cordia verbenacea D.C. Leaf 100300 3050 20100 kg

CO2

kg

1

sample

Antitumor activity [327]

Coriandrum sativum L. Coriander Seed 0.82.0 116280 3858 Spectrophotometry Hydrodistillation [328]

Coriandrum sativum L. Coriander Seed 0.050.6 90150 4050 47 kg

CO2

kg

1

sample

GC

GCMS

Particle size effect

Hydrodistillation

SEM

[329]

Coriandrum sativum L. Coriander Seed 016.4 200300 35 040 kg

CO2

kg

1

sample

GC Organic solvent extraction [330]

Corylus avellana L.

Juglans regia

Hazel

Walnut

Fruit 0.050.6 180234 3548 501500 kg

CO2

kg

1

sample

Gravimetric analysis Modeling [331]

Corylus avellana L. Hazel Fruit 6080 180234 3548 Rancimat method

HPLC

GC

Solvent extraction

DoE

RSM

[332]

Corylus avellana L. Hazel Fruit 150600 4060 0127 kg

CO2

kg

1

sample

GC Solubility measurements

Modeling

[333]

Corylus avellana L. Hazel Fruit 117 300450 4060 218 kg

CO2

kg

1

sample

Gravimetric Analysis RSM

DoE

[334]

Cratoxylum prunifolium Dyer Leaf Catechins 125250 4080 4.8 L

CO2

kg

1

sample

HPLC DoE [335]

Croton zehntneri Pax et Hoff Leaf 00.9 6779 1028 3 kg

CO2

kg

1

sample

GC Modeling [336]

Cucumis melo

Cantalupensis

Cucumis melo var.

reticulatus

Cantaloupe Seed Linoleic acid 22.730.4 600 40 270 kg

CO2

kg

1

sample

GC Antioxidant activity

Soxhlet

[337]

Cucurbita cifolia Fig leaf gourd Seed 4043 180200 3545 GC Modeling [338]

Cucurbita cifolia Pumpkin Seed 8693 180200 3545 Soxhlet extraction [146]

Cucurbita maxima Pumpkin Seed 630 151344 3575 3001500 L

CO2

kg

1

sample

GC DoE

RSM

[148]

Cucurbita moschata

Cucurbita cifolia

Pumpkin Seed 1098 250300 55 GCMS Solvent extraction

Flow rates efffect

[150]

Cucurbita moschata Pumpkin Fruit -Carotene,

-carotene

lutein ester

250371 4076 150 L

CO2

kg

1

sample

HPLC Solvent extraction

DoE

RSM

[149]

Cucurbita pepo convar.

citrullina

Pumpkin Seed Spinasterol

7,22,25-stigmastatrienol

36.1 400 40 30 kg

CO2

kg

1

sample

GCMS Solvent extraction [147]

Cuminum cyminum L. Cumin Seed Cuminaldehyde 1.73.5 550 100 513 kg

CO2

kg

1

sample

GC-FID [339]

Curcuma longa L. Turmeric Rhizome 57 125325 3555 1.76.7 L

CO2

kg

1

sample

GCMS RSM

DoE

[161]

Curcuma longa L. Turmeric Rhizome Turmerone

ar-turmerone

25 200400 4060 6130 kg

CO2

kg

1

sample

GCMS Steam distillation [157]

Curcuma longa L. Turmeric Rhizome 07 300 30 01 kg

CO2

kg

1

sample

6.916.1% EtOH/Isopropyl

GC-FID Organic solvent extraction

Soxhlet extraction

Hydrodistillation

[160]

Curcuma longa L. Turmeric Rhizome Curcuminoids 4.56.5 250300 45105 Spectrophotometry Modeling

Pilot plant

Drying pretreatment

[159]

Curcuma longa L. Turmeric Rhizome Curcuminoids 4.522.6 250300 45 EtOH Spectrophotometry

HPLC

GC

Soxhlet extraction

Modeling

Drying pretreatment

[158]

Cydonia oblonga Miller Quince Seed 100345 3065 24 L

CO2

kg

1

sample

0.81.1% (v/v) MEtOH

GCMS DoE

RSM

Ultrasound assisted

extraction

[340]

Cymbopogon citratus Lemongrass 80 50 19144 L

CO2

kg

1

sample

030% Hexane

030% Dichloromethane

GC-FID Solvent extraction

Steam distillation

Accelerated solvent

extraction

[341]

M

.

M

.

R

.

d

e

M

e

l

o

e

t

a

l

.

/

J

.

o

f

S

u

p

e

r

c

r

i

t

i

c

a

l

F

l

u

i

d

s

9

2

(

2

0

1

4

)

1

1

5

1

7

6

1

2

3

Cymbopogon citratus Lemongrass Leaf 0.41.7 80120 2350 2.83.7 kg

CO2

kg

1

sample

GCMS [342]

Cynanchum paniculatum

(Bge.) Kitag

Root Paenol 0.16.0 100200 4555 02000 L

CO2

kg

1

sample

HPLC-PDA

HSCCC

Particle size efffect

DoE

Ultrasonic extraction

Steam distillation

Soxhlet extraction

Microwave-assisted

extraction

[343]

Cynara cardunculus L. Cardoon Seed 4.724 150300 3555 180 kg

CO2

kg

1

sample

TLC

GC

HPLC

Soxhlet extraction

Biodiesel production

[183]

Cyperus rotundus Rhizome -Cyperone 2.6 200 40 HPLC

MS

Purication [174]

Daucus carota L. Carrot Root Carotenes 0.25 330 40 24kg

CO2

kg

1

sample

EtOH

NMR

HPLC

GC

Pilot scale [108]

Daucus carota L. Carrot Root Carotenoids 1.52.5 276551 4070 2.55.0% (w/w) Canola oil HPLC Particle sizes effect

Solvent extraction

ANOVA

[107]

Daucus carota L. subsp. carota Carrot Umbels 90 40 GCMS Antifungal activity

Hydrodistillation

[110]

Daucus carrota L., cultivar

Chanteney

Carrot Root Carotol 90100 4050 016 kg

CO2

kg

1

sample

GC-FID

GCMS

Antimicrobial activity

Hydrodistillation

Particle size study

[109]

Diospyros kaki Thunb. Persimmon Fruit Carotenoids 36 300 4080 520% EtOH

280000L

CO2

kg

1

sample

HPLC [344]

Diplotaenia cachrydifolia Aerial parts 0.32.5 101304 3575 GCMS RSM

DoE

[345]

Diplotaenia cachrydifolia Aerial parts Dillapiole

limonene

-calacorene

0.02.4 101304 3575 315 L

CO2

kg

1

sample

03.8% (v/v) MeOH

GC

GCMS

Articial neural network [346]

Dracocephalum moldavica L. Moldavian dragonhead Herb Geraniol 1.3 450 40 518 kg

CO2

kg

1

sample

GCMS Hydrodistillation

Soxhlet extraction

Solvent extraction

Two-step decompression

system

[193]

Drosera intermedia Plant Plumbagin 0.6 200 40 87kg

CO2

kg

1

sample

HPLCDAD [347]

Echinacea purpurea Kava Aerial parts 23 250300 4060 020 kg

CO2

kg

1

sample

HPLC [348]

Saw Palmetto Fruit 212

St. Johns wort Flower/stem 1012

Root 38

Ekebergia capensis Wood 405 80 2% (mol) H

2

0 NMR Uterotonic activity [349]

Elaeis guineensis Palm Kernel Triglycerides 80 207483 4080 GC Fractionation

Solubility analysis

Micrograph

[350]

Elaeis guineensis Palm Kernel cake 09.26 275413 4070 6.6610 L

CO2

kg

1

sample

Particle sized effect

ANOVA

[351]

Elaeis guineensis Palm Fruit Oil 77.8 140300 4080 GC-FID Soxhlet extraction [352]

Elaes guineensis Palm Fiber Fatty acids

Carotene, Lipids

2.95.3 200300 4555 317 kg

CO2

kg

1

sample

Spectrophotometry Modeling [187]

Elettaria cardamomum L. Elettaria Seed 25 90110 4050 218 kg

CO2

kg

1

sample

GCMS Hydrodistillation

Particle size effect

[353]

Elettaria cardamomum Maton Cardamom Seed 100300 3555 25% (w/w) EtOH HPLC

GCMS

Subcritical propane extraction

Solvent extraction

[354]

Ephedra sinica Aerial parts 136340 4080 010% H

2

O

010% MeOH

GC Organic solvent extraction [355]

Equisetum giganteum L. Horsetail Aerial parts 00.9 120300 3040 053 kg

CO2

kg

1

sample

GC

GCMS

Organic solvent extraction [356]

1

2

4

M

.

M

.

R

.

d

e

M

e

l

o

e

t

a

l

.

/

J

.

o

f

S

u

p

e

r

c

r

i

t

i

c

a

l

F

l

u

i

d

s

9

2

(

2

0

1

4

)

1

1

5

1

7

6

Table 1 (Continued)

Scientic name Common name Plant part Target Extraction

yield (wt%)

P (bar) T (

C) CO

2

& co-solvent Analytical technique Other Features Ref.

Erythroxylum coca var. coca Coca Leaf Cocaine 150250 40100 515% (v/v) MeOH/H

2

O (29:71) GC-FID

GCMS

DoE

RSM

[357]

Eucalyptus camaldulensis Eucalypt Leaf 1,8-Cineole 1.42.0 80250 4060 2500 L

CO2

kg

1

sample

GCMS Hidrodistillation [51]

Eucalyptus camaldulensis

var.brevirostris

Eucalypt Leaf Gallic acid 12.016.6 400 70 15% EtOH

200L

CO2

kg

1

sample

RP-HPLC Antioxidant activity

Hydrodistillation

[50]

Eucalyptus citriodora

Melissa ofcinalis

Monarda citriodora

Cymbopogon citratus

Lemon eucalypt

Lemon balm

Leaf 138414 4060 100240 L

CO2

kg

1

sample

GC

GCMS

Hydrodistillation

MANOVA

[358]

Eucalyptus globulus Eucalypt Bark Betulinic acid

betulonic acid

oleanolic acid

ursolic acid

3-acetyloleanolic acid

3-acetylursolic acid

-sitosterol

0.01.3 100200 4060 80 kg

CO2

kg

1

sample

GCMS Soxhlet extraction

Kinetic and equilibrium

properties calculation

[46]

Eucalyptus globulus Eucalypt Bark Phenolic 0.280.51 300 5070 45 L

CO2

kg

1

sample

EtOH (1520% w/w)

HPLC-UV

ESI-MS

Antioxidant activity

DoE

RSM

[53]

Eucalyptus globulus Eucalypt Bark Betulinic acid

betulonic,acid

oleanolic acid

ursolic acid

3-acetyloleanolic acid

3-acetylursolic acid

-sitosterol

120200 4060 551 kg

CO2

kg

1

sample

05% (wt.) EtOH

GCMS Modeling [47]

Eucalyptus globulus Eucalypt Bark Betulinic acid

betulonic,acid

oleanolic acid

ursolic acid

3-acetyloleanolic acid

3-acetylursolic acid

-sitosterol

0.51.7 100200 40 8110 kg

CO2

kg

1

sample

08% (wt.) EtOH

GCMS Soxhlet extraction

Fractionation

[49]

Eucalyptus globulus Eucalypt Bark Betulinic acid

betulonic,acid

oleanolic acid

ursolic acid

3-acetyloleanolic acid

3-acetylursolic acid

-sitosterol

0.041.2 100200 4060 31 kg

CO2

kg

1

sample

05% (wt.) EtOH

GCMS DoE [48]

Eucalyptus grandis

Eucalyptus globulus

Eucalypt Bark Methyl morolate 200 60 551 kg

CO2

kg

1

sample

GCMS

NMR

Soxhlet extraction [52]

Eucalyptus spathulata

Eucalyptus microtheca

Eucalyptus Leaf 100300 4555 MeOH GC-FID Hydrodistillation [45]

Eucalyptus tereticornis

Zingiber ofcinale Roscoe

Eucalyptus

Clove

Ginger

Bud

leaf

rhizome

0.811 67250 1540 2.5 kg

CO2

kg

1

sample

GCMS Modeling

Solubility measurement

Flowrate study

[359]

Eucommia ulmoides Seed Aucubin 0.62.0 180300 45330 400 L

CO2

kg

1

sample

03% (v/v) H

2

OEtOH

03% (v/v) H

2

O

03% (v/v) MeOH

03% (v/v) EtOH

03% (v/v) H

2

OMeOH

03% (v/v) H

2

OEtOH

HPLC Soxhlet extraction [360]

Eugenia caryophillus Clove Bud 66150 1550 Gravimetric analysis Modeling

Scale-up

[361]

Eugenia caryophillus

Vetiveria zizanioides (L.)

Nash ex Small

Clove

Vetiver

Bud

root

5.813.3 100200 3540 436 kg

CO2

kg

1

sample

Gravimetric Modeling

Extractor geometry study

Flow rates effect

Scale-up

[362]

Eugenia caryophyllata Thunb. Bud Eugenol 17.1 300 50 HPLC SFC [363]

Eugenia caryophyllata Thunb. Clove Bud Eugenol 1823 100300 3050 16,000 L

CO2

kg

1

sample

GC

GCMS

Hidrodistillation

Soxhlet extraction

Particle sizes effect

DoE

[364]

M

.

M

.

R

.

d

e

M

e

l

o

e

t

a

l

.

/

J

.

o

f

S

u

p

e

r

c

r

i

t

i

c

a

l

F

l

u

i

d

s

9

2

(

2

0

1

4

)

1

1

5

1

7

6

1

2

5

Eugenia uniora L Brazilian cherry Fruit Sesquiterpenes

ketones

0.420.56% 150250 4060 36kg

CO2

kg

1

sample

GCMS ANOVA

PCA

FDA

[365]

Euphorbia rigida Euphorbia Leaf + stalk Hydrocarbons 8.6 400 50 0.6 kg

CO2

kg

1

sample

010% MEtOH

GC-FID

GCMS

Soxhlet extraction [366]

Evodia rutaecarpa Fruit Evodiamine

rutaecarpine

0.66.5 200400 5070 180,000 L

CO2

kg

1

sample

16% (v/v) MeOH

HPLC Soxhlet extraction [367]

Ferula assa-foetida 0.85.5 101303 4565 1.54.7 L

CO2

kg

1

sample

4.8% (v/v) MeOH

GC

GCMS

Hydrodistillation [368]

Ferulago Angulata Aerial parts 0.050.82 90190 3555 [369]

Foeniculum vulgare

Thymus vulgaris

Fennel

Thyme

Seed

leaf

120 40 GCMS

GC-O

Coupled distillation [37]

Foeniculum vulgare Fennel Seed (E)-anethol 200350 4555 3.65.4 L

CO2

kg

1

sample

05% MEtOH

GCMS Hydrodistillation [370]

Foeniculum vulgare Fennel Seed 213 100300 3040 0449 kg

CO2

kg

1

sample

GC

TLC

Hydrodistillation

Modeling

[371]

Foeniculum vulgare Fennel Fruit 098 90100 4050 35106 kg

CO2

kg

1

sample

GC

GCMS

Gravimetric analysis

Two-step decompression

Hydrodistillation

[372]

Foeniculum vulgare Mill Fennel Seed 1.55.5 80150 4057 36285 kg

CO2

kg

1

sample

GC

GCMS

Hydrodistillation [373]

Garcinia mangostana L. Mangosteen Fruit Xanthones 0.236.5 200300 4060 100300 kg

CO2

kg

1

sample

HPLC RSM

DoE

Antioxidant activity

[374]

Garcinia mangostana L. Mangosteen Fruit Xanthones 5.3715.14 180380 4060 EtOH (5% w/w) HPLCESI/MS Antioxidant activity [375]

Ginkgo biloba Ginkgo biloba Leaf Flavonoids 00.24 100300 3565 616 L

CO2

kg

1

sample

60% (v/w) EtOH

UVvis

spectrophotometry

SEM [239]

Ginko biloba Ginko biloba Leaf Flavonoids

terpenoids

0.02.3 100300 5080 110% EtOH HPLC DoE

EtOH preextraction

[376]

Ginko biloba Ginko biloba Leaf Terpene lactone

avonoids

4.511.4 242312 60120 524% (mol) EtOH HPLC Soxhlet extraction [377]

Ginko biloba Ginko biloba Leaf Bilobalide

ginkolides

204340 4080 520% (v/v) MeOH

16/4% (v/v) MeOH/H

2

O

HPLCESI-MS Organic solvent extraction [378]

Glycine variety Soybean Distillate Fatty acids, tocopherols,

sterols, squalene

3265 241310 5090 RP-HPLC [152]

Glycine variety Soybean Flakes Lecithin 655 80 6.7 L

CO2

kg

1

sample

15% EtOH

HPLC SCF

Fractionation

[155]

Glycine variety Soybean Distillate Tocopherols 110318 5060 (14.7) 10

4

L

CO2

L

1

sample

GC ODS traps [151]

Glycine variety Soybean Bean 219 300500 4060 1820 kg

CO2

kg

1

sample

Gravimetric analysis Particle sizes effect

Modeling

Scale-up

[153]

Glycine variety Soybean Bean Triglycerides 07 100300 4050 814.5 L

CO2

kg

1

sample

HPLC RSM

DoE

[154]

Glycyrrhiza uralensis Fisch Glycyrrhiza Root 1.22.8 150350 4060 614 kg

CO2

kg

1

sample

GCMS Antibacterial activity [379]

Gossypium spp. Cotton Seed Gossypol 2.143.1 350550 6080 12003600 L

CO2

kg

1

sample

RSM

DoE

[380]

Guaicum Bulnesia Wood 0.7 120 80 GCMS Hydrostillation [381]

Guilielma speciosa Pupunha Fruit Fatty acids

carotenes

13 250300 5045 6593 kg

CO2

kg

1

sample

GC Modeling [189]

Helianthus annuus L. Sunower Seed 090 250 40 0650 kg

CO2

kg

1

sample

HPLC Modeling

Two-step decompression

system

[67]

Helianthus annuus L. Sunower Distillate Polyphenol 20100 200700 4080 6119 kg

CO2

kg

1

sample

Gravimetric analysis Three-step SFE extraction

Soxhlet extraction

Modeling

[63]

Helianthus annuus L. Sunower Distillate Tocopherols

phytosterols

20100 150230 65 HPLCUV/Vis

HPLC-ELSD

GC

Pilot-scale [69]

Helianthus annuus L. Sunower Leaf Allelopathic compounds 02 100500 3550 5% MeOH

5% DSMO

5% H

2

O

DoE

Cluster Analysis

[66]

Helianthus annuus L. Sunower Leaf Allelopathic compounds 0.21.6 380 50 42126 kg

CO2

kg

1

sample

3.84.7% H

2

O

Pilot scale

Flow rates effect

Cluster Analysis

Biological activity

[64]

1

2

6

M

.

M

.

R

.

d

e

M

e

l

o

e

t

a

l

.

/

J

.

o

f

S

u

p

e

r

c

r

i

t

i

c

a

l

F

l

u

i

d

s

9

2

(

2

0

1

4

)

1

1

5

1

7

6

Table 1 (Continued)

Scientic name Common name Plant part Target Extraction

yield (wt%)

P (bar) T (

C) CO

2

& co-solvent Analytical technique Other Features Ref.

Helianthus annuus L. Sunower Leaf Allelopathic compounds 0.11.2 300500 50 2126 kg

CO2

kg

1

sample

Gravimetric analysis Cluster Analysis

Pilot scale

[65]

Helianthus annuus L. Sunower Seed 095 200600 4080 425 kg

CO2

kg

1

sample

Gravimetric analysis Modeling

Flow rates study

Particle sizes effect

[68]

Helichrysum italicum Flower 04.5 100200 4060 36 kg

CO2

kg

1

sample

GCMS

GC-FID

[382]

Hemerocallis disticha Daylily owers Flower Lutein

zeaxanthin

4.868.12 300600 5095 HPLC Antioxidant activity [383]

Hibiscus cannabinus L. Kenaf Seed 0.520 200600 4080 038 kg

CO2

kg

1

sample

Gravimetric analysis Soxhlet extraction

Ultra-sonic assisted solvent

extraction

[384]

Hibiscus cannabinus L Kenaf Seed 400600 4080 38 kg

CO2

kg

1

sample

[385]

Hippophae rhamnoides L Seabuckthorn Fruit Tocopherol

carotene

150350 3555 2.4 kg

CO2

kg

1

sample

030% (v/w) mEtOH

030% (v/w) EtOH

030% (v/w) 2-Propanol

GCMS

HPLC

DoE

Soxhlet extraction

Antioxidant activity

RSM

[202]

Hippophae rhamnoides L. Sea buckthorn Fruit -Sitosterol 9.910.9 150600 4080 0137 kg

CO2

kg

1

sample

HPLC Solvent extraction

Soxhlet extraction

[226]

Hippophae rhamnoides L. Sea buckthorn Seed 0.12.9 150300 3045 267 L

CO2

kg

1

sample

Gravimetric Analysis 2-Step decompression

Particle size effect

[386]

Hippophae rhamnoides L. Sea buckthorn Seed 16 200300 3540 GC Particle size effect

Organic solvent extraction

[387]

Hippophae rhamnoides L. Sea buckthorn Fruit -Sitosterol 111 150600 4080 0140 kg

CO2

kg

1

sample

HPLC Modeling [227]

Hippophae rhamnoides L. Seabuckthorn Seed 2.489.28

7.609.68

100400 4575 24 kg

CO2

kg

1

sample

EtOH, MeOH, 2-propanol

HPLC DoE

RSM

Antioxidant activity

[388]

Hippophae rhamnoides L. Sea buckthorn Fruit Aliphatic hydrocarbons 81 138276 4065 Micrograph

ANOVA

Sensory evaluations

[527]

Hordeum vulgare L.

Zea mays

Malt

Corn

Seed 1.11.4 650 60100 Gravimetric Soxhlet extraction [389]

Hordeum vulgare L. var. Robur Barley Tocochromanols 4.04.7 200450 40 30 L

CO2

kg

1

sample

TLC

HPLC

Fractionation

Soxhlet extraction

Folch method

[390]

Hordeum vulgare L. Brewers Spent Grain Tocopherol 0.21.7 100350 4080 66400 L

CO2

kg

1

sample

HPLC Economic analysis [391]

Hylocereus undatus White pitaya Seed 5.54 250 40 GCMS Soxhlet extraction

Microwave-assistant

extraction

Aqueous enzymatic

extraction

[392]

Hypericum carinatum: Flower Phloroglucinol,

benzophenone derivatives

1.053.04 90/120/150/200

(sequence)

4060 76 kg

CO2

kg

1

sample

HPLC ANOVA [393]

Hypericum perforatum L.

Ginkgo biloba

St. Johns wort

Ginko biloba Leaf

Hyperforin, dhyperforin

bilobalide, ginkgolide A, B, Q

80

350

30

100

EtOH/acetic acid (9:1) [394]

Hypericum perforatum L. St. Johns Wort 14 100350 40 2675 L

CO2

kg

1

sample

GCMS Steam distillation

Particle size effect

[395]

Hypericum perforatum L. St. Johns Wort 04.8 100200 4050 45 kg

CO2

kg

1

sample

Modeling

Optimization

[246]

Hyssopus ofcinalis Hyssop Leaf + ower Terpinen-4-ol

1,8-cineol

1.02.3 90100 4050 0.28 kg

CO2

kg

1

sample

GC-FID Hydrodistillation

Modeling

SEM

[396]

Hyssopus ofcinalis Hyssop Root 0.12.9 100350 4575 0.06.0% (v/v) MeOH GC

GCMS

DoE

Hydrodistiilation

[397]

Ilex paraguariensis Yerba mate Leaf Methylxantines caffeine 03.79 120200 4070 HPLC [398]

Illicium verum Chinese star anise Seed Fatty acids 6.8023.72 100300 3050 (015%) (v/v) EtOH HPLC RSM

DoE

[186]

Inula viscosa (L.) Aiton

Inula graveolens (L.) Desf

Leaf Sesquiterpene

lactones, sesquiterpene acids

and avonoids

0.65 90 50 GCMS Hydrodistillation

2-step decompression

[399]

Jatropha curcas L. Seed Triglycerides 14.448.9 250350 4060 GC RSM

Soxhlet extraction

[184]

Juglans regia L. Walnut Fruit 095 180234 3548 0550 kg

CO2

kg

1

sample

HPLC Soxhlet extraction

Rancimat method

[400]

Juglans regia L. Walnut 68.2 689 85 70 L

CO2

kg

1

sample

Gravimetric Subcritical solvent extractions [401]

M

.

M

.

R

.

d

e

M

e

l

o

e

t

a

l

.

/

J

.

o

f

S

u

p

e

r

c

r

i

t

i

c

a

l

F

l

u

i

d

s

9

2

(

2

0

1

4

)

1

1

5

1

7

6

1

2

7

Juniperus communis L. Juniper Fruit 0.20.4 90200 40 30 kg

CO2

kg

1

sample

GC-FID

GCMS

Hydrodistillation [402]

Juniperus communis L. Juniper Fruit 4.512.5 90125 4050 618 kg

CO2

kg

1

sample

GC

GCMS

Hydrodistillation [403]

Juniperus communis L. Juniper Fruit 0.14 80100 40 180 kg

CO2

kg

1

sample

GCMS

GC-FID

Steam distillation [404]

Juniperus communis L. Juniper Fruit 0.20.5 90200 40 30 kg

CO2

kg

1

sample

GC-FID

GCMS

Hydrodistillation

Particle sizes effect

[405]

Juniperus communis L. Juniper Leaf 200350 4555 05% MeOH GCMS

GC-FID

Hydrodistillation [406]

Juniperus oxycedrus L. Juniper Leaf + fruit 015 80100 50 GCMS 2-Step decompression

Hydrodistillation

Antiviral activity test

[407]

Juniperus virginiana L. Cedarwood Wood 4.510.4 103689 40100 20.8 L

CO2

kg

1

sample

GC Steam distillation [408]

Juniperus Virginiana L. Cedarwood Wood Cedrol

cedrene

2.53.9 414 100 9097273 L

CO2

kg

1

sample

GC Water extraction [409]

L. Stoechas subspecies C. Boiss Lavender Flower 1.2 80140 3550 1040 kg

CO2

kg

1

sample

GC Modeling [410]

Laurus nobilis Bay

Basil

Coriander

Dill

Spearmint

Marjoram

Peppermint

Oregano

Parsley

Rosemary

Sage

Thyme

Leaf Tocopherol 101405 40 HPLC Algae extraction [135]

Laurus nobilis L. Laurel Leaf Monoterpenes, oxygenated

derivates

1.37 100 40 17kg

CO2

kg

1

sample

GC-FID

GC-M

[132]

Laurus nobilis L. Laurel Leaf 1,8-Cineole 0.82 90 50 21kg

CO2

kg

1

sample

GCMS Hydrodistillation

2-step decompression system

[133]

Laurus nobilis L. Daphne Seed 028 340 3575 015 L

CO2

kg

1

sample

HPLC [134]

Laurus nobilis L. Fruit 0.9 90250 40 HPLC Hydrodistillation [131]

Lavandula angustifolia Lavender Flower 5.59.8 73207 4653 112 L

CO2

kg

1

sample

GCMS RSM

DoE

Antioxidant activity

[411]

Lavandula angustifolia Lavender Flower Linalyl acetate 7795 80120 4555 GC-FID DoE

Periodic static-dynamic

procedure

[412]

Lavandula hybrida Lavandin Flower Linalool

linalyl acetate

camphor

1,8-cineole

79.499.0 10130 3595 0.10.93 L

CO2

kg

1

sample

GC-FID RSM

DoE

Soxhlet extraction

[413]

Lavandula stoechas L. ssp.

cariensis (Boiss.) Rozeira

Flower RSM

DoE

Solvent extraction

[414]

Lavandula viridis LHr Aerial parts Camphor 12.212.7 120180 40 GCFID

GCITMS

Hydrodistillation

Fractionation

Antioxidant activity

[212]

Lepidium apetalum Seed 11.7935.56 200300 5070 375 L

CO2

kg

1

sample

GCMS DoE

RSM

Antioxidant activity

[415]

Levisticum ofcinale Koch.

Apium graveolens L.

Lovage

Celery

Seed

leaf

root

1.62.2 200350 40 100200 kg

CO2

kg

1

sample

GCMS Extractor size study [416]

Ligusticum chuanxiong Ligusticum Root 05 200350 5570 880 L

CO2

kg

1

sample

GCMS [417]

Lingusticum chuanxiong Ligustilide

butylidenephalide

03.85 350 70 16L

CO2

kg

1

sample

GCMS (SIM) [418]

Linum usitatissimum L. Flax Waste Policosanols 7.4 552 60 110% (v/v) EtOH

60L

CO2

kg

1

sample

GCMS Organic solvent extraction [74]

Linum usitatissimum L. Flax Seed 35.741.0 413620 100 (0.61.2) 10

5

L

CO2

kg

1

sample

01 L

EtOH

kg

1

sample

GC-FID RSM

Soxhlet extraction

Particle sizes effect

[73]

1

2

8

M

.

M

.

R

.

d

e

M

e

l

o

e

t

a

l

.

/

J

.

o

f

S

u

p

e

r

c

r

i

t

i

c

a

l

F

l

u

i

d

s

9

2

(

2

0

1

4

)

1

1

5

1

7

6

Table 1 (Continued)

Scientic name Common name Plant part Target Extraction

yield (wt%)

P (bar) T (

C) CO

2

& co-solvent Analytical technique Other Features Ref.

Linum usitatissimum L. Flax Seed 2125 210550 5070 10210 kg

CO2

kg

1

sample

HPLC

GC-FID

Soxhlet extraction [71]

Linum usitatissimum L. Flax Seed Lignans 1.42.7 350450 4060 163 kg

CO2

kg

1

sample

HPLC RSM

DoE

[72]

Linum usitatissimum L. Flax Straw Wax 0.521.23 200400 4070 GCMS RSM

DoE

[70]

Linum usitatissimum L. Flax Seed 1040 300500 5070 272 kg

CO2

kg

1

sample

Gravimetric analysis Particle size effect

Flow rate effect

RSM

DoE

[75]

Linum usitatissimum L. Linseed Seed 8.628.8 250 50 05% (v/v) EtOH Economic analysis

Modeling

[419]

Linum usitatissimum

Brassica rapa

Brassica napus

Brassica juncea

Sinapis alba

Flax

solin

canola

mustard

Seed 2149 517 100 7.5132 L

CO2

kg

1

sample

015% EtOH

GC Reference method extraction [420]

Lippia alba Mill. Lippia Leaf Limonene

carvone

0.25.7 80120 4050 51654 kg

CO2

kg

1

sample

GC Hydrodistillation

Solvent extraction

Soxhlet extraction

SEM

[210]

Lippia alba Mill. Leaf/stem Carvone GCMS Hydrodistillation

Simultaneous distillation

Microwave-assisted

Hydrodistillation

Antioxidant activity

[421]

Lippia dulcis Trev. Lippia Leaf + ower 1.63.2 100140 4550 23 kg

CO2

kg

1

sample

GCMS,

LCMS

HPLC

Hydrodistillation [422]

Lippia sidoides Lippia Leaf Thymol 1.21.8 6779 1025 2 kg

CO2

kg

1

sample

GCMS Steam distillation

Solvent extraction

Modeling

[423]

Lycopersicum esculentum

Corylus avellana

Tomato

Hazelnut

Pulp/fruit Lycopene 72.580.0 400 60 2151 kg

CO2

kg

1

sample

HPLC Mixture of raw materials [203]

Macadamia integrifolia Macadamia Fruit 00.65 100180 4080 53 L

CO2

kg

1

sample

GC Modeling [424]

Majorana hortensis Moench Marjoram Leaf 1.4 200 50 80 L

CO2

kg

1

sample

GCMS Hydrodistillation [209]

Mangifera indica L. Mango Leaf Mangiferin

quercetin

100400 3575 240 kg

CO2

kg

1

sample

020% EtOH

020% MEtOH

HPLC Antioxidant activity

Hydrodistillation

[425]

Marchantia convoluta 0.84.7 50200 3565 1.85.3 L

CO2

kg

1

sample

GCMS Organic solvent extraction [426]

Marchantia convoluta Whole plant 0.74.7 50200 3565 6 L

CO2

kg

1

sample

MeOH

GCMS [427]

Matricaria chamomilla Chamomile Flower Matricine

chamazulene

-bisabolol

24 100250 3040 GCMS

HPLC

Soxhlet extraction

Steam distillation

Scale-up

Fractionation

[428]

Matricaria recutita Chamomile Flower 240 40 GCMS Modeling [429]

Maydis stigma Flower Flavonoids 250450 4060 EtOH

4000 L

CO2

kg

1

sample

UVVis

Spectrophotometry

DoE [237]

Maytenus aquifolium Martius

(Celastraceae)

Leaf 1.06.6 101 50 020% (v/v) pentane

010% (v/v) EtOH

010% (v/v) MeOH

HRGCFID Soxhlet extraction

Maceration/Sonication

extraction

[430]

Maytenus ilicifolia Leaf 100250 2040 GCMS Particle sizes study [431]

Melaleuca cajuputi Leaf Sesquiterpenes,

oxygenated derivatives

1.64.2 83197 4486 GC-FID

GC-MS

Organic solvent extraction

ANOVA

[432]

Melissa ofcinalis L. Lemon balm Aerial parts Gallic acid, protocatechuic

acid,

p-hydroxybenzoic acid

vanillic acid, syringic acid

100300 4080 MeOH HPLC Soxhlet extraction

Organic solvent extraction

[433]

Melissa ofcinalis, L. Lemon balm Leaf Phenols 230 100180 3540 Rancimat method [434]

Mentha pulegium L. Pennyroyal Leaf + lower 1098 100 50 50100 kg

CO2

kg

1

sample

Gravimetric Steam distillation

Modeling

[435]

Mentha pulegium L. Pennyroyal Aerial parts Pulegone

menthone

100200 3555 15 kg

CO2

kg

1

sample

053% MEtOH

GCMS Hydrodistillation [436]

Mentha spicata

Salvia desoleana

Mint

Sage

Leaf 90 50 GCMS Fractionation

Hydrodistillation

[437]

M

.

M

.

R

.

d

e

M

e

l

o

e

t

a

l

.

/

J

.

o

f

S

u

p

e

r

c

r

i

t

i

c

a

l

F

l

u

i

d

s

9

2

(

2