Escolar Documentos

Profissional Documentos

Cultura Documentos

Argillon Insulators English

Enviado por

Hillary McgowanDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Argillon Insulators English

Enviado por

Hillary McgowanDireitos autorais:

Formatos disponíveis

Insulators

for

Circuit Breakers

Disconnectors

Instrument Transformers

Surge Arresters

Cable Terminations

Substations

Overhead Lines

Railway Electrication

History

2

1859

Founding of the porcelain works in Sophienau

Poland (formerly Silesia).

1913

Acquistion of the porcelain plant (PN) in Neuhaus

near Sonneberg / Germany by the Siemens-Schu-

ckert works.

1942

Acquisition of the plant in Redwitz / Germany and

start of the bakelite production; expansion of the

existing manufacturing sites in Neuhaus-Schier-

schnitz, Rodach and Hochstadt.

1946

Abandonment of the Neuhaus plant due to the

Second World War.

1952

With the building of a state-of-the-art insulator

plant in Redwitz Siemens-Schuckert then owned

the most advanced porcelain insulator manufactu-

ring facility in Europe.

1958

Manufacturing of the tallest ceramic insulator and

introduction of the cast resin manufacturing line.

1975

Expansion of the product line with special ceramic

parts, steatite and additional cast resin applicati-

ons.

1993

DIN EN ISO 9001 accreditation of the Redwitz

plant.

1995

Start of Simotec

composite insulator production.

1998

Acquisition of the insulator plant in Jedlina Zdroj

Poland - and founding of SFI (Siemens Fabryka

Izolatorow)

2002

Extension and modernization of the porcelain

manufacturing unit.

2003

Founding of Argillon after separation from Siemens

Power Generation.

3

Safety, Quality and Reliabilty

Argillon originated from the former business

segment of Siemens Power Generation Ceramics

and is a worldwide acknowledged manufacturer of

high quality insulators for high voltage enginee-

ring.

At Argillons manufacturing sites in Germany and

Poland we produce a vast spectrum of different

insulators for our worldwide customers. Our

product line includes porcelain insulators as well

as composite polymeric insulators for DC and AC

applications, for high voltage apparatus, and over-

head line applications. For this reason Argillon is

able to offer the most suitable, economic solutions

to our customers.

Our know-how reaches from the manufacturing of

sophisticated apparatus and overhead line insula-

tors till simpler designs of low and medium voltage

applications, from the lowest to the highest

voltage levels of 800 kV.

Insulators manufactured by Argillon stand for a

maximum safety, quality and reliability. This is

backed more than 140 years of experience and

reference projects from all over the world.

Reliability is the highest priority in high voltage

engineering. This is especially important for insu-

lators, which are used in energy transmission and

distribution equipment and must fulll important

tasks.

Argillon is a rst-class supplier of high quality pro-

ducts providing excellent long-term performance.

By developing a quality system which includes all

processes and material parameters, nonconfor-

mance and the associated cost is eliminated.

Fullling customer requirements is our primary

commitment. Our activities in international and

national standards organiszations as well as

excellent customer partnerships create the basis for

product improvement and new development. The

foundation for our worldwide success is a combi-

nation of experienced employees and the efcient

use of carefully inspected and proven production

components.

4

Argillons composite insulator research and

development was started in the early 1970s. For

almost 10 years, Argillon has been producing

composite polymeric insulators using a direct in-

jection moulding process for serial production. Our

manufacturing process and equipment represents

state-of-the-art technology.

The following advantages can be achieved by using

Argillons superior Simotec

composite insulators

when designing your overhead lines and appara-

tus.

More economy due to the lower costs of your

total design

Improved dielectric properties

Higher reliability even under adverse conditions

Superior pollution layer performance

Compliance with national and international

standards, fulllment of the requested design,

type, and routine tests.

With your support, we are able to develop

and test customized design solutions for optimal

performance.

Our customized manufacturing concept enables

Argillon to take into consideration creepage length

requirements and the requested metal tting

design for each customer. By careful selection of

quality components such as glass ber reinforced

epoxy rods (FRP), silicone elastomer and metal t-

tings combined with Argillons sophisticated repro-

ducible manufacturing process, we can create the

basis for excellent performance, reliability and long

service life. Our manufacturing molds are suitable

for one-piece solid core insulators up to 8 meters in

lengths for all voltage levels and applications.

Utilize the Benets of our Simotec

-Overhead

Line Insulators:

Simpler installation and design benets due to

lower weight

Superior pollution layer performance

Withstands vandalism

Various design possibilities in terms of creepage

length

More economical erection, maintenance and

operation

Simotec

-Composite Insulators

Simotec

-Overhead Line Insulators

SC-Profile

Creepage

= 2,5 x

Arcing distance

Creepage

= 3,6 x

Arcing distance

per shed

+ 60 mm

creepage

HC-Profile

Arcing distance

5

Simotec

-Apparatus Insulators

SC-Profile

Creepage

= 2,5 x

Arcing distance

Creepage

= 3,6 x

Arcing distance

per shed

+ 60 mm

creepage

HC-Profile

Arcing distance

Argillon hollow insulators are manufactured using

an advanced, modern manufacturing technology.

The silicone injection process allows one-piece

molding for FRP tubes up to 6 meters in length and

a tube diameter of up to 560 mm. Our knowledge

of applied manufacturing processes, for example

gluing the metal ttings to the FRP tube and mol-

ding the silicone shed housing, are very important

in the production of high quality insulators. Our

sophisticated logistics system supplements the core

processes and enables short and reliable delivery

periods. A variety of FRP tubes allows the specic

utilization of these insulators for pressure, bending

or combined pressure-bending stress.

Benets from our Simotec

-Composite Insula-

tors:

Higher personal safety during operational faults

Increased operational safety in seismic areas

Improved performance in high-pollution areas

Reduced risk of transporation damages

Lower weigth than comparable porcelain

insulators and therefore easier to handle

6

With the invention of the electrodynamic principle

by Werner von Siemens in 1866, electrical engi-

neering developed rapidly and porcelain became

the ideal insulation material with high mechanical

stability. Since then, porcelain has been one of the

most important insulating materials in high voltage

engineering and must withstand both mechanical

and electrical load requirements.

At Argillon we produce a wide range of high

quality porcelain insulators for applications in

voltage levels from 72,5 to 800 kV. We manufactu-

re hollow insulators for circuit breakers, bushings,

surge arresters, instrument transformers and cable

terminations as well as post insulators for discon-

nectors and substations. Longrod type insulators

sublement the product spectrum.

Porcelain Insulators

Argillon produces single-piece long rod insulators

up to 125 mm core diameter and maximum tensile

load of 360 kN used in overhead power lines.

Long-rod insulators are designed with a solid

cylindrical core in order to withstand these high

mechanical loads.

Suspension String Insulators

7

Outdoor post insulators are solid core insulators

with cylindrical shapes. The eld of application

reaches from disconnector and earthing switches

to busbur support in substations. A variety of

different shed proles fulll the requirements of

diverse climatic conditions. The armatures are

usually made from malleable cast iron and are hot

dip galvanized.

Post Insulators

Hollow insulators are manufactured in cylindric as

well as in conical shapes. The wall thickness can

be varied according to the requested bending and

internal pressure loads. Circuit breaker insulators

are designed primarily for withstanding internal

pressure loads. Moreover circuit breaker insulators

must fulll individual requirements of the sealing

surfaces. Hollow insulators are also used in trans-

former bushings, converters and cable terminations

to protect the internals from weathering under

high-voltage conditions.

Hollow Insulators

Argillon also offers a wide range of medium

voltage insulators for use in overhead lines, post

applications, railway electrication, transformer

bushings, coil insulators and insulators for special

applications up to a voltage level of 72,5 kV.

Argillon porcelain insulators are marked with

our manufacturers marking P . Our composite

polymeric insulators show the protected trademark

SIMOTEC

.

Redwitz / Germany

Argillon GmbH

Isolatoren

Bahnhofstr. 43

D-96267 Redwitz

Germany

Telephone +49 95 74 81 -338

Telefax +49 957 4 81 -607

E-Mail insulators@argillon.com

Online www.argillon.com

Jedlina Zdroj / Poland

Argillon Polska Sp.z o.o.

Ul. B. 330 Chrobrego 7

58-330 Jedlina Zdroj

Poland

Telephone +48 74 84 55 545

Telefax +48 74 84 55 549

Alpharetta / USA

Argillon LLC

Power Insulators

1345 Ridgeland Parkway

Suite 116

Alpharetta, GA 30004

USA

Telephone +1 678 256 1672

Telefax +1 678 256 1550

Medium Voltage Insulators

Você também pode gostar

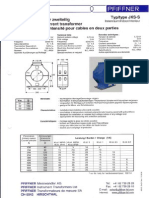

- Inst TRX TRENCH PDFDocumento20 páginasInst TRX TRENCH PDFBruce CoxAinda não há avaliações

- Inverter System 07Documento8 páginasInverter System 07kylegazeAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- Inst TRX TRENCH PDFDocumento20 páginasInst TRX TRENCH PDFBruce CoxAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Corp Brochure TrenchDocumento24 páginasCorp Brochure TrenchHillary McgowanAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Southern States BPA and HPADocumento8 páginasSouthern States BPA and HPAHillary McgowanAinda não há avaliações

- JKS-S, Split Core CTDocumento1 páginaJKS-S, Split Core CTHillary McgowanAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- UPS-Systems: World Class Power SystemsDocumento6 páginasUPS-Systems: World Class Power SystemsHillary McgowanAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Corp Brochure TrenchDocumento24 páginasCorp Brochure TrenchHillary McgowanAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- CatalogueOEM Utility ProductsDocumento80 páginasCatalogueOEM Utility ProductsHillary McgowanAinda não há avaliações

- 766E - DRIESCHER Con Cámaras de Extinción de Arco en VacíoDocumento4 páginas766E - DRIESCHER Con Cámaras de Extinción de Arco en VacíoHillary McgowanAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Catalogue TD InsulatorsDocumento24 páginasCatalogue TD InsulatorsmartinpellsAinda não há avaliações

- High Voltage Disconnectors: The SpecialistsDocumento6 páginasHigh Voltage Disconnectors: The SpecialistsHillary McgowanAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Power System Manager Mcu - 07-02Documento8 páginasPower System Manager Mcu - 07-02Hillary McgowanAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- PPC Insulator - Solid CoreDocumento16 páginasPPC Insulator - Solid CoreAriel Ghigliotto100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- Lucy Overhead Line EquipmentDocumento8 páginasLucy Overhead Line EquipmentHillary McgowanAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- LUCY SwitchgearDocumento8 páginasLUCY SwitchgearHillary McgowanAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- DC DC Converters 07 02Documento4 páginasDC DC Converters 07 02Hillary McgowanAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- RX RC 12Documento1 páginaRX RC 12Hillary McgowanAinda não há avaliações

- Merkblatt 06eDocumento2 páginasMerkblatt 06eHillary McgowanAinda não há avaliações

- CONNECTIONS N41.2dfe PDFDocumento4 páginasCONNECTIONS N41.2dfe PDFHillary McgowanAinda não há avaliações

- JKS-S, Split Core CTDocumento1 páginaJKS-S, Split Core CTHillary McgowanAinda não há avaliações

- High Voltage Disconnectors: The SpecialistsDocumento6 páginasHigh Voltage Disconnectors: The SpecialistsHillary McgowanAinda não há avaliações

- Power System Manager Mcu - 07-02Documento8 páginasPower System Manager Mcu - 07-02Hillary McgowanAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Fachverband Batterien: Instructions For The Safe Handling of Lead-Acid Accumulators (Lead-Acid Batteries)Documento6 páginasFachverband Batterien: Instructions For The Safe Handling of Lead-Acid Accumulators (Lead-Acid Batteries)Hillary McgowanAinda não há avaliações

- Merkblatt 06eDocumento2 páginasMerkblatt 06eHillary McgowanAinda não há avaliações

- Fachverband Batterien: Instructions For The Safe Handling of Lead-Acid Accumulators (Lead-Acid Batteries)Documento6 páginasFachverband Batterien: Instructions For The Safe Handling of Lead-Acid Accumulators (Lead-Acid Batteries)Hillary McgowanAinda não há avaliações

- Merkblatt 04eDocumento4 páginasMerkblatt 04eHillary McgowanAinda não há avaliações

- PPC Insulator - Solid CoreDocumento16 páginasPPC Insulator - Solid CoreAriel Ghigliotto100% (1)

- BT280Documento2 páginasBT280Hillary McgowanAinda não há avaliações

- Catalogue Ans I Post EvcvcDocumento10 páginasCatalogue Ans I Post EvcvcHillary McgowanAinda não há avaliações

- Denso Mitsubishi L200 Common Rail PDFDocumento53 páginasDenso Mitsubishi L200 Common Rail PDFAlex Renne Chambi100% (8)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- ABC AccessoriesDocumento15 páginasABC Accessorieshd2000bwAinda não há avaliações

- E4-E5 - Text - Chapter 5. OPTICAL TRANSPORT NETWORK (OTN)Documento9 páginasE4-E5 - Text - Chapter 5. OPTICAL TRANSPORT NETWORK (OTN)nilesh_2014Ainda não há avaliações

- CatalogueDocumento3 páginasCatalogueGrayloupAinda não há avaliações

- 160513071421Documento5 páginas160513071421VJ ChaudharyAinda não há avaliações

- 03 2566Documento382 páginas03 2566Luis Enrique PeñaAinda não há avaliações

- Probit AnalysisDocumento7 páginasProbit AnalysisUfuoma BabatundeAinda não há avaliações

- Analog TV StandardsDocumento5 páginasAnalog TV StandardsJayson AlvaAinda não há avaliações

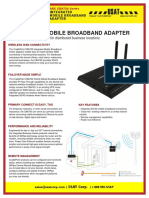

- CradlePoint ARC CBA 750 SpecsheetDocumento3 páginasCradlePoint ARC CBA 750 SpecsheetBuchi ReddyAinda não há avaliações

- DF107 E2Documento2 páginasDF107 E2Kaushik SinghaAinda não há avaliações

- How Custody Transfer Works: Accuracy Critical for Financial ExposureDocumento4 páginasHow Custody Transfer Works: Accuracy Critical for Financial ExposureJoanna George - Joseph100% (1)

- Manual Implem Note 1982417 CONTRATOS SEPEDocumento24 páginasManual Implem Note 1982417 CONTRATOS SEPEfrubenvegaAinda não há avaliações

- Putty For Windows, Linux and Mac - Install SSH in PuTTYDocumento10 páginasPutty For Windows, Linux and Mac - Install SSH in PuTTYRiris Sigit PramonoAinda não há avaliações

- Aectp-300 Edd v1 eDocumento462 páginasAectp-300 Edd v1 eLjubomirSinđelićAinda não há avaliações

- Basics of Motor Starters and ContactorsDocumento37 páginasBasics of Motor Starters and ContactorsTrifonas Krommidas100% (1)

- Epson L805Documento144 páginasEpson L805olufemiAinda não há avaliações

- CAD Standards Manual 17Documento12 páginasCAD Standards Manual 17ed bookerAinda não há avaliações

- Setting Up Your Programming Assignment EnvironmentDocumento13 páginasSetting Up Your Programming Assignment EnvironmentAgus LesmanaAinda não há avaliações

- mfl68280101 Im Multifodu-Idu 20140911071153Documento55 páginasmfl68280101 Im Multifodu-Idu 20140911071153ANDERSON HERRERAAinda não há avaliações

- Marking Scheme For Computer Networks ExamDocumento18 páginasMarking Scheme For Computer Networks Examtuyambaze jean claudeAinda não há avaliações

- Nokia ReportsDocumento2 páginasNokia Reportsnarendraiit2003100% (3)

- CIS Red Hat Enterprise Linux 7 Benchmark v2.2.0Documento386 páginasCIS Red Hat Enterprise Linux 7 Benchmark v2.2.0Sandro MeloAinda não há avaliações

- E0900048-V4 LIGO UHV Welding SpecDocumento7 páginasE0900048-V4 LIGO UHV Welding SpecBenjamin BrownAinda não há avaliações

- Architect's ResumeDocumento3 páginasArchitect's ResumeovaishashmiAinda não há avaliações

- Edgenta Ar2022Documento223 páginasEdgenta Ar2022TetAtEdAinda não há avaliações

- Rail Wheel Int. TOTPDocumento93 páginasRail Wheel Int. TOTPkr_abhijeet72356587100% (3)

- Code For Offshore Personnel Transfer Systems July 2022Documento92 páginasCode For Offshore Personnel Transfer Systems July 2022Ozan DurmazogluAinda não há avaliações

- Type 15082, Type 15083 - Ball Valve Full BoreDocumento1 páginaType 15082, Type 15083 - Ball Valve Full BoreJay Van BuurninkAinda não há avaliações

- 6500 MaintenanceDocumento563 páginas6500 MaintenanceStanisław ZakrzewskiAinda não há avaliações

- Build Your Own Electric Vehicle, Third EditionNo EverandBuild Your Own Electric Vehicle, Third EditionNota: 4.5 de 5 estrelas4.5/5 (3)

- The Rare Metals War: the dark side of clean energy and digital technologiesNo EverandThe Rare Metals War: the dark side of clean energy and digital technologiesNota: 5 de 5 estrelas5/5 (2)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionNo EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionNota: 4.5 de 5 estrelas4.5/5 (542)

- Industrial Piping and Equipment Estimating ManualNo EverandIndustrial Piping and Equipment Estimating ManualNota: 5 de 5 estrelas5/5 (7)

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsNo EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsNota: 4 de 5 estrelas4/5 (1)

- Asset Integrity Management for Offshore and Onshore StructuresNo EverandAsset Integrity Management for Offshore and Onshore StructuresAinda não há avaliações

- Digital Gold: The Beginner's Guide to Digital Product Success, Learn Useful Tips and Methods on How to Create Digital Products and Earn Massive ProfitsNo EverandDigital Gold: The Beginner's Guide to Digital Product Success, Learn Useful Tips and Methods on How to Create Digital Products and Earn Massive ProfitsNota: 5 de 5 estrelas5/5 (3)