Escolar Documentos

Profissional Documentos

Cultura Documentos

Pilling

Enviado por

Gopal KrishnanDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Pilling

Enviado por

Gopal KrishnanDireitos autorais:

Formatos disponíveis

Pilling

Introduction:

Fabric pilling, is a process that results in the formation of small fuzzy balls or pills on the

fabric surface. In the short term, pilling may lead to unattractive fuzzy fabric; over time,

especially with natural fabrics, it can lead to a complete wear-through of the fabric.

A pills evolution involves three major steps: first, abrasion on the fabricthe fibers rubbing

against themselves or another surface cause fuzz.

Further agitation then causes a collection of fiber to appear as clinging balls, anchored to the

fabric much like a burrs tiny hooks (see Figure 1). Finally, as mechanical and physical action

weakens the pills ability to cling over time, it falls off the fabric in its last stage known as

depletion or removal.

Figure 1: Fiber Ends Entangle to Create Pill on Fabric (50x magnification).

Although pilling has been with us for some time, it wasnt a significant problem with wool and

cotton fibers. With the invention of synthetic fibers, however, consumers and manufacturers

began to take note of the undesirable pilling syndrome.

2-Causes:

Pills are formed by a rubbing action on loose fibres which are present on the fabric surface.

Pilling was originally a fault found mainly in knitted woolen goods made from soft twisted yarns.

The introduction of man-made fibres into clothing has aggravated its seriousness. The

explanation for this is that these fibres are stronger than wool so that the pills remain attached to

the fabric surface rather than breaking away as would be the case with wool.

The initial effect of abrasion on the surface of a fabric is the formation of fuzz as the result of two

processes, the brushing up of free fibre ends not enclosed within the yarn structure and the

conversion of fibre loops into free fibre ends by the pulling out of one of the two ends of the

loop. The fuzz formation must reach a critical height, which is dependent on fibre

characteristics, before pill formation can occur. The greater the breaking strength and the lower

the bending stiffness of the fibres, the more likely they are to be pulled out of the fabric structure

producing long protruding fibres. Fibre with low breaking strength and high bending stiffness will

tend to break before being pulled fully out of the structure leading to shorter protruding fibres.

The next stage is the entanglement of the loose fibres and the formation of them into a roughly

spherical mass of fibres which is held to the surface by anchor fibres. As the pill undergoes

further rubbing, the anchor fibres can be pulled further out of the structure or fatigued and

eventually fractured depending on the fibre properties and how tightly they are held by the

structure. In the case of low-strength fibres the pills will easily be detached from the fabric but

with fabrics made from high-strength fibres the pills will tend to remain in place. This factor is

responsible for the increase in the propensity for fabrics to pill with the introduction of synthetic

fibres. Low twist factors and loose fabric structures such as knitwear have a rapid fibre pull-out

rate and long staple length resulting in the development of numerous large pills. The life of

these pills depends on the balance between the rate of fibre fatigue and the rate of roll-up. Pill

density can increase steadily, reach a plateau or pass through a maximum and decrease with

time depending on the relative rates of pill formation and pill detachment. The pill density is also

governed by the number of loose fibre ends on the surface and this may set an upper limit to the

number of pills that will potentially develop. This has important implications for the length of a

pilling test because if the test is carried on too long the pill density may have passed its

maximum.

Fibres with reduced flex life will increase the rate of pill wear-off. Because the fibres that make

up the pills come from the yarns in the fabric any changes which hold the fibres more firmly in

the yarns will reduce the amount of pilling. The use of higher twist in the yarn, reduced yarn

hairiness, longer fibres, increased inter-fibre friction, increased linear density of the fibre,

brushing and cropping of the fabric surface to remove loose fibre ends, a high number of

threads per unit length and special chemical treatments to reduce fibre migration will reduce the

tendency to pill. The presence of softeners or fibre lubricants on a fabric will increase pilling.

Fabrics made from blended fibres often have a greater tendency to pill as it has been found [3]

that the finer fibres in a blend preferentially migrate towards the yarnexterior due to the

difference in properties.

Adverse effects:

Pilling is an important problem not only for textile and clothes manufacturers but also for users.

The effect of the pilling process

Você também pode gostar

- Pilling-Fabric Defect: Mechanism ofDocumento6 páginasPilling-Fabric Defect: Mechanism ofনাজীম সরোয়ারAinda não há avaliações

- PILLING Textile Testing by Abubakkar MarwatDocumento8 páginasPILLING Textile Testing by Abubakkar MarwatAbu Bakkar100% (1)

- Fabric Pilling Test ProcedureDocumento2 páginasFabric Pilling Test ProcedureMizanur RahmanAinda não há avaliações

- How To Determine The Tensile Strength of Plant Fibres PracticallyDocumento4 páginasHow To Determine The Tensile Strength of Plant Fibres Practicallyeclipsegirl_1994100% (5)

- Fabric Shrinkage GuideDocumento9 páginasFabric Shrinkage Guideনাজীম সরোয়ারAinda não há avaliações

- Pilling of TextilesDocumento16 páginasPilling of TextilesAthirah Mansor100% (2)

- PillingDocumento4 páginasPillingRamesh IyerAinda não há avaliações

- Fibre FinenessDocumento10 páginasFibre Finenessgokul saravananAinda não há avaliações

- Non WovenDocumento9 páginasNon WovenIbrahim Khalil100% (1)

- Anti-Pilling Finishes for TextilesDocumento18 páginasAnti-Pilling Finishes for TextilesBeyene Dumecha100% (1)

- <!DOCTYPE HTML PUBLIC "-//W3C//DTD HTML 4.01 Transitional//EN" "http://www.w3.org/TR/html4/loose.dtd"> <HTML><HEAD><META HTTP-EQUIV="Content-Type" CONTENT="text/html; charset=iso-8859-1"> <TITLE>ERROR: The requested URL could not be retrieved</TITLE> <STYLE type="text/css"><!--BODY{background-color:#ffffff;font-family:verdana,sans-serif}PRE{font-family:sans-serif}--></STYLE> </HEAD><BODY> <H1>ERROR</H1> <H2>The requested URL could not be retrieved</H2> <HR noshade size="1px"> <P> While trying to process the request: <PRE> TEXT http://www.scribd.com/titlecleaner?title=pilling.ppt HTTP/1.1 Host: www.scribd.com Proxy-Connection: keep-alive Accept: */* Origin: http://www.scribd.com X-CSRF-Token: 447cf3288df1dd989d922e56a01523c5ad58edc9 User-Agent: Mozilla/5.0 (Windows NT 6.1) AppleWebKit/537.36 (KHTML, like Gecko) Chrome/29.0.1547.76 Safari/537.36 X-Requested-With: XMLHttpRequest Referer: http://www.scribd.com/upload-document?archive_doc=47022268&metadata=%7B%22actioDocumento15 páginas<!DOCTYPE HTML PUBLIC "-//W3C//DTD HTML 4.01 Transitional//EN" "http://www.w3.org/TR/html4/loose.dtd"> <HTML><HEAD><META HTTP-EQUIV="Content-Type" CONTENT="text/html; charset=iso-8859-1"> <TITLE>ERROR: The requested URL could not be retrieved</TITLE> <STYLE type="text/css"><!--BODY{background-color:#ffffff;font-family:verdana,sans-serif}PRE{font-family:sans-serif}--></STYLE> </HEAD><BODY> <H1>ERROR</H1> <H2>The requested URL could not be retrieved</H2> <HR noshade size="1px"> <P> While trying to process the request: <PRE> TEXT http://www.scribd.com/titlecleaner?title=pilling.ppt HTTP/1.1 Host: www.scribd.com Proxy-Connection: keep-alive Accept: */* Origin: http://www.scribd.com X-CSRF-Token: 447cf3288df1dd989d922e56a01523c5ad58edc9 User-Agent: Mozilla/5.0 (Windows NT 6.1) AppleWebKit/537.36 (KHTML, like Gecko) Chrome/29.0.1547.76 Safari/537.36 X-Requested-With: XMLHttpRequest Referer: http://www.scribd.com/upload-document?archive_doc=47022268&metadata=%7B%22actiovishnuvardhinikjAinda não há avaliações

- Factors Affecting Fabric ShrinkageDocumento6 páginasFactors Affecting Fabric Shrinkageনাজীম সরোয়ারAinda não há avaliações

- Fibre IntroductionDocumento18 páginasFibre IntroductionKunal SuvarnaAinda não há avaliações

- ShrinkageDocumento2 páginasShrinkageArsh SidhuAinda não há avaliações

- Introduction To FiberDocumento12 páginasIntroduction To FiberTowfic Aziz KanonAinda não há avaliações

- Filament SpinningDocumento31 páginasFilament SpinningGopal KrishnanAinda não há avaliações

- The Manufacturing Process of FabricDocumento3 páginasThe Manufacturing Process of FabricCyber VirginAinda não há avaliações

- Pill (Textile) - WikipediaDocumento5 páginasPill (Textile) - WikipediaMd Ariful IslamAinda não há avaliações

- Introduction to Textile Fibers and ProcessesDocumento70 páginasIntroduction to Textile Fibers and ProcessesDiwakar KumarAinda não há avaliações

- Non Woven FabricsDocumento3 páginasNon Woven Fabricskhushi savlaAinda não há avaliações

- Textile Yarns PDFDocumento35 páginasTextile Yarns PDFVu Ngo Tuan100% (1)

- Shrinkage: Types and Control MethodsDocumento54 páginasShrinkage: Types and Control MethodsRichardValenciaAinda não há avaliações

- Non WovenDocumento13 páginasNon Wovenmichelle_athukoralaAinda não há avaliações

- Non WovenDocumento28 páginasNon WovenAl AminAinda não há avaliações

- Fiber Textile Fashion IndustriesDocumento33 páginasFiber Textile Fashion IndustriesRishi KumarAinda não há avaliações

- Question Answer 1 PDFDocumento12 páginasQuestion Answer 1 PDFArsalan Ahmed SheikhAinda não há avaliações

- Properties of FibersDocumento10 páginasProperties of FibersARYAN RATHOREAinda não há avaliações

- Cotton Fabric SewabilityDocumento9 páginasCotton Fabric SewabilityTuan Nguyen MinhAinda não há avaliações

- Nonwovens HandoutsDocumento9 páginasNonwovens HandoutsTamer Farouk KhalifaAinda não há avaliações

- Advancements and Modifications in Conventional Fiber and Yarn Manufacturing ProcessesDocumento33 páginasAdvancements and Modifications in Conventional Fiber and Yarn Manufacturing ProcessesShahan AkhtarAinda não há avaliações

- Disposable DiaperDocumento11 páginasDisposable DiaperAnna Maria TorcelinoAinda não há avaliações

- Two or More Yarns Are Intertwined To Form An Elongated Structure. The Long Direction IsDocumento4 páginasTwo or More Yarns Are Intertwined To Form An Elongated Structure. The Long Direction Isblakk archimedesAinda não há avaliações

- Different Types of FabricsDocumento17 páginasDifferent Types of Fabricsdr beshoy awadAinda não há avaliações

- Ov Ov Ov Ov OvDocumento6 páginasOv Ov Ov Ov Ovkasun148Ainda não há avaliações

- Introduction To TextilesDocumento13 páginasIntroduction To TextilesJashwa Paul ChhettriAinda não há avaliações

- Unit-3 SyntheticsDocumento10 páginasUnit-3 SyntheticsumidgrtAinda não há avaliações

- Non Woven FabricDocumento5 páginasNon Woven FabricK.s. RameshAinda não há avaliações

- Multicomponent Quilted FabricDocumento31 páginasMulticomponent Quilted FabricEstihak Bhuiyan EftiAinda não há avaliações

- 561566642977unit-3 - TextilesDocumento11 páginas561566642977unit-3 - TextilesGaganpreet Kaur Fashion DesigningAinda não há avaliações

- 1.classification of Fibers and Their General Properties: I. II. IiiDocumento5 páginas1.classification of Fibers and Their General Properties: I. II. IiizubairAinda não há avaliações

- Textile Basics NotesDocumento33 páginasTextile Basics Notesparthraj89100% (3)

- Paper On Textile Materials - Matter or SubstanceDocumento38 páginasPaper On Textile Materials - Matter or SubstanceKristie LaurierAinda não há avaliações

- Escanear 0004Documento1 páginaEscanear 0004Diana Marcela Sierra VarelaAinda não há avaliações

- Jute Fiber AssignmentDocumento4 páginasJute Fiber AssignmentSharifur Rahman FaheemAinda não há avaliações

- Fibre in DetailsDocumento32 páginasFibre in Detailssundarcheers33320% (1)

- Unit-5 Cutting of Synthetic MaterialsDocumento7 páginasUnit-5 Cutting of Synthetic MaterialsumidgrtAinda não há avaliações

- Affect of Acid and Alkaline On Tensile Stength of Fibers.Documento26 páginasAffect of Acid and Alkaline On Tensile Stength of Fibers.Pranjal Mehta57% (70)

- Types of Non-Woven Fabric, Manufacturing Processes and ApplicationsDocumento11 páginasTypes of Non-Woven Fabric, Manufacturing Processes and Applicationsjemms16Ainda não há avaliações

- Nonwoven Fabric - Wikipedia, The Free EncyclopediaDocumento5 páginasNonwoven Fabric - Wikipedia, The Free EncyclopediasangareeeAinda não há avaliações

- Non WovenDocumento73 páginasNon Wovenসময়ের বাহকAinda não há avaliações

- Dry FinishingDocumento3 páginasDry FinishingRonik JAinda não há avaliações

- Textile Finishing PDFDocumento17 páginasTextile Finishing PDFGemeda Gebino33% (3)

- Processing of Man-Made Fibres and Blended Textiles: BlendingDocumento23 páginasProcessing of Man-Made Fibres and Blended Textiles: BlendinghawAinda não há avaliações

- All About TextileDocumento8 páginasAll About Textilesathieswaran100% (2)

- Centuries AgoDocumento2 páginasCenturies AgoAulia MaghfirahAinda não há avaliações

- Eoj52jdur1azduktpypb Different Types of Fabrics 220813191820 7d5d1a08Documento43 páginasEoj52jdur1azduktpypb Different Types of Fabrics 220813191820 7d5d1a08dr beshoy awadAinda não há avaliações

- Pilling Resistance PropertiesDocumento6 páginasPilling Resistance PropertiesMomtaz Islam SobujAinda não há avaliações

- Sewing Knits from Fit to Finish: Proven Methods for Conventional Machine and SergerNo EverandSewing Knits from Fit to Finish: Proven Methods for Conventional Machine and SergerNota: 4 de 5 estrelas4/5 (3)

- Filament SpinningDocumento31 páginasFilament SpinningGopal KrishnanAinda não há avaliações

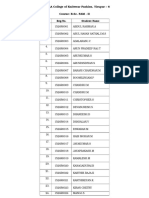

- Bharathiar University Woven Garment Construction Practical ExamDocumento1 páginaBharathiar University Woven Garment Construction Practical ExamGopal KrishnanAinda não há avaliações

- NIFT-TEA College of Knitwear Fashion: UG Third Year Apparel Fashion DesigningDocumento2 páginasNIFT-TEA College of Knitwear Fashion: UG Third Year Apparel Fashion DesigningGopal KrishnanAinda não há avaliações

- NIFT-TEA College of Knitwear Fashion, Tirupur – 6 Student Lists B.Sc., B.Com., and B.Com. (CA) - IIDocumento30 páginasNIFT-TEA College of Knitwear Fashion, Tirupur – 6 Student Lists B.Sc., B.Com., and B.Com. (CA) - IIGopal KrishnanAinda não há avaliações

- Spiro ChemicalsDocumento4 páginasSpiro ChemicalsGopal KrishnanAinda não há avaliações

- Filament SpinningDocumento31 páginasFilament SpinningGopal KrishnanAinda não há avaliações

- Statement On The Status of Tamil As A Classical LanguageDocumento3 páginasStatement On The Status of Tamil As A Classical LanguageGopal KrishnanAinda não há avaliações

- Statement On The Status of Tamil As A Classical LanguageDocumento3 páginasStatement On The Status of Tamil As A Classical LanguageGopal KrishnanAinda não há avaliações

- Contribution of Fabric Characteristics and Laundering To Shrinkage of Weft Knitted FabricsDocumento9 páginasContribution of Fabric Characteristics and Laundering To Shrinkage of Weft Knitted FabricsGopal KrishnanAinda não há avaliações

- Tfy & KFS CT I QPDocumento2 páginasTfy & KFS CT I QPGopal KrishnanAinda não há avaliações

- Fabrics Faults or DefectsDocumento13 páginasFabrics Faults or DefectsGopal KrishnanAinda não há avaliações

- Fabrics Faults or DefectsDocumento13 páginasFabrics Faults or DefectsGopal KrishnanAinda não há avaliações

- Kfs - I M.SC CT II QPDocumento1 páginaKfs - I M.SC CT II QPGopal KrishnanAinda não há avaliações

- Model Exam QP AQM 13Documento2 páginasModel Exam QP AQM 13Gopal KrishnanAinda não há avaliações

- Aqm QPDocumento2 páginasAqm QPGopal KrishnanAinda não há avaliações

- 2010-AGBA SMJafariDocumento12 páginas2010-AGBA SMJafariGopal KrishnanAinda não há avaliações

- Antimicrobial Textile Prepared by Silver Deposition On Dielectric Barrier Discharge Treated Cotton/Polyester FabricDocumento3 páginasAntimicrobial Textile Prepared by Silver Deposition On Dielectric Barrier Discharge Treated Cotton/Polyester FabricGopal KrishnanAinda não há avaliações

- Reactive DyesDocumento1 páginaReactive DyesGopal KrishnanAinda não há avaliações

- Aqm QPDocumento2 páginasAqm QPGopal KrishnanAinda não há avaliações

- Common Problems in DesizingDocumento4 páginasCommon Problems in DesizingGopal Krishnan100% (1)

- Common Problems in DesizingDocumento4 páginasCommon Problems in DesizingGopal Krishnan100% (1)

- 1.2 - Sewing Machine and Special AttachmentsDocumento3 páginas1.2 - Sewing Machine and Special Attachmentsmaya_muth0% (1)

- KNIT - Dollytime - Toffee TedDocumento7 páginasKNIT - Dollytime - Toffee TedClaireAinda não há avaliações

- Crochet Tiny Present PatternDocumento9 páginasCrochet Tiny Present Patternssmika09100% (1)

- Azelis PDF FinalDocumento32 páginasAzelis PDF Finalapi-322253649Ainda não há avaliações

- Quality Assurance Circular in KnittingDocumento10 páginasQuality Assurance Circular in KnittingyunathemeAinda não há avaliações

- Arif ProjectDocumento75 páginasArif ProjectWaqas Mehmood BaigAinda não há avaliações

- Katie Jones - Carnaby CAL ENGDocumento41 páginasKatie Jones - Carnaby CAL ENGCamille SantosAinda não há avaliações

- Primary Base Weft Knitted StructuresDocumento5 páginasPrimary Base Weft Knitted StructuresShantnu MittalAinda não há avaliações

- Dragón ?Documento56 páginasDragón ?Joy Cáceres100% (5)

- 2019-08-04 Crochet World - Sanet.St PDFDocumento68 páginas2019-08-04 Crochet World - Sanet.St PDFSharon Taylor100% (6)

- CRDDocumento33 páginasCRDAnonymous JIxU3T8Ainda não há avaliações

- Crochet Rosemary SweaterDocumento4 páginasCrochet Rosemary SweaterDee100% (1)

- Temple To Hold The Fabric Width Way On The LoomDocumento7 páginasTemple To Hold The Fabric Width Way On The LoomTejas pimpleAinda não há avaliações

- Fashion Designer's Passion for Ancient Culture and NatureDocumento2 páginasFashion Designer's Passion for Ancient Culture and NatureRavi KetavAinda não há avaliações

- Apron SewDocumento8 páginasApron SewjosembranaAinda não há avaliações

- Reducing Fullness Methods ExplainedDocumento5 páginasReducing Fullness Methods ExplainedCaphas Kaptain100% (1)

- Pattern 06 - TATA BTSDocumento6 páginasPattern 06 - TATA BTSPara JogosAinda não há avaliações

- PS-1 Suit Design and PatternsDocumento22 páginasPS-1 Suit Design and PatternsyeraAinda não há avaliações

- Peachfuzz and Butter Crocheted HamstersDocumento8 páginasPeachfuzz and Butter Crocheted HamstersCammy87100% (2)

- Sewing Thread: Types of Sewing Thread Being Used in The Garments Industry of BangladeshDocumento9 páginasSewing Thread: Types of Sewing Thread Being Used in The Garments Industry of BangladeshAbdur Rahim RumonAinda não há avaliações

- HM Group Supplier List APR 2022Documento461 páginasHM Group Supplier List APR 2022Emdad HossainAinda não há avaliações

- Rpet UpgratedDocumento11 páginasRpet UpgratedAdnan Sanzid Ali 211-23-999Ainda não há avaliações

- Camion de Bomberos InglesDocumento4 páginasCamion de Bomberos InglesMaria Eva PerezAinda não há avaliações

- Introduction To TextileDocumento30 páginasIntroduction To Textileumar.niift3049100% (1)

- Kenmore 158.1020 Sewing Machine Instruction ManualDocumento46 páginasKenmore 158.1020 Sewing Machine Instruction ManualiliiexpugnansAinda não há avaliações

- Final PresentationDocumento49 páginasFinal PresentationMizanur RahmanAinda não há avaliações

- Inside Crochet Issue 146 - 2022Documento136 páginasInside Crochet Issue 146 - 2022miriamvarela100% (4)

- Fabric Burn Test IdentificationDocumento5 páginasFabric Burn Test IdentificationARIFUL ISLAMAinda não há avaliações

- Reviving India's ancient craft of natural dyeing for sustainabilityDocumento31 páginasReviving India's ancient craft of natural dyeing for sustainabilityAnne CalyxAinda não há avaliações

- Chanderi SareeDocumento7 páginasChanderi Sareealeena raviAinda não há avaliações