Escolar Documentos

Profissional Documentos

Cultura Documentos

SV Pilot Crosby Type-93

Enviado por

MarcelocrossDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

SV Pilot Crosby Type-93

Enviado por

MarcelocrossDireitos autorais:

Formatos disponíveis

******

* EX *

******

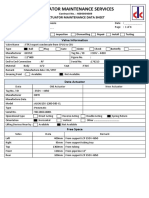

DWN B.TSEKOURAS 1983

MAINTENANCE INSTRUCTIONS FOR

CHK R.DALTON 1983

TYPE 93 POSITIVE PRESSURE

APPR D.PAPA 1983

POSRVS

APPR

SIZE

REPORT NUMBER

REV

APPR A

05.9040.081

J

APPR PAGE 1 OF 22

FORM NO. 910 J 5/93

ANDERSON GREENWOOD CROSBY PART NUMBER

05.9040.081 Page 2 See Revision

Status Below

REVISIONS

REV. DESCRIPTION APPROVALS/DATE

H

ECN #98-125-13

Revised entire report.

S.WILLIS 5-12-98

J.DIAL 5-19-98

D.PAPA 5-20-98

I

ECN #99-1053

Deleted 4.6.

S.WILLIS 5-07-99

C.PORTER 5-10-99

D.PAPA 5-10-99

J

ECN #01-1059

S.WILLIS 8-01-01

S.CONNALLY 8-01-01

E.TEZZO 8-01-01

FORM NO. 915 12/96

ANDERSON GREENWOOD CROSBY REPORT NUMBER

05.9040.081 Page 3 Rev. J

INSTRUCTIONS MAINTENANCE FOR

TYPE 93 POSITIVE PRESSURE POSRV'S

The intent of these instructions is to acquaint the user with the storage, installation and operation of this

product. Please read these instructions carefully before installation.

WARNING

Removal of the seal wires in an attempt to adjust and/or repair this product by unauthorized or

unqualified persons voids the product warranty and may cause damage to equipment and serious injury or

death to persons.

The product is a safety related component intended for use in critical applications. The improper

application, installation or maintenance of the product or the use of parts or components not

manufactured by Anderson Greenwood Crosby may result in a failure of the product.

Any installation, maintenance, adjustment, test, etc. performed on the Product must be done in

accordance with the requirements of all applicable Anderson Greenwood Crosby Procedures and

Instructions as well as applicable National and International Codes and Standards.

SAFETY PRECAUTIONS

When the pressure relief valve is under pressure never place any part of your body near the pilot exhaust

nor the outlet of the main valve.

The main valve outlet should be piped or vented to a safe location.

Always wear proper safety gear to protect head, eyes, ears, etc. anytime you are near pressurized valves.

Never attempt to remove the pressure relief valve from a system that is pressurized.

Never make adjustments to or perform maintenance on the pressure relief valve while in service unless

the valve is isolated from the system pressure. If not properly isolated from the system pressure, the

pressure relief valve may inadvertently open resulting in serious injury.

Remove the pressure relief valve prior to performing any pressure testing of the system.

The safety of lives and property often depends on the proper operation of the pressure relief valve. The

valve must be maintained according to appropriate instructions and must be periodically tested and

reconditioned to ensure correct function.

STORAGE AND HANDLING

Pressure relief valve performance may be adversely affected if the valve is stored for an extended period

without proper protection. Rough handling and dirt may damage, deform, or cause misalignment of

valve parts and may alter the pressure setting and adversely affect valve performance and seat tightness.

It is recommended that the valve be stored in the original shipping container in a warehouse or as a

minimum on a dry surface with a protective covering until installation. Inlet and outlet protectors should

remain in place until the valve is ready to be installed in the system.

ANDERSON GREENWOOD CROSBY REPORT NUMBER

05.9040.081 Page 4 Rev. J

TABLE OF CONTENTS

1.0 GENERAL VALVE DESCRIPTION AND START-UP5

2.0 MAIN VALVE MAINTENANCE6

3.0 PILOT MAINTENANCE10

4.0 PILOT SET PRESSURE ADJUSTMENT14

5.0 ACCESSORY REPAIR17

6.0 LEAK TESTING ASSEMBLY19

7.0 PILOT SET PRESSURE FIELD TEST PROCEDURE19

8.0 SOFT GOODS REPAIR KITS.21

ANDERSON GREENWOOD CROSBY REPORT NUMBER

05.9040.081 Page 5 Rev. J

1.0 GENERAL VALVE DESCRIPTION & START-UP

1.1 OPERATION

The AGCO Pilot Operated Safety Relief Valves utilize the

principle of back-loading the top of a differential area

diaphragm with line pressure to hold the diaphragm closed up to

set pressure. At set pressure the pilot valve relieves,

partially evacuating the dome (volume above the diaphragm) and

the seat assembly lifts permitting discharge from the main

valve. When the pilot reseats, line pressure is diverted to

the dome closing the main valve.

1.2 INSTALLATION

Both inlet and outlet may be standard ANSI or DIN flange

connections and are to be installed in accordance with accepted

piping practices.

The installed position of the safety valve should be in the

upright position as shown in Figure 1.

When remote pressure pick-up is used the pilot supply tube is

connected to a remote location rather than to the inlet neck of

the valve. If a block valve is used in the remote pilot supply

line, be sure it is opened before pressurizing the system.

NOTE: Remote pressure pick-up piping must have the equivalent

flow area of 1/2 tubing for lengths up to 20 feet. For

lengths greater than 20 feet, larger tubing or pipe

should be used.

ANDERSON GREENWOOD CROSBY REPORT NUMBER

05.9040.081 Page 6 Rev. J

1.3 START-UP

There must be pressure at the valve inlet to establish a

differential in force across the diaphragm and load it in the

closed position. Pressure must pass through the pilot supply

tube and pilot and exert force on the diaphragm. On normal

start-up the valve loads itself without incident as pressure

increases.

Block valves are often used under safety valves in order to

isolate them when maintenance is required. When putting the

safety valve in service be sure the block valve is fully

opened. If the block valve is opened after system start-up,

the safety valve may briefly vent to the atmosphere before the

dome gets pressurized. It will then close.

2.0 MAIN VALVE MAINTENANCE (Refer to Figures 2 & 2A)

2.1 Valve Configuration

Two different valve internals are used in the main valve,

depending on set pressure. The sponge seat is used for the set

pressures shown below. The O-Ring seat with guide is used for

all pressures above these values. For some applications, a

guide may be used in place of Item 11 with a sponge seat.

SET PRESSURES WHERE SPONGE SEAT IS USED

VALVE SIZE 2 X 3 3 X 4 4 X 6 6 X 8 8 X 10 10 X 12 12 X 16

SET PRESSURE

(PSIG)

BELOW

2.5 PSIG

BELOW

1.5

PSIG

BELOW 1.0 PSIG

2.2 DISASSEMBLY

Disconnect the supply tube from the pilot, remove the cap

bolts, lift the cap from the valve body and lift the diaphragm,

seat and guide (where used) from the valve. Remove the seat

bolt(s) to separate the diaphragm from the seat, guide, and

retainer plates.

2.3 REPAIR

Inspect the nozzle seating area for nicks or scratches. If

they cannot be removed with crocus cloth or fine sandpaper, the

nozzle must be remachined. On steel valves the nozzle may be

removed from the body. Machining of the nozzles should be

limited to .06 material removal.

ANDERSON GREENWOOD CROSBY REPORT NUMBER

05.9040.081 Page 7 Rev. J

2.4 ASSEMBLY

Reassemble the diaphragm, seat guide, and pilot supply tube in

the reverse order of disassembly. Apply a light film of

lubricant to all threaded parts. Care should be taken to

adequately tighten the seat bolt(s) on those valves with guides

to prevent the diaphragm from pulling away from the bolt under

pressure.

On valves with sponge seats (no guide), the seat bolt need not

be tightened as much since these valves are used at lower

pressures and excessive tightening will distort the seat.

Carefully insert the guide (where used) squarely into the

nozzle and lower the diaphragm assembly into place. Align the

holes on the diaphragm O.D. with those on the body.

The guide spring, Item 3, is used to create frictional drag to

prevent valve chatter caused by excessive inlet piping pressure

losses. The tension of these springs is correct when the

diaphragm/guide assembly slowly free falls to the closed

position. If the assembly will not do this, adjust the spring

tension by bending the tail or lower half of the spring.

Refer to Page 20 for Soft goods Repair Kits.

ANDERSON GREENWOOD CROSBY REPORT NUMBER

05.9040.081 Page 8 Rev. J

ANDERSON GREENWOOD CROSBY REPORT NUMBER

05.9040.081 Page 9 Rev. J

ANDERSON GREENWOOD CROSBY REPORT NUMBER

05.9040.081 Page 10 Rev. J

3.0 PILOT MAINTENANCE (Refer to Figures 3 & 4)

3.1 DISASSEMBLY

To facilitate assembly, place all parts removed in an orderly

arrangement so the correct parts are assembled in the proper

sequence. Refer to Figure 3 for parts description and

location.

3.1.1 Begin by removing spring bonnet (Remove the spring

compression before attempting to removing bonnet).

Remove case bolts and upper case. Loosen tube fittings

on boost tube at lower case and body. Remove spindle

nut while holding hex spacer. Remove diaphragms, sense

and boost plates and spacers. Remove lower case and

spindle/seat assembly. Remove blowdown adjustment screw

and supply port tube fitting.

Note: Shim washers (33) may be in assembly to accomplish

proper stack height. If so, note location and

quantity.

3.1.2 Clean all parts and replace all soft goods. The

spindle/seat assembly is factory assembled and must be

replaced as a unit. If the nozzle is nicked or

scratched, it should be replaced. To remove it, use a

deep socket.

3.2 ASSEMBLY

Assembly is done in the reverse order of disassembly.

Lubricate all screw threads and end of spring adjusting screw

that bears against spring washer. Use Down Corning No. 33

Silicone grease or equivalent. When assembling pilot, the

following should be observed:

3.2.1 Place seat/spindle assembly (11) into pilot body.

Install spindle spacer (32) on top of shim washers. Lay

straight edge across pilot body (14) and check gap

between spindle spacer and straight edge. Add or remove

shim washers (33) as required to have top of spindle

spacer (32) even with top of body (14).

ANDERSON GREENWOOD CROSBY REPORT NUMBER

05.9040.081 Page 11 Rev. J

3.2.2 The holes in spindle diaphragm must be aligned with all

holes in the body. The small hole in lower case must be

aligned with hole in the body. Two of the six case

bolts for the medium pressure pilot (Figure 4) must be

assembled though holes in the lower case before it is

attached to the body. After attachment there is

insufficient clearance to do so.

3.2.3 For the medium pressure pilot the hole in the boost

(lower) diaphragm and spacer ring must be aligned with

boost tube port in lower case. The hole in the upper

diaphragm must be positioned away from boost tube part.

3.2.4 Before tightening spindle nut, align holes in lower

case, spacer ring and diaphragms with case bolts.

Tighten spindle nut snugly but not excessively. Three

diaphragms are sandwiched/stack assembly and excessive

tightening will damage them. Hold the hex spacer when

tightening spindle nut to prevent the stack from

rotating.

Refer to Page 21 for Soft Goods Repair Kits.

ANDERSON GREENWOOD CROSBY REPORT NUMBER

05.9040.081 Page 12 Rev. J

ANDERSON GREENWOOD CROSBY REPORT NUMBER

05.9040.081 Page 13 Rev. J

ANDERSON GREENWOOD CROSBY REPORT NUMBER

05.9040.081 Page 14 Rev. J

4.0 PILOT ADJUSTMENT

4.1 GENERAL

Two adjustments are provided; one for varying the pressure at

which the pilot opens and one for varying the pressure at which

the pilot closes. The first adjustment controls the set or

popping pressure, the second the reseat or blowdown

pressure. To adjust set pressure, a test set-up similar to

that shown in Figure 5 should be used.

4.2 SET PRESSURE

This adjustment is obtained by turning the pressure adjusting

bolt, clockwise (in) to increase set pressure and counter-

clockwise (out) to decrease set pressure.

4.3 RESEAT PRESSURE

This adjustment is obtained by turning the blowdown needle

adjusting screw, clockwise (in) to increase blowdown, counter-

clockwise (out) to decrease blowdown. A small interaction

between set pressure and reseat pressure adjustments will

occur, therefore it may be necessary to readjust the set

pressure after setting reseat pressure.

NOTE: If the blowdown adjusting screw has been moved or turned

to either extreme, positioning it midway will aid in

obtaining the correct blowdown. There are approximately

7 to 8 turns to obtain full travel of the adjustment.

Midway from either end should produce a blowdown for

snap action. For modulating pilot action, back the

adjustment screw out (counter-clockwise) to obtain the

adjustment limits given in paragraph 4.5.

4.4 RANGE OF ADJUSTMENT

All Pilots can be adjusted + 10% beyond the nameplate setting.

ANDERSON GREENWOOD CROSBY REPORT NUMBER

05.9040.081 Page 15 Rev. J

4.5 ADJUSTMENT TOLERANCES

(1)

PILOT

ACTION

SET PRESSURE SET PRESSURE

TOLERANCE

(2)

MINIMUM CRACK

PRESSURE AS %

OF NAMEPLATE

SET

SUPPLY PRESSURE

AS

% OF SET FOR

DOME

PRESSURE

RECOVERY

(3)

2WC TO 7WC + .2WC 75 90 + 1

7WC TO 1.0 PSIG

ABOVE 1.0 PSIG

+3%

+3%

90

95

90 + 1

92 1/2 + 1/2

-2WC TO 7WC + .2WC 75 90 + 1

SNAP

-7WC TO-1.0 PSIG

-1 PSI TO 14.7

+3%

+3%

90

95

90 + 1

92 1/2 + 1/2

2WC TO 7WC

7WC TO 1.0 PSIG

ABOVE 1.0 PSIG

+ 2WC

+3%

+3%

75

90

95

100

100

100

MOD-

ULATING

-2WC TO 7WC

-7WC TO 1.0 PSIG

-1.0 PSI TO 14.7

PSIG

+ .2WC

+3%

+3%

75

90

95

100

100

100

NOTES:

(1) SNAP ACTION DOME PRESSURE DECREASES RAPIDLY WITH A SNAP TO 15% + 10%

OF SET PRESSURE AT SET PRESSURE. PILOT SEAT SHOULD BE BUBBLE TIGHT AT

DOME PRESSURE RECOVERY.

MODULATING ACTION DOME PRESSURE DECREASES SLOWLY TO 30% + 5% OF SET

PRESSURE AND RECOVERS TO 60% + 10% OF SET PRESSURE AT SET PRESSURE.

(2) ADJUST SET PRESSURE ON TEST STAND TO 101% + 1% OF NAMEPLATE SETTING TO

ALLOW FOR SPRING TENSION RELAXATION CAUSED BY COMPRESSION OF THE

ELASTOMER IN THE DIAPHRAGM STACK.

(3) PILOT SEAT SHOULD BE BUBBLE TIGHT AT DOME RECOVERY FOR SNAP PILOT

ACTION AND AT 90% OF SET PRESSURE FOR MODULATING PILOT ACTION FOR

VALVES SET ABOVE 7WC. FOR VALVES SET 7WC AND BELOW, THE PILOT SEAT

SHALL BE BUBBLE TIGHT AT 75% OF SET PRESSURE.

ANDERSON GREENWOOD CROSBY REPORT NUMBER

05.9040.081 Page 16 Rev. J

ANDERSON GREENWOOD CROSBY REPORT NUMBER

05.9040.081 Page 17 Rev. J

5.0 ACCESSORY REPAIR

5.1 CHECK VALVE

A check valve is used in the pressure sense line to the pilot

when the safety valve is equipped with a field test or backflow

preventer accessory. A check valve is also installed between

the pilot dome connection and main valve when the safety relief

valve is equipped with a backflow preventer.

The check valve used in the pressure sense line is shown in

Figure 6. This type of check valve is also used for the

backflow preventer accessory between the pilot dome connection

and main valve for set pressures below 15 psig. The diaphragm

is the only part that should require servicing. If the

diaphragm is to be replaced, care should be taken not to

scratch or distort it in the center nozzle sealing area. When

reassembling the check valve, uniformly tighten the body bolts,

first one side, then the opposite side until all are tight. DO

NOT OVERTIGHTEN bolts as this will distort the diaphragm and

cause leakage. For set pressures below 1.0 psig, a diaphragm

gasket, Item 9, may be used between the diaphragm and lower

body. If the check valve has one, replace it with a new one.

If the check valve is not equipped with one, do not put one in.

ANDERSON GREENWOOD CROSBY REPORT NUMBER

05.9040.081 Page 18 Rev. J

The check valve used for the backflow preventer accessory between the pilot

dome connection and main valve for set pressures 15 psig and above is shown in

Figure 6A. The O-ring, Item 4, is the only part that should require

servicing. Remove Item 1 to replace O-ring.

ANDERSON GREENWOOD CROSBY REPORT NUMBER

05.9040.081 Page 19 Rev. J

6.0 LEAK TESTING ASSEMBLY

6.1 GENERAL

The complete valve assembly should be leak tested for internal

and external leaks using a pressure equal to 30% and 90% of

set.

6.2 INTERNAL LEAK TEST

Cover valve outlet with wet piece of paper and observe paper

for movement. Any outward movement indicates a leak. If

leakage is detected, remove paper and spray leak test solution

around nozzle/seat to locate leak. Leakage my be caused by

damaged seat sealing surface or improper squeeze of O-ring or

sponge seat.

6.3 EXTERNAL LEAK TEST

Following the internal leak test, check for external leakage by

applying leak test solution to all joints and seals. Tighten

bolts or fittings as required.

7.0 PILOT SET PRESSURE FIELD TEST PROCEDURE

7.1 GENERAL

The pilot set pressure can be checked in the field by applying

an external test pressure to the pilot through the Field Test

Hand Valve as shown in Figure 7.

NOTE: If the process pressure at the time of test is less than

approximately 30% of the pilot set pressure, the main

valve will not open. If the process pressure is greater

than 30% and the main valve must remain closed,

temporarily replace the pilot exhaust vent with an orifice

plug having an orifice diameter of .040/.060. This

orifice must be removed on completion of Field Testing as

it prevents the Main Valve from opening.

ANDERSON GREENWOOD CROSBY REPORT NUMBER

05.9040.081 Page 20 Rev. J

7.2 PROCEDURE

A. Connect test gas bottle as shown in FIGURE 7.

B. Close vent valve C.

C. Open Field Test Valve B. Test gauge will read process

pressure.

D. Open block Valve A SLOWLY to increase pressure until pilot

pops. The set pressure will be the pressure indicated on

the test gauge at the time of pop.

E. To remove test set up, close valves A and B, open valve

C.

ANDERSON GREENWOOD CROSBY REPORT NUMBER

05.9040.081 Page 21 Rev. J

8.0 REPAIR KITS

Soft goods repair kits contain all the seals, seats and diaphragms to

repair a valve. To order a kit, specify the base number and select

the last three digits from the following tables. To ensure the

purchase of the correct repair kit, the order should specify the valve

model and serial number.

The external bolts on the main valve and pilot are 300 Series

stainless steel. Corrosion of these fasteners may occur however due

to local environmental conditions. The bolt kits listed below contain

the necessary parts to replace these fasteners.

KIT BASE NUMBER: 04.4744.XXX

MAIN VALVE

SPONGE SEAT

KIT MATERIAL 2X3 3X4 4X6 6X8 8X10 10X12 12X16

BUNA-N .232 .242 .252 .262 .272 .282 .292

VITON .233 .243 .253 .263 .273 .283 .293

EPR .234 .244 .254 .264 .274 .284 .294

BUNA-N (1) .235 .245 .255 .265 .275 .285 .295

SOFT

GOODS

VITON (1) .236 .246 .256 .266 .276 .286 .296

BOLT SST .347 .348 .349 .350 .351 .351 .351

(1) TEFLON DIAPHRAGMS.

MAIN VALVE

O-RING SEAT

KIT MATERIAL 2X3 3X4 4X6 6X8 8X10 10X12 12X16

BUNA-N

(5PSI & BELOW)

.237 .247 .257 .267 .277 .287 .297

BUNA-N

(ABOVE 5 PSI)

.542 .543 .544 .545 .546 .547 .548

VITON .238 .248 .258 .268 .278 .288 .298

EPR .239 .249 .259 .269 .279 .289 .299

BUNA-N (1) .240 .250 .260 .270 .280 .290 .300

SOFT

GOODS

VITON (1) .241 .251 .261 .271 .281 .291 .301

BOLT SST .347 .348 .349 .350 .351 .351 .351

(1) TEFLON DIAPHRAGMS.

ANDERSON GREENWOOD CROSBY REPORT NUMBER

05.9040.081 Page 22 Rev. J

PILOT

LOW PRESSURE (BELOW 15 PSI) KIT MATERIAL

VACUUM PRESSURE

MEDIUM

PRESSURE

BUNA-N

VITON

EPR

.010

.013

.016

.011

.014

.017

.012

.015

.018

SOFT

GOODS

BUNA-N (6)

VITON (6)

EPR (6)

.019

.021

.023

.020

.022

.024

.896

.897

.898

BOLT SST .342 .342 .343

(6) TEFLON DIAPHRAGMS.

BACKFLOW PREVENTER CHECK VALVE

KIT TYPE MATERIAL ALL PRESSURE

DIAPHRAGM TEFLON .781 SOFT

GOODS BALL BUNA

VITON

EPR

KALREZ

.344

.345

.346

.782

BOLT DIAPHRAGM SST .335

Você também pode gostar

- Maintenance Manual: Models 8300, 8400, and 8500 Pallet Trucks and Model 8600 Tow TractorDocumento291 páginasMaintenance Manual: Models 8300, 8400, and 8500 Pallet Trucks and Model 8600 Tow TractorJosé Luis Ang Soto92% (13)

- 02-A Kinetico Owners Manual - Commercial Plus Softener SeriesDocumento32 páginas02-A Kinetico Owners Manual - Commercial Plus Softener SeriesCastoriadisAinda não há avaliações

- Mosque BOQDocumento17 páginasMosque BOQHossam Al-Dein Mostafa HelmyAinda não há avaliações

- 5 3 17Documento14 páginas5 3 17Raymond de WeeverAinda não há avaliações

- Level Gauges Definition Types Measuring Range Ordering InformationDocumento3 páginasLevel Gauges Definition Types Measuring Range Ordering Informationkamala 123Ainda não há avaliações

- Centrifugal Compressor: Key Components and ApplicationsDocumento14 páginasCentrifugal Compressor: Key Components and ApplicationsAnis FarhanaAinda não há avaliações

- Statistics for Process Control Engineers: A Practical ApproachNo EverandStatistics for Process Control Engineers: A Practical ApproachAinda não há avaliações

- Installation Procedure - 1200ADocumento18 páginasInstallation Procedure - 1200AHarshkumar PatelAinda não há avaliações

- Handbook Valve Technology 03.04.2020Documento132 páginasHandbook Valve Technology 03.04.2020Ramazan YaşarAinda não há avaliações

- SC/V - Valve Actuator Spring Return: Instruction Manual 5018Documento49 páginasSC/V - Valve Actuator Spring Return: Instruction Manual 5018kaicyemAinda não há avaliações

- Pressure - Vacuum Relief Valve - Part 1Documento10 páginasPressure - Vacuum Relief Valve - Part 1winarnobAinda não há avaliações

- Orifice Plate BrochureDocumento39 páginasOrifice Plate Brochureronzies100% (1)

- Displacer Type Level SwitchDocumento10 páginasDisplacer Type Level SwitchKarthik Chockkalingam100% (1)

- Regulator's Swegelok (High PressuDocumento64 páginasRegulator's Swegelok (High PressuhoangcokhiAinda não há avaliações

- ABO Ball ValveDocumento6 páginasABO Ball ValveSunil BajpaiAinda não há avaliações

- Aligning HR Interventions With Business StrategiesDocumento14 páginasAligning HR Interventions With Business StrategiesSunielAinda não há avaliações

- Liquid Cylinder Manual Cryo-DuraCyl (Contoh Tabung)Documento70 páginasLiquid Cylinder Manual Cryo-DuraCyl (Contoh Tabung)Achmadda FebiyonoAinda não há avaliações

- Velan Forged Steel CatalogueDocumento26 páginasVelan Forged Steel CatalogueJuan Carlos Ojeda RamirezAinda não há avaliações

- Protec SPD BrochureDocumento4 páginasProtec SPD BrochureCrestAinda não há avaliações

- Safety Relief Valves Flanged Type: Makali Valves and Engineering ServiceDocumento6 páginasSafety Relief Valves Flanged Type: Makali Valves and Engineering ServiceHetal Patel100% (1)

- CMPAPPP Separator Vessel and Filter Design GuideDocumento18 páginasCMPAPPP Separator Vessel and Filter Design GuideJWilson73Ainda não há avaliações

- C22-Yb60-M-4763 - 0 Sa3-Ps2, Butterfly Valve, Operating ManualsDocumento173 páginasC22-Yb60-M-4763 - 0 Sa3-Ps2, Butterfly Valve, Operating ManualssartajAinda não há avaliações

- How to select gland packing cross sectionDocumento2 páginasHow to select gland packing cross sectionPramod Kumar GiriAinda não há avaliações

- Shell MESC Number 774133.010.1 (NEAREST)Documento2 páginasShell MESC Number 774133.010.1 (NEAREST)Ehsan Ur Rehman100% (1)

- Actuator Maintenance ServicesDocumento7 páginasActuator Maintenance ServicesKevin MuhalingAinda não há avaliações

- Atmospheric Relief Valve ManualDocumento12 páginasAtmospheric Relief Valve ManualTarun ChandraAinda não há avaliações

- Products Valves Sanitary PBM Series 9, 2 WayDocumento40 páginasProducts Valves Sanitary PBM Series 9, 2 Waydingobk1Ainda não há avaliações

- Operation Instructions - Multi-Turn - Actuators - SAEx - 07.2-SAEx - 16.2 - SAREx - 07.2-SAREx - 16.2 - Control - HART - enDocumento108 páginasOperation Instructions - Multi-Turn - Actuators - SAEx - 07.2-SAEx - 16.2 - SAREx - 07.2-SAREx - 16.2 - Control - HART - enPeter RhoadsAinda não há avaliações

- Installation Design and Back Pressure CompensationDocumento0 páginaInstallation Design and Back Pressure CompensationDana GuerreroAinda não há avaliações

- Cameron t32 IomDocumento20 páginasCameron t32 IomJuan Carlos Sua SuaAinda não há avaliações

- SI500.11r5e - GrafoilDocumento5 páginasSI500.11r5e - GrafoilHumayun NawazAinda não há avaliações

- Durco Plug Valve Dimensions PDFDocumento28 páginasDurco Plug Valve Dimensions PDFjtai1983Ainda não há avaliações

- Pressure Seal Valves-GateDocumento24 páginasPressure Seal Valves-GateHieu NguyenAinda não há avaliações

- Danfoss SFVLDocumento8 páginasDanfoss SFVLTorres Ivan100% (1)

- ZG 0054 011217AM Rev01Documento87 páginasZG 0054 011217AM Rev01rourouAinda não há avaliações

- 28.GOMA Pump T-8000 CatalougeDocumento2 páginas28.GOMA Pump T-8000 Catalougeramesh babuAinda não há avaliações

- Manual Flare Sim ExproDocumento69 páginasManual Flare Sim ExproJuan Pablo AlonsoAinda não há avaliações

- 4505 DiaphragmValves RWDocumento49 páginas4505 DiaphragmValves RWdbmingoAinda não há avaliações

- Butterfly Valve Info PDFDocumento14 páginasButterfly Valve Info PDFCS100% (1)

- Flanged Basket Strainers IOMDocumento4 páginasFlanged Basket Strainers IOMSteve NewmanAinda não há avaliações

- Is Your Section 1 Boiler Safety Valve Body Wall ErodingDocumento3 páginasIs Your Section 1 Boiler Safety Valve Body Wall ErodingFabio Peres de LimaAinda não há avaliações

- Otc20820 - Taking The Gas Lift Valves To A New Level of RealiabilityDocumento5 páginasOtc20820 - Taking The Gas Lift Valves To A New Level of Realiabilityomatiaspe2328Ainda não há avaliações

- Pneumatic Actuated Ball Valve PE4320Documento2 páginasPneumatic Actuated Ball Valve PE4320Fa ChAinda não há avaliações

- Design ET, EAT, and ETR Sliding-Stem Control ValvesDocumento28 páginasDesign ET, EAT, and ETR Sliding-Stem Control ValvesDatt NguyenAinda não há avaliações

- AnsiDocumento2 páginasAnsiSonu SinghAinda não há avaliações

- Butterfly Torque Selection GuideDocumento3 páginasButterfly Torque Selection Guidedragon2065Ainda não há avaliações

- Bv421 Pressure Reducing ValveDocumento4 páginasBv421 Pressure Reducing ValveFAIYAZ AHMEDAinda não há avaliações

- Pleated Filter Pressure Drop PDFDocumento12 páginasPleated Filter Pressure Drop PDFAmbrish SinghAinda não há avaliações

- Tech Sheet 128Documento1 páginaTech Sheet 128Sriram RamanujamAinda não há avaliações

- KT & Ky Parafin OilDocumento45 páginasKT & Ky Parafin OilaberAinda não há avaliações

- Corken ButanoDocumento48 páginasCorken ButanoCristobal CherigoAinda não há avaliações

- Grove g4n Gate Valve BrochureDocumento24 páginasGrove g4n Gate Valve BrochureFrancis Almia100% (1)

- Datasheet Pneumatic Actuator Pa 11 21 PDFDocumento4 páginasDatasheet Pneumatic Actuator Pa 11 21 PDFFuad OtsutsukiAinda não há avaliações

- OZKAN Butterfly ValvesDocumento11 páginasOZKAN Butterfly ValvesAhmed AbdelwaneesAinda não há avaliações

- Long Weld Necks 600Documento1 páginaLong Weld Necks 600Nice OrioleAinda não há avaliações

- Daniel Series 700 - Model V707: Spring Loaded Back Pressure ValveDocumento8 páginasDaniel Series 700 - Model V707: Spring Loaded Back Pressure ValveMarcelo PinheiroAinda não há avaliações

- DBB vs. DIB: Understanding the Difference Between Double Block and Bleed vs. Double Isolation and Bleed Valve SeatsDocumento1 páginaDBB vs. DIB: Understanding the Difference Between Double Block and Bleed vs. Double Isolation and Bleed Valve SeatsDidit SusantoAinda não há avaliações

- Project ReportDocumento36 páginasProject Reportvishi89Ainda não há avaliações

- Scotch Yoke or Rack-and-Pinion Quarter-Turn Actuator?Documento2 páginasScotch Yoke or Rack-and-Pinion Quarter-Turn Actuator?Assured AutomationAinda não há avaliações

- The A To Z of Valve MaterialsDocumento4 páginasThe A To Z of Valve Materialscool47guy09Ainda não há avaliações

- Stainless Steel Evaporator Engineering ManualDocumento52 páginasStainless Steel Evaporator Engineering ManualGerber GarciaAinda não há avaliações

- Series 9200 ManualDocumento31 páginasSeries 9200 Manualtxlucky80Ainda não há avaliações

- Installation and Maintenance Instructions: Anderson Greenwood Series 93T Pilot Operated Safety Relief ValvesDocumento8 páginasInstallation and Maintenance Instructions: Anderson Greenwood Series 93T Pilot Operated Safety Relief Valvesharshkumar patelAinda não há avaliações

- Maintain Series 800 Pressure Relief ValvesDocumento24 páginasMaintain Series 800 Pressure Relief ValvesJohnny VargasAinda não há avaliações

- Packard CatalogDocumento22 páginasPackard CatalogMarcelocross100% (1)

- Sistemas Digitais Cap 2Documento6 páginasSistemas Digitais Cap 2MarcelocrossAinda não há avaliações

- Sistemas DigitaisDocumento13 páginasSistemas DigitaisMarcelocrossAinda não há avaliações

- Neural Networks in Robotics A SurveyDocumento16 páginasNeural Networks in Robotics A SurveyGuilherme NolascoAinda não há avaliações

- Refrigeration Cycles and Systems: A Review: ArticleDocumento18 páginasRefrigeration Cycles and Systems: A Review: ArticleSuneel KallaAinda não há avaliações

- Negotiation - Course Outline APR17Documento8 páginasNegotiation - Course Outline APR17ravindrarao_mAinda não há avaliações

- Project ScopeDocumento2 páginasProject ScopeRahul SinhaAinda não há avaliações

- OSCA Individual AssignmentDocumento33 páginasOSCA Individual AssignmentVincent LimAinda não há avaliações

- ETA 11 0006 For HAC Cast in Anchor ETAG Option Approval Document ASSET DOC APPROVAL 0198 EnglishDocumento27 páginasETA 11 0006 For HAC Cast in Anchor ETAG Option Approval Document ASSET DOC APPROVAL 0198 Englishlaeim017Ainda não há avaliações

- Emision StandardsDocumento4 páginasEmision StandardsAshish RoongtaAinda não há avaliações

- Caracterización Y Zonificación Edáfica Y Climática de La Región de Coquimbo, ChileDocumento23 páginasCaracterización Y Zonificación Edáfica Y Climática de La Región de Coquimbo, ChileSantos DamasAinda não há avaliações

- Terra Point White PaperDocumento10 páginasTerra Point White Paperobi SalamAinda não há avaliações

- Material Tech Questions Solved BitsDocumento22 páginasMaterial Tech Questions Solved BitsBalakumarAinda não há avaliações

- Chinese Material To AstmDocumento4 páginasChinese Material To Astmvalli rajuAinda não há avaliações

- AJD275Documento5 páginasAJD275mhmmd14Ainda não há avaliações

- Seismic Gripple Cable BracingDocumento6 páginasSeismic Gripple Cable BracingThanh HuyAinda não há avaliações

- Bhawesh BajajDocumento2 páginasBhawesh BajajJacob PruittAinda não há avaliações

- C - TurretDocumento25 páginasC - TurretNathan BukoskiAinda não há avaliações

- List of Portmanteau Words: GeneralDocumento7 páginasList of Portmanteau Words: GeneraltarzanAinda não há avaliações

- Question (1) :-AnswerDocumento27 páginasQuestion (1) :-Answerprofessor_manojAinda não há avaliações

- MOHID Water Training Courses: Project InformationDocumento1 páginaMOHID Water Training Courses: Project InformationSaaz ZeeAinda não há avaliações

- Broadcast Servers for all WorkflowsDocumento2 páginasBroadcast Servers for all WorkflowsJosé FélixAinda não há avaliações

- Hydraulic Cylinder Joints: Understanding Loads and DesignDocumento16 páginasHydraulic Cylinder Joints: Understanding Loads and DesignVinaySeebaAinda não há avaliações

- Turan Balik - ResumeDocumento3 páginasTuran Balik - Resumeapi-250561031Ainda não há avaliações

- TNEB vacancy cut-off datesDocumento7 páginasTNEB vacancy cut-off dateswinvenuAinda não há avaliações

- MFXi MPMi User Guide 02122010 DraggedDocumento1 páginaMFXi MPMi User Guide 02122010 DraggedDani BalanAinda não há avaliações

- Apps Associates - Introductory Profile GENDocumento15 páginasApps Associates - Introductory Profile GENRodrigo MarquesAinda não há avaliações

- K2225 MosfetDocumento7 páginasK2225 MosfetDavid Eduardo Drew PerezAinda não há avaliações

- PSR 640Documento188 páginasPSR 640fer_12_328307Ainda não há avaliações

- 431510nt PDFDocumento14 páginas431510nt PDFkbryantperez2012Ainda não há avaliações