Escolar Documentos

Profissional Documentos

Cultura Documentos

Ijtra 140156

0 notas0% acharam este documento útil (0 voto)

16 visualizações5 páginasExperimental comparison between a commercial vapor compression refrigerator and a laboratory built thermoelectric beverage cooler. Temperature of 325 ml of water in a glass jar to be reduced from 32 o C to below 6 o C. Thermoelectric elements perform the same cooling function as Freon-based vapor compression or absorption refrigerators.

Descrição original:

Título original

ijtra140156

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoExperimental comparison between a commercial vapor compression refrigerator and a laboratory built thermoelectric beverage cooler. Temperature of 325 ml of water in a glass jar to be reduced from 32 o C to below 6 o C. Thermoelectric elements perform the same cooling function as Freon-based vapor compression or absorption refrigerators.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

16 visualizações5 páginasIjtra 140156

Experimental comparison between a commercial vapor compression refrigerator and a laboratory built thermoelectric beverage cooler. Temperature of 325 ml of water in a glass jar to be reduced from 32 o C to below 6 o C. Thermoelectric elements perform the same cooling function as Freon-based vapor compression or absorption refrigerators.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 5

International Journal of Technical Research and Applications e-ISSN: 2320-8163,

www.ijtra.com Volume 2, Issue 3 (May-J une 2014), PP. 01-05

1 | P age

COMPARISON OF THE EXPERIMENTAL

PERFORMANCE OF A THERMOELECTRIC

REFRIGERATOR WITH A VAPOUR

COMPRESSION REFRIGERATOR

Krishpersad Manohar

1

, Ademola Anthony Adeyanju

2

1

Mechanical and Manufacturing Engineering Department

The University of the West Indies

St. Augustine, Trinidad and Tobago

2

Mechanical Engineering Department

Ekiti State University

P.M.B. 5363, Ado-Ekiti, Nigeria

Abstract This study shows the experimental comparison

between a commercial vapor compression refrigerator and a

laboratory built thermoelectric beverage cooler. Tests were

carried out to determine the time taken for the temperature of

325 ml of water in a glass jar to be reduced from 32

o

C to below

6

o

C. The result shows that in the freezer compartment of the

commercial refrigerator, the temperature of the water decreased

linearly with increasing time. However, for the thermoelectric

refrigerator, the water temperature decreased exponentially with

increasing time. In other words, cooling rate for the refrigerator

was constant while for the thermoelectric it decreased

exponentially. The study also shows that that in the freezer

compartment of the commercial refrigerator the water took 61

min to cool to 6C while the thermoelectric beverage cooler took

69 min. It can be seen that for the majority of the cooling time,

the thermoelectric refrigerator was cooling at a faster rate than

the commercial refrigerator.

Index TermsThermoelectric cooling, Vapour power

refrigeration, Cooling rate.

I. INTRODUCTION

A thermoelectric device is one that operates on a circuit that

incorporates both thermal and electrical effects to convert heat

energy into electrical energy or electrical energy to a

temperature gradient [1]. Thermoelectric elements perform the

same cooling function as Freon-based vapor compression or

absorption refrigerators. Energy in the form of heat is taken

from a region thereby reducing its temperature and this energy

is then rejected to a heat sink region with a higher temperature

[2].

Thermoelectric elements are in a totally solid state while

vapor cycle devices have moving mechanical parts that require

a working fluid. A schematic of a thermoelectric module

shown in Fig. 1 can be a small, sturdy and quiet heat pumps

operated by a DC power source [3].

These usually last about 200,000 h in continuous mode. When

power is supplied, the surface where heat energy is absorbed

becomes cold; the opposite surface where heat energy is

released becomes hot. If the polarity of current-flow through

the module is reversed, the cold side will become the hot side

and vice-versa [3].

Thermoelectric devices can also be used as refrigerators on

the bases of the Peltier effect [1]. To create a thermoelectric

refrigerator (Fig.2), heat is absorbed from a refrigerated space

and then rejected to a warmer environment. The difference

between these two quantities is the net electrical work that

needs to be supplied. These refrigerators are not overly popular

because they have a low coefficient of performance. However,

in specialized applications they are useful.

Fig. 1: A thermoelectric refrigerator based on the peltier effect [1]

Thermoelectric modules can be used as thermocouples for

temperature measurement or as generators to supply power to

spacecraft and electrical equipment. Thermo electronic devices

are used in a variety of applications. They are used by the

military for night vision equipment, electronic equipment

cooling, portable refrigerators and inertial guidance systems

[4].

These products are useful to the military during war and

training because they are reliable, small and quiet. Another

advantage with thermoelectric products is that they can run on

batteries or out of a car accessory power supply port. The

medical community uses thermoelectric applications for

hypothermia blankets for patients to rest on during surgery and

keep their body at a specified temperature, blood analyzers

and tissue preparation and storage. The main advantage of

thermoelectric devices to the medical community is that the

devices allow doctors precise temperature control which is

useful in handling tissue samples [4].

Thermoelectric devices are probably most well known for

their contribution to powering spacecraft like the Voyager.

Radioisotope Thermoelectric Generators provided all of the

on-board electrical power for NASAs Voyager. The

Thermoelectric devices proved reliable since they were still

performing to specification 14 years after launch. The power

system provided the equivalent of 100-300 watts electrical

International Journal of Technical Research and Applications e-ISSN: 2320-8163,

www.ijtra.com Volume 2, Issue 3 (May-J une 2014), PP. 01-05

2 | P age

power and multiples thereof. NASA is now requiring higher

efficiency rates out of smaller units.

The interaction between thermal and electric phenomena;

Seebeck effect (1821), Peltier effect (1834), Joule effect

(1841) and Thomson effect (1857) was known since the 19th

century [4]. In 1885, the English physicist J .W. Rayleigh

outlined the possibility of using thermoelectric devices as

electricity generators but this development was stopped

because of the low efficiency achieved. However, the major

advancement was made in the 1950s with the introduction of

semiconductors as thermoelectric materials. It was observed

that they had a high Seebeck coefficient, good electrical

conductivity and low thermal conductivity.

In those moments thermoelectric refrigeration began to

look more promising and Peltier devices were developed for

refrigeration applications mostly for the military field. Work

on semiconductor thermocouples also led to the construction

of thermoelectric generators with a high enough efficiency for

special applications.

There was little improvement in thermoelectric materials from

the time of the introduction of semiconductor thermo-elements

until the end of the 20th century. However, in recent years,

several new ideas for the improvement of materials have been

put forward and significant advances are being made [3].

Presently, in the civil market, thermoelectric refrigeration has

a place in medical applications and scientific mechanisms and

devices where accurate temperature control is needed.

Nevertheless, there are other applications with great potential,

in which companies are starting to show interest, e.g.,

dehumidifiers [5], domestic and automobile air conditioning

systems, portable iceboxes, domestic refrigerators, devices to

transport perishable products, computer processor coolers, etc.

For these applications, thermoelectric refrigeration competes

with conventional refrigeration systems like Vapor

compression refrigeration. For a typical conventional

refrigeration system, a temperature difference between the

ambient and the cabinet of about 25-30 K at T

h

=300 K is

usually required to achieve satisfactory cooling performance.

This indicates that the maximum COP of a thermoelectric

refrigerator comprised of a commercially available module is

around 0.9-1.2. However, the practical COP of a

thermoelectric refrigerator is much lower than this because the

temperature difference between the hot and cold side of the

thermoelectric module is larger than the temperature

difference between the ambient and the cabinet. In other

words, the hot side temperature is higher than the ambient and

the cold side temperature is lower than the cabinet temperature

[6]. For a practical thermoelectric cooling system, the hot side

heat exchanger rejects the heat produced on the hot side of the

thermoelectric module to the ambient.

The cold side heat exchanger removes the heat from the

cold region to the cold side of thermoelectric module and so

increases the temperature of the cold side. Because the

thermoelectric module is very high heat intensity equipment,

the high efficiency thermoelectric heat exchangers is

necessity. Use of a heat pipe will not be of benefit for natural

convection, because the dominant thermal resistance in this

case is the convection resistance [7]. Water-cooled forced

convection heat exchangers have excellent performance. The

main drawback of a water-cooled heat exchanger is that it

needs a convenient source of cooling water. Without a source

of cooling water, a forced convection water heat exchanger

would require a pump and radiator and associated fittings and

tubing. The added resistance of the radiator would increase the

overall resistance.

Air-cooled systems are therefore often more desirable.

Many heat exchange systems based on the afore-mentioned

forced air convection exchangers and the use of heat pipes

have been reported [6]. Using a double fan in an appropriate

position could significantly increase the efficiency of the

forced air exchanger compared to using the single fan in a

refrigerator [8]. A long chimney for a natural-convection heat

exchanger may also improve the performance of the

refrigerator without the need to use fans that of course, require

the electrical power input. A novel, air-cooled thermosyphon

reboiler-condenser system has been reported [7] and has been

used as a heat exchanger of a thermoelectric refrigerator [2, 7].

This system is capable of providing very low heat sink

resistance values with air cooling and a thermal resistance as

low as 0.0194-0.0505KW

-1

was obtained for cooling a 45 mm

2

module. The system promises significantly higher COP for

thermoelectric coolers than is possible using existing heat

exchange technology.

A thermoelectric refrigeration system which employed a

Phase Change Material (PCM) as a cold side heat exchanger

for cooling storage showed improvement of the COP [8]. The

refrigeration system was first fabricated and tested using a

conventional heat sink system (bonded fin heat sink system) at

the cold heat sink. In order to improve the performance and

storage capability, the system was reconstructed and tested

using an encapsulated Phase Change Material (PCM) as a cold

sink.

Both configurations used heat pipe embedded fins as the

heat sink on the hot side. Results of tests on the latter system

showed an increased performance. This was because the PCM

had a large storage capacity allowing most of the cooling

energy to be absorbed by the PCM and therefore, the cold side

temperature fell more slowly than when the PCM was not

used. During the phase change process, the temperature of the

refrigeration system was almost constant until the phase

change process was complete. This helped to keep the

temperature difference across the thermoelectric module to a

minimum, thus improving its performance. In general,

thermoelectric modules are very high heat intensity equipment

which need high efficiency heat exchangers to lower the hot

side temperature and increase the cold side temperature in

order to improve the COP. Use of a greater number of

modules would also improve the COP of the system. Use of

more modules would reduce the heat load on each module and

so lower the heat flux densities of both the hot and cold side of

each module.

II. EXPERIMENTAL APPARATUS

A thermoelectric control beverage cooler was constructed

using four (4) TEC modules arranged as shown in the

schematic diagram Figure 2. The outer compartment of the

beverage cooler was constructed from 6 mm thick plywood

and coated with a waterproof clear varnish. The duct

connecting the air blowers was constructed from 0.5 mm thick

sheet metal (aluzinc). Figure 3 shows a picture of the test

apparatus. The TEC modules were rated for a 12 V dc power

supply and the air blowers operated with a 120 V ac power

International Journal of Technical Research and Applications e-ISSN: 2320-8163,

www.ijtra.com Volume 2, Issue 3 (May-J une 2014), PP. 01-05

3 | P age

supply. The airflow rates through the two warm compartments

were measured using a hot wire anemometer at locations

before the first heat sink, after the first heat sink (between the

two heat sinks) and after the second heat sink on both sides for

the two warm compartments. Thermocouples were

strategically placed as shown in the schematic (Figure 2) to

measure the respective temperatures. T

1

indicated the

temperature at the hot side heat sink base, T

base hot

; T

2

measured the temperature at the cold side heat sink base, T

base

cold

; T

3

measured the cold compartment Temperature, T

cold

and

T

4

measured the water Temperature, T

water

.

Fig. 2: Schematic of TEC beverage cooler showing the placement

of thermocouples (T1, T2, T3 and T4)

Fig. 3: TEC Thermoelectric refrigerator

III. TEST RESULTS

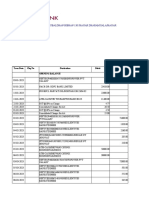

Comparative experiments were conducted to determine the

time taken for the temperature of 325 ml of water in a glass

container to reach 6

o

C. The water was initially at room

temperature. The power to the TEC modules were measured

and shown in Table 1. The average values of the measured air

flow through the warm compartments of the TEC beverage

cooler are given in Table 2. The time taken for the TEC

beverage cooler cold compartment with no thermal load to

reach below 5

o

C was measured and shown in table 3. The

time taken for 325 ml of water at room temperature placed in

the cold compartment of the TEC beverage cooler was

monitored and the results shown in table 4. Comparison of the

effectiveness of the TEC beverage cooler was made with a 10

cubic meter commercial refrigerator by placing 325 ml of

water in similar containers in the freezer compartment and the

cold space compartment of the refrigerator. These results are

shown in Table 5.

TEC module Voltage (V) Current (A) Power (W)

1 11.42 8.5 97.07

2 11.7 8.3 97.11

3 11.69 8.4 98.20

4 11.03 8.5 93.76

TABLE 1: THE VOLTAGE AND CURRENT READINGS

Left side warm

compartment

Right side warm

compartment

Position Air speed

(ft/min)

Air

Flow

(CFM)

Air

speed

(ft/min)

Air Flow

(CFM)

Before heat

sink

1879 530 3114 880

After heat

sink 1

587 160 1593 450

After heat

sink 2

452 120 1278 361

TABLE 2: THE AIR FLOW-RATE THROUGH THE TWO WARM

COMPARTMENT

Time (min) T

basehot

(

o

C)

T

cold

(

o

C)

T

basecold

(

o

C)

0 32.7 32.7 32.7

5 61.7 21.6 20.6

10 60.9 14.3 12.8

15 60.4 11.4 10.1

20 59.7 8.4 6.9

25 58.9 6.1 4.8

30 59.0 5.2 3.8

35 58.8 4.4 2.9

40 58.8 3.8 2.3

45 58.7 3.2 1.7

TABLE 3: TEMPERATURE READINGS FOR THE COLD AND

HOT COMPARTMENT

Time after

water is

placed inside

(min)

Total

time

chiller is

on

(min)

T

basehot

(

o

C)

T

basecold

(

o

C)

T

cold

(

o

C)

T

water

(

o

C)

0 46 59.0 4.0 5.7 31.5

5 51 59.2 5.5 5.6 25.9

10 56 59.4 6.0 5.6 22.4

International Journal of Technical Research and Applications e-ISSN: 2320-8163,

www.ijtra.com Volume 2, Issue 3 (May-J une 2014), PP. 01-05

4 | P age

15 61 59.4 6.0 5.5 19.4

20 66 59.5 5.9 5.3 17.0

25 71 59.4 5.7 4.8 14.8

30 76 59.5 5.5 4.6 13.2

35 81 59.5 5.2 4.1 11.7

40 86 59.5 5.0 3.9 10.4

45 91 59.5 4.8 3.7 9.4

50 96 59.5 4.6 3.4 8.3

55 101 59.4 4.5 3.2 7.7

60 106 59.3 4.3 3.0 7.0

65 111 59.5 4.2 2.9 6.2

69 115 59.4 4.1 2.7 6.0

TABLE 4: TEMPERATURE READINGS FOR THE COLD AND

HOT COMPARTMENT WHEN WATER WAS TESTED

Freezer compartment Cold space compartment

Time

(min)

Temperature

(

o

C)

Time

(min)

Temperature

(

o

C)

0 31.7 0 31.7

10 26.3 15 28.1

20 21.2 30 24.3

30 16.8 45 21.2

40 13.0 60 19.5

50 10.1 75 19.0

60 6.3 90 17.5

70 5.9 105 16.2

120 14.8

135 13.2

150 12.5

165 11.7

180 11.0

195 10.5

210 9.8

225 9.3

240 8.5

255 7.3

TABLE 5: VARIATION OF TEMPERATURE WITH TIME FOR

325 ML WATER PLACED IN FREEZER AND COLD SPACE OF

REFRIGERATOR

IV. RESULTS AND DISCUSSION

The design power input obtained in the calculations for the

TEC modules used was 98W. Figure 4 shows the performance

of a TEC module variation with input power (Goldsmid, 2009).

Performance in this case refers to the cooling rate Q

c

. The

Figure 4 shows that as the input power increases, performance

also increases. Operating at close to the maximum is

inefficient; most applications do operate at 40-80% of input

maximum power of TEC modules. For the selected TEC

modules 40% input power max is 160.16 Watt. Therefore the

effectiveness of the beverage chiller would have been improved

if the TEC modules were operated between the 40-80% range.

Fig. 4: Variation of performance with input power for a TEC

module

Inefficient forced convective heat transfer within the cold

compartment mat has adversely affected the cooling rate of the

thermoelectric refrigeration since a small fan was used to

circulate air within the cold compartment. The fan had small

cubic feet per minute (cfm) rating and its positioning also was

not optimal. Having an internal fan capable of circulating air

through the fins of all the cold side heat sinks and then

directing a blast of cold air over the jar containing the water to

be cooled would have resulted in shorter cooling time. Hence,

the time for cooling the 325 ml water as shown in Figure 5

would have been less.

Fig. 6 compares the thermoelectric refrigerations cooling

time with cooling times obtained from the freezer space and

cold space of a vapour compression refrigerator. All three tests

were carried out on 325 mL of water in a glass jar. The result

indicate that for the refrigerator freezer space, the temperature

of the water decreased linearly with increasing time.

Fig. 5: Variation of temperature with time of the cold

compartment of the Thermoelectric Refrigeration and of 325 mL

water placed inside the cold compartment

International Journal of Technical Research and Applications e-ISSN: 2320-8163,

www.ijtra.com Volume 2, Issue 3 (May-J une 2014), PP. 01-05

5 | P age

Fig. 6: Variation of temperature with time of 325 mL of water

placed inside various cold spaces

However, for the thermoelectric refrigeration, the water

temperature decreased exponentially with increasing time. In

other words, cooling rate for the refrigerator was constant

while for the thermoelectric refrigeration it decreased

exponentially. Figure 6 also shows that the freezer took 61 min

to cool the water to 6C while the thermoelectric refrigeration

took 69 min.

It can be seen that for the majority of the cooling time, the

thermoelectric refrigeration was cooling at a faster rate than

the freezer. But by virtue of the exponential cooling versus

linear cooling, the rate for the vapour compression refrigerator

was decreasing while the TEC beverage cooler rate was

leveling off. This caused the thermoelectric refrigerations

cooling rate to eventually reach a point where it was lower

than the refrigerator freezer cooling rate. This happened at

around 7C as shown in the Fig. 6, where the lines crossed. It

must also be noted that the temperature within the freezer

space was measured at -17.4C while that of the

thermoelectric refrigerations cold compartment was on

average around 3.9C (it started at 5.7C and dropped to 2.7C

during the water cooling process). Therefore, at the point in

time at which the required water temperature of 6C was

attained, the temperature difference between water and cold

space was 23.4C for the refrigerator freezer and only 3.30C

for the thermoelectric beverage cooler. Therefore, the TEC

beverage cooler showed comparative cooling capabalities to

that of the freezer compartment of a commercial refrigerator

and can effectively serve as a beverage cooler.

V. CONCLUSIONS

The thermoelectric refrigeration took comparatively the

same time to cool the water to approximately 6

o

C. The heat

transfer process from the water to the cold compartment was

more efficient than in the freezer of vapour compression

refrigerator as the temperature difference with the

surroundings was significantly higher for the commercial

refrigerator then that of the TEC beverage cooler. The cold

space of the refrigerator was measured at 5.1C and took over

2 h to cool to 7.2

o

C, which was very much slower than the

thermoelectric refrigeration.

REFERENCES

[1] Cengal, Y. and B. Michael, Thermodynamics: An Engineering

Approach. McGraw Hill, Hightstown,1998.

[2] Gilley, M.D. and R.L. Webb, 1999. Thermoelectric refrigerator

with evaporating/condensing heat exchanger. United States

Patent, No. 6003319, December 21.

http://www.freepatentsonline.com/6003319.html.

[3] Goldsmid, H.J ., Introduction to Thermoelectricity. Springer

Heodelberg Dordrecht, London, 2009, pp: 1-3.

[4] Rowe, D.M. and C.M. Bhandari, Modern Thermoelectric. Holt,

Rinehart and Winston, London, 1983, pp: 7-25.

[5] Vian, J.G., D. Astrain and M. Dominguez, Numerical modeling

and design of a thermoelectric dehumidifier. Applied Thermal

Eng., vol. 22. pp.407-422, 2002.

[6] Sofrata, H., Heat rejection alternatives for thermoelectric

refrigerators. Energy Conservation J ournal. vol. 37, pp.269-280,

1996.

[7] Webb, R.L., Advanced heat exchange technology for

thermoelectric cooling. J ournal of Electrical Engineering.

vol. 120, pp.98-105, 1998.

[8] Riffat, S.B., S.A. Omer and M.A. Xiaoli,. A novel thermoelectric

refrigeration system employing heat pipes and a phase change

material: An experimental investigation. Renewable Energy,

vol. 23, pp. 313-323, 2001.

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Energy Gap Investigation and Characterization of Kesterite Cu2znsns4 Thin Film For Solar Cell ApplicationsDocumento4 páginasEnergy Gap Investigation and Characterization of Kesterite Cu2znsns4 Thin Film For Solar Cell ApplicationsInternational Jpurnal Of Technical Research And Applications100% (1)

- Sumita PDFDocumento5 páginasSumita PDFInternational Jpurnal Of Technical Research And ApplicationsAinda não há avaliações

- Exponential Smoothing of Postponement Rates in Operation Theatres of Advanced Pediatric Centre - Time Series Forecasting With Regression AnalysisDocumento7 páginasExponential Smoothing of Postponement Rates in Operation Theatres of Advanced Pediatric Centre - Time Series Forecasting With Regression AnalysisInternational Jpurnal Of Technical Research And Applications100% (2)

- Postponement of Scheduled General Surgeries in A Tertiary Care Hospital - A Time Series Forecasting and Regression AnalysisDocumento6 páginasPostponement of Scheduled General Surgeries in A Tertiary Care Hospital - A Time Series Forecasting and Regression AnalysisInternational Jpurnal Of Technical Research And Applications100% (2)

- Study of Nano-Systems For Computer SimulationsDocumento6 páginasStudy of Nano-Systems For Computer SimulationsInternational Jpurnal Of Technical Research And ApplicationsAinda não há avaliações

- Sumita PDFDocumento5 páginasSumita PDFInternational Jpurnal Of Technical Research And ApplicationsAinda não há avaliações

- Qualitative Risk Assessment and Mitigation Measures For Real Estate Projects in MaharashtraDocumento9 páginasQualitative Risk Assessment and Mitigation Measures For Real Estate Projects in MaharashtraInternational Jpurnal Of Technical Research And ApplicationsAinda não há avaliações

- Digital Compressing of A BPCM Signal According To Barker Code Using FpgaDocumento7 páginasDigital Compressing of A BPCM Signal According To Barker Code Using FpgaInternational Jpurnal Of Technical Research And ApplicationsAinda não há avaliações

- Aesthetics of The Triumphant Tone of The Black Woman in Alice Walker's The Color PurpleDocumento30 páginasAesthetics of The Triumphant Tone of The Black Woman in Alice Walker's The Color PurpleInternational Jpurnal Of Technical Research And Applications100% (2)

- An Experimental Study On Separation of Water From The Atmospheric AirDocumento5 páginasAn Experimental Study On Separation of Water From The Atmospheric AirInternational Jpurnal Of Technical Research And ApplicationsAinda não há avaliações

- Modelling The Impact of Flooding Using Geographic Information System and Remote SensingDocumento6 páginasModelling The Impact of Flooding Using Geographic Information System and Remote SensingInternational Jpurnal Of Technical Research And ApplicationsAinda não há avaliações

- Overview of TCP Performance in Satellite Communication NetworksDocumento5 páginasOverview of TCP Performance in Satellite Communication NetworksInternational Jpurnal Of Technical Research And ApplicationsAinda não há avaliações

- Pod-Pwm Based Capacitor Clamped Multilevel InverterDocumento3 páginasPod-Pwm Based Capacitor Clamped Multilevel InverterInternational Jpurnal Of Technical Research And ApplicationsAinda não há avaliações

- Li-Ion Battery Testing From Manufacturing To Operation ProcessDocumento4 páginasLi-Ion Battery Testing From Manufacturing To Operation ProcessInternational Jpurnal Of Technical Research And ApplicationsAinda não há avaliações

- An Inside Look in The Electrical Structure of The Battery Management System Topic Number: Renewable Power Sources, Power Systems and Energy ConversionDocumento5 páginasAn Inside Look in The Electrical Structure of The Battery Management System Topic Number: Renewable Power Sources, Power Systems and Energy ConversionInternational Jpurnal Of Technical Research And ApplicationsAinda não há avaliações

- Implementation of Methods For Transaction in Secure Online BankingDocumento3 páginasImplementation of Methods For Transaction in Secure Online BankingInternational Jpurnal Of Technical Research And ApplicationsAinda não há avaliações

- Scope of Replacing Fine Aggregate With Copper Slag in Concrete - A ReviewDocumento5 páginasScope of Replacing Fine Aggregate With Copper Slag in Concrete - A ReviewInternational Jpurnal Of Technical Research And Applications100% (1)

- Time Efficient Baylis-Hillman Reaction On Steroidal Nucleus of Withaferin-A To Synthesize Anticancer AgentsDocumento5 páginasTime Efficient Baylis-Hillman Reaction On Steroidal Nucleus of Withaferin-A To Synthesize Anticancer AgentsInternational Jpurnal Of Technical Research And ApplicationsAinda não há avaliações

- The Construction Procedure and Advantage of The Rail Cable-Lifting Construction Method and The Cable-Hoisting MethodDocumento3 páginasThe Construction Procedure and Advantage of The Rail Cable-Lifting Construction Method and The Cable-Hoisting MethodInternational Jpurnal Of Technical Research And ApplicationsAinda não há avaliações

- Evaluation of Drainage Water Quality For Irrigation by Integration Between Irrigation Water Quality Index and GisDocumento9 páginasEvaluation of Drainage Water Quality For Irrigation by Integration Between Irrigation Water Quality Index and GisInternational Jpurnal Of Technical Research And ApplicationsAinda não há avaliações

- Open Loop Analysis of Cascaded Hbridge Multilevel Inverter Using PDPWM For Photovoltaic SystemsDocumento3 páginasOpen Loop Analysis of Cascaded Hbridge Multilevel Inverter Using PDPWM For Photovoltaic SystemsInternational Jpurnal Of Technical Research And ApplicationsAinda não há avaliações

- Physico-Chemical and Bacteriological Assessment of River Mudzira Water in Mubi, Adamawa State.Documento4 páginasPhysico-Chemical and Bacteriological Assessment of River Mudzira Water in Mubi, Adamawa State.International Jpurnal Of Technical Research And ApplicationsAinda não há avaliações

- Performance Analysis of Microstrip Patch Antenna Using Coaxial Probe Feed TechniqueDocumento3 páginasPerformance Analysis of Microstrip Patch Antenna Using Coaxial Probe Feed TechniqueInternational Jpurnal Of Technical Research And Applications100% (1)

- Effect of Trans-Septal Suture Technique Versus Nasal Packing After SeptoplastyDocumento8 páginasEffect of Trans-Septal Suture Technique Versus Nasal Packing After SeptoplastyInternational Jpurnal Of Technical Research And ApplicationsAinda não há avaliações

- A Study On The Fresh Properties of SCC With Fly AshDocumento3 páginasA Study On The Fresh Properties of SCC With Fly AshInternational Jpurnal Of Technical Research And ApplicationsAinda não há avaliações

- Investigation of Coverage Level and The Availability of GSM Signal in Ekpoma, NigeriaDocumento6 páginasInvestigation of Coverage Level and The Availability of GSM Signal in Ekpoma, NigeriaInternational Jpurnal Of Technical Research And ApplicationsAinda não há avaliações

- Parametric Modeling of Voltage Drop in Power Distribution NetworksDocumento4 páginasParametric Modeling of Voltage Drop in Power Distribution NetworksInternational Jpurnal Of Technical Research And ApplicationsAinda não há avaliações

- Study of Carbohydrate Metabolism in Severe Acute Malnutrition and Correlations of Weight and Height With Pp-Sugar and BmiDocumento9 páginasStudy of Carbohydrate Metabolism in Severe Acute Malnutrition and Correlations of Weight and Height With Pp-Sugar and BmiInternational Jpurnal Of Technical Research And ApplicationsAinda não há avaliações

- Production of Starch From Mango (Mangifera Indica.l) Seed Kernel and Its CharacterizationDocumento4 páginasProduction of Starch From Mango (Mangifera Indica.l) Seed Kernel and Its CharacterizationInternational Jpurnal Of Technical Research And Applications100% (1)

- Structural and Dielectric Studies of Terbium Substituted Nickel Ferrite NanoparticlesDocumento3 páginasStructural and Dielectric Studies of Terbium Substituted Nickel Ferrite NanoparticlesInternational Jpurnal Of Technical Research And ApplicationsAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (120)

- Krishna TejaDocumento71 páginasKrishna TejaHimanshu GaurAinda não há avaliações

- Construction Drawing: Legend Notes For Sanitary Piping Installation General Notes NotesDocumento1 páginaConstruction Drawing: Legend Notes For Sanitary Piping Installation General Notes NotesrajavelAinda não há avaliações

- Operator's ManualDocumento110 páginasOperator's ManualAdam0% (1)

- Chain: SRB Series (With Insulation Grip)Documento1 páginaChain: SRB Series (With Insulation Grip)shankarAinda não há avaliações

- Shelly Cashman Series Microsoft Office 365 Excel 2016 Comprehensive 1st Edition Freund Solutions ManualDocumento5 páginasShelly Cashman Series Microsoft Office 365 Excel 2016 Comprehensive 1st Edition Freund Solutions Manualjuanlucerofdqegwntai100% (10)

- Kingroon ConfiguracoesDocumento3 páginasKingroon ConfiguracoesanafrancaAinda não há avaliações

- (Schottel) Aspects of The Design Procedure For Propellers Providing Max Bollard PullDocumento10 páginas(Schottel) Aspects of The Design Procedure For Propellers Providing Max Bollard Pulldevu2chodankarAinda não há avaliações

- Arc Hydro - Identifying and Managing SinksDocumento35 páginasArc Hydro - Identifying and Managing SinkskbalAinda não há avaliações

- 3DS 2017 GEO GEMS Brochure A4 WEBDocumento4 páginas3DS 2017 GEO GEMS Brochure A4 WEBlazarpaladinAinda não há avaliações

- Anykycaccount Com Product Payoneer Bank Account PDFDocumento2 páginasAnykycaccount Com Product Payoneer Bank Account PDFAnykycaccountAinda não há avaliações

- World BankDocumento28 páginasWorld BankFiora FarnazAinda não há avaliações

- Storage-Tanks Titik Berat PDFDocumento72 páginasStorage-Tanks Titik Berat PDF'viki Art100% (1)

- Department of Education: Republic of The PhilippinesDocumento2 páginasDepartment of Education: Republic of The PhilippinesISMAEL KRIS DELA CRUZAinda não há avaliações

- Coal Mining Technology and SafetyDocumento313 páginasCoal Mining Technology and Safetymuratandac3357Ainda não há avaliações

- Corrosion Performance of Mild Steel and GalvanizedDocumento18 páginasCorrosion Performance of Mild Steel and GalvanizedNarasimha DvlAinda não há avaliações

- Sousa2019 PDFDocumento38 páginasSousa2019 PDFWilly PurbaAinda não há avaliações

- Effects of Corneal Scars and Their Treatment With Rigid Contact Lenses On Quality of VisionDocumento5 páginasEffects of Corneal Scars and Their Treatment With Rigid Contact Lenses On Quality of VisionJasmine EffendiAinda não há avaliações

- ASTR 323 Homework 4Documento2 páginasASTR 323 Homework 4Andrew IvanovAinda não há avaliações

- DeadlocksDocumento41 páginasDeadlocksSanjal DesaiAinda não há avaliações

- CrimDocumento29 páginasCrimkeziahmae.bagacinaAinda não há avaliações

- Chapter 1 INTRODUCTION TO LITERATUREDocumento4 páginasChapter 1 INTRODUCTION TO LITERATUREDominique TurlaAinda não há avaliações

- Aman Singh Rathore Prelms Strategy For UPSCDocumento26 páginasAman Singh Rathore Prelms Strategy For UPSCNanju NAinda não há avaliações

- XXXX96 01 01 2023to28 08 2023Documento18 páginasXXXX96 01 01 2023to28 08 2023dabu choudharyAinda não há avaliações

- The Ethics of Peacebuilding PDFDocumento201 páginasThe Ethics of Peacebuilding PDFTomas Kvedaras100% (2)

- Lesson Plan 1Documento3 páginasLesson Plan 1api-311983208Ainda não há avaliações

- Project Report For Tunnel ExcavationDocumento19 páginasProject Report For Tunnel ExcavationAbhishek Sarkar50% (2)

- Carbohydrates StainsDocumento43 páginasCarbohydrates StainssupahvyAinda não há avaliações

- WoundVite®, The #1 Most Comprehensive Wound, Scar and Post-Surgical Repair Formula Receives Amazon's Choice High RatingsDocumento3 páginasWoundVite®, The #1 Most Comprehensive Wound, Scar and Post-Surgical Repair Formula Receives Amazon's Choice High RatingsPR.comAinda não há avaliações

- Lecture BouffonDocumento1 páginaLecture BouffonCarlos Enrique GuerraAinda não há avaliações