Escolar Documentos

Profissional Documentos

Cultura Documentos

002

Enviado por

Lava SatDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

002

Enviado por

Lava SatDireitos autorais:

Formatos disponíveis

P

R

E

M

I

U

M

Q

U

A

L

I

T

Y

DEEP WATER

Wide range of deep water and ultra-deep water floats

Deep water floats for Single Point

Mooring Systems, FPSO and FSO

Resinex has developed Deep

Water Floats for Single Point

Mooring Systems since the early

seventies. Previously manufac-

tured in PVC then developed

using roto-moulded linear polye-

thylene, they operate on Calm

buoys (Lazy-S or Chinese Lan-

tern configurations) or SALM

buoys and now also on FPSO

and FSO Systems. Resinex prod-

ucts always comply with OCIMF

1991 specifications.

Resinex manufactures three different types of deep water floats for Single Point Mooring Systems and FPSO-FSO Systems

with various characteristics and performances. The standard floats cover a range of internal diameter adaptations from 240

mm to 970 mm and a range of net buoyancy from 32 kg to 430 kg.

1 2

3

1

Hinged type: high assembling angle; high adaptation at oil

pumping pressure; wide range of diameters and net buoy-

ancy.

2

Grooved type: super strong-heavy duty performance, simple

metallic part; high buoyancy.

3

Bolted type: high strength; high hydrodynamicity; simple

metallic part.

Hinged

type

HINGED TYPE

SIZE mm. WATER DEPTH

O.D. I.D. H K

ADJUSTABLE

RANGE I.D.

0+40m. 40+80m.

Weight

Kg.

N.B.

Kg.

Weight

Kg.

N.B.

Kg.

06 BODY 630 250 330 205 240 270 30 32 32 30

06 END - 08 BODY 630 310 330 205 270 340 21 41 26 36

08 END - 10 BODY 700 360 350 205 340 400 25 55 32 48

10 END - 12 BODY 780 420 400 205 410 440 35 76 43 68

12 EXTRA 940 495 550 205 445 520 58 123 70 111

12 END - 16 BODY 940 520 550 205 500 550 61 153 74 140

16 END - 20 BODY 1060 620 540 205 530 660 72 184 84 172

20 EXTRA 1250 800 600 205 785 840 107 273 124 256

20 END - 24 BODY 1160 700 600 205 620 785 89 231 104 216

24 END 1350 876 600 205 876 910 109 291 137 263

Grooved

type

GROOVED TYPE

SIZE mm. WATER DEPTH

O.D. I.D. H K

ADJUSTABLE

RANGE I.D.

0+40m. 40+80m.

Weight

Kg.

N.B.

Kg.

Weight

Kg.

N.B.

Kg.

16 END - 20 BODY 1050 640 550 205 640 697 73 168 90 151

20 END - 24 BODY 1200 640 600 205 700 832 95 267 120 242

24 EXTRA 1370 940 800 205 860 970 138 430 190 376

Bolted

type

BOLTED TYPE

SIZE mm. WATER DEPTH

O.D. I.D. H K

ADJUSTABLE

RANGE I.D.

0+40m. 40+80m.

Weight

Kg.

N.B.

Kg.

Weight

Kg.

N.B.

Kg.

12 HE - 16 HB 971 530 550 205 450 550 68 140 81 127

24 HE 1390 876 600 205 750 890 122 312 162 272

N.B.: the buoyancy is considered in fresh water. - K: the width collar range can be adapted at every hose float mount from 135 to 205 mm.

Water depth: higher depth (till 7.000 mts.) can be reached, weight will be higher, net buoyancy reduced.

Assembling and use

Resinex deep water floats are studied to give

the best tightening performance on the float

mounts of hoses and on the clamps of risers.

Tightening can be obtained directly or through

rotomoulded reducers assembled on the float

itself. Their particular shape has been studied to

allow the higher bending of hoses and risers.

The hinged solution adopted by each Resinex

type of floats, maximized by the Hinged Type,

facilitates all the assembling procedures that

can be done also underwater. In case of under-

water installation, Resinex supplies plate sinkers

to give neutral buoyancy at the float.

Assembling test of a complete float set for rubber hose in house. Resinex hinged floats in operation in the blue sea.

Easy installation around float mount.

Right: plate sinkers for

underwater assembly.

Also supports for umbilicals can be easily installed on

Resinex Deep Water Floats.

Riser floats

Natural evolution of deep water floats for S.P.M. are the

Riser Floats. Resinex, with more 45 years of experience

in producing buoyancy modules, gives the capability to

develop the best solutions also for Risers.

Study of bending and of tightening, together with the

capability to give the best ratio between net buoyancy and

pressure resistance are the components of Resinex experi-

ence in deep waters that allow us to facilitate our presence

in the riser floats market.

CAD study for double riser float for parallel risers.

Cable floats

Not only hoses but also cables, ropes and umbilicals need to

be lightened under water. Resinex gives its customers a com-

plete range of floats with reduced diameters.

The key success factor of this activity is tightening. The floats

cannot slip on the cable when assembled.

Resinex has developed particular polyurethane clamps and

reducers to maximize the grip on the cable surface.

Particular stud-

ies have been car-

ried on to give our

products the best

mix between loads,

weight of materi-

als and tightening

forces.

Now we can supply

different solutions

to garantee the

higher tightening

force together with

the usual high resis-

tance to pressure

until a 7.000 meter

depth.

Cable floatation

collar 100 kg N.B.

Bending control on umbilical bundle.

Rov floats

Resinex R&D has studied, tested and produced the Synt: a Resinex syntactic foam com-

pound which with the utilization of a particular hardering system and microspheres

can resist up to 700 bar pressure and so reach a depth of 7000 metres.

The development of new Nautex compounds increases the maximum ratio between

pressure resistance and specific weight, thus allowing a remarkable cost decrease for

our Customers.

Five big autoclaves assure precise pressure test procedures in the Adro Marine

Research Centre.

Compared with previous tables, weight and net buoyancy may change in relation to

the materials used to reach the requested depth.

Rov floating modules are allways studied ad hoc for every customer.

Needs of net buoyancy given by the end user, together with particular

shapes able to fit in the machine structure, bring Resinex technical depart-

ment to develop new floats for each Remote Vehicle.

Adaptability to customer needs together with deep reliability are the main

key factors requested by the ROV market.

Range of deepwaters

FROM ZERO TO 7000 METRES, RESINEX TECHNOLOGY FOR HIGH DEPTHS

Nautex

25

Nautex

50

Nautex

100

Nautex

150

Synt

1000

Synt

2000

Synt

2500

Depth

(metres)

0-250

250-500

500-1000

1000-1500

1500-2000

2000-2500

2500-3500

3500-5000

5000-7000

Synt

3500

Synt

5000

Synt

7000

2

1

Particular shape for ROV

modules.

2

ROV modules allready

assembled: operational

depth 1.000 meters.

3

Modules tested at hight

pressure.

1

3

Quality control and tests

Deep waters are not a friendly envi-

ronment. Being aware of this, Resinex

produces deep water floats, monitor-

ing every step of the manufactur-

ing plan. Starting from rotomould-

ing polyethylene thickness, passing

through the quality control of AISI

316 or Titanium metallic part Resinex

Quality Assurance Department finally

arrives at the strict controls of Nautex

compounds or Syntactic foam filling.

Resinex, with its products, has always

anticipated market needs and invest-

ed hefty sums in research thereby

always keeping one step ahead of the

competition: an example of this is the

new set of five autoclaves installed in

the Adro Marine Research Centre. No

other similar autoclave exists in con-

tinental Europe in size for those able

to carry out testing to 4000 metres

depth. It is 1.1 metres in diameter by

2.2 metres in height. Among the four

other autoclaves available to Resinex

laboratory technicians, there is a giant

of 2.1 metres in diameter by 3.5

metres in height which can simulate

pressure conditions of upto depths of

500 metres.

In this way our company is once again

the vanguard in quality and safety

in its floats, offering an always more

advanced service to the customer.

Quality Management of materials

and production process is certified

by Lloyds Register Quality Assurance

norm ISO 9001:2000.

Exhaustive laboratory tests are car-

ried out on samples taken during the

work process. But before being con-

signed, the floats that come off the

production line in Torbiato (Brescia)

are first passed through to the nearby

Adro Resinex Marine Research Centre

which is equipped with the most up-

to-date and sophisticated analysis

systems. Besides weight and dimen-

sion, traction resistance is tested,

both of pressure and floatability (net

buoyancy) and the data are fed into

a computerized system which gives

a report of all the characteristics of

the piece in question. This is a type

of Identity Card which represents an

extra guarantee of Resinex quality.

1

Traction strength test on

hinged floats.

2

Weight procedures at

electronic scales.

3

Hight pressure tests in the

Adro Resinex Marine

Research Centre.

1

2

3

Resinex Trading S.r.l

Via Cappuccio, 14 - 20123 Milano (Italy)

Milan:

tel: 02.7201 3463

fax: 02.7201 6182

e-mail: marketing@resinextrad.com

Torbiato di Adro:

tel: 030.745 7245

fax: 030.745 0162

e-mail: production@resinextrad.com

www. r es i nex t r ad. c om

Você também pode gostar

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- 7day PrimerDocumento15 páginas7day PrimerGospodin Covek100% (5)

- Chapter 7 - Transient Heat Conduction PDFDocumento64 páginasChapter 7 - Transient Heat Conduction PDFhaqjmiAinda não há avaliações

- Chainman Catalogue EditDocumento57 páginasChainman Catalogue EditRem LaraziAinda não há avaliações

- Anchor ManualDocumento187 páginasAnchor ManualAde Aris Satria100% (5)

- AtmDocumento2 páginasAtmJegan RichardAinda não há avaliações

- Rcs454: Python Language Programming LAB: Write A Python Program ToDocumento39 páginasRcs454: Python Language Programming LAB: Write A Python Program ToShikha AryaAinda não há avaliações

- Advanced 100% Solids Rigid Polyurethane Coatings Technology For Pipeline Field Joints and RehabilitationDocumento14 páginasAdvanced 100% Solids Rigid Polyurethane Coatings Technology For Pipeline Field Joints and RehabilitationLava SatAinda não há avaliações

- Planning - THERM - Timber - H-I - H-V - 2016 (RAICO)Documento542 páginasPlanning - THERM - Timber - H-I - H-V - 2016 (RAICO)AnrStukAinda não há avaliações

- Oil and Gas FAQsDocumento6 páginasOil and Gas FAQsLava SatAinda não há avaliações

- Developing Fair Pipeline Contract ConditionsDocumento4 páginasDeveloping Fair Pipeline Contract ConditionsLava SatAinda não há avaliações

- 1 PDFDocumento2 páginas1 PDFSam ShahAinda não há avaliações

- 3 1Documento3 páginas3 1Lava SatAinda não há avaliações

- 3.2 Programming The Work: Created by Guy Henley, Last Modified by Mustafa Abusalah On Nov 20, 2014Documento2 páginas3.2 Programming The Work: Created by Guy Henley, Last Modified by Mustafa Abusalah On Nov 20, 2014Lava SatAinda não há avaliações

- Construction Contract BaselineDocumento1 páginaConstruction Contract BaselineLava SatAinda não há avaliações

- 3.3 Contract Price Information To Facilitate Evaluation of ChangesDocumento1 página3.3 Contract Price Information To Facilitate Evaluation of ChangesLava SatAinda não há avaliações

- Fabrication Sequence of JacketDocumento37 páginasFabrication Sequence of JacketLava SatAinda não há avaliações

- Meaningful Hindu tenets explained by Tamil poet KannadhasanDocumento599 páginasMeaningful Hindu tenets explained by Tamil poet KannadhasanLava Sat100% (1)

- Numerical Simulation of F Rost Heave in Soils Around The Buried Oil Pipeline in Island Talik Permafrost RegionDocumento12 páginasNumerical Simulation of F Rost Heave in Soils Around The Buried Oil Pipeline in Island Talik Permafrost RegionLava SatAinda não há avaliações

- 3 1Documento3 páginas3 1Lava SatAinda não há avaliações

- Abaqus/CFD – Sample Problems for Simulating Fluid FlowDocumento42 páginasAbaqus/CFD – Sample Problems for Simulating Fluid FlowLava SatAinda não há avaliações

- Icc Cricket World Cup 2015 Schedule With TimeDocumento3 páginasIcc Cricket World Cup 2015 Schedule With TimeMuhammad NaeemAinda não há avaliações

- Introduction To Beam Theory Theory: Area Moments of Inertia, Deflection, and Volumes of BeamsDocumento41 páginasIntroduction To Beam Theory Theory: Area Moments of Inertia, Deflection, and Volumes of BeamsDrAmit DuttaAinda não há avaliações

- Short Term Pleasure vs. Long Term GainDocumento31 páginasShort Term Pleasure vs. Long Term Gainunreal2Ainda não há avaliações

- How To Select A Heat Shrink SleeveDocumento2 páginasHow To Select A Heat Shrink SleeveLava SatAinda não há avaliações

- Non Linear Waves - Michael BrorsenDocumento40 páginasNon Linear Waves - Michael BrorsenLava SatAinda não há avaliações

- 1977 OTC 2827 The Design of Single Point MooringsDocumento8 páginas1977 OTC 2827 The Design of Single Point MooringsLava SatAinda não há avaliações

- Interpolating Tabular Data With MathcadDocumento2 páginasInterpolating Tabular Data With MathcadLava SatAinda não há avaliações

- DRAFT Calculation Supposed To Be in Line With DNV-RP-F105 (Feb 2006) Sec. 3.5 and 3.6Documento4 páginasDRAFT Calculation Supposed To Be in Line With DNV-RP-F105 (Feb 2006) Sec. 3.5 and 3.6Lava SatAinda não há avaliações

- Exercise Chart: PN 303731 © 2010 ICON Health & Fitness, Inc. All Rights Reserved. Specifications Subject To ChangeDocumento1 páginaExercise Chart: PN 303731 © 2010 ICON Health & Fitness, Inc. All Rights Reserved. Specifications Subject To ChangeLava SatAinda não há avaliações

- Properties of British Universal Steel Columns and BeamsDocumento4 páginasProperties of British Universal Steel Columns and BeamsLava SatAinda não há avaliações

- Annex D - Stw-Comflow3Documento45 páginasAnnex D - Stw-Comflow3Lava SatAinda não há avaliações

- AP Bearings For Industrial ApplicationsDocumento79 páginasAP Bearings For Industrial Applicationsmikab25Ainda não há avaliações

- 107 Insert Control ButtonsDocumento3 páginas107 Insert Control ButtonsLava SatAinda não há avaliações

- 107 Insert Control ButtonsDocumento3 páginas107 Insert Control ButtonsLava SatAinda não há avaliações

- System 1: Bently NevadaDocumento4 páginasSystem 1: Bently Nevadanabil160874Ainda não há avaliações

- E1 - Controlled Rectifiers PDF NotesDocumento84 páginasE1 - Controlled Rectifiers PDF NotesSatyanarayana Gurram100% (1)

- Saudi Technical Trade Test - Welder CategoryDocumento4 páginasSaudi Technical Trade Test - Welder CategoryshabashakkimAinda não há avaliações

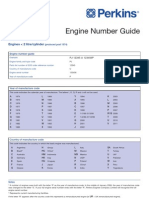

- Perkins Engine Number Guide PP827Documento6 páginasPerkins Engine Number Guide PP827Muthu Manikandan100% (1)

- Oracle Silent InstallDocumento5 páginasOracle Silent InstallAnuj SinghAinda não há avaliações

- 11 Iso 10110Documento28 páginas11 Iso 10110fmeylanAinda não há avaliações

- Naval Arch - Incline TestDocumento11 páginasNaval Arch - Incline TestDheerajKaushalAinda não há avaliações

- Lars Part Ix - Safety Managment System Requirements-SmsDocumento24 páginasLars Part Ix - Safety Managment System Requirements-SmssebastienAinda não há avaliações

- Fertilizer Granulating Machine TypesDocumento4 páginasFertilizer Granulating Machine TypesMichael MedinaAinda não há avaliações

- Satrack Full Report New2Documento17 páginasSatrack Full Report New2ammayi9845_930467904Ainda não há avaliações

- Mine Design and SchedulingDocumento10 páginasMine Design and SchedulingLeandro FagundesAinda não há avaliações

- Transmission Line Surveyors Face Challenges in Projecting Data onto MapsDocumento3 páginasTransmission Line Surveyors Face Challenges in Projecting Data onto MapsTATAVARTHYCH HANUMANRAOAinda não há avaliações

- PHCbi Refrigerators MPRS163 MPRS313Documento2 páginasPHCbi Refrigerators MPRS163 MPRS313Eslam HassanAinda não há avaliações

- MIMO Capacity Increase in UMTS/HSPA+ SystemsDocumento159 páginasMIMO Capacity Increase in UMTS/HSPA+ SystemslikameleAinda não há avaliações

- Weigelt Experience With Stator End-Winding Vibrations Causes, Solutions and Monitoring EPRI 2011, AlbanyDocumento53 páginasWeigelt Experience With Stator End-Winding Vibrations Causes, Solutions and Monitoring EPRI 2011, AlbanyKevin Luis Perez QuirozAinda não há avaliações

- Heat 4e Chap02 LectureDocumento48 páginasHeat 4e Chap02 LectureAbdul MohsinAinda não há avaliações

- CHEMISTRY MID-TERM ASSESSMENTDocumento12 páginasCHEMISTRY MID-TERM ASSESSMENTRamana PadalaAinda não há avaliações

- WRCLA Designers HandbookDocumento11 páginasWRCLA Designers HandbookHoang NguyenAinda não há avaliações

- Slope Stability Then and Now: Professor Emeritus, Virginia Tech, 1600 Carlson DR., Blacksburg, VA, 24060Documento20 páginasSlope Stability Then and Now: Professor Emeritus, Virginia Tech, 1600 Carlson DR., Blacksburg, VA, 24060anarAinda não há avaliações

- How Objects Are Discovered and Monitored in Operations ManagerDocumento2 páginasHow Objects Are Discovered and Monitored in Operations ManagerAkhilesh NandanwarAinda não há avaliações

- Tsi 20040109 PDFDocumento2 páginasTsi 20040109 PDFenache_marian0% (1)

- Net Positive Suction HeadDocumento4 páginasNet Positive Suction Headjorge alarconAinda não há avaliações

- FRL GoyenDocumento12 páginasFRL GoyenAbigael92Ainda não há avaliações

- RGD AccessAbility Handbook 2015 ForWebFINAL-s PDFDocumento32 páginasRGD AccessAbility Handbook 2015 ForWebFINAL-s PDFtiago87pintoAinda não há avaliações

- Geotech Civ150 CompressDocumento4 páginasGeotech Civ150 CompressismaeelAinda não há avaliações

- NCP1117, NCV1117Documento17 páginasNCP1117, NCV1117kalimbaloAinda não há avaliações