Escolar Documentos

Profissional Documentos

Cultura Documentos

Main Refer

Enviado por

Ilaiyaa RajaDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Main Refer

Enviado por

Ilaiyaa RajaDireitos autorais:

Formatos disponíveis

B Morrison / Feb 2010 / Rev 0

GUIDELINE

Document Classification: Controlled Disclosure

Title: Distribution Guide Part 18

TELECONTROL: D20

CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Document Type: DGL

Revision: 0

Published date: FEBRUARY 2010

Total pages: 40

Review date: FEBRUARY 2015

COMPILED BY APPROVED BY FUNCTIONAL RESP AUTHORISED BY

_ _ _ _ _ _

T RAMULONDI

_ _ _ _ _ _ _

S MBANGA

_ _ _ _2009/08/27

PR GROENEWALD

SIGNED

_ _ _ _ _ _ _

MN BAILEY

EDNS Technology (NWR) Telecontrol SC

Chairman

for TESCOD CMDT for MD (Dx)

Content

Page

Foreword .............................................................................................................................................. 2

Introduction .......................................................................................................................................... 2

1 Scope .......................................................................................................................................... 3

2 Normative references .................................................................................................................. 3

3 Definitions and abbreviations ...................................................................................................... 3

3.1 Definitions ............................................................................................................................... 3

3.2 Abbreviations .......................................................................................................................... 3

4 D20 Configuration General Settings ........................................................................................ 4

4.1 Data Collection Application (DCA).......................................................................................... 4

4.2 Data Translation Application ................................................................................................. 23

4.3 Data Processing Application ................................................................................................. 28

4.4 Summary .............................................................................................................................. 34

5 Tests ......................................................................................................................................... 35

6 Marking, labeling and packaging .............................................................................................. 35

7 Spares ....................................................................................................................................... 35

Annex A - Impact assessment ........................................................................................................... 36

Annex B Analogue Scaling ............................................................................................................. 40

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 2 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

Foreword

This guide describes the basic settings to be configured using Config Pro to ensure optimal operation of

the GE D20 Telecontrol RTU.

Revision history

This is a new document.

Date Rev. Clause Remarks

Feb 2010 0 - Compiled By: T Ramulondi, S Mbanga and M Pillay

- First Issue.

Authorisation

This document has been seen and accepted by:

Name Designation

MN Bailey Corporate Manager Divisional Technology

PR Groenewald Technology Development Manager - Control Technologies

S Mbanga Telecontrol Study Committee Chairman

This document shall apply throughout Eskom Distribution.

Development team

Name Designation

Marlini Pillay IARC Control Technologies

Thendo Ramulondi EDNS Technology: North West Region

Simphiwe Mbanga EDNS Technology: Southern Region

Introduction

The GE D20 Remote Terminal Unit (RTU) is an approved product used by the Eskom Distribution

Business. The purpose of this document is to provide a guideline on the general settings of the GE D20

RTU. This guideline does not include the configuration of the RTU for serial communications to Intelligent

Electronic Devices (IEDs). This is covered in the D20 Configuration Settings for communications to DNP3

IEDs. It is essential that personnel using this guide have a basic understanding of Config Pro. GE D20

RTU manuals can be consulted for further information on the D20 settings.

Keywords

Telecontrol, D20, RTU, Config Pro, DCA, DPA, DTA.

Bibliography

1. IST GE D20 Course Manuals

2. GE D20 Software Reference Documents:

a) B015 Bridgeman Configuration c) B013 DNP V3.00 Data Link Configuration

b) B003 Peripheral Link Configuration d) B021 DNP V3.00 DCA Configuration

3. DGL_34-1793: D20 Configuration Settings for communications to DNP3 IEDs

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 3 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

1 Scope

The purpose of this document is to provide a guideline on the general settings of the GE D20 RTU. This

guideline does not include the configuration of the RTU for serial communications to Intelligent Electronic

Devices (IEDs) which is dealt with in the D20 Configuration Settings for Communications to DNP3 IEDs

Guideline (DGL_341793). It is essential that personnel using this guide have a basic understanding of

Config Pro. GE D20 RTU manuals can be consulted for further information on the D20 configuration

settings.

A Config Pro configuration template can be created with the settings recommended in this document.

This template can thus be used as a foundation for all D20 RTU configurations.

2 Normative references

The following document contains provisions that, through reference in the text, constitute requirements of

this standard. At the time of publication, the edition indicated was valid. All controlled documents are

subject to revision, and parties to agreements based on this standard are encouraged to investigate the

possibility of applying the most recent edition of the documents listed below. Information on currently valid

national and international standards and specifications can be obtained from the Information Centre and

Eskom Documentation Centre at Megawatt Park.

DST_34-401: DNP3 Addressing Standard

DST_34-897: Telecontrol DNP3 Class Allocation Standard

3 Definitions and abbreviations

3.1 Definitions

DNP3: Telecontrol communications protocol

3.2 Abbreviations

BCD: Binary Coded Decimal

CTS: Clear to Send

DCA: Data Collection Application

DCD: Data Carrier Detect

DI: Digital Input

DTA: Data Translation Application

DPA: Data Processing Application

DRTU: Distribution Remote Terminal Unit

GE: General Electric

GPRS: General Packets Radio Service

HLDC: High Level Data Link

IED: Intelligent Electronic Device

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 4 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

I/O: Input /Output

LAN: Local Area Network

LAT: Local Application Table

MSB: Most Significant Bit

NACK: Not Acknowledge

PMRTU: Pole Mounted Remote Terminal Unit

RAT: Remote Application Table

RTS: Request to Send

RTU: Remote Terminal Unit

SMART: Standard Master for Regional Telecontrol

SPD: System Point Database

STC: Signal Termination Cards

UHF: Ultra High Frequency

UR: Unsolicited Response

WIN: Wesdac Interface Node

4 D20 Configuration General Settings

4.1 Data Collection Application (DCA)

4.1.1 Peripheral Modules - General

The peripheral modules are responsible for the actual data acquisition. They interface directly to the

external devices. Communications to the main processor of the D20 is achieved via the D.20 Link. As

indicated by the GE Services D20 Guide (See Bibliography), The D20 peripheral I/O modules provide

specialized processing and storing/buffering functions for digital inputs, Analogue inputs, control outputs,

Analogue outputs, pulse accumulator inputs and combinations of the above, by gathering data from field

sources or acting as an output unit to interface with field devices.

There are four peripheral I/O modules available for the D20 RTU namely:

D20A Analogue Input Card (32 Analogue inputs)

D20S Digital Input Card (64 digital inputs)

D20K Control Output Card (32 digital outputs)

D20C Combination Input/Output Card (16 count digital inputs, 8 trip/close control outputs and 16

Analogue inputs or 8 Analogue inputs and 8 Analogue outputs.

These peripheral modules are regarded as Data Collection Applications. These applications poll various

devices to collect data.

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 5 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

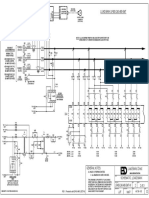

Config Pro software is used to configure the settings on these peripheral modules. The settings for each

peripheral card can be viewed and edited by double clicking the D.20 Peripheral Link icon as indicated in

Figure 1.

Figure 1: Config Pro 5.03 screen displaying the D.20 Peripheral Link

On double clicking this icon, the peripheral modules found on that specific D20 RTU is indicated. The

Config Pro screen demonstrating this view is shown in Figure 2. The settings of each peripheral can be

accessed from these icons.

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 6 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

Figure 2: Config Pro 5.03 screen displaying the D.20 Peripheral Modules

The configuration settings of each of the different peripheral cards are presented in the sections to follow.

4.1.2 Peripheral D20A (Analogue Input Points)

4.1.2.1 General

Figure 3: Config Pro 5.03 screen displaying the General Settings for D20A Card

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 7 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

Table 1: D20A peripheral board settings (General)

D20A Peripheral Board Settings Table

Settings

Name

Settings Options Description GE Default Value

Eskom

Value

Reason for

Selection of

Setting Value

Information

Peripheral

Type

WESDAC D20A

This setting indicates

the type of peripheral

board and cannot be

changed by the user.

-

Cannot be

Changed

-

Termination

Board

No Termination Board

WESTERM D20A

WESTERM D20AD

WESTERM D20OAD

WESTERM D20AZ

WESTERM D20AB

WESTERM D10 A

This setting indicates

the termination board

on which the D20

Analogue card will be

terminated.

-

Generally use

WESTERM

D20A

-

Description To be entered by user

A user defined

description describing

the card

-

e.g. D20A

Analogue

Input

Peripheral (32

AI)

-

Cabinet

Number

To be entered by user

A user defined

description indicating in

which RTU cabinet this

particular peripheral

card is based

- User Defined -

Rack Position To be entered by user

A user defined

description indicating in

which cabinet rack this

particular peripheral

card is based

- User Defined -

Communication Parameters

Time Out

(ms)

0 to 65535

Length of time the D.20

Peripheral Link

application waits for a

response after polling

the peripheral board.

21 21

GE

Recommended

Value

Retries 0 to 32767

Maximum number of

times the D.20

Peripheral Link

application tries to

consecutively poll the

peripheral after it

detects a failure.

3 3

GE

Recommended

Value

Scan Priority

(ms)

1 to 10

The number of times

the D.20 Peripheral

Link application scans

the peripheral board.

Increments of 100ms

1 1

GE

Recommended

Value

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 8 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

4.1.2.2 I/O Configuration

Figure 4: Config Pro 5.03 screen displaying I/O Configuration settings for a D20A Card

The scaling parameters i.e. D20M High Scale, D20M Low Scale, Peripheral High Scale and Peripheral Low

Scale, are utilised to return a scaled value to the System Point Database Application, The equation used to

calculate this scaled value is shown below.

( )( )

( ) Scale Low Peripheral - Scale High Peripheral

Scale Low Peripheral - Value Input Analogue Raw Scale Low D20M Scale High D20M

Value Scaled

=

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 9 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

Table 2: D20A peripheral board settings (I/O Settings)

D20A Peripheral Board I/O Settings

Settings Name

Settings

Options

Description

GE Default

Value

Eskom

Value

Reason for

Selection of

Setting Value

Description

To be

entered by

user

Information of the field point.

This description will also appear

in WESMAINT

User

Defined

User

Defined

-

Scan Enable Yes or No

Indicates if the particular point

must be scanned and its value

sent to the RTU

Yes Yes

GE

Recommended

Value

Range Select (V)

01V,

05V,

010V

Specifies the maximum positive

and negative full scale voltage to

be applied to the input point

05V 05V

GE

Recommended

Value

Report Deadband 0 to 13

Specify the least significant bits

of the Analogue value that must

change before the application

reports the value to the system

point database. (2^n)

4 4

GE

Recommended

Value

D20M High Scale

(%)

0 to 100

Maximum value to return to the

system point database, as a

percentage of 32767.

100 100

GE

Recommended

Value

D20M Low Scale

(%)

0 to -100

Minimum value to return to the

system point database, as a

percentage of 32767.

-100 -100

GE

Recommended

Value

Peripheral High

Scale (%)

0 to 100

Maximum value expected from

the Analogue input peripheral

100 100

GE

Recommended

Value

Peripheral Low

Scale (%)

0 to -100

Minimum value expected from

the Analogue input peripheral

-100 -100

GE

Recommended

Value

4.1.2.3 Advanced Settings

Figure 5: Config Pro 5.03 screen displaying the Advanced Settings for a D20A Card

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 10 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

Table 3: D20A peripheral board settings (Advanced)

D20A Peripheral Board Advanced Settings

Settings Name

Settings

Options

Description

GE Default

Value

Eskom

Value

Reason for

Selection of

Setting Value

Input Setting Time

(s)

0 to 3276

Length of time (in microseconds)

the application allows an

Analogue input signal to settle

for before the application takes a

sample.

500 500

GE

Recommended

Value

Reference Check 20 to 255

The number of conversions of

field inputs before the application

updates the on board Analogue

input reference.

100 100

GE

Recommended

Value

Reference

Deadband

0 to 32767

The allowable difference

between the running references

and the EPROM references

before an error is generated.

256 256

GE

Recommended

Value

Line Frequency

(Hz)

50 or 60 Power Utility's Line Frequency 50 or 60 50 -

4.1.3 Peripheral D20S (Digital Input Points)

4.1.3.1 General

Figure 6: Config Pro 5.03 screen displaying the General settings page for a D20S Card

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 11 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

Table 4: D20S peripheral board settings (General)

D20S Peripheral Board General Settings

Settings Name Settings Options Description

GE Default

Value

Eskom

Value

Reason for

Selection of

Setting Value

Information

Peripheral Type WESDAC D20S

This setting indicates the

type of peripheral board

and cannot be changed

by the user.

-

Cannot be

Changed

-

Termination Board

No Termination Board

WESTERM D20S

WESTERM D20SD

WESTERM D20OSD

WESTERM D20SZ

WESTERM D20SZ2

WESTERM D10 S

This setting indicates on

which termination board

the D20 digital input card

will be terminated.

-

Generally use

WESTERM

D20S

-

Description To be entered by user

A user defined description

describing the card

-

e.g.D20S

Digital Input

Peripheral (64

DI)

-

Cabinet Number To be entered by user

A user defined description

indicating in which RTU

cabinet this particular

peripheral card is based

- User Defined -

Rack Position To be entered by user

A user defined description

indicating in which cabinet

rack this particular

peripheral card is based

- User Defined -

Communication Parameters

Time Out (ms) 0 to 65535

Length of time the D.20

Peripheral Link

application waits for a

response after polling the

peripheral board.

21 21

GE

Recommende

d Value

Retries 0 to 32767

Maximum number of

times the D.20 Peripheral

Link application tries to

consecutively poll the

peripheral after it detects

a failure.

3 3

GE

Recommende

d Value

Scan Priority (ms) 1 to 10

The number of times the

D.20 Peripheral Link

application scans the

peripheral board.

Increments in 100ms

1 1

GE

Recommende

d Value

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 12 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

4.1.3.2 I/O Configuration

Figure 7: Config Pro 5.03 screen displaying I/O Configuration settings for a D20S Card

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 13 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

Table 5: D20S board settings (I/O configuration)

D20S Peripheral Board Settings Table

Settings

Name

Settings

Options

Description

GE Default

Value

Eskom

Value

Reason for

Selection of

Setting Value

Description

To be entered

by user

Information of the field point. This

description will also appear in

WESMAINT

User Defined

User

Defined

-

Point Type

Single Point

Double Point

Transition

Counters

Form C

Counter

Single Point: This type of point monitors

change of state. The point is either ON of

OFF.

Double Point: Uses two separate digital

inputs to represent four different states.

Two of these states are valid and the

other two are invalid.

Transition Counter: This type of point

counts every change of state - or

transition

Form C Counter: This type of point

counts every valid double point transition.

Single Point

Single Pt /

Double Pt

-

COS Yes or No

If set to YES, allows a point to generate a

change-of-state alarm in the RTUs COS

archive/buffer. Volatile memory

- Yes -

SOE Yes or No

If set to YES, allows a point to generate

time stamped change-of-state alarm in

the RTU's SOE archive / buffer. Non

volatile memory

- Yes -

Report Limit

0 to 255

times

Only applicable to accumulator inputs.

Maximum number of counts that must

occur before a report is sent to the RTU.

0 0

Tolerant

Period (ms)

0 to 255

Specify the time period in first-level

debouncing where the application allows

changes in state (for contact bounce). It

is a period during which contact bounce

is "acceptable".

0 0

GE

Recommended

Value

Intolerant

Period (ms)

0 to 255

It is a period of time following the tolerant

phase during which contact bounce is

"unacceptable. It ensures contact

bounce is not mistaken for a valid change

of state.

6 6

GE

Recommended

Value

Valid Period

(ms)

0 to 255

(in 256 ms

increments)

0 to 255

(in multiples of

10ms)

For a single point state/ Form A counter.

Defines the period of time during which

the point state must be ON.

For a double point state/Form C counter.

Defines the period of time (in multiples of

10ms) during which both points must be

in a "valid" state.

0 Default = 0

Value as per

application (e.g.

AC fail)

Invalid Period

(ms)

0 to 255

(in 256 ms

increments)

0 to 255 (in

multiples of

10ms)

For a single point state/ Form A counter.

Defines the period of time during which

the point state must be OFF.

For a double point state/Form C counter.

Defines the period of time (in multiples of

10ms) during which both points must be

in an "invalid" state. (11 and 00)

0 Default = 0

Value as per

application (e.g.

AC fail, breaker

states)

Transitions 0 to 255

Specify the maximum number of

transitions in a filter period before turning

ON digital input chatter filtering. (0

disables chatter filtering). If number of

state transitions during a filter period

equals or exceeds this value, the chatter

filter turns ON

0 25

Safe number to

pick up 50

cycles per

second. As was

experienced

with STC.

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 14 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

D20S Peripheral Board Settings Table

Settings

Name

Settings

Options

Description

GE Default

Value

Eskom

Value

Reason for

Selection of

Setting Value

Lock Out 0 to 255

Specify the number of filter periods

before turning OFF the digital input

chatter filtering. If 0, the chatter filter turns

OFF if the number of transitions in one

filter period is less than the maximum. If

(1 to 255), the chatter filter turns OFF if

there are no transitions in the number of

filter periods that you specify here.

0 5

This means that

the filter turns

off after 5

periods of

chattering

4.1.3.3 Advanced

Figure 8: Config Pro 5.03 screen displaying the Advanced settings for a D20A Card

Table 6: D20S board settings (Advanced)

D20S Peripheral Board Settings Table

Settings

Name

Settings

Options

Description

GE Default

Value

Eskom

Value

Reason for

Selection of

Setting Value

Filter Period 0 to 65535 ms

Length of time used as the sample time

window for chatter filtering. A non-zero

value enables the chatter filter for all

digital input points.

0 1000

Allows only 50

STC alarms to

be transmitted

before chatter

filtering is

initiated.

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 15 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

4.1.4 Peripheral D20K (Digital Output Points)

4.1.4.1 General

Figure 9: Config Pro 5.03 screen displaying the General Settings for a D20K Card

Table 7: D20K peripheral board settings (General)

D20K Peripheral Board Settings Table

Settings

Name

Settings Options Description

GE

Default

Value

Eskom

Value

Reason for

Selection of

Setting Value

Information

Peripheral

Type

WESDAC D20K

This setting indicates the type of

peripheral board and cannot be

changed by the user.

-

Cannot be

Changed

-

Termination

Board

No Termination Board

WESTERM D20K

WESTERM D20KR

WESTERM D20 OKR

WESTERM D20K4Z

WESTERM D20K

WESTERM D10 KR

This setting indicates on which

termination board the D20K Digital

output card will be terminated.

-

Generally

use

WESTERM

D20K

-

Description To be entered by user

A user defined description

describing the card

-

e.g. D20K

Digital

Output

Peripheral

(32 DO)

-

Cabinet

Number

To be entered by user

A user defined description

indicating in which RTU cabinet

this particular peripheral card is

based

-

User

Defined

-

Rack

Position

To be entered by user

A user defined description

indicating in which cabinet rack this

particular peripheral card is based

-

User

Defined

-

Communication Parameters

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 16 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

D20K Peripheral Board Settings Table

Settings

Name

Settings Options Description

GE

Default

Value

Eskom

Value

Reason for

Selection of

Setting Value

Time Out

(ms)

0 to 65535

Length of time the D.20 Peripheral

Link application waits for a

response after polling the

peripheral board.

21 21

GE

Recommended

Value

Retries 0 to 32767

Maximum number of times the

D.20 Peripheral Link application

tries to consecutively poll the

peripheral after it detects a failure.

3 3

GE

Recommended

Value

Scan Priority

(ms)

1 to 10

The number of times the D.20

Peripheral Link application scans

the peripheral board. Increments in

100ms

1 1

GE

Recommended

Value

4.1.4.2 I/O Configuration

Figure 10: Config Pro 5.03 screen displaying the I/O Configuration Settings for a D20K Card

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 17 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

Table 8: D20K peripheral board settings (I/O Configuration)

D20K Peripheral Board I/O Configuration Settings

Settings

Name

Settings

Options

Description

GE Default

Value

Eskom

Value

Reason for

Selection of

Setting Value

R/L Point

To be entered by

user

List of pairs of raise / lower point numbers

associated with the output points. These

numbers cannot be changed.

N/A N/A -

Description

To be entered by

user

User description of the point. This will

appear on the WESMAINT

N/A

User

Defined

-

Termination

Type

Trip/Close

Raise/Lower

Form C

Open Collector

Defines the configuration of the

termination board. A type of digital output

that turns something on and off using a

master relay and a select relay.

Trip/Close Trip/Close

Relay Type XXXXXX

Type of relay used to terminate the point.

Only for KI DB25 Boards

N/A N/A -

Reset on

Start Up

Yes or No

Determines if a latched relay is

automatically reset when the RTU starts

up.

No No

GE

Recommended

Value

4.1.4.3 Advanced Settings

Figure 11: Config Pro 5.03 screen displaying the Advanced Settings for a D20K Card

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 18 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

Table 9: D20K peripheral board settings (Advanced)

D20K Peripheral Board Advanced Settings Table

Settings Name

Settings

Options

Description

GE

Default

Value

Eskom

Value

Reason for

Selection of

Setting Value

Select Time

(ms)

1 to 255

The amount of time the select relay will

operate prior to the master trip or master

close relay (Select before operate)

10 10

GE

Recommended

Value

Clear Time (ms) 1 to 255

The amount of time the select relay will

remain ON after the master trip or master

close relay operated

10 10

GE

Recommended

Value

Control Arm

Time Out (ms)

100 to 255

The amount of time a K board will wait

for an execute command (from RTU)

after receiving an arm command.

100 100

GE

Recommended

Value

Retry Time (ms) 1 to 255

The amount of time the D20K will wait

and restart after a shutdown has taken

place

10 10

GE

Recommended

Value

Retry Attempts 0 to 255

The amount of times that a D20K will try

to restart after a failure.

0 0

GE

Recommended

Value

Communication

Fail

Time Out (ms)

0 to 65535

Length of time the D.20 Peripheral Link

application waits for communication over

the HDLC link before shutting down all

the relays. 0 ms (disabled).

0 0

GE

Recommended

Value

4.1.5 Peripheral D20C (Digital Input/Output Analogue Inputs/Outputs)

4.1.5.1 General

Figure 12: Config Pro 5.03 screen displaying the General Settings for a D20 C Card

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 19 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

Table 10: D20C peripheral board settings (General)

D20C Peripheral Board General Settings

Settings Name Settings Options Description

GE

Default

Value

Eskom

Value

Reason for

Selection of

Setting Value

Peripheral

Type

WESDAC D20 C

This setting indicates the type of

peripheral board and cannot be

changed by the user.

-

Cannot be

Changed

-

Termination

Board

No Termination Board

WESTERM D20 C

WESTERM D20 CD

WESTERM D20 C4Z

WESTERM D20 C4Z2

WESTERM D20 CB

WESTERM D10 C

WESTERM D20 CDI

This setting indicates on which

termination board the D20C

Combo card will be terminated.

-

Generally

use

WESTERM

D20 C

-

Description To be entered by user

A user defined description

describing the card

-

e.g. D20 C

Combo

Peripheral

-

Cabinet

Number

To be entered by user

A user defined description

indicating in which RTU cabinet

this particular peripheral card is

based

-

User

Defined

-

Rack Position To be entered by user

A user defined description

indicating in which cabinet rack

this particular peripheral card is

based

-

User

Defined

-

Communication Parameters

Time Out (ms) 0 to 65535

Length of time the D.20

Peripheral Link application waits

for a response after polling the

peripheral board.

21 21

GE

Recommended

Value

Retries 0 to 32767

Maximum number of times the

D.20 Peripheral Link application

tries to consecutively poll the

peripheral after it detects a

failure.

3 3

GE

Recommended

Value

Scan Priority

(ms)

1 to 10

The number of times the D.20

Peripheral Link application scans

the peripheral board. Increments

of 100ms

1 1

GE

Recommended

Value

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 20 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

4.1.5.2 I/O Configuration

Figure 13: Config Pro 5.03 screen displaying the I/O Config Settings for a D20 C Card Digital

Figure 14: Config Pro 5.03 screen displaying the I/O Config Settings for a D20 C Card Digital Outputs

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 21 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

Figure 15: Config Pro 5.03 screen displaying the I/O Config Settings for a D20 C Card Analogue Inputs

Table 11: D20C peripheral board settings (I/O Configuration)

D20C Peripheral Board General Settings

Settings Name Settings Options Description

GE

Default

Value

Eskom

Value

Reason for

Selection of

Setting Value

Digital Inputs

See D20S Settings

Digital Outputs

See D20K Settings

Analogue Inputs

See D20A Settings

Analogue Outputs

Description XXXXXX Only available with C2 card N/A N/A -

Into Value XXXXXX Only available with C2 card N/A N/A -

Output Mode XXXXXX Only available with C2 card N/A N/A -

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 22 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

4.1.5.3 Advanced

Figure 16: Config Pro 5.03 screen displaying the Advanced Settings for a D20 C Card

Table 12: D20C peripheral board settings (Advanced)

D20C Peripheral Board Advanced Settings

Settings Name Settings Options Description

GE

Default

Value

Eskom

Value

Reason for

Selection of

Setting Value

Input Setting

Time (s)

0 to 32767

Length of time (in microseconds)

the application allows an

Analogue input signal to settle

for before the application takes a

sample.

500 500

Reference

Check

20 to 255

The number of conversions of

field inputs before the application

updates the on board Analogue

input reference.

100 100

GE

Recommended

Value

Reference

Deadband

0 to 32767

The allowable difference

between the running references

and the EPROM references

before an error is generated.

256 256

Line Frequency

(Hz)

50 or 60 Power Utilitys Line Frequency 50 or 60 50 -

Filter Period

(ms)

0 to 65535

Length of time used as the

sample time window for chatter

filtering. A non-zero value

enables the chatter filter for all

digital input points.

0 1000

GE

Recommended

Value

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 23 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

D20C Peripheral Board Advanced Settings

Settings Name Settings Options Description

GE

Default

Value

Eskom

Value

Reason for

Selection of

Setting Value

Select Time

(ms)

1 to 255

The amount of time the select

relay will operate prior to the

master trip or master close relay

10 10

GE

Recommended

Value

Clear Time (ms) 1 to 255

The amount of time the select

relay will remain ON after the

master trip or master close relay

operated

10 10

GE

Recommended

Value

Control Arm

Time Out (ms)

100 to 255

The amount of time a K board

will wait for an execute

command (from RTU) after

receiving an arm command.

100 100

GE

Recommended

Value

Retry Time (ms) 1 to 255

The amount of time the D20K

will wait and restart after a

shutdown has taken place

10 10

GE

Recommended

Value

Retry Attempts 0 to 255

The amount of times that a D20K

will try to restart after a failure.

0 0

GE

Recommended

Value

Communication

Fail Time Out

(ms)

0 to 65535

Length of time the D.20

Peripheral Link application waits

for communication over the

HDLC link before shutting down

all the relays. 0 ms (disabled).

0 0

GE

Recommended

Value

4.2 Data Translation Application

Figure 17: DTA Main configuration window

4.2.1 Functions of the DTA

The functions of the DTA are as follows:

1. Interfaces between the DTA and the DPA to process request and control information.

2. For viewing points that are in the system point database.

For normal D20 configurations, the applications that are normally enabled are the following:

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 24 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

i. D/A Conversion DTA

ii. DNP V3.00 Data Link

iii. Bridgeman

4.2.2 DNP V3.00 Data Link Configuration

Figure 18: Port configuration window

Figure 19: Port configuration parameters

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 25 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

Table 13: DNP V3.00 Data Link Configuration Settings Communications to the Master Station

DNP V3.00 Data Link Configuration

Port configuration parameters

Settings

Name

Settings Options Description

GE

Default

Value

Eskom

Value

Reason for

Selection of

Setting Value

Port COM 0 to 7

This setting indicates the port that will

be used for communication

1 COM 1 to 7

Any port can be

selected, except

for COM 0, as it

will result in losing

the use of that port

for configuration.

Baud Rate

(75,300, 600,

1200, 2400, 4800,

9600, 19K2, 38K4

or 57K6 baud)

The speed of the link in bits per

second.

9600

300, 1200, 4800,

9K6, 19K2,

38K4

Depends on

Telecomms type

Reset Link

on Rx

NACK

Enabled/Disabled

Whether to reset the link and resend

the user request after receiving a

data link NACK with the Data Flow

Control (DFC) bit clear in response to

a frame transmitted using the

SEND/CONFIRM EXPECTED

service.

Enabled Enabled -

DCD Enabled/Disabled

Whether to use the Data Carrier

Detect (DCD) line,

Disabled

Disabled except

for UHF radio

Used in UHF for

collision avoidance

RTS Enabled/Disabled

Whether to use the Request To Send

(RTS) line.

Disabled Enabled

This is set for pre-

amble purposes

CTS Enabled / Disabled

Whether to use the Clear To Send

(CTS) line.

Disabled Disabled

All present comms

devices cater for

DCD.

DCD to Rx

Enable

0 to 32767 ms

Time to wait after the DCD line is

asserted before receiving data.

10

10 for Analogue

UHF

0 for Digital

UHF (TRIO

Digital Radios

only)

To ensure that the

channel is opened

only for proper

comms not

spurious noise.

RTS

Preamble

(ms)

0 to 65535

The length of time to assert RTS

before transmitting data.

50

Analogue UHF

300 - 750ms

Digital UHF -

0ms

GPRS = 0ms

Depends on

settings per area

as long as it is

within the specified

range.

RTS

Postamble

(ms)

0 to 65535

The length of time to continue to

assert RTS after transmitting data.

50

DRTU/PMRTU

connected to

IST FFSK

modem - 100ms

All others - 0ms

Depends on

settings per area

as long as it is

within the specified

range.

Confirm

Timeout

(ms)

0 to 4294967295

The maximum time the

communications link can be idle

while the Data Link waits for a

secondary response frame (i.e. a

data link confirm) from a remote

device. The timeout is reset with

every valid frame transmission or

reception.

2000 2000

GE Recommended

Value

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 26 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

DNP V3.00 Data Link Configuration

Port configuration parameters

Settings

Name

Settings Options Description

GE

Default

Value

Eskom

Value

Reason for

Selection of

Setting Value

Response

Timeout

(ms)

0 to 4294967295

The maximum time the

communications link can be idle

while the Data Link waits for a

primary frame from a remote device.

This is the timeout between frames of

an incoming, multiframe message. In

addition, when the user requests the

data link to wait with timeout for a

response from a remote device, the

data link adds the Response Timeout

to the application processing delay

supplied by the user to wait for the

first frame of the response. The

timeout is cancelled with every valid

frame transmission or reception, and

then restarted where it left off. At a

minimum, the timer is restarted with

the Confirm Timeout.

10000

Analogue UHF:

10000 30000

Digital UHF:

2000 - 6000

GPRS:

5000 - 10000

Depends on the

max frame size,

baud rate and

network topology

4.2.3 Bridgeman Configuration

Figure 20: Bridgeman Application window

There are 2 tables that are used for the Bridgeman configuration namely, the Local application table and

Remote application table.

The Local application table as shown in Figure 20 refers to the addresses of the ports on the D20 unit,

whereas the Remote application table shown in Figure 21 refers to the Master or IED addresses. For both

applications, the application address and the LAN address on the same row have to be the same, with the

LAN address being the HEX representation of the Decimal address in the application address column.

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 27 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

Figure 21: Local Application table

Figure 22: Remote application table

4.2.4 D/A Conversion DTA

This application is used for the tap changer position D/A BCD conversion. The bits that are used for the

BCD conversion are converted to a Pseudo Analogue DCA point which is available to the DCA. On the

system point database application window, under the DCA/DTA list an instance/application with the D/A

Conversion DTA is added, this is where the column Analogue inputs needs to be updated to reflect the

number of tap changer Analogues selected.

Figure 23: AI Information table

The AI information table selections are the Input type (BCD) and the Unipolar /Bipolar (Unipolar) selections

with no strobe. The Number of DI and the Map Offset is an indication based on the selections made on the

digital inputs selected on the digital input map.

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 28 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

Figure 24: Map offset drop down window

Note that the MSB is always on top for the BCD conversion. The number of selected DIs is as per the

number of DI column in the AI Information table.

4.3 Data Processing Application

In this section, the configuration of the DNP3 Data Processing Application shall be discussed. In Config

Pro, Double click on the application as shown on the screen below.

Figure 25: DPA Main window

Double click on the DPA configuration table.

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 29 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

Figure 26: DPA configuration table icon

Select the DPA configuration tab. Under the DPA address field, set the RTU address and under the

master address field, set the DNP3 masters address. Once you have set the RTU address and the

masters address double click on the DPA Points column. See the table below for the DPA settings.

Master Address

RTU

Address

Double Click

Figure 27: DPA configuration table

Table 14: DNP 3 Configuration table

DNP V3.00 DPA Configuration Settings Table

Settings

Name

Settings

Options

Description

GE

Default

Value

Eskom

Value

Reason for

Selection of

Setting Value

DPA

Address

0 - 65535 This numeric field specifies the address of the

DPA/RTU. It has to be unique within the

network

-

User Defined

Must conform to

standard DNP 3

Addressing

Standard 34-401

Master

Address

0 - 65535 This numeric field specifies the default address

of the master station.

-

User Defined

Must conform to

standard DNP 3

Addressing

Standard 34-401

Under DPA points, configure the points to be displayed to the master by configuring First Binary Input, First

Binary Output and First Analogue Input columns. Double click on each column and select points which are

to be displayed to the master by highlighting them and click OK. This is demonstrated in Figure 28.

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 30 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

Double Click

Figure 28: DPA points configuration window

4.3.1 Binary Input Settings

Table 15: Binary inputs settings

Binary Input Point Settings

Settings

Name

Settings

Options

Description

GE

Default

Value

Eskom

Value

Reason for

Selection of

Setting Value

Binary

Input

Point

-

System Point Number of the binary input

in the RTU database

-

Defined binary

inputs should be

selected

-

Invert

Status

Disabled/

Enabled

Inverts binary input point to be reported in

the inverted state

Disabled Disabled

Normally there is

no need to invert

the status of the

digital input.

COS

(Change

of State)

Disabled/

Enabled

Generates events Disabled Disabled

All events should

preferably be

time-stamped

SOE

(Sequence

of Events)

Disabled/

Enabled

Generates time-stamped events Enabled Enabled

All events should

preferably be

time-stamped

Event

Class

Class 1, 2 or

3

Describes the default class for each event

generated for each point

Class 1

Refer to DNP3

Class Allocation

Document 34-897

Refer to DNP3

Class Allocation

Document 34-

897

Once all the settings have been configured as described on the table above, one should highlight all the

selected points and click OK. See the figure below.

Figure 29: DPA digital inputs table

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 31 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

4.3.2 Binary Outputs Settings

Under binary outputs, select the desired digital outputs, highlight them and click OK.

Figure 30: DPA digital outputs table

Analogue Input Settings

Table 16: Analogue input setting

Analogue Input Settings Table

Settings

Name

Settings

Options

Description

GE

Default

Value

Eskom

Value

Reason for

Selection of

Setting Value

Analogue

Input Point

-

System Point Number of the Analogue

input in the RTU database

-

Defined Analogue

inputs should be

selected

-

Analogue

Size

16 or 32 Default reported analogue size in bits - 16

Do not need the

resolution of 32

bits

Event Class

Class 1, 2

or 3

Describes the default class for each event

generated for each point

-

Refer to DNP3

Class Allocation

Document

34-897

Refer to DNP3

Class Allocation

Document

34-897

Event

Deadband

-1 to 32767

Specifies the deadband value, in

normalized RTU database counts, that

the Analogue must exceed before an

event is created.

-1

Please refer to

Annex B

Buffer

Events

Buffered/

not buffered

Specifies whether the Analogue events

will be buffered in the RTUs memory

Not

Buffered

Not Buffered

Instantaneous

values are

reported to the

master

Time Tag

Enabled/

Disabled

Specifies whether the Analogue events

will be time tagged or not

Disabled Disabled

Time tagging is

disabled to

reduce the

message sizes

Processing

options

Current

Value &

Time/

1st Value &

Time

This value specifies how analogue input

events are reported to the DNP master

station The selection can be Current

Value & Time or First Value & Time. For

further details refer to DNP V3.00 DPA

Configuration Guide B021-0 CG

Current

Value &

Time

Current Value &

Time

Analogue events

reported will

contain current

values and time.

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 32 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

Analogue Input Settings Table

Settings

Name

Settings

Options

Description

GE

Default

Value

Eskom

Value

Reason for

Selection of

Setting Value

Range 0 - 32767

This parameter is the analogue input

scaling range. The range defines the

maximum DNP protocol value that will be

reported when the WIN analogue input

reaches its full-scale value.

32767 1*

This value

depends on

scaling applied on

the IED. For e.g.

if a scaling factor

of 10 is applied in

the IED, then the

Range and

Divisor should

negate this

scaling factor. For

peripheral cards

I/O cards, a value

of 1 is acceptable.

Divisor 0 - 32767

This parameter is the analogue input

scaling divisor. The divisor defines the

WIN analogue input full-scale value. The

analogue scaling factor is determined by

the combination of the Range and Divisor

parameters.

32767 1*

This value

depends on

scaling applied on

the IED. For e.g.

if a scaling factor

of 10 is applied in

the IED, then the

Range and

Divisor should

negate this

scaling factor. For

peripheral cards

I/O cards, a value

of 1 is acceptable

Offset 0 - 32767

This parameter specifies a compensation

offset factor for a WIN analogue input

value. The value configured is in terms of

number of DNP value counts.

0 0

Do not need to

offset analogue

values.

Unsolicited Responses

Once you have configured the DPA points under the DPA Configuration table scroll to your right to

configure the Unsolicited Responses parameters.

Figure 31: Unsolicited responses tab

Under the Unsolicited Responses table, you can then select the type of data to be reported. See the screen

shown below.

Double Click

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 33 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

Figure 32: Unsolicited responses settings

See the table below for detailed settings on unsolicited responses

Table 17: Unsolicited Responses Settings

Unsolicited Responses

Settings Name Settings Options Description

GE

Default

Value

Eskom

Value

Reason for

Selection of

Setting Value

Class 1 Enabled/Disabled

Specifies that Class 1 data should

be included in unsolicited

responses

- Enabled -

Class 2 Enabled/Disabled

Specifies that Class 2 data should

be included in unsolicited

responses

- Enabled -

Class 3 Enabled/Disabled

Specifies that Class 3 data should

be included in unsolicited

responses

- Enabled -

Hold Time

(ms)

Time in ms

Specifies the maximum time that

the DPA will hold an unsolicited

response before it is reported to the

master

1000 1000 GE default value

Hold count Number of events

number of events that should occur

before an unsolicited event is

reported

1 1

GE

recommended

value

Idle Report

Period

Enabled/Disabled

Specifies the time in ms to idle

before sending an unsolicited event

0 0

GE

recommended

value

Back-off

Period

Time in ms

Period used for back-off timer. It is

started when all UR retries have

elapsed.

300000 300000

GE

recommended

value

Silent Master Enabled/Disabled

Enables all unsolicited responses

and never asks for confirmation.

Disabled Disabled

Confirmation not

required

Offset 0 - 32767

This parameter specifies a

compensation offset factor for a

WIN Analogue output value.

0 0 -

Auto Data

Dump

Enabled/Disabled

if a point is reported by UR, send

all value of the same data type

Disabled Disabled

Only the point

with the change

should be

reported

UR Enable By master/By DPA

UR can be enabled by master or by

DPA

By DPA By Master

UR is enabled by

the SCADA

master

Select the data type

to be reported

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 34 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

4.4 Summary

1. Define all devices

2. Assign DNP3 addresses , DTA links

3. Determine all :

Digital Input points

Digital output points

Analogue Input points

Counters

Enable all applications to use.

4. Complete the SPD WIN

4.1 DI =3 Global +x Actual +16 Pseudo

4.2 DO =9 Global +x Actual +10 Pseudo

4.3 AI =0 Global +x Actual +5 Pseudo

5. DCA Application

1. Device Poll Table

2. Device Point map

3. Device Configuration map

4. Device DCA map

6. DTA DNP 3

6.1 Bridgeman

6.1.1 Local Application Table (LAT)

6.1.2 Remote Application Table (RAT)

6.1.3 Configuration Table

6.2 DNP 3 Data Link

6.2.1 Port configuration

7. DPA DNP 3

7.1 Binary Input map

7.2 Binary Output map

7.3 Analogue Input map

7.4 Counters

7.5 DPA configuration table

Go back to Bridgeman to complete.

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 35 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

8. Generate

Clear Errors

9. Download

Check error logs.

NOTE: Downloading a file

Firstly, to login to westmaint one needs the login name plus the password.

GOTO Westmain

Then System functions

Then 68K Monitor

Then on the D25M prompt press F7

To change the Baud rate:

On the D25m>prompt type BAUD XXXXX (Xxxx =desired rate, 1200 38400)

Once the baud rate has been changed on the unit, the baud rate on the PC needs to be changed.

To change the computer baud rate:

Left click on the terminal emulator window, choose disconnect>>

GOTO Options>>Port settings>>select baud rate chose above and connect again at the new baud rate by selecting con

5 Tests

n/a

6 Marking, labeling and packaging

n/a

7 Spares

n/a

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 36 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

Annex A - Impact assessment

(informative)

Impact assessment form to be completed for all documents.

1 Guidelines

o All comments must be completed.

o Motivate why items are N/A (not applicable)

o Indicate actions to be taken, persons or organisations responsible for actions and deadline for action.

o Change control committees to discuss the impact assessment, and if necessary give feedback to the

compiler of any omissions or errors.

2 Critical points

2.1 Importance of this document. E.g. is implementation required due to safety deficiencies,

statutory requirements, technology changes, document revisions, improved service quality,

improved service performance, optimised costs.

Comment: To provide assistance and guidance to the telecontrol EDFS Staff during commissioning of the

D20 RTUs.

2.2 If the document to be released impacts on statutory or legal compliance - this need to be very

clearly stated and so highlighted.

Comment: Does not impact

2.3 Impact on stock holding and depletion of existing stock prior to switch over.

Comment: No Impact

2.4 When will new stock be available?

Comment: n/a

2.5 Has the interchangeability of the product or item been verified - i.e. when it fails is a straight

swop possible with a competitor's product?

Comment: n/a

2.6 Identify and provide details of other critical (items required for the successful implementation

of this document) points to be considered in the implementation of this document.

Comment: n/a

2.7 Provide details of any comments made by the Regions regarding the implementation of this

document.

Comment: No comments received.

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 37 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

Annex A

(continued)

3 Implementation timeframe

3.1 Time period for implementation of requirements.

Comment: This document shall be used as a reference whenever necessary.

3.2 Deadline for changeover to new item and personnel to be informed of DX wide change-over.

Comment: n/a

4 Buyers Guide and Power Office

4.1 Does the Buyers Guide or Buyers List need updating?

Comment: No

4.2 What Buyers Guides or items have been created?

Comment: n/a

4.3 List all assembly drawing changes that have been revised in conjunction with this document.

Comment: n/a

4.4 If the implementation of this document requires assessment by CAP, provide details under 5

4.5 Which Power Office packages have been created, modified or removed?

Comment: None

5 CAP / LAP Pre-Qualification Process related impacts

5.1 Is an ad-hoc re-evaluation of all currently accepted suppliers required as a result of

implementation of this document?

Comment: No

5.2 If NO, provide motivation for issuing this specification before Acceptance Cycle Expiry date.

Comment: n/a

5.3 Are ALL suppliers (currently accepted per LAP), aware of the nature of changes contained in

this document?

Comment: n/a

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 38 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

Annex A

(continued)

5.4 Is implementation of the provisions of this document required during the current supplier

qualification period?

Comment: n/a

5.5 If Yes to 5.4, what date has been set for all currently accepted suppliers to comply fully?

Comment: n/a

5.6 If Yes to 5.4, have all currently accepted suppliers been sent a prior formal notification

informing them of Eskoms expectations, including the implementation date deadline?

Comment: n/a

5.7 Can the changes made, potentially impact upon the purchase price of the material/equipment?

Comment: n/a

5.8 Material group(s) affected by specification: (Refer to Pre-Qualification invitation schedule for

list of material groups)

Comment: n/a

6 Training or communication

6.1 State the level of training or communication required to implement this document. (E.g. none,

communiqus, awareness training, practical / on job, module, etc.)

Comment: IST GE D20 training Part 1

6.2 State designations of personnel that will require training.

Comment: Telecontrol Staff

6.3 Is the training material available? Identify person responsible for the development of training

material.

Comment: Telecontrol Technology

6.4 If applicable, provide details of training that will take place. (E.G. sponsor, costs, trainer,

schedule of training, course material availability, training in erection / use of new equipment,

maintenance training, etc).

Comment: n/a

6.5 Was Training & Development Section consulted w.r.t training requirements?

Comment: No

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 39 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

Annex A

(continued)

7 Special tools, equipment, software

7.1 What special tools, equipment, software, etc will need to be purchased by the Region to

effectively implement?

Comment: Config Pro is required and this is provided to each Telecontrol Technician in their laptops via

the EDFS laptop image.

7.2 Are there stock numbers available for the new equipment?

Comment: n/a

7.3 What will be the costs of these special tools, equipment, software?

Comment: None.

8 Finances

8.1 What total costs would the Regions be required to incur in implementing this document?

Identify all cost activities associated with implementation, e.g. labour, training, tooling, stock,

obsolescence

Comment: None.

.

Impact assessment completed by:

Name: Kenneth Brwon

Designation: Telecontrol Discipline Specialist

DOCUMENT CLASSIFICATION: CONTROLLED DISCLOSURE

TELECONTROL: D20 CONFIGURATION GUIDE

GENERAL SETTINGS

Unique Identifier: 34-1990

Type: DGL

Revision: 0

Page: 40 of 40

When downloaded from the DT WEB, this document is uncontrolled and the responsibility rests with the user

to ensure it is in line with the authorised version on the WEB.

Annex B Analogue Scaling

Serial Communications

The SEL351S relay provides scaled engineering analogue values.

Since the SEL351S also conforms to the DNP3 standard, it must provide a 16 bit 2s complement value for

the analogues. The range is -32768 to +32767

IED manufacturers can represent measured values as either Engineering Values or Raw Values.

Assume the IED is measuring the busbar voltage which is 11kV. If the IED represents the measured values

as Engineering values then:

The Engineering value (11000 V) in 16 bit binary would be

0010 1010 1111 1000.

The RAW value would be:

0000 1110 0101 0010

Jitter Settings/Event Deadband

After discussion with Network Optimisation, it was decided that the following jitter values would be suitable:

Analogue Description Jitter Settings (%)

Current 2%

Voltage 1%

Power 2%

The Event Deadband is now much less complicated to set. Assume the measured current for a feeder is

200A therefore the event deadband setting must be 2% of 200 which is 4.

The IED also has analogue deadband settings. It is recommended that these jitter settings must be less

than the jitter of the RTU therefore a jitter of 1% should be adequate.

Você também pode gostar

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- 507-0101-ML Rev 04Documento1 página507-0101-ML Rev 04Ilaiyaa RajaAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- 977-0556-AD Rev 03Documento1 página977-0556-AD Rev 03Ilaiyaa RajaAinda não há avaliações

- P010-0UG PROMAINT User Guide V307 R4Documento81 páginasP010-0UG PROMAINT User Guide V307 R4Ilaiyaa RajaAinda não há avaliações

- Workbench User ManualDocumento89 páginasWorkbench User ManualIlaiyaa RajaAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- 994 0152 G500 Instruction Manual V260 R1Documento121 páginas994 0152 G500 Instruction Manual V260 R1Ilaiyaa RajaAinda não há avaliações

- MICROSOL XELL - CONITEL C300 SLAVE Config. Guide For DMTDocumento32 páginasMICROSOL XELL - CONITEL C300 SLAVE Config. Guide For DMTIlaiyaa RajaAinda não há avaliações

- XCell User GuideDocumento49 páginasXCell User GuideIlaiyaa RajaAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- 994 0146 d20mx v1.5x Product Documentation Set BinderDocumento4.073 páginas994 0146 d20mx v1.5x Product Documentation Set BinderIlaiyaa RajaAinda não há avaliações