Escolar Documentos

Profissional Documentos

Cultura Documentos

Manual

Enviado por

Atul GargDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Manual

Enviado por

Atul GargDireitos autorais:

Formatos disponíveis

1

ALTHOUGH EACH PLANT OF OUR COMPLEX

HAS ITS OWN, DESCRIPTIVE AND OPERATING

MANUALS, THE NEED FOR A DESCRIPTIVE

MANUAL OF ALL PLANTS IN A COMPOSITE

FORM TO PROVIDE BASIC INFORMATIONS ON

FEATURES AND PROCESS OF EVERY PLANT

WAS BEING FELT. THIS MANUAL HAS BEEN

BROUGHT OUT WITH THE ABOVE OBJECTIVE

AND IT IS EXPECTED THAT THE INFORMATION

CONTAINED IT WILL BE USEFUL.

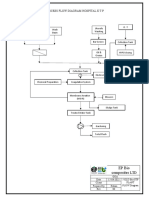

RAW WATER

FILTERATION

PLANT

RAW WATER FILTERATION PLANT

Raw Water Filtration plant supplies filtered water to Factory and drinking water to

Township. The capacity of this plant is 2400 M 3/hr. and it has been supplied by M/s

Geomiller and Co. Pvt. Ltd., New Delhi.

Raw Water is received from Bathinda Canal through a channel into two

reservoirs, which have capacity to store 724400 and 473800 M3 of water respectively.

This capacity is normally sufficient for 21 days of filtered water consumption.

Suspended impurities get sufficient time for settling down in these Reservoirs.

Raw water is pumped from the Reservoirs to Clarifloculators by RAW WATER

PUMPS. There are total three pumps available and capacity of each pump is 1200 M 3/hr.

In between ALUM [ K2SO4 Al2(SO4)3 24 H2O] solution is dosed at rate to achieve around

30 ppm alum concentration in the water.

After alum dosing raw water enters the clariflocculators. Clariflocculators

consists of two parts. Inner portion with a diameter of 16.540 Mtrs. Is FLOCULLATION

ZONE and outer Portion is CLARIFYING ZONE. Total dia is 38.710 Mtrs. Residence

time of water in flocculation zone is 30 Mts. And for clarifying zone it is 2.25 Hrs. water

enters the flocculation zone from the top of central hollow column. The water is

subjected to slow spiral motion due to the rotation of the flocculator paddles. The fine

precipitates agglomerate to form defined and distinct flocs. These enter the clarifier

through openings at the bottom of the separation wall of two zones. The water in the

clarification zone flows upwards at a very slow rate thereby giving enough time and

moves to rapid gravity filters. The settled sludge is scrapped and is collected in the

central pit and it is drained at regular intervals from this point.

For filtration action of the water coming out of the clariflocculator, water is

passed through 7 Nos. of rapid gravity filter beds. Each bed is having a filtration area

65.33 M2 and are filled with 5 different sizes of gravel and sand ranging from 2 to 30

mesh when a bed gets exhausted, it is back washed with filtered water stored in an

overhead back wash water tank.

Filtered water from rapid gravity filters is received into two underground filtered

water reservoirs, each having a capacity of 2400 M3 and is pumped to Factory with the

help of 4 Nos. Filter water pumps each having a capacity of 700 M 3/hr. Around 50M3/hr

of filtered water is tapped from the discharge heads of the filtered water pumps and after

chlorine dosing it is sent to overhead tank to meet the drinking water requirements of the

Township.

COOLING WATER

SYSTEMS

COOLING WATER SYSTEMS

The Cooling Water Systems provided at NFL Bathinda are closed recirculating

type supplying cooling water to various consumers in the plant. There are total three

systems supplying cooling water to different sections as mentioned in Table 1

TABLE 1

SL.NO.

1.

2.

SYSTEM

CT-1

CT-2

3.

4.

CT-3

Emergency Pumps

CONSUMER

Ammonia Plant

Urea Plant, Boilers, Instrument, Air

Compressors,

Service Air Compressors, Caustic dissolving

Facility and Sulphur Recovery Plant.

Crystallisation Section of Urea Plant.

Ammonia Storage area.

Instrument Air Compressors Emergency

Diesel Set.

(Can be connected with

CT-2 or CT-1

Emergency cooling water pump is in continuous service for Ammonia storage

area. It takes suction nomally from CT-2, however, provision is there so that it can take

suction from CT-1.

DESIGN BASIC

Barometric Pr.

Dry bulb temp.

Wet bulb temp.

Degree of approach

Relative humidity

=

=

=

=

=

971 Millibars

39oC

28oC

5oC

81.1 % at 31.4oC

Various other design condition for all the three cooling water systems are given in

TABLE-2

COOLING WATER TREATMENT

Cooling water treatment is done to avoid following problems:

1. Corrosion

3. Fouling

2. Scaling

4. Microbiological growth.

1.CORROSION

Corrosion is basically an electro chemical reaction by which metal tends to return

to its more stable natural state of oxide. The main factors responsible for corrosion in

cooling water systems are low ph, dissolved gases, conductivity of water, presence of

certain corrosive ions such as chlorides and sulphates.

Various types of corrosion occurring in cooling water systems are general

corrosion, pitting, galvanic corrosion cracking, stress corrosion cracking erosion and

microbiological attack.

The approach to protect metal from corroding in cooling water systems involves

the formation and maintenance of a sufficiently strong inhibitor film on the cathodic

anodic or both areas.

2. S C A L I N G

Scaling is the deposition of sparingly soluble salts. The most common scalants in

cooling water systems are carbonates and sulphates of calcium and magnesium and

phosphates of calcium, magnesium zinc and iron. The carbonates and sulphates of

calcium have inverse solubility with respect to temp. and PH when the solubility of these

salts exceed, they tend to precipitate out of solution and deposit on metal surface.

Scale inhibitors are used which keep the scaling salts in dispersed state and do not

allow them to deposit.

3. F O U L I N G

Fouling is the deposition of suspended matter. The most common foulants in

cooling water systems are dust, silt, clay organics like oils and hydrocarbons and the

microbiological slime. These foulants are air borne as well as water borne. Fouling does

not merely results in drop in heat transfer efficiency but also gives rise to under deposit

corrosion leading severe pitting. Fouling is normally enhanced due to low water velocity.

Low molecular weight polyanionic compounds are used as anti foulants. These

components get absorbed on the surface of the foulest particles and increase the negative

charge. Thus when all particles are sufficiency negatively charged they repel each other

and thus dispersion is achieved.

4. MICROBIOLOGICAL GROWTH

Following three types of micro organisms are responsible for this type of

problem:

a)

b)

ALGAE: It is normally observed on the exposed area of cooling tower as it

requires sunlight for growth.

FUNGUS: fungus is found on the wooden surface as it requires surface and

carbon source.

c)

BACTERIA: Three important type of Bacteria are

i)

NITRIFYING BACTERIA: These bacteria oxidize ammonia to nitrates and

nitrites which when dissolved in water reduce the pH of circulating water and

cause general corrosion. It is the most severe problem at NFL Bathinda.

SULPHATE REDUCING BACTERIA: These anaerobic bacterias reduce

sulphate ions to H2S.

ii)

This causes local pH drop. The hydrogen sulphide thus formed reacts with

metal surface to form metal sulphide. These deposits are very hard to remove

and lead to severe pitting.

iii)

IRON BACTERIA: Iron bacteria directly oxidize the metal causing severe

pitting.

In general most of the species of bacteria present in cooling water secrete slime. This

slime acts as a binding medium for the suspended matter and leads to fouling. The

fouling deposits in turn give shelter to an aerobic bacteria which causes direct

corrosion.

In addition to chlorine and Bromine use of non oxidizing type of Biocides is most

various types of non oxidizing types of Biocides are methylene bis thiocyanate

quaternary ammonium compounds, isothiazoline, dichlorophenes etc. these biocides

are normally blended with effective surface active and penetrating agents. There by

they can penetrate into the deposit layers and can kill anaerobic bacteria.

TREATMENT PROGRAMMES AT NFL BATHINDA

In the earlier years of opertion at NFL Bathinda, lot of difficulties were

experienced due to poor quality of cooling water. This led to leakages in heat

exchangers and untimely production interruptions. Over the years cooling water

treatment has been improved upon a lot. Presently treatment programmes supplied by

M/s Aquapharm Chemicals Co. Ltd,Pune are used in CT-1 and CT-2. salient features

of these programmes have been highlighted in TABLE-3.

SULPHUR

RECOVERY

PLANT

SULPHUR RECOVERY PLANT

Sulphur Recovery Plant of NFL Bathinda has been designed and engineered by

M/s TOYO ENGINEERING CORPORATION , JAPAN. It was originally designed for

processing 1710 NM3/hr or claus gas and for 26.5 MT/day of sulphur production but due

to the switch over to LSHS for ammonia production only 800 to 1000 NM 3/hr of claus

gas is generated and 18-20 TPD SULPHUR is produced. Presently claus gas contains 3040% H2S against 47.5% in original design.

The essential parameters design of S.R.P. incorporates split flow scheme by 30%

of acid gas by pass, two catalytic convertors with CSR-2 catalysts, water cooled furnace

with direct heating by main steam to produce 3.5 Kg/cm2 (g) saturated steam and overall

sulphur recovery efficiency of 85%. Claus gas feed and air are burnt together in a acid

gas heat exchange to oxidize 1/3 of the hydrogen sulphide to obtain an ultimate mole

ratio of H2S to CO2 as 2 : 1. As the oxidation occurs hydrogen sulphide and sulphur

dioxide react with each other to produce sulpur. A part of the claus gas feed is by passed

around the acid gas heat exchanger to feed it directly to the first catalytic convertor. The

flame temp. at the burner tip is around 110oC and the following reactions take place

thermally.

1. H2S + 3/2 O2

2. H2S + O2

SO2 + H2O

H 2O + S2

The combustion products are cooled through the fire tunnel the second pass and

the third pass of acid gas heat exchanger. About 20% of the second pass effluent is

extracted as hot by pass gas to warm up the feed gas to catalytic reaction stages. In the

third pass most of the sulphur produced in the fire tunnel is condensed. Then the third

pass effluent gas accompanied with liquid sulphur goes to separation chamber of sulphur

storage tank. In the separation chamber the liquid sulphur enters the storage tank through

a seal leg. The gas is mixed with acid gas by pass and then, to keep the first stage of the

catalysis reactor feed temp., is heated up by a part of the second pass effluent gas. The

temp. of the reactor feed gas is controlled at 215oC.

10

The heated gas containing H2S and SO2 in the ratio of 2 : 1 enters the first reactor and

additional sulphur is produced by catalytic reaction.

2H2S + SO2

Catalyst

2H2O + 3S

The catalyst used is 99.9% Alumna Balls in both the reactors.

The reactor effluent gas goes to the fourth pass of acid gas heat exchanger to be

cooled and sulphur is condensed. Then the liquid sulphur and the gas enters sulphur

storage tank and are separated in the separation chamber. The gas is mixed with the hot

by pass gas from the second pass to control the inlet temp. of the reactor at 215 oC and fed

to the 2nd reactor. The sulphur in the second reactor effluent gas is condensed through

the fifth pass of the acid gas heat exchanger and separated from gas in sulphur storage

tank. The gas from sulphur storage tank enters coalescer and sulphur mist is removed

and drained to sulphur storage tank.

3.5 kg/cm2 (g) steam is generated in acid gas heat exchanger and is sent to

Ammonia plant. The effluent gas from coalescer is directed to incinerator where

unreacted hydrogen sulphide and sulphur vapors are converted to sulphur dioxide with

the help of process gas from Ammonia Plant . the temp. of incinerator is controlled at

650oC.

The heat of the effluent gas from incinerator is removed in heat recovery

exchanger and 10kg/cm2 steam is generated. The steam pr. is determined to prevent

condensation of SO3 on the tube surface, which causes severe corrosion problem.

The 10kg/cm2 steam is let down to 3.5 k and sent to 3K header. The cooled down

gas is finally vented to atmosphere through stack. Here the gases should not contain

more than 0.5% SO2.

The liquid sulphur collected in Sulphur Storage tank is transferred to Flaker by

sulphur pump. The flaked sulphur contains minimum 99.5% by wt. of sulphur.

11

D.M. WATER

PLANT

12

D.M. WATER PLANT

Water in its natural form contains a no. of dissolved salts such as sulphates,

chlorides and Nitrates of calcium Magnesium and Sodium. If water is used as such

in Boilers for raising steam, these salts will form scale on the tubes , which in

addition to heat losses leads to many other problems. Hence, removal of these salts

from the water becomes quite essential. ION exchange resins are used for this

purpose of salts removal.

The deminerlising water plant of NFL Bathinda was supplied by M/s ION

Exchange (India) Ltd. Delhi.

It consisted of three units each of cation, anion, Primary Mixed bed, four

secondary Mixed Bed and three units of condensate cation. At the time of setting

up of captive power plant, another stream to augment the existing capacity of

Polish Water generation was installed by M/s BPMEL. It consisted of one unit

each of cation, Anion, Primary Mixed Bed, two secondary mixed beds and two

condensate cations.

Filtered water is received from Raw Water Filtration Plant into two filtered

water reservoirs Feed water pumps discharge water from these reservoirs to cation

units. There are total five feed water pumps each having a capacity of 130 M 3/hr

and four cation units. Three of these are charged with 13125 litres of cation resin

and fourth unit is having 11900 of resin. Cationic lons like Na +, Ca++ and Mg++

present in the water are removed in the CATION UNITS Once exhausted, these

units are regenerated with the counter current flow of dilute sulphuric acid.

The present day resins are made of cross linked polystyrene and cross

linking is done by Di-vinyl Benzene.

Cationic resins are made of sulphonated Polystyrene SO 3 H+ can be

represented as RH+ . Anionic resin is similarly made but is chloromethylated and

then aminated. The final product is quarternary ammonium compound a strong

base and is represented by ROH.

13

C AT I O N U N I T

In the cation unit free H+ lon of the resin is replace by Ca++ . Mg++ or Na+

lons as per the following reactions:

RH + NaCl

Rna + HCl

2RH + Mg SO4

R2Mg+H2SO4

2RH + Ca (HCO3)2 =

R2Ca + 2 CO2 + 2 H 2O

Neutral salts are converted to respective mineral acid and alkaline salt spilt

into CO2 gas. The outlet water will have a low pH.

D E G AS S E R

From the cation units water move to degasser. Here free CO2 content of

the water is stripped off with the help of air by passing the water over rasching

ring packed bed. Water from Degasser is received into three Nos. degassed water

sumps each having a capacity of 40 M3. From these sumps degassed water pumps

discharge water into anion units. There are total five Nos. of pumps and each

having a capacity of 150 M3/hr.

ANION UNITS

Anionic impurities of water besides CO2 and Silica are removed in the

Anion Units. There are total four nos. of Anion Units. Two; units are having

7920 Ltrs. Of resin while rest of the two are having 5965 and 8400 Ltrs. Of resin.

Anions present in the water get removed as per the following reactions :

2 ROH + H2SO4

R2 SO4+2H2O

ROH+HCl

RCl+H2O

2 ROH + H2SiO3

R2 Sio3 + 2 H2O

14

Once the unit gets exhausted, it is regenerated with counter current flow of

4% NaoH solution.

M I X E D B E D U N I T S (PRIMARY)

Certain amount of sodium and silica ions get slipped from cation and anion

units. Very large volume of resin is required to check these leakage if tackled

individually. Hence, these are removed in mixed bed units. It consists of a bed of

mixed cation and anion resins which acts as infinite pairs of cation and anion

units.

A mixed bed unit will produce water of conductivity around 0.5 micro mho/cm.

This water is stored in DM water tanks. These are two Nos. of DM water tanks

each having a capacity of 1500 M3. 1400 Ltrs. Each of cation and anion resin is

charged in three mixed bed units while in fourth unit this quantity is 1800 Ltrs.

C O N DE N S A T E C A T I O N U N I T S

Steam condensate is received from Ammonia, Urea and CPP. It contains

lonic and colloidal iron. Colloidal iron is removed in colloidal filters while ionic

iron is removed in condensate cation units. Condensate coming from Ammonia

and Urea Plants is first cooled to around 45 OC in condensate cooler. There are

total five Nos. of condensate cation units. Three units are charged with 1810 Ltrs.

Of resin while two are charged with 4200 Ltrs. Of resin. After polishing the

condensate it is stored in DM Water Tanks.

SECONDARY MIXED BED UNITS

DM Water from DM water tank is pumped to secondary mixed bed units

with the help of DM water pumps, for achieving the desired level of purity of

water there are total 5 Nos. of pumps and each having a capacity of 190 M 3/hr.in

the secondary mixed bed units final traces of impurities are removed again with

the help of mixed bed of cation and anion resins. There are total six Nos. of these

units. Four of these are charged with 1400 Ltrs. Of cation resin and 2200 Ltrs.of

ANION Resin while rest of the two are charged with 1600 Ltrs.and 2600 Ltrs.of

cation and anion resins. After passing through secondary mixed bed units polish

water of following specifications is obtained.

15

PH

7 +_ 0.2

Conductivity

Total iron as Fe

Silica

Hardness

0.2 Micro mhos/cm

0.015 mg/lit

0.015 mg/lit

Nil.

Polish water thus obtained is stored in Polish Water Tanks. There are two

polish water tanks each having a capacity of 1500 M 3. It is pumped to Ammonia

Plant and Captive Power Plant with the help of five Nos. Polish water pumps each

having a capacity of 220 M3/hr.

16

EFFLUENT

TREATMENT

PLANT

17

EFFLUENT TREATMENT PLANT

During the process of Urea manufacturing, various effluents generated in

different plants viz. Ammonia, Urea, Steam Generation and offsites and Utilities

etc. are treated in Effluent, Treatment Plant so that treated water meets the

Minimal National Standards. Effluents Treatment Plant has been designed to treat

the effluent with following characteristics:

1.

2.

3.

4.

Flow 200 M3/hr

Ammonia 520 mg/Lit.

Urea 340 Mg/Lit.

PH 8 to 8.5

Chemical waste generated in different plants(Except Urea bearing waste

from Urea Plant) is received in a chemical waste sump having a storage

capacity of 200 M3. Urea bearing waste is separately treated in Urea

Hydrolyser and its outlet is discharged into chemical waste sump. Alkali

Waste, which gets generated in DM Plant during the regeneration of anion

units etc. is received in Alkali Waste sump having a storage capacity of 200

M3. This waste is pumped to chemical waste sump, with the help of two

Alkali waste pump each having a capacity of 75 M 3/hr to raise the pH of

chemical waste water to 11. At this higher pH 97% of ammonium ions

remain in the form of free ammonia as shown by this reaction:

NH4 + = NH3 + H +

This free ammonia can be removed from the water with the help of air

stripping. For this purpose, Effluent Water from chemical sump is pumped to the

top of Ammonia Stripping Tower with the help of chemical waste pumps. Two

pumps each with a capacity of 200 M3/hr have been provided. At the top of

Ammonia Stripping Tower, water is distributed evenly throughout the operational

area of the tower by distribution nozzles into the form of fine droplets. Air is

sucked in from the sides of the tower by three induced fans. Free Ammonia

present in the water gets stripped off by this air. Water is collected in the basin if

the tower and flows to Ammonia Fixing Tank.

Acid waste, which is received in 170 M 3 acid waste sump from the

regeneration of cation units etc. in DM plant is added in the ammonia fixing tank,

with the help of two acid waste pumps each having capacity of 75 M 3/hr to bring

down the pH of the water to 7-7.5 Agitation is given to the water for proper

18

mixing of the acid waste with the help of service air capacity of the Ammonia

Fixing Tank is 100 M3. Free ammonia still present in the water gets converted

back to ammonium ions.

The effluent from ammonia fixing tank is collected in Ammonia Fix Liquor

Sump (AMFL) of 43 M3 capacity . Sanitary sewage from factory as well as from

township is also collected in this sump. Factory sewage is however first received

in the receiving sump of 10 M3 capacity. Two pumps each with the capacity of

20M3/hr pump the sewage to AMFL sump. Similarly Township Sewage is

received in a 90M3 capacity sump and is pumped by 100 M3/hr capacity two No.

pumps. This sump is however located in Township itself.

The chemical waste mixed with sanitary sewage is pumped by two AMFL

pumps each having a capacity of 260 M 3/hr The discharge flow is bifurcated with

the help of a splitter box. Out of this, 110M 3/hr is discharged into Nitrification

Tank and 150 M3/hr into Primary clarifier. Settled sludge in this clarifier is led to

Denitrification tank by gravity. The effluent from primary clarifier flows to

trickling filter in which water is distributed uniformly across the cross section of

trickling filter by a rotating arm. This arm rotates with the reactional force

provided by the water. Biological oxygen Demand (BOD) and Chemical Oxygen

Demand (COD)of the effluent is partially fulfilled in Primary Clarifier and

trickling filter.

Water from Trickling filter received in a 37.5 M3 Trickling filter sump is

pumped by two pumps, each having capacity of 150 M3/hr, to nitrification tank.

Nitrification tank is made of two parts, the first one housing six aerators

and the second eight aerators. Total storage capacity of the tank is 1900 M 3 and

Oxygenation capacity is 332 kg/hr. Hydrolysis of urea to ammonium ions and

then nitrification of these ions to Nitrates takes place in the nitrification tank with

the help of aerobic ureolytic and nitrification autotrophic bacterias as per the

following reactions :

NH2CO NH2 + 2H2O

Urease

(NH4)2 CO 3 ------1

19

Enzyme

NH4 +

202

Nitrifying

Bacteria

NO3 --+2H+ +H2O 2

Urea enzyme is produced by ureolytic bacteria. The process of nitrification

destroys alkalinity and lowers pH due to generation of H+ ions

Activated sludge settled in the final clarifier is also fed to the nitrification tank.

Micro organisms particularly bacterial present in this sludge purify the sewage

biological. For this purpose, proper concentration of Micro organisms or mixed

liquor suspended solids (MLSS) is to be maintained at a level of min. 1000 mg/lit.

Air requirement for different bacterial action is supplied by Aerators. In addition

to this these aerators enable mixing of waste water with MLSS.

The effluent from nitrification tank overflows to Denitrification tank. It is

500 M capacity RCC Tank equipped with 4 Nos. agitators . Denitfication is a

biological process by which nitrates are anaerobically converted into Nitrogen gas.

Waste methanol is added as a source of carbon for the organism. Nitrates get

converted into Nitrogen gas as per the following reaction :

3

6NO3 + 5 CH3 OH

5CO2 + 3N2 + 7 H2O + 6 OH

The agitators provided keep the sludge into suspension. Effluent from

dentrification tank overflows to aeration tank equipped with two aerators having

total oxidation capacity of 25 kg/hr. the effluent is aerated to; remove BOD and

the gas evolved in the dentrification process.

Effluent from aerator tank flows to final clarifier. The settled sludge in this

clarifier is collected in a 43 M3 capacity sump. Two pumps each with a capacity

of 260 M3/hr have been provided for pumping it to nitrification tank. After

maintaining the desired level of MLSS in Nitrification and Denitrification Tank,

provision is there to take out the excess sludge and it can be dried ina lagoon.

Clear water from final clarifier over flows to final Effluent Sump, having a

capacity of 175 M3. storm water is also collected into this sump. This treated

water is pumped to the final disposal area with the help of two pumps. Each pump

is having a capacity of 350 M 3/hr. This final Treated water conforms to the

following Minimal National Standard (MINAS)

1.

pH

5.5 9.0

20

2.

3.

4

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

Ammonical Nitrogen as N

Total kjeldhahl Nitrogen

Nitrate Nitrogen

Free Ammonical Nitrogen

Cyanide as CN

Vanadium as V

Arsenic as As

0.2

Suspended solids

Oil and grease

Hexavlent Chromium (Cr+6)

Total Chromium as Cr

BOD

COD

50 ppm

100

10 ppm

5

0.2

0.2

100

10

0.1

2.0

30

250

UREA HYROLYSIS

As already mentioned the existing effluent treatment plant was designed for

treating effluent containing 520 mg/ltr. Of Ammonia and 340 mg/Ltr.of Urea. But

effluent from Urea Plant sometime contains as high as 500 1000 ppm of

ammonia and 1 3% of Urea. This effluent used to disturb the complete operating

conditions of the plant. Hence to check this problem, with In-house efforts a

facility for Urea Hydrolysis was developed. In this facility around 5 M 3/hr of Urea

effluent, with 3 % urea concentration, is fed to the Urea Hydrolysis Reactor. It is a

300 M3 capacity RCC Tank having nine compartments. Urea Effluent under flow

and over flow the partition walls of these compartments and a residence time of 45

to 50 hrs. is achieved . Molasses, DAP, Decomposed cow dung and other

nutrients like chlorides of sodium, calcium, potassium, sulphates of ammonia,

magnesium and Iron are dosed for survival and growth of ureolytic Bacteria.

About 90% of the urea get hydrolyzed into this system. The effluent from Urea

hydrolysis tank after stripping the free ammonia in a stripping tower flows to

chemical sump and is mixed with the chemical waste and then follows the normal

treatment route.

21

FINAL DISPOSAL

AREA

FINAL DISPOSAL AREA

22

This area is used for receiving storing and finally disposing off the treated

water from ETP and storm water. This area is having five ponds. Their capacities

and services for which these are used, are given in Table 1 below.

_________________________________________________________________

TABLE - 1

_________________________________________________________________

SL.No.

NAME

CAPACITY M3

SERVICE

1.

Pond No. 1

25,000

Ash Pond overflow & off

grade effluent.

2.

Pond. No. 2

25,000

-----------do---------3.

Pond. No. 3

26,000

Treated Water

4.

pond No. 4

48,000

Storm Water

5.

Pond No.5

60,000

Treated Water

__________________________________________________________________

Treated water meeting the MINAS standard is received in Pond No. 3 and 5

from final effluent pump discharge located in EFFLUENT TREATMENT PLANT.

If this water is not conforming to the MINAS standard, then provision is

there to receive it in Pond No. 1 & 2 . Overflow from ash ponds is also received

in Pond No. 1 & 2 . Storm water from the FACTORY is received in Pond No. 4

and stagnant water area. It is then pumped from this place to Ponds No. 1 & 2

with the help of four vertical pumps. Effluent from Ponds No. 1 & 2 is pumped to

factory for deashing in SGP and CPP. Three pumps each with a capacity of 500

M3/hr, have been provided for this purpose.

Treated water received in Ponds No. 3 and 5 is supplied for irrigation in

fields and Township. Provision is also being made to use this water as fire water

and for kitchen garden in Township. Two pumps each with a capacity of 275

M3/hr have been provided for this purpose.

WATER BALANCE ACROSS FINAL DISPOSAL AREA

23

WATER IN

WATER OUT

SL No.

Source

Qty.

M3

Sl.No.

supplied to

Qty

M3

1.

From ETP

230

1.

For deashing

in SGP

350

2.

Ash Ponds

388

2.

For deashing

in CPP

139

3.

For Irrigation

in Township.

73

4.

For Fire header

changing and for

use in township.

56

__________________________________________________________________

Total

618

618

__________________________________________________________________

24

STEAM GENERATION,

CAPTIVE POWER PLANT

AND MATERIAL

HANDLING PLANT

STEAM GENERATION, CAPTIVE POWER PLANT

AND

25

MATERIAL HANDLING PLANT

The three plants are grouped together for ease of operation as these are inter

related to each other. The main function of this group is to generate and supply

high pressure steam, to produce power required for the Fertilizer Plant and to store

and supply raw materials like coal, Heavy Oil, Liquefied petroleum gas and

methanol.

1.

STEAM GENERATION PLANT:

Steam Generation Plant produces and supplied steam at 100 kg/cm 2

pressure and 480oC temperature to Ammonia Plant.

WHY IS STEAM REQUIRED

Major consumption of steam is in Ammonia Plant and roughly 6.5 to 7 Te

of steam is required for producing one Te of Ammonia. This steam is used :

a)

b)

c)

For driving the Turbo Compressors

As Process steam for various reactions

For heating purpose

The designing and introduction of high pressure Turbines and Compressors

has revolutionized the industry especially the Fertilizer Industry. Single stream

high capacity plants of 2200 Te/day Urea and 1350 Te/day. Ammonia have come

up which was not feasible a few decades back. The turbines used to run these

compressors are driven by high pressure and high temperature steam. If we add

the output power of various turbines run by steam, it comes to around 50 MW. In

other words we are saving 50MW of electricity.

In our Factory where heavy fuel oil is used as feed stock, requirement of

steam is very high i.e. 7 Ton per tonne of Ammonia as compared to plants using

natural gas or Naptha as feed where steam requirement is 0.3 Te per ton of

Ammonia. It shows the importance of steam and steam generation plant.

Moreover steady pressure and temperature is very essential for the life and

efficiency these turbines. Hence the role of SGP is very important.

Steam in SGP is generated by three number VU-40 Type Boilers supplied

by M/s BHARAT HEAVY ELECTRICALS LTD. These are in operation from

26

1977 and each Boiler can generate upto 150 Te/ of steam per hour. These are

water tube Boilers which means the water used for steam formation is insides the

tubes and the heating material that is coal or oil is burnt in the outer furnace.

Roughly speaking about 750 K. cal of heat is required to generate one Ton of

steam at the present efficiency of these boilers. This heat is mainly supplied by

Pulverized coal. Heavy Fuel Oil is used for initial start up and continuous support

to coal burners and light Diesel Oil is also used for initial start up.

FIRING SYSTEM :

Pulverised coal is the coal grinded to easily combustible and economically

viable level so that it burns completely with in the available time inside the

furnace. BOWL MILLS are used for grinding the coal. Coal received from

Material Handling Plant is stored in Coal Bunker and is fed to the Bowl Mill

through a COAL FEEDER. Hot air is also supplied in the mill for heating the coal

and conveying it to the furnace through a fan called EXHAUSTER FAN which

takes suction from the mill and maintains it under negative pressure. Oversize and

un grindable material like stones are thrown out by the mill. Coal and Air mixture

called Pulverised Fuel from the exhauster is supplier to COAL BURNER. Coal

burners are arranged tangentially on all the four corners of the rectangular furnace

at three elevation levels. Thus there are 12 coal burners. In between these three

elevations OIL BURNERS AND START UP BURNERS or IGNITORS are

arranged at two elevations. Thus there are 8 oil burners and 8 ignitors. As coal

requires some minimum temp. for ignition, ingnitors are lighted up for initial start

up then oil burners and finally coal burners. Ignitors use LIGHT DIESEL OIL

(LDO) and can be lighted up by remote control. Oil burners use Heavy Fuel Oil

(HFO) or LSHS.

The FURNACE is a cubical suspended enclosure with water tubes forming

its four walls. The furnace is designed with sufficient volume to provide for

complete and efficient combustion at all loads without flame impingment on

furnace water wall and other internals. Heat is generated in the furnace by the

reaction of carbon present in coal and oxygen present in air to form carbon-dioxide.

C + O2

CO2 + Heat

27

These gases called FLUE GASES heat up the water in tubes to form steam.

As the FLUE GASES rise up, their heat is utilized in various ways as shall be

discussed later. The Furnace is maintained at a negative pressure of 5 mm water.

WATER AND STEAM SYSTEM

The steam generated should be free of all imputies like minerals, silica

oxygen, iron etc. for the safety and efficiency of steam turbines and boilers. For

this purpose RAW WATER is physically and chemically treated and finally

supplied to SGP from Ammonia Plant. This water is called BOILER FEED

WATER. Feed water is further heated to around 240 oC by flue gases and taken to

STEAM DRUM. Steam drum acts as storage tank and also separates water from

the steam at 314oC and 106 kg/cm2 pressure water then enters MUD DRUM

through BANK TUBES heated by Flue gases. This drum helps to maintain

circulation of water. Water from Mud Drum enters the RING HEADER formed at

the bottom outside the furnace and rises by gravity through water wall tubes on all

the four sides, takes heat from furnace and enters steam drum as a mixture of

steam and water. Water is separated here and steam at about 315 oC is taken

through two SUPER HEATERS called PLATEN SUPERHEATER AND FINAL

SUPERHEATER heated by the Flue gases to attain final temperature of steam

around 490oC. The outlet temperature from these super heaters is controlled by

adding Boiler Feed Water.

FLUE GAS SYSTEM

The products of combustion in the furnace of carbon-di-oxide, Nitrogen,

Ash, Oxygen, and Sulphur-di-oxide. After leaving the furnace the heat of these

gases called FLUE GASES, is utilized at various levels as shown in the block

diagram.

First the steam from steam drum is heated in two superheaters to get the

required temperatures of 495oC and then feed water in BANK TUBES is also

heated and the gases leave Bank Tubes at around 497oC next the heat is utilized to

heat feed water in the ECONOMIZER and gases are cooled down to 320 oC. These

gases are further cooled down to 150oC in ROTARY AIR HEATER where the air

required for combustion and conveying the coal is heated up. Temperature is not

reduced further because at lower temp. oxides of sulphur present in flue gases are

converted to ACID which damages the Down Stream equipments. These gases

then pass through ELECTRO STATIC PRECIPITATORS (ESP) where ash is

removed. From ESP these gases pass on to INDUCED DRAFT FAN

28

Which maintains draft in the furnace and finally the gases are let off to the

atmosphere through a chimney about 80 Mtr. High.

POLLUTION AND THEIR DISPOSAL

Alongwith optimum utilization of companys resources to achieve

maximum profitability, our Unit has always performed its duty to keep the

environment clean.

We have installed latest available pollution control

instruments and equipments. The Chief Pollutants generated in SGP are ASH and

SULPHUR- DI-OXIDE. Their separation and disposal are discussed in brief.

ASH:

Ash is the incombustible material contained in Raw Coal which has about

40% ash. It also consists of heavy metals like vanadium and Nickel. If in hailed it

can be harmful to human beings.

After combustion of coal, ash remain as such. About 20% of total ash

generated consist of higher wt. particles with fall down to BOTTOM ASH

HOPPER provided at the bottom of the Furnace. Ash slurry is formed here due to

water level maintained in the Bottom Ash Hopper. This is taken out by water

ejector once in eight hours and sent for disposal in lagoons.

FLY AS H

Fly ash is the ash containing light particles. If forms the major portion that

is 80% of the ash generated. It is carried away from the furnace alongwith the flue

gases. The ash particles are removes from the gases in Electro-static precipitators

as shown in Block j diagram after the Air-Pre-heaters.

29

ELECTRO STATIC PRECIPITATORS (E.S.P)

The Electro-static Precipitator forces to separate dust particles from flue

gas. High voltage is applied between electrodes arranged in rows alternatively.

Due to high voltage gas particles are ionized. Most of the ions are negatively

charged. They stick to dust particles and carry them to positively charged

electrodes, which is in the form of a rectangular plate. Thus dust particles stick to

those plates. These plates are rapped periodically to dislodge the deposited dust

which is collected in the hopper below.

Ash is ejected from these hoppers by water jet and it forms ash slurry. Fly

ash slurry and bottom ash slurry are mixed together and sent to Ash slurry disposal

ponds outside the Factory where slurry settles down and overflowing clear water is

recycled back to the system.

SULPHUR DI OXIDE

Sulphur-di-oxide is formed due to the presence of sulphur in coal which

vary from 0.1 to 0.5% . For safe disposal of SO 2 minimum height has been

recommended by pollution boards, depending upon the quantity of Sulphur-dioxide generated per hour. In our case it comes out to be around 75 Mts. Taking

maximum amount of SO2 generated. Chimney height of SHP Boiler is 80 Mtrs.

Suitable instrumentation has been provided for monitoring all the

parameters and important analysers and cut outs of a part or even complete boiler

has been provided in case of emergency.

30

CAPTIVE POWER PLANT ( C.P.P )

Since inception, Bathinda Unit was drawing electric power from the Punjab

State Electricity Board. Electricity is the main driving force after steam, being

used for moving auxiliary equipments. The unit requires about 27 Megawatts of

Power per hour when running at full load.

NEED FOR C.P.P

It was thought to install a Captive power Plant in which electric power for

our requirement shall be generated from Electro Generator run by TURBINES for

which STEAM shall be generated in a COAL FIRED BOILER. The benefits

envisaged were :

1.

2.

Any disturbance in the PSEB Grid used to trip the whole plant. Lot

of money was lost due to this as each re-start-up costs around 40 to

50 lakhs rupees. Moreover, frequent tripping had an ill effect on

machines and equipments extending the re-start-up period.

Three Boilers of 150 Te/hr steam capacity were initially installed in

SGP to keep 2 Boilers running and one stand by as designed steam

requirement was less than 300 Te/hr. But in actual operation steam

requirement was more and all three Boilers had to be run and there

was no breathing time for their maintenance. As new boiler was to

be installed for CPP, its capacity was so designed that it could export

around 60 Te of steam for process requirement so that only 2 boilers

of SGP would be run keeping the 3rd as stand by.

With these points in mind CPP was installed. The functioning of CPP can

be sub-divided into parts :

1.

Boiler and its auxiliaries:

For generation of high pressure superheated

steam.

2.

Turbo-Generators ( 2 Nos. of 15MW each ) and their Auxiliaries

generate power using steam from the boiler.

to

31

Operation of CPP is based upon Micro-processor based computerized

instrumentation which allows automatic operation, start up, shut down of the

whole or part of the plant.

B OILE R

Boiler has been supplied by M/s MITSUI ENGINEERING AND SHIP

BUILDING CO. (MES) of JAPAN. It has a capacity of produce maximum 230

Te/her of steam at 105 kg/cm2 pressure and 495oC Temp. 150 te/hr steam is used

for power Generation if both Turbo Generators are running at 15 MWH each.

Around 60 Te steam per hr. is drawn for process use and joins with the SGP steam

header.

The basic principle of this boiler is the same as discussed earlier for SGP

Boiler that is formation of steam by heating Boiler Feed Water inside Furnace

fired by coal and Heavy Oil, utilization of heat of the gases by heating water and

air, removal of dust particles from flue gases and venting these gases at a safe

height. Main differences between the two boilers are :

1. SGP Boiler is tangentially fired where as CPP Boiler is front fired with

6 coal burners and 6 oil gun fixed inside the coal housing.

2. SGP Boiler can be loaded upto 30% load with oil firing only whereas CPP

Boiler can be fully loaded with oil alone.

3. Height of combustible zone in CPP Boiler is more and it has residence time

1.5 Sec. Where SGP Boiler has 1.0 second.

4. Mills used for pulverizations of coal in SGP are negative pressure bowl

Mills whereas in CPP ball tube mills are used which are positive pressure

mills.

5. Due to more residence time and better pulverization the efficiency of CPP

Boiler is about 4% higher.

6. Boiler Feed Water required for steam generation can be fully generated in

CPP it self.

32

A block diagram of CPP Boiler alongwith important parameters is

separately given. A part of the steam generated is exported for process use in

Ammonia Plant and rest is utilized for power generation in Turbo-Generators as

described below :

POWER GENERATION

There are two 15 Megawatt Turbines Generator sets to generate power at 11

KV which is fed into 132 KV Bus of PSEB and again distribution network.

TURBINES

The turbine used is supplied by M/s SGP of Austria. It is condensing cum

extraction turbines designed as single casing reaction turbine with single control

stage and high pressure (HP), Mild Pressure (MP) and Low Pressure (LP) reaction

parts.

The Turbines is fed with high pressure steam at 100 kg from Boiler and

flows through various control valves for normal and emergency operation. It gets

high velocity through the nozzle group and then passes over various impellers

fixed on to the rotor and fixed diffusers thus rotating the turbine. The enthalpy of

steam is utilized in steps. Steam is also extracted from various stages. HP 1 at 10.4

kg/cm2, HP2 at 8.1 kg/cm2 , Feed Water bleed at 4.3 kg/cm 2 and L.P bleed at 0.9

kg/cm2.

The exhaust steam from the turbine is condensed in a condenser maintained

under vacuum to extract maximum steam enthalpy. The output of the turbine

depends on flow of steam and heat difference that is no condition of steam at the

main steam valve and the pressure at the turbine outlet or condenser pressure. The

turbine is connected to the generator through speed reducing gears.

The exhaust steam is condensed in a condenser using cooling water. The

resulting condensate can be fed back to L.P. heater but is normally sent to the

polishing water plant.

33

As shall be clear from the attached block diagram various bleeds from the

turbines are utilized for heating purpose. HP1 and HP2 bleeds are used for heating

Boiler feed water in HP1 and HP2 heaters. Feed water bleeds is used for heating

the feed water tank and L.P. bleed is used for heating the polish water make-up to

the feed water tank.

A lubrication system is also there to lubricate the various bearings of the

turbine, gears and generator. Normally the oil pump driven by the turbine shaft

supplies oil but auxiliary motor driven pumps are used for start up and during

shut-down . A turning gear has been provided for slow cooling of turbine rotor.

Latest instrumentation has been used in this plant. Baileys Net work-90

micro-processor based instrumentation system is being used. The NET WORK 90

SYSTEM is a distributed process control system. Using series of integrated

control nodes, the Net Work 90 system allows to control process variables like

flow, pressure and temperature according to a control configuration. There is

operator interface Unit (OIU) like a TV screen on which various parameters can be

displayed and controlled. It allows fully automatic start-up/shut-down of Boiler,

Turbine and other auxiliaries.The network 90 system is upgraded to ABB

Harmony DCS system recently.

G E N E R AT O R S

CPP is having two number Turbo-Generators of capacity 15MW each. The

generators Type SAT three phase, 50 HZ 11 KV 984 Amp.at 0.8 power factor

rating supplied by M/s Jeumont Schneider of France. These are totally enclosed

self ventilated type, with two lateral air to water coolers for cooling. The

alternators are able to bear 10% overload for one Hr. with an increase in Temp. of

10oC while maintaining the voltage as near as possible to the rated one. The

excitation is compound and brush less with exciter rotor and rectifier bridge

mounted on the extended main shaft on non driving end. The excitation is

controlled automatically with Automatic Voltage Regulator and a PLC Controller.

All protection relays installed for protection of Generator are solid state having

high accuracy, quick response and low power consumption.

34

Under normal running condition of the plant and healthiness of PSEB Grid,

we generally run in synchronous with the grid merely drawing the power

corresponding to minimum charges to be paid to State Electricity Board. In case

of any disturbance in the grid measured by higher low frequency, high rate of

change of frequency, low voltage etc, our system gets isolated from the grid

automatically. With both generators running, we are able to feed power to the

whole plant, thus production is not affected. In case only one TG is in line and

grid cuts off, Urea plant is cut off automatically to balance the load with one

Generator. As soon as the grid becomes stable, the generators are again

synchronized with it.

A brief single line diagram of the power distribution is shown along with

the turbine block diagram.

3.

MATERIAL HANDLING PLANT (MHP)

Many raw materials required for use in various plants are toxic, explosive

and hazardous in nature. These materials have to be stored in isolated places.

Coal, heavy Oil, Methanol and Liquified Petroleum Gas (LPG) are such materials

which are being stored in and supplied from Material Handling Plant

COAL HANDLING

The main raw material used in SGP and CPP Plants for producing steam is

COAL. About 1700 Te of coal is burnt daily when the plant is running on full load.

Coal is stored in open yard called coal yard which is having rail lines for the

movements of rail wagons in which coal is received from coal mines located in

Bihar and West Bangal. As shown in the block diagram of MHP various wagons

of a rake of coal can be distributed on various rail tracks for unloading. Unloading

is done in two, ways, Manual Unloading or Tippling. Tippling is done for open

wagons only. For this, wagons are placed on the tippling track. Each wagon is

weighed, lifted by the Tippler, emptied into the tippling hopper over underground

Conveyor No. 2 and by running the unloading system that is conveyors 1,2 & 3

coal is continuously transferred to the ground at the required place by the

movement of wing Conveyor Conv. No. 3. Wing Conveyor discharges on both

sides. In case of closed wagons unloading is done manually on the rail track

conveyor No. 2 from where coal is transferred by running unloading system of

belts.

35

Manual unloading of coal is also done on rail tracks over underground

conveyors No. 4 and ET-1. The coal is transferred to belts through overhead grills

by means of Bull Dozers and conveyed to the required destination by the down

stream system of belts as shown in the block diagram.

The system of conveyor belts No. 4,5,6,7 alongwith crusher and screen is

called Reclaiming System. And the reclaiming system of belts ET-1, ET-2, ET-4,

ET-6 alongwith crusher, screen and inter-connections reversible belts ET-3 and ET5 was installed later on to supply coal for C.P.P.

As will be seen from block diagram both SGP and CPP can be fed by

running only one reclaiming system. Unloading coal can also be directly fed by

running the unloading system, Reclaiming System one or reclaiming system-2

alongwith belt ET-3. So many options are available. A continuous belt weightier

mounted on Conveyor No. 5 and ET-2 records the total amount of coal passing

over. All conveyors are motor driven on rollers. Gears are used for speed

reduction. Pull chords are provided along the belt for emergency stoppage. All

conveyors can be operated from the control room. Various switches have been

provided for stoppage of the system in case any one of the belts stops, to avoid

spillage of coal.

3. FUEL OIL SYSTEM

Fuel oil is used as raw material in Ammonia plant for the production of

Ammonia and also as supporting fuel in coal fired boilers. Around 1000 Te/day of

fuel is consumed.

Fuel oil has a carbon to hydrogen ratio of 8.5 specific gravity 0.85 to 0.9,

viscosity 150 CS at 50oC, heating value 10000K Cal/kg, flash point 60oC and pour

point 36oC. It is inflammable and can be unloaded and transported in hot

condition only at around 65-70oC. So special precautions have to be taken.

Fuel oil is unloaded from rail wagons in fuel oil unloading area. Wagons

can be placed on both sides of the header and wagons connected to the header by

hose connection. Oil in wagons has to be heated by steam. It flows to the

unloading header. Transfer pumps are used for transferring this from unloading

header to heavy oil storage tanks.

36

3 number storage tanks of F.O. are provided each having a capacity of

10,000 M3 oil. Each tank is equipped with internal steam heating coil to maintain

oil Temp. 60-70oC. A suction Heater to heat oil at 65-70 oC, a temperature gauge a

flames arrestor, a locally mounted level indication and a high level alarm with an

extra level switch which trips the Fuel Oil unloading pumps automatically. 4 No.s

Fuel oil transfer pumps are there which can take suction from any of the tanks

through a suction header and these pumps supply oil to Ammonia Plant and

Boilers.

METHANOL HANDLING

Methyl Alcohal (CH3 OH) or methanol is required in the Rectisol Unit of

Ammonia Plant for removal of carbon-di-oxide and Hydrogen sulphide from the

gases.

Methanol is a highly flammable liquid and dangerous hazard with low

boiling point of 65.7oC. Explosive limits of methanol vapours in dry air are 6.0

36.5% by volume. Its vapours are very toxic. Max. allowable concentration for 8

Hr. working is 200 ppm in air. Blindness may result when it is absorbed into

blood stream through skin or by other means.

Fresh Methanol is stored at ambient temperature in a fixed cum floating

storage tank of capacity 400 M 3. Slop methanol pumps of 20 M 3/hr capacity have

been provided to supply these types of methanol to Ammonia Plant as per

requirement. Annual requirement of fresh methanol is about 1200-1500 Te. Fresh

Methanol is received in road tankers and unload through fresh methanol pumps.

Because of the flammability of methanol, the storage tanks are located at a

safe distance from the plants and are surrounded by a dyke wall.

Storage area is provided with the following :1.

2.

3.

4.

Foam type fire extinguishing system

Nitrogen sealing of methanol tanks

Water spray system for cooling the tanks

Eye Showers

37

L.P.G. SYSTEM

LPG Gas required for start-up of Ammonia Plant as a heating medium in

gasification reactors and for pilot burners of the flare stack.

The LPG System consists of road tanker unloading station, unloading

pump, storage drum and vaporizes as shown in the block diagram. LPG is

received in road tankers and unloaded into Storage tank of 100 M 3 capacity means

of a LPG Unloading pump of 10 M 3/hr capacity which is located underground.

Pressure of 5-7 kg/cm2 is maintained in the tank.

For supplying to Ammonia, LPG from Storage Tank is vaporized in a

vaporizer using steam as heating medium. Pressure control valves control the

pressure at the desired value. During start-up of gasification a pressure of 5-7

kg/cm2 is maintained.

LPG is highly flammable and its explosive range is 1.8 to 9.5 % by volume.

So LPG area is isolated and enclosed from all sides.

For spray purpose N2 connections have been given in the system. Water

spray system has been provided on the storage tank. In case of overheating of the

tanks, water spray will start automatically and some valves in LPG system will

close to isolate the system. This safety system can be operated manually also.

38

AMMONIA PLANT

39

AMMONIA

PLANT

The Ammonia Plant of NFL, Bathinda is based on the partial Oxidation

route of Fuel oil. The plant went into commercial production in August 1979 and

has been built with M/s Toyo Engineering Corporation as the main Engineering

Contractor.

The Ammonia plant has the following processing units:SL

No.

1.

Unit/Section

___________

Air Separation

Unit.

Supplier

Features

___________

________________________

M/s Hitachi, Japan Mol. Sieve and Activated

Alumina Gel bed for CO2 &

Moisture Removal, cold

recovery from the products in

Plate and fin type heat

exchangers and conventional double column for

distillation.

2.

Gasification

M/s TEC under

Process Licence

Of M/s Shell

International.

3 Refractory

Gasifiers of 700 series.

3.

Rectisol

De-SulfuriSation

M/s TEC under

Process Licence

of M/s Lurgi

Selective absorption of

H2S and CO2 by low

Temperature Methanol

4.

Rectisol

De-carbonation

--do-

Total regeneration of

partial stream only.

5.

CO Shift

T.E.C.

Double bed high Temp.

CO Shift Convertor.

6.

Absorption

Refrigeration

M/s Borsig

Part of heat duty is supplied

by the converted gas from

Shift convertor.

40

7.

Nitrogen

Wash

M/s Hitachi

Mol. Sieve Adsorbers for

removal of Methanol and CO2

8.

Ammonia

Synthesis

M/s TEC under

Process Licence

Of M/s HALDOR

TOPSOE

Topsoe S-200 radial flow

basket, waste Heat Recovery

of the Convertor exit gases

in BFW Economizers.

The Compressor house of Ammonia Plant has the following major

equipments:

1.

Air Compressor

M/s Mitsui, Japan

1,40,000 NM3/hr capacity

15.45 MW Turbine.

2.

Nitrogen

Compressor

--do--

30,000 NM3/hr capacity

6.9 MW Turbine.

3.

Oxygen

Compressor

Compr.=DEMAG 24,970 NM3/hr capacity

Turbine=M/s AEG 6.597 MW Turbine

Kennis (WG)

4.

Synthesis

Compressor

B.H.E.L.

Hyderabad

1,10,000 NM3/hr for Ist,

2nd and 3rd stages.

4,64,000 NM3/hr for

Recycle Stage.

15.983 MW Turbine

5.

Refrigeration

Coimpressor

--do--

41,330 NM3/hr Capacity

2.8 MW Turbine.

Against the rated capacity of 900 Te/day, Plant has produced a record

Production of 1011 Te and has been constantly running above 105% for the past

few Years.

41

The basic chemistry for production of Ammonia is based on the HABERs

Bosch Process for Ammonia synthesis. The reactants in the Ammonia Synthesis

Process are Nitrogen and Hydrogen. Nitrogen is obtained from its abundant

source i.e

Atmosphere and Hydrogen is obtained from fuel oil which is a hydro carbon with

C/H

Ratio of approximately 8.

As will be evident from the above, the constituents in the synthesis gas

other than Nitrogen and Hydrogen does not play any part in the Ammonia

Synthesis Reaction, rather they exercise undesirable effects like exerting their own

partial pressure, poisoning the catalysts etc. As such, the Ammonia Plant process

is laid down such that the undesirable constituents in the raw gas are removed in

the process of purification before the synthesis gas mixture, containing Hydrogen

and nitrogen in the ratio of 3:1 at the required pressure, is sent to Ammonia

Synthesis Convertor for Synthesis reaction.

The plant has been provided with a fail safe safety system to take care of all

eventualities. The periodical review of the safety system is also done and

incorporations whenever necessary are done.

The plant is also equipped with a flare system with 80M height flare stack

provided with Pilot and main burners capable of burning around 90,000 NM 3/hr of

process gas at a time and also Mol. Seal to prevent back flow of the gas into the

flare gas system. The pilot burner is of automatic ignition system.

The harmless gases like CO2 and Nitrogen are vented through a cold flare

outlet also at 80M height. The flare system has been so designed that the toxic

gases are burnt so that their combustion products are not harmful to the

environment.

Adequate measures have been taken to contain the air and water pollutants

with in the MINAS Standard. As in this process of Ammonia manufacturing, the

gases, CO and H2S are extremely toxic. Monitors have been provided in the

Control Room with sensors installed at sensitive locations of the plant for

continuous monitoring of the environment.

42

BRIEF DESCRIPTION OF VAIROUS PROCESS UNITS IS GIVEN HERE

UNDER

The Air Separation plant has been supplied as a package Unit by M/s

HITACHI and was plagued with constraints during the initial years of operation.

These constraints have now been overcome by:

1. Inter-connecting the screw refrigeration compressor with the main

refrigeration compressor of the Synthesis section.

2. Changing the material of construction of the Air precoolers at the upstream

of the chilling unit from CS Tubes to SS Tubes

3. Increasing the packed volume of Mol. Sieve in the ASU Dryers.

4. Modifying the Air Drier Post Filtration System of air before entering the

cold box.

Air separation Unit provides Nitrogen while section No. 2 to 7 are for

Generation and purification of Hydrogen. Eighth one is for synthesis of

Ammonia.

1.

AIR SEPARATION UNIT

Supplier of air to ASU is Air Compressor. It draws 1,40,000 NM 3/hr of air

from atmosphere, compresses it to around 7.0 kgf/cm2 pressure and sends the

compressed air to A.S.U. Air Compressor is a multi stage axial flow Compressor

supplied by M/s Mitsui Shipbuilding & Engg. Co. Ltd., Japan coupled with a

steam Turbine of 15,455 KW rated output supplied by M/s Mitsui Bown Boveri,

Japan. It consumes a maximum of 60 Te/hr of steam. Capacity of the air

compressor can be varied with the movement of blades fitted into the stators of

LPC and HPC casings. For running the plant at higher loads extra quantity of air

is required. To augment this shortfall, a small centrifugal compressor has been

installed. It supplies around 4500 NM 3/hr of air and is fitted with an electrical

motor of 650 KW rated output. Air Separation Unit is having the capacity to

supply maximum 25,920 NM3/hr Oxygen (Minimum 98% purity) and 30,000

NM3/hr of Nitrogen (Min. 99.99%pure, Min. Oxygen content less than 8 ppm.)

Feed Air is first cooled in an Ammonia Chiller equipped with a screw

Compressor (GB-5 with a refrigeration capacity of 825 Refrigeration Ton) and

43

then atmospheric moisture and carbon-di-oxide are removed from the air in Air

Dryers,filled with Alumina gel and molecular sieves. This purified air is further

cooled upto its liquification temperature with cold outgoing product streams in the

multi path Main Air Heat Exchanger.

The cooled air gets partially liquefied. This liquid air is distilled in specially

designed two columns, lower column and upper column and a main condenser,

which acts as condenser for lower column and Reboiler for upper column.

In the distillation column liquid air is separated into Pure Oxygen and

Nitrogen Streams. The cold stream (alongwith impure and high Pr. N 2 stream ) are

used to cool and liquefy the incoming air and subsequently oxygen is sent to

gasification section and Nitrogen to Nitrogen Wash Unit and for stripping in

Rectisol Section.

To avoid cold loss from the equipments/piping etc. operating at very low

temperatures, these equipments have been installed in a box known as Cold Box

and this box has been filled with PERLITE insulation.

Since all the cold can be recovered from the outgoing cold streams, some

cold loss occurs which is compensated by expansion turbines provided inside the

cold box. The expansion turbines generate cold by expanding air from 7 Kg/cm 2

to 0.7 kg/cm2.

Liquid oxygen and liquid nitrogen are also drawn for selling as by product.

Refrigeration capacity of the screw Compressor GB-5 provided for chilling air

prior to adsorption of CO2 and moisture is 825 Refrigeration Ton.

2.

GASIFICATION SECTION

The Hydrogen generation takes place in Gasification Section. This section

is provided with three No.s 700 series gasifiers supplied by M/s SHELL

GASIFICATION. 700 series signifies the generation capacity of a gasifier i.e 700

x 1000 Nm3 of gas per day.

Fuel oil at a pr. Of 130 kg/cm 2 and a temp. 230oC is partially oxidized in

the gasifiers with oxygen and 64 kg/cm 2 steam. As the reactions involved are

highly exothermic, the inside temp. of the gasifier are maintained at 1360 oC with

the help of steam and endothermic reaction. The gaseous mixture formed by the

44

partial oxidation of fuel oil leaves the gasifier at 1360 oC. The operating pr. For

gasifier is 55 kg/cm2.

The waste heat of the gas is recovered in a Boiler where 100 kg/cm 2 steam

is generated and in turn gas is cooled to 318 oC .from 1360oC further the temp. of

these gases is brought down to 200oC in the Economizer by preheating the boiler

feed water. Residual carbon formed during the gasification of oil is separated in

the form of carbon slurry in quench pipes and carbon separator, with the help of

quench water. Gases leaving the carbon separators of all the three streams are

mixed together and further cooled in BFW Preheater and scrubbed with water for

removal of the remaining content of carbon in the carbon scrubber. It is necessary

to remove the carbon completely from the gas otherwise it will choke the down

stream equipments in Rectisol Desulphurisation Section. The raw gas contains

mainly CO and H2 while other constituents like H2S, Methane etc. are also present

composition of these constituents are given in Table T-1.

Oxygen is fed to the Gasifier in a controlled quantity which is lower than

that required for total oxidation, with the intention of only partially oxidizing the

hydro-carbon content of the fuel oil, and this results in the formation of 48%

carbon mono oxide in raw gas. This CO content is then reacted with steam in CO

shift section to form further quantity of hydrogen and hence the name of the

Process i.e PARTIAL OXIDATION OF FUEL OIL.

100 kg/cm2 saturated steam is superheated to 480oC from 314oC in the

steam superheater with the help of Tail Gas combustion (obtained from Nitrogen

Wash Unit), and is then mixed with main steam header coming from Auxiliary

Reboilers. In order to have flame stability in the Superheater, oil support is also

provided.

3.

RECTISOL 1 (DESULPHIRISATION)

The feed stock contains around 2.5% Sulphur and this leads to the

formation of Hydrogen sulphide in the gasifiers. This impurity of H 2S has to be

removed from the gaseous mixture as sulphur is a serious poison for the catalysts

used in CO shift and Synthesis Sections. Rectisol Desulphurisation Section is

employed for the purpose of removal of H2S by absorption in low temperature

methanol.

45

The gaseous mixture coming from gasification section is first cooled to

22 C in Ammonia Chiller and with cold desulphurised gas in Exchangers. It is

then fed to a tall tower called H2S Absorber, equipped with valve type trays. Cold

methanol at a temp of -31oC is fed at the top of the tower. As the gas moves up

and cold methanol flows downward, these have intimate contact with each other

on the trays. Here the H2 in the gas is absorbed by methanol and desulphurised

gas (H2S content 0.4 ppm maxm.) leaves at the top of the tower. The operating

pressure of the tower is 46.1 kg/cm2.

o

H2S loaded methanol withdrawn from the bottom of H2S absorber is flashed

to 12 kg/cm2, 0.5 kg/.cm2 and then heated to 88 oC. Regenerated methanol is

subsequently cooled and recycled back to H 2S absorber, one of the gases

generated during regenration process of methanol in hot regenerator is known as

claus gas and is rich in H2S content.( On an average around 35%). It is sent to

sulphur recovery plant, where sulphur is produced from this gas as a by-product.

4.

CO SHIFT SECTION

Desulphurised gas coming from Rectisol-1 is led to this section. In this

section CO in the gases reacts with steam as per the following CO Shift Reaction.

CO + H2O

Catalyst

CO2 + H2 + Heat

34.7 Te/hr of 64 kg/cm2 steam is added form outside sources. Though the actual

steam consumed in CO Shift is only 37 Te/hr but due to kinetics of the reaction

involved steam to gas ratio has to be maintained at 1.5 and for this, large amount

of steam will be required. But this demand of excess steam is met by

Humidification of the gas. For this purpose gas is contacted with hot process

condensate, saturating the gas with water vapours and after the CO Shift reaction

excess water is removed from the gas by dehumidification process.

Heat of the shifted gas is utilized in the Reboiler of Absorption

Refrigenration unit and subsequently 3 kg/cm2 steam is generated. Gas is sent to

Rectisol (Decarbonation) after cooling to 45 oC. Gases leaving CO Shift section

contain 3.5 % CO. Other constituents are given in Table T-1.

46

5.

RECTISOL-II (DECARBONATION):

This section is employed for the removal of CO2 content of the gas. Here

again methanol is used for absorption of CO2 though at a relatively colder

temperature than those in Rectisol (Desulphurisation).

Similar to Desulphurisation Process, CO shifted gas is first cooled with

cold CO2, Synthesis gas from Nitrogen Wash Unit washing column outlet and

Ammonia Chiller, and then fed at the bottom of CO 2 absorber, which is tall tower

equipped with valve type trays. Methanol at Temps. Of 58 oC and 70oC is

charged at the top and middle of the tower respectively. With the intimate contact

of gas and liquid methanol on trays, CO2 is absorbed by methanol and

decarbonated gas (CO2 content 10ppm maxm.) leaves at the top of the tower.

Operating Pressure of this Tower is 39.5 kg/cm2.

CO2 loaded methanol is withdrawn from the bottom of the tower and is

flashed to 0.8 kg/cm2 and (-) 0.4 kg/cm2 pr.and is then stripped with Nitrogen for

regeneration. A Blower is used for generating vacuum for the 2 nd stage

regeneration of the methanol. Generated CO 2 from the flash and vacuum sections

of the tower is sent to the Urea plant.

6.

A.R.U.

For cooling Rectisol (Desulphurisation) and Rectisol (Decarbonation)

incoming gas streams and circulating methanol streams, Ammonia Chillers are

employed in which cooling is done by Evaporating Liquid Ammonia. These

chillers are linked with Absorption Refrigeration Unit (ARU),

In this section Ammonia vapors are absorbed in lean Ammonia Sol. Rich

Ammonia solution thus formed is raised to a Pr. of around 15.5 kg/cm 2 and Pure

Ammonia vapours and lean Ammonia solution are separated in a distillation tower.

High Pr. Ammonia vapours are condensed with cooling water and liquid

Ammonia thus formed is sent to Ammonia Chillers. Lean Ammonia solution

formed is reused for absorbing low Pr. Ammonia vapours coming from chillers.

Refrigeration capacity of ARU is 1600 Refrigeration ton.

47

7.

NITROGEN WASH UNIT

Decarbonated gas coming to NWU from Rectisol (Decarbonation) at 39.5

kg/cm and 55oC contains 5.21% CO, 0.50% CH4 in addition to 93.62% of

Hydrogen and 0.67% of N2 + Ar. CO and CH4 are undesirable constituents in

Synthesis Section, where these will act as Catalyst Poison and inert respectively.

Hence these are removed from the gaseous mixture by giving a Liquid Nitrogen

Wash to the gaseous mixture in NWU. Hydrogen boils at a considerably lower

temperature than all other impurities i.e CO and CH 4 present in the decarbonated

gas. This difference in boiling points allow to remove these impurities by

fractional condensation. Boiling points of Hydrogen, Nitrogen, Carbon-monooxide, and methane at atmospheric pressure are 249.4 oC, -195.8oC, -191.5oC and

161.5oC respectively. Nitrogen wash unit has been supplied by M/s HITACHI of

Japan as a package Unit.

2

Decarbonated gas coming from Rectisol (Decarbonation) Unit at 55 oC

contains a maxm. 10 ppm of methanol. These constituents are removed

completely by passing the gas through molecular sieve adsorber beds. There are

three adsorber beds filled with 5A type 7.0 Te (for each Adsorber) molecular

sieves. These adsorbers operate on a ten Hour Cycle. One adsorber remain in line

and other two go under regeneration with 6 kg/cm 2 N2 obtained from A.S.U

Nitrogen Wash Unit operation takes place at very low temperatures, of the order of

195oC. Hence the equipments, down stream of adsorbers, are installed in cold

box filled with Perlite.

After CO2 and methanol removal, in adsorber, the gases enter the cold box.

Here the gas is first cooled to 190 oC by outgoing washed gas in raw gas

exchangers. It is then fed to the bottom of a washing column in which Liquid

Nitrogen at a Temp. of 195oC is charged from the top of the tower. This tower

consists of sieve trays and on these trays undesired components i.e CO and CH 4

are carried along by the downward flow of Liquid Nitrogen.

Purified gas (with a Maxm. 5 ppm of CO ), slightly rich in nitrogen, leaves

at the top of the Tower. After frigory recovery of the gases in exchangers of

Rectisol Section, where the incoming gases to CO 2 Absorber are cooled, and

addition of balance amount of Nitrogen, for making 3 : 1 ratio of H 2 to N2 this gas

goes to Synthesis Compressor suction as make up gas for synthesis section. Tail

48

liquid formed at the bottom of the column is flashed to 0.6 0.8 kg/cm 2 Pr.and the

tail gas is burned in steam Super heater, as it has high calorific value.

Cold requirement of NWU is fulfilled by sending a partially cooled

Nitrogen stream to ASU for Liquification and supercooling. In the course of

operation of adsorbers, due to attrition, fine dust of molecular sieve is formed.

During the earlier operation of the plant upto 1983-84, this dust used to get

deposited on the heat-transfer area of the Heat Exchangers causing higher cold

loss which used to result in Stoppage of plant for back-blowing of the equipment

for dust removal leading to production losses. To overcome this problem 2 MOTT

filters consisting of sintered iron candles with pore size of 5 microns were

installed. With this modification, problems due to dust has been overcome.

Nitrogen to NWU is supplied by Nitrogen Compressor. It takes suction

Nitrogen from Air Separation Unit, compresses it to 45 k/cm 2 and feeds to NWU.

It is a centrifugal type Compressor having two casings i.e. high Pr. casing and Low

Pr. casing. Each casing having two compression stages. Compressor is coupled

with a steam Turbine, supplied by M/s Mitsui ship building and Engg. Co. Ltd.,

Japan. The turbine is a single cylinder, impulse type extraction condensing type

Turbine with rated output as 6890 KW (Maxm.) and requires a Maxm. Of 83 te/hr

of 100 kg/cm2 superheated steam. For normal operation it supplies 5659 KW of

Power with a steam draw of 75 Te/hr. Out of this 54 Te/hr of steam at Pr. of 64

kg/cm2 is drawn as extraction steam which is used in gasification and CO Shift

section.

8.

SYNTHESIS SECTION

Make up gas coming from NWU is compressed to around 220 kg/cm 2

Pressure by synthesis Compressor. Upto three stages of the Compressor make up

gas is compressed, while at the suction of fourth stage known as Recycle Stage, it

is mixed with recycle gas coming from Synthesis section (3 rd and 4th stages are

housed in a single barrel). The compressor is of BHEL make and the Turbine of

Siemens. The compressor is of multi-stage vertically split casing type and consists

of three Barrels. Steam Turbine of Synthesis Compressor is an Extraction

condensing type with rated output of 15983 KW. It requires 181 Te/hr of 100

kg/cm2 super heated steam (480oC), out of this 145 Te/hr at 40 kg/cm2is drawn as

extraction.

The compressed make up gas alongwith recycle gas is fed to the Ammonia

Converter after preheating with outgoing gases. Ammonia Converter is S-200

49