Escolar Documentos

Profissional Documentos

Cultura Documentos

Risk Classification of Good Manufacturing Practices (GMP) Observations

Enviado por

jefftroyDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Risk Classification of Good Manufacturing Practices (GMP) Observations

Enviado por

jefftroyDireitos autorais:

Formatos disponíveis

Our Mandate:

To manage and deliver a national compliance and enforcement program for blood and donor semen; cells,

tissues and organs; drugs (human and veterinary); medical devices and natural health products, collaborating

with and across, all regions.

Health Products and Food Branch Inspectorate

Risk Classification of Good Manufacturing Practices (GMP)

Observations

GUI-0023

Supersedes:

2003-06-01

Date issued:

2012-09-11

Date of implementation:

2012-09-11

Disclaimer:

This document does not constitute part of the Food and Drugs Act (Act) or its associated Regulations and in

the event of any inconsistency or conflict between that Act or Regulations and this document, the Act or the

Regulations take precedence. This document is an administrative document that is intended to facilitate

compliance by the regulated party with the Act, the Regulations and the applicable administrative policies.

This document is not intended to provide legal advice regarding the interpretation of the Act or Regulations.

If a regulated party has questions about their legal obligations or responsibilities under the Act or

Regulations, they should seek the advice of legal counsel.

Health Canada / Health Products and Food Branch Inspectorate

Risk Classification of Good Manufacturing Practices (GMP) Observations (GUI-0023) / 2012-09-11 Page 2 of 16

Table of Contents

1.0 Purpose ......................................................................................................................................................... 3

2.0 Background ................................................................................................................................................... 3

3.0 Scope ............................................................................................................................................................. 3

4.0 Guide ............................................................................................................................................................. 4

4.1 Assignment of the Risk to an Observation ....................................................................................... 4

4.2 Assignment of the Inspection Rating ................................................................................................ 4

4.3 Additional Guidance ......................................................................................................................... 5

Appendix A ......................................................................................................................................................... 6

Premises C.02.004 .................................................................................................................................. 6

Equipment C.02.005 ............................................................................................................................... 6

Personnel C.02.006 ................................................................................................................................. 7

Sanitation C.02.007 C.02.008 .............................................................................................................. 8

Raw Material Testing C.02.009 C.02.010 ........................................................................................... 8

Manufacturing Control C.02.011 C.02.012 ......................................................................................... 9

Quality Control Department C.02.013 C.02.015 ............................................................................... 10

Packaging Material Testing C.02.016 C.02.017 ................................................................................ 11

Finished Product Testing C.02.018 C.02.019 .................................................................................... 11

Records C.02.020 C.02.024 ............................................................................................................... 12

Samples C.02.025 C.02.026 ............................................................................................................... 12

Stability C.02.027 C.02.028 ............................................................................................................... 13

Sterile Products C.02.029 ..................................................................................................................... 13

Appendix B ....................................................................................................................................................... 15

Glossary of Terms ................................................................................................................................. 15

Health Canada / Health Products and Food Branch Inspectorate

Risk Classification of Good Manufacturing Practices (GMP) Observations (GUI-0023) / 2012-09-11 Page 3 of 16

1.0 Purpose

To classify the observations noted during establishment inspections according to their risk.

To ensure uniformity among the inspectors of the Health Products and Food Branch Inspectorate

(Inspectorate) in the attribution of the rating following establishment inspections.

To inform the industry of the situations that the Inspectorate considers unacceptable and that will generate a

Non-Compliant (NC) rating following an inspection.

2.0 Background

During an establishment inspection, deviations from the Food and Drug Regulations and the current edition

of the Good Manufacturing Practices (GMP) Guidelines - 2009 Edition, Version 2 (GUI-0001) are noted by

the inspector and these deviations appear as observations in the inspection Exit Notice. A judgement based

on these observations is then made by the inspector and an overall recommendation is given. The possible

ratings are defined below:

C (Compliant): At the time of the inspection, the regulated party has demonstrated that the activities it

conducts are in compliance with the Food and Drugs Act and its associated Regulations.

A C rating does not mean that there are no observations or corrective actions required.

NC (Non-Compliant): At the time of the inspection, the regulated party has not demonstrated that the

activities it conducts are in compliance with the Food and Drugs Act and its

associated Regulations.

Attribution of a NC rating may have serious consequences for a company, ranging from the implementation

of important corrective measures to the temporary suspension or termination of the Establishment Licence

(EL). Therefore, these situations of non-conformity have to be well defined, unambiguous and directly

supported by the applicable regulations.

3.0 Scope

The definition of a drug in Canada covers a wide variety of products including pharmaceuticals and biologics

products. This guidance document covers these products to which Division 2 of Part C of the Food and Drug

Regulations applies and is based on the current edition of the Good Manufacturing Practices (GMP)

Guidelines - 2009 Edition, Version 2 (GUI-0001). It is recognized that the evaluation of the conformity to the

Good Manufacturing Practices (GMP) should be commensurate with the risk involved taking into account

the nature and extent of the deviation in relation with the category of products evaluated. Nonetheless, most

of the situations involving fraud, misrepresentation or falsification of products or data will generate a NC

rating, irrespective of the category of products involved.

The appendix attached to the present document describes the observations related to each category of risk.

Please note that the list of observations in the appendix is not exhaustive and that additional observations

may be added where appropriate.

The numbering system assigned to each section in the appendix is a reference to the applicable regulations in

the current edition of the Good Manufacturing Practices (GMP) Guidelines - 2009 Edition, Version 2 (GUI-

0001).

Health Canada / Health Products and Food Branch Inspectorate

Risk Classification of Good Manufacturing Practices (GMP) Observations (GUI-0023) / 2012-09-11 Page 4 of 16

4.0 Guide

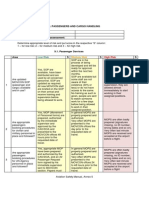

4.1 Assignment of the Risk to an Observation

Whereas it is recognized that it is impossible to encompass every situation that may generate a risk, the

following principles should be considered:

The risk assigned will be in relation to the nature of the deviation as well as the number of

occurrences.

Generally, when only low risk products are involved, a risk 1 will not be assigned to observations

described in Appendix 1, except for extreme situations such as fraud or widespread cross-

contamination, infestation or unsanitary conditions.

Where a risk 2 observation is re-evaluated as a risk 1 (risk 2 observation with an arrow), this situation

is immediately brought to the attention of the companys officials, proper explanation will be

provided to the establishment and this explanation should be captured in the Inspectors Comments

field of the Inspection Summary in the Inspection Reporting System (IRS).

4.2 Assignment of the Inspection Rating

The overall inspection rating assigned is based on the risk involved taking into account the nature and extent

of the deviations with the category of products evaluated.

Generally, a NC rating is assigned when a Risk 1 observation is noted during an inspection.

Such situation is immediately brought to the attention of the companys officials. The Inspectorate

management is to be notified in a timely manner.

Where in the opinion of the inspector the resulting products present a significant health hazard, appropriate

enforcement actions may be initiated.

A NC rating may also be assigned in the following situations:

When numerous Risk 2 observations are noted during an inspection indicating that the company does

not control its processes and operations sufficiently.

Repetition of many Risk 2 and Risk 3 observations noted during previous inspections indicating that

the company did not:

implement the corrective actions submitted following the previous inspection or

did not put in place adequate preventive actions in a timely manner to avoid recurrence of such

deviations.

Generally, a C rating is assigned when Risk 2 observations are noted and in all situations where only Risk 3

observations are noted during an inspection.

Health Canada / Health Products and Food Branch Inspectorate

Risk Classification of Good Manufacturing Practices (GMP) Observations (GUI-0023) / 2012-09-11 Page 5 of 16

4.3 Additional Guidance

When a NC rating is assigned, the inspector will issue a draft inspection Exit Notice during the exit meeting.

The draft inspection Exit Notice will be reviewed for quality assurance purposes before the final report is

issued to an establishment.

When observation(s) leading to a NC rating are made, the inspection Exit Notice could be issued with a C

rating if, during the inspection:

the establishment immediately implements all necessary actions to resolve the cause(s) of the

observation(s) leading to the NC rating and,

sufficient assurance can be provided to prevent a recurrence.

In such instances, the risk assigned to the observation will remain the same.

If the management of the company wishes to dispute the results of the inspection report, the Dispute

resolution and appeals mechanism described in the Drug Good Manufacturing Practices (GMP) and

Establishment Licencing (EL) Enforcement Directive (POL-0004) () should be followed.

Health Canada / Health Products and Food Branch Inspectorate

Risk Classification of Good Manufacturing Practices (GMP) Observations (GUI-0023) / 2012-09-11 Page 6 of 16

Appendix A

Premises C.02.004

Note: Certain Risk 2 observations may be upgraded to a Risk 1. They are indicated with an arrow ()

Risk (Critical) Observations

No air filtration system to eliminate airborne contaminants that are likely to be generated during

fabrication or packaging.

Generalized malfunctioning of the ventilation system(s) with evidence of widespread cross-

contamination.

Inadequate segregation of manufacturing or testing areas from other manufacturing areas for high risk

products.

Risk 2 (Major) Observations

Malfunctioning of the ventilation system that could result in possible localized or occasional cross-

contamination.

Maintenance/periodic verification such as air filter replacement, monitoring of pressure differentials

not performed. ()

Accessory supplies (steam, air, nitrogen, dust collection, etc.) not qualified.

Heat, Ventilation, Air Conditioning (HVAC) and purified water system not qualified. ()

Temperature and humidity not controlled or monitored when necessary (for example, storage not in

accordance with labelling requirements).

Damages (holes, cracks or peeling paint) to walls/ceilings immediately adjacent or above

manufacturing areas or equipment where the product is exposed.

Un-cleanable surfaces created by pipes, fixtures or ducts directly above products or manufacturing

equipment.

Surfaces finish (floors, walls and ceilings) that do not permit effective cleaning.

Unsealed porous finish in manufacturing areas with evidence of contamination (mildew, mould,

powder from previous productions, etc.). ()

Insufficient manufacturing space that could lead to mix-ups. ()

Physical and electronic quarantine accessible to unauthorized personnel/Physical quarantine area not

well marked and/or not respected when used. ()

No separate area/Insufficient precautions to prevent contamination or cross-contamination during raw

material sampling.

Risk 3 (Other) Observations

Doors giving direct access to exterior from manufacturing and packaging areas used by personnel.

Un-screened/Un-trapped floor drains.

Outlets for liquids and gases not identified.

Damages to surfaces not directly adjacent or above exposed products.

Non-production activities performed in production areas.

Inadequate rest, change, wash-up and toilet facilities.

Equipment C.02.005

Note: Certain Risk 2 observations may be upgraded to a Risk 1. They are indicated with an arrow ()

Health Canada / Health Products and Food Branch Inspectorate

Risk Classification of Good Manufacturing Practices (GMP) Observations (GUI-0023) / 2012-09-11 Page 7 of 16

Risk 1 (Critical) Observations

Equipment used for complex manufacturing operations of critical products not qualified and with

evidence of malfunctioning or lack of appropriate monitoring.

Risk 2 (Major) Observations

Equipment does not operate within its specifications. ()

Equipment used during the critical steps of fabrication, packaging/labelling, and testing, including

computerized systems, is not qualified. ()

Tanks for manufacturing of liquids and ointments not equipped with sanitary clamps.

Stored equipment not protected from contamination. ()

Inappropriate equipment for production: surfaces porous and non-cleanable/material sheds particles.

()

Evidence of contamination of products by foreign materials such as grease, oil, rust and particles from

the equipment. ()

No covers for tanks, hoppers or similar manufacturing equipment.

No inadequate precautions taken when equipment such as oven or autoclave contains more than one

product (possibility of cross-contamination or mix-ups). ()

Equipment location does not prevent cross-contamination or possible mix-ups for operations

performed in common area. ()

Purified water system not maintained or operated to provide water of adequate quality. ()

Leaking gaskets with potential impact on product quality. ()

No calibration program for automatic, mechanical, electronic or measuring equipment/no records

maintained.

No preventative maintenance program for major equipment/no records maintained.

No equipment usage logs.

Risk 3 (Other) Observations

Insufficient distance between equipment and walls to permit cleaning.

Base of immovable equipment not adequately sealed at points of contact.

Use of temporary means or devices for repair.

Defective or unused equipment not removed or appropriately labelled.

Minor equipment used for non critical products not qualified.

Personnel C.02.006

Risk 1 (Critical) Observations

Individual in charge of Quality Control (QC) or production for a fabricator of critical/high risk

products does not hold a university degree in a science related to the work being conducted and does

not have sufficient practical experience in their responsibility area.

Risk 2 (Major) Observations

Individual in charge of QC or Production for a fabricator, packager/labeller, importer, distributor or

tester does not hold a university degree in a science related to the work being conducted.

Individual in charge of QC or Production for a fabricator, packager/labeller, importer, distributor or

tester does not have sufficient practical experience in their responsibility area.

Health Canada / Health Products and Food Branch Inspectorate

Risk Classification of Good Manufacturing Practices (GMP) Observations (GUI-0023) / 2012-09-11 Page 8 of 16

Individual in charge of QC for a wholesaler or secondary labeller is not qualified by academic

training and experience.

Delegation of responsibilities for QC or Production to insufficiently qualified persons.

Insufficient personnel for QC or Production operations resulting in a high probability of error.

Insufficient training for personnel involved in production and QC resulting in related GMP deviations

Risk 3 (Other) Observations

Inadequate training records.

Insufficient written training program

Sanitation C.02.007 C.02.008

Note: Certain Risk 2 observations may be upgraded to a Risk 1. They are indicated with an arrow ()

Risk 1 (Critical) Observations

Evidence of widespread accumulation of residues/extraneous matter indicative of inadequate

cleaning.

Evidence of gross infestation.

Risk 2 (Major) Observations

Sanitation program not in writing but premises in acceptable state of cleanliness.

No standard operating procedures (SOP) for microbial/environmental monitoring, no action limits for

areas where susceptible non-sterile products are manufactured.

Cleaning procedures for production equipment not validated (including analytical methods). ()

Inadequate written health requirements and/or hygiene program.

Health requirements and/or hygiene program not properly implemented or followed.

Risk 3 (Other) Observations

Incomplete written sanitation procedure.

Incomplete implementation of the written sanitation program.

Raw Material Testing C.02.009 C.02.010

Risk 1 (Critical) Observations

Evidence of falsification or misrepresentation of analytical results.

No evidence of testing Certificate of Analysis (COA) available from the supplier/synthesizer and no

testing done by the Canadian fabricator

Risk 2 (Major) Observations

Reduced testing program in place without adequate certification of the vendors/suppliers.

Water used in the formulation is not of acceptable quality.

Insufficient testing of raw material.

Incomplete specifications.

Specifications not approved by QC.

Test methods not validated.

Health Canada / Health Products and Food Branch Inspectorate

Risk Classification of Good Manufacturing Practices (GMP) Observations (GUI-0023) / 2012-09-11 Page 9 of 16

Use of raw material after retest date without proper retesting.

Use of raw material after the expiration date.

Multiple lots of the same raw material, comprising of one reception, are not considered as separate for

sampling, testing and release.

No SOP for conditions of transportation and storage.

Certification of brokers or wholesalers allowed without proper documentation.

Risk 3 (Other) Observations

Lots identified for confirmatory testing used in production without QC approval.

Incomplete validation of test methods.

Manufacturing Control C.02.011 C.02.012

Note: Certain Risk 2 observations may be upgraded to a Risk 1. They are indicated with an arrow ()

Risk 1 (Critical) Observations

No written Master Formula.

Master Formula or manufacturing batch document showing gross deviations or significant calculation

errors.

Evidence of falsification or misrepresentation of manufacturing and packaging orders.

Risk 2 (Major) Observations

Master Formula prepared/verified by unqualified personnel.

Lack of or incomplete validation studies/reports for critical manufacturing process (lack of

evaluation/approval). ()

Inadequate validation of changeover procedures. ()

Unapproved/undocumented major changes compared to Master Production Documents. ()

Deviations from instructions during production not documented and not approved by QC.

Discrepancies in yield or reconciliation following production not investigated.

Line clearance between production of different products not covered by SOP and not documented.

No regular checks for measuring devices/no records.

Lack of proper identification of in-process materials and production rooms resulting in a high

probability of mix-ups.

Inadequate labelling/storage of rejected materials and products that could generate mix-ups.

Upon receipt, bulk and in-process drugs, raw material and packaging material not held in quarantine

until released by QC.

Labels are not properly controlled. ()

Production personnel using bulk and in-process drugs, raw material and packaging material without

prior authorization by QC. ()

Inadequate/inaccurate labelling of bulk/in-process drugs, raw material and packaging material

Raw material dispensing not done by qualified persons, according to an SOP.

Master Formula incomplete or showing inaccuracies in the processing operations.

Changes in batch size not prepared/verified by qualified personnel.

Inaccurate/incomplete information in manufacturing/packaging batch documents.

Although documented, combination of batches done without QC approval/not covered by SOP.

No written procedures for packaging operations.

Health Canada / Health Products and Food Branch Inspectorate

Risk Classification of Good Manufacturing Practices (GMP) Observations (GUI-0023) / 2012-09-11 Page 10 of 16

Non-standard occurrences during packaging not investigated by qualified personnel.

Inadequate control of coded and non-coded printed packaging material (including storage, dispensing,

printing, disposal).

Inadequate handling of outdated/obsolete packaging material.

No or inadequate self-inspection program/Program does not address all applicable sections of

GMPs/Records incomplete or not maintained.

Fabrication, packaging/labelling and testing operations carried out at a Canadian site not holding an

EL. ()

No agreement between the contractor, the importer and the distributor covering the fabrication and

packaging/labelling operations.

Products imported from foreign sites that are not listed on the Foreign Site Annex of the EL. ().

Recall:

Absence of recall procedure combined with distribution practices that would not permit an

adequate recall (distribution records unavailable or not kept).

Improper quarantine and disposal practices that would allow recalled/rejected units to be returned

for sale.

Risk 3 (Other) Observations

Incomplete SOPs for handling of materials and products.

Access to production areas not restricted to authorized personnel.

Inadequate checks for incoming materials.

Written procedures incomplete for packaging operations.

Incomplete recall procedure.

No agreement between the wholesaler, the importer and the distributor relative to a recall of a drug

when the importer or distributor assumes wholesalers responsibilities with respect to recalls.

Incomplete/inaccurate annual product quality review.

Quality Control Department C.02.013 C.02.015

Note: Certain Risk 2 observations may be upgraded to a Risk 1. They are indicated with an arrow ()

Risk 1 (Critical) Observations

No person in charge of QC available on premises in Canada.

Quality Control department is not a distinct and independent unit, lacking real decisional power, with

evidence that QC decisions are often overruled by production department or management.

Risk 2 (Major) Observations

Inadequate facilities, personnel and testing equipment.

No authority to enter production areas. ()

No SOPs approved and available for sampling, inspection and testing of materials.

Products made available for sale without approval of QC department. ()

Products released for sale by QC without proper verification of manufacturing and packaging

documentation.

Master production documents not in compliance with marketing authorization. ()

Health Canada / Health Products and Food Branch Inspectorate

Risk Classification of Good Manufacturing Practices (GMP) Observations (GUI-0023) / 2012-09-11 Page 11 of 16

Out of specification test results, deviations and borderline conformances not properly investigated and

documented, according to a SOP. ()

Raw material/packaging material used in production without prior approval of QC.

Reprocessing/Reworking done without prior approval of QC department. ()

Lack of or inadequate system for complaint handling.

Returned goods are made available for sale without assessment and/or approval by QC.

SOPs covering operations that can affect the quality of a product such as transportation, storage, etc...

not approved by QC department/not implemented.

Inadequate evidence to demonstrate that storage and transportation conditions are appropriate.

Lack of or insufficient change control system.

For testing laboratories (in house or contract), the systems and controls in place for the proper

qualification, operation, calibration and maintenance of equipment, standards, solutions, and records

keeping do not assure that the results and conclusions generated are accurate, precise and reliable. ()

Products tested at a Canadian site not holding an EL. ()

Products tested at foreign sites that are not listed on the Foreign Site Annex of the EL. ()

Sterility testing not performed in a Grade A environment within a Grade B background or in an

isolator of a Grade A within an appropriate background and limited access to non-essential personnel.

Risk 3 (Other) Observations

No agreement between the contract laboratory and the establishment covering the testing activities.

Investigations of non-conformances not completed in timely manner.

Packaging Material Testing C.02.016 C.02.017

Note: Certain Risk 2 observations may be upgraded to a Risk 1. They are indicated with an arrow ()

Risk 2 (Major) Observations

Reduced testing program in place without adequate certification of vendors/suppliers.

Lack of or insufficient testing of packaging material. ()

Inadequate specifications.

Specifications not approved by QC.

No identity test done by the packager/labeller after receipt on its premises.

Certification of brokers or wholesalers done without proper documentation.

Risk 3 (Other) Observations

Inadequate procedures of transportation and storage.

Inappropriate environment and/or precautions to prevent contamination of packaging material during

sampling.

Finished Product Testing C.02.018 C.02.019

Note: Certain Risk 2 observations may be upgraded to a Risk 1. They are indicated with an arrow ()

Risk 1 (Critical) Observations

Health Canada / Health Products and Food Branch Inspectorate

Risk Classification of Good Manufacturing Practices (GMP) Observations (GUI-0023) / 2012-09-11 Page 12 of 16

Finished product not tested for compliance with applicable specifications by the importer/distributor

before release for sale and no evidence is available that the products have been tested by the

fabricator.

Evidence of falsification or misrepresentation of testing results/forgery of COA.

Risk 2 (Major) Observations

Non-compliant products made available for sale. ()

Incomplete/inadequate specifications.

Finished product specifications not approved by QC.

Incomplete testing. ()

No identity testing upon receipt in Canada from non-Mutual Recognition Agreement (MRA) country

and/or no periodic complete confirmatory testing.

Lack of or insufficient validation of test methods. ()

No SOP for conditions of transportation and storage.

Use of unique identifier principles not meeting the acceptable options.

Risk 3 (Other) Observations

Inadequate method transfer for a validated analytical method.

Method validation report does not specify the revision of the analytical method used at the time of

validation.

Records C.02.020 C.02.024

Risk 1 (Critical) Observations

Evidence of falsification or misrepresentation of records.

Risk 2 (Major) Observations

Lack of or incomplete Master Production Documents.

Unavailability of documentation from suppliers in a timely manner.

Lack of or incomplete records of sale.

Lack of or incomplete records of complaints received respecting the quality of a drug.

Risk 3 (Other) Observations

Incomplete plans and specifications for the manufacturing buildings

Insufficient retention time for evidence and records to be maintained.

No organization charts.

Incomplete records for the sanitation program.

Samples C.02.025 C.02.026

Risk 2 (Major) Observations

Retained samples not kept for finished products.

Failure to submit retained samples when alternative sample retention granted.

Risk 3 (Other) Observations

Health Canada / Health Products and Food Branch Inspectorate

Risk Classification of Good Manufacturing Practices (GMP) Observations (GUI-0023) / 2012-09-11 Page 13 of 16

Samples of raw material not available.

Insufficient quantity for finished products or active pharmaceutical ingredients (API).

Improper storage conditions.

Stability C.02.027 - C.02.028

Note: Certain Risk 2 observations may be upgraded to a Risk 1. They are indicated with an arrow ()

Risk 1 (Critical) Observations

No data available to establish the shelf-life of products.

Evidence of falsification or misrepresentation of stability data/forgery of COA.

Risk 2 (Major) Observations

Insufficient number of lots to establish shelf-life.

Insufficient data to establish shelf-life.

No action taken when data shows that the products do not meet their specifications prior to the expiry

date. ()

Lack of or inadequate continuing stability program.

No stability studies pertaining to changes in manufacturing (formulation)/packaging material.

Testing methods not validated.

No consideration given to enroll worst case scenarios (for example, reworked/reprocessed lots).

Inappropriate storage conditions for stability samples.

Risk 3 (Other) Observations

Stability testing not performed at the time required by the written program.

Review of stability data not performed in a timely manner.

Sterile Products C.02.029

Note: Certain Risk 2 observations may be upgraded to a Risk 1. They are indicated with an arrow ()

Risk 1 (Critical) Observations

Lack of or inadequate validation of critical sterilization cycles.

Water for Injection (WFI) systems not validated with evidence of problems such as

microbial/endotoxin counts not within specifications.

No media fills performed to demonstrate the validity of aseptic filling operations.

No environmental controls/No monitoring for viable microorganisms during filling for aseptically

filled products.

Aseptic filling operations continued following unsatisfactory media fill results obtained.

Batches failing initial sterility test released for sale on the basis of a second test without proper

investigation.

Inadequate environmental conditions for aseptic operations.

Absence of leak test for ampules

Health Canada / Health Products and Food Branch Inspectorate

Risk Classification of Good Manufacturing Practices (GMP) Observations (GUI-0023) / 2012-09-11 Page 14 of 16

Risk 2 (Major) Observations

Aqueous-based products not subject to terminal steam sterilization without proper justification or

approval through the marketing authorization.

Inadequate room classification for processing/filling operations. ()

Aseptic manufacturing suites under negative pressure compared to clean areas (C-D). Clean areas (C-

D) under negative pressure to unclassified areas. ()

Insufficient number of samples taken for environmental monitoring/inadequate sampling methods. ()

Insufficient environmental controls/Insufficient monitoring for viable microorganisms during filling

for aseptically filled products. ()Premises and equipment not designed or maintained to minimize

contamination/generation of particles. ()

Inadequate maintenance of purified water and WFI systems.

Inadequate re-validation of purified water and WFI systems after maintenance, upgrading, out-of-

specs trends.

Inadequate training of personnel.

Personnel involved in aseptic filling prior to completing successful media fill.

Inadequate gowning practices for clean and aseptic areas.

Inadequate sanitation/disinfection program.

Inadequate practices/precautions to minimize contamination or prevent mix-ups.

Non-validated time lapse between cleaning, sterilization, and use of components, containers and

equipment.

No consideration given to bioburden prior to sterilization.

Non-validated time lapse between start of manufacturing and sterilization or filtration.

Inadequate program for media fill.

Capability of media to grow a wide spectrum of microorganisms not demonstrated.

Misinterpretation of results for media fill.

Samples for sterility testing insufficient in number or not representative of the entire production run.

Each sterilizer load not considered as a separate lot for sterility testing.

Purified water is not used as the feed water for the WFI system and the clean steam generator.

Inadequate testing program for WFI. ()

The WFI used for the final rinsing of containers and components used for parenteral drugs is not

tested for endotoxins when those containers and components are not depyrogenated subsequently.

Inappropriate environment/controls for crimping following aseptic filling.

Inadequate inspection for particles and defects. ()

Gases used to purge solutions or blanket products not passed through a sterilizing filter. ()

Inadequate integrity testing of sterilizing or vent filters. ()

Risk 3 (Other) Observations

Steam used for sterilization not monitored to assure suitable quality.

Inadequate control on the maximum number of personnel present in clean and aseptic areas.

Health Canada / Health Products and Food Branch Inspectorate

Risk Classification of Good Manufacturing Practices (GMP) Observations (GUI-0023) / 2012-09-11 Page 15 of 16

Appendix B

Glossary of Terms

The following definitions supplement the definitions provided under the Glossary of Terms in the guideline

Good Manufacturing Practices (GMP) Guidelines - 2009 Edition, Version 2 (GUI-0001).

Critical Product - A critical product is one for which any of the following criteria may apply:

narrow therapeutic window

high toxicity

sterile product

biological drug

complex manufacturing process: process for which slight deviations in the control of parameters

could result in a non-uniform product or product not meeting its

specifications. As examples, powder mixing or granulation for

low dosage solid forms, long acting/delayed action products,

sterile products.

Note: Category IV products (as listed in Annex 1 to the Current Edition of the Good Manufacturing

Practices Guidelines - Selected Category IV Monograph Drugs (GUI-0066)) should not be considered

as critical products even when the manufacturing processes involved are complex.

High Risk Product - Any product that may trigger a health risk even at low levels, following cross-

contamination. Those include but are not limited to penicillins, certain cytotoxic and biological products.

Low Risk Product - Products such as Category IV product (as listed in Annex 1 to the Current Edition of the

Good Manufacturing Practices Guidelines - Selected Category IV Monograph Drugs (GUI-0066)), that are

not a schedule drug or a sterile drug, and certain topical non prescription veterinary formulations registered

as old drugs.

Observation - A deviation or deficiency to GMPs noted by an inspector during the inspection of a drug

establishment that is confirmed in writing to the company in the inspection Exit Notice. The observations are

classified as Critical, Major and Other and are assigned a risk classification, ranging from 1 for

critical to 2 for major to 3 for other.

Critical observation (Risk 1):

Observation describing a situation that is likely to result in a NC product or a situation that may result

in an immediate or latent health risk and any observation that involves fraud, misrepresentation or

falsification of products or data.

Refer to Appendix 1 for the list of observations that the Inspectorate considers critical which will be

assigned a Risk 1.

Major observation (Risk 2):

Observation that may result in the production of a drug not consistently meeting its marketing

authorization.

Health Canada / Health Products and Food Branch Inspectorate

Risk Classification of Good Manufacturing Practices (GMP) Observations (GUI-0023) / 2012-09-11 Page 16 of 16

Refer to Appendix 1 for the list of observations that are considered major and which will be assigned

a Risk 2. Certain Risk 2 observations may be upgraded to Risk 1. They are indicated with an arrow

().

Other observation (Risk 3):

Observation that is neither critical nor major but is a departure from the GMPs.

Other observations are not listed as such (Observations that are neither critical nor major are

considered as other and will be assigned a Risk 3). All Risk 3 observations could be upgraded to

Risk 2. Refer to Appendix 1 for the list.

Você também pode gostar

- Guidlines On Recall by CDSCODocumento28 páginasGuidlines On Recall by CDSCONAVNEET BAGGA100% (1)

- Good Distribution Practices A Complete Guide - 2021 EditionNo EverandGood Distribution Practices A Complete Guide - 2021 EditionAinda não há avaliações

- Capa Sop ExampleDocumento4 páginasCapa Sop ExampleAKSAinda não há avaliações

- Progress in Pharmaceutical and Biomedical AnalysisNo EverandProgress in Pharmaceutical and Biomedical AnalysisAinda não há avaliações

- FDS StudyDocumento8 páginasFDS StudyAnnisaIndahPAinda não há avaliações

- A Comprehensive Text Book on Self-emulsifying Drug Delivery SystemsNo EverandA Comprehensive Text Book on Self-emulsifying Drug Delivery SystemsAinda não há avaliações

- PV 01Documento20 páginasPV 01Logan KandanAinda não há avaliações

- QA & RA ProfessionalDocumento2 páginasQA & RA ProfessionalaksshinyAinda não há avaliações

- Antimicrobial Effectiveness Test GMP InvestigationsDocumento8 páginasAntimicrobial Effectiveness Test GMP Investigationsgge2502Ainda não há avaliações

- The 4 Annual: Unleash The Full Market Potential of India' S Biopharma IndustryDocumento8 páginasThe 4 Annual: Unleash The Full Market Potential of India' S Biopharma IndustryBabbooAinda não há avaliações

- Biosimilars ManuDocumento6 páginasBiosimilars ManuIshan GhaiAinda não há avaliações

- BIOPHARMACEUTICS Part1aDocumento225 páginasBIOPHARMACEUTICS Part1aAmirabbas SaffariAinda não há avaliações

- Sterility Test FailuresDocumento8 páginasSterility Test FailuresAyman EshraAinda não há avaliações

- DR - Yuvaraj Chromosoft CRC ChennaiDocumento15 páginasDR - Yuvaraj Chromosoft CRC ChennaisunilAinda não há avaliações

- ICH GuidelinesDocumento39 páginasICH GuidelinesMd GayasuddinAinda não há avaliações

- Sterlization ProtocolsDocumento10 páginasSterlization ProtocolsSarathchandran BalachandranAinda não há avaliações

- Prospective Process Validation of Gliclazide TabletDocumento11 páginasProspective Process Validation of Gliclazide Tabletanandhra2010Ainda não há avaliações

- Dr. A. Puratchikody: Problems and Prospectus of Pharmaceutical Industries in IndiaDocumento14 páginasDr. A. Puratchikody: Problems and Prospectus of Pharmaceutical Industries in IndiairfanAinda não há avaliações

- Analytic Method Development and Validation: MT MVDocumento2 páginasAnalytic Method Development and Validation: MT MVRaja AbhilashAinda não há avaliações

- BrochureDocumento26 páginasBrochuredirepublicAinda não há avaliações

- Generation and Validation of Standard Operating Procedure For Dissolution ApparatusDocumento18 páginasGeneration and Validation of Standard Operating Procedure For Dissolution ApparatusAbhishek JhaAinda não há avaliações

- ICH Guidelines IndexDocumento5 páginasICH Guidelines Indexyashpandya01Ainda não há avaliações

- Bisimilar Final Draft 23-01-2018 PDFDocumento59 páginasBisimilar Final Draft 23-01-2018 PDFmailtorubal2573Ainda não há avaliações

- Multidimensional Component Inspection DevicesDocumento81 páginasMultidimensional Component Inspection DevicesMiltos BoboulosAinda não há avaliações

- Pharmaceutical Product Complaints:: Causes Behind The Market ComplaintsDocumento15 páginasPharmaceutical Product Complaints:: Causes Behind The Market ComplaintsKakon AhmedAinda não há avaliações

- Module 1 Pharmaceutical Quality SystemDocumento25 páginasModule 1 Pharmaceutical Quality SystemElton SubijanoAinda não há avaliações

- GMPJBK1 Scribd Uploaded JBK 001Documento9 páginasGMPJBK1 Scribd Uploaded JBK 001Jaya Bir KarmacharyaAinda não há avaliações

- FDA ANDA ChecklistDocumento11 páginasFDA ANDA Checklistraghu_kausikasaAinda não há avaliações

- Xrex 50mg CapDocumento20 páginasXrex 50mg Capziauddin bukhariAinda não há avaliações

- SMF Update SOLITAIRE PDFDocumento35 páginasSMF Update SOLITAIRE PDFmaheshAinda não há avaliações

- Biopharmaceuticals Are Among The Most Sophisticated and ElegantDocumento8 páginasBiopharmaceuticals Are Among The Most Sophisticated and ElegantRuza MazlanAinda não há avaliações

- Sop For Market Complaint HandlingDocumento4 páginasSop For Market Complaint HandlingneetdhroovAinda não há avaliações

- Asean GMP Recal ModuleDocumento29 páginasAsean GMP Recal ModuleDonny LoAinda não há avaliações

- Final Cadila On Customer SatisfactionDocumento54 páginasFinal Cadila On Customer SatisfactionAmit YadavAinda não há avaliações

- Sterille Production AreaDocumento12 páginasSterille Production AreaNavdeep ChaudharyAinda não há avaliações

- Ashok ResumeDocumento5 páginasAshok ResumeRamboAinda não há avaliações

- KadakDocumento84 páginasKadakRavindra WalkundeAinda não há avaliações

- 3 2 - MicrobiologicalQualityControl 1Documento37 páginas3 2 - MicrobiologicalQualityControl 1Tong ChanAinda não há avaliações

- Abbreviations and acronyms in pharmacovigilanceDocumento4 páginasAbbreviations and acronyms in pharmacovigilanceCuriousMan87100% (1)

- GMP Audit Checklist for WHO ComplianceDocumento32 páginasGMP Audit Checklist for WHO ComplianceNavdeep Chaudhary100% (1)

- Bromelain MonographDocumento5 páginasBromelain MonographLizbeth Aura CebrianAinda não há avaliações

- HOKLAS - SC-20 Procedure For Validation MethodDocumento17 páginasHOKLAS - SC-20 Procedure For Validation MethodAgeng Wahyu PatrianitaAinda não há avaliações

- SOP For Operation of Carton Coding MachineDocumento3 páginasSOP For Operation of Carton Coding MachineJayant Kumar JhaAinda não há avaliações

- 2019 04 29 SSC Presentation To SDG AcceleratorDocumento23 páginas2019 04 29 SSC Presentation To SDG AcceleratorLaura CristanchoAinda não há avaliações

- WHOPIR LPR 04-06dec2019Documento13 páginasWHOPIR LPR 04-06dec20196E.57Pawar RushiAinda não há avaliações

- Type III DMF White Papr (1) .Rev 1 Final - Doc5!8!023Documento65 páginasType III DMF White Papr (1) .Rev 1 Final - Doc5!8!023bot38100% (2)

- Asean Process Validation GuidelineDocumento6 páginasAsean Process Validation GuidelineWilliam Chandra100% (1)

- Medical Device Import Rules in IndiaDocumento4 páginasMedical Device Import Rules in IndiaRavia SharmaAinda não há avaliações

- Documents To Be Produced For Inspection: Water SystemDocumento2 páginasDocuments To Be Produced For Inspection: Water SystemNaveenbabu SoundararajanAinda não há avaliações

- Protocol PQDX 241 v4 Capillary BloodDocumento18 páginasProtocol PQDX 241 v4 Capillary Bloodludi100% (1)

- BiosimilarsDocumento22 páginasBiosimilarsMichel HalimAinda não há avaliações

- Validation of sterile facilitiesDocumento41 páginasValidation of sterile facilitieskavya nainitaAinda não há avaliações

- 51 PDFDocumento3 páginas51 PDFChetalee NaikAinda não há avaliações

- SOP Bacterial Endotoxin LAL TestDocumento3 páginasSOP Bacterial Endotoxin LAL TestKranti yadavAinda não há avaliações

- Clinical: Trials ApprovalDocumento39 páginasClinical: Trials Approvaliftekhar islamAinda não há avaliações

- Upsteam ProcessingDocumento21 páginasUpsteam ProcessingAdithyaAinda não há avaliações

- Biopharmaceutical Considerations in Drug Product Design and in Vitro Introduction (Biopharm)Documento22 páginasBiopharmaceutical Considerations in Drug Product Design and in Vitro Introduction (Biopharm)vipinkv99Ainda não há avaliações

- Gu A Clasificaci N de Desviaciones Enfoque Riesgo 1625141315Documento30 páginasGu A Clasificaci N de Desviaciones Enfoque Riesgo 1625141315Helena Herrada ManchónAinda não há avaliações

- Risk Classification Drug GMP Observations 0023 Eng CANDA OJODocumento30 páginasRisk Classification Drug GMP Observations 0023 Eng CANDA OJOEddy TeranAinda não há avaliações

- Business Continuity Plan FormsDocumento16 páginasBusiness Continuity Plan Formsjefftroy92% (13)

- Self Assessments PDFDocumento24 páginasSelf Assessments PDFjefftroyAinda não há avaliações

- Prepare Small Business with BCP ChecklistDocumento1 páginaPrepare Small Business with BCP ChecklistjefftroyAinda não há avaliações

- ERM StructuredDocumento20 páginasERM StructuredaymanaymAinda não há avaliações

- Ethical CrackingDocumento6 páginasEthical Crackingjefftroy100% (1)

- ACL Tip - "Unfreezing ACL" - ITauditSecurityDocumento4 páginasACL Tip - "Unfreezing ACL" - ITauditSecurityjefftroyAinda não há avaliações

- Love Poetry (Literature)Documento2 páginasLove Poetry (Literature)jefftroyAinda não há avaliações

- Trade AgreementsDocumento13 páginasTrade AgreementsjefftroyAinda não há avaliações

- Client-Server Application Testing Plan: EDISON Software Development CentreDocumento7 páginasClient-Server Application Testing Plan: EDISON Software Development CentreEDISON Software Development Centre100% (1)

- Passenger Safety HandlingDocumento7 páginasPassenger Safety Handlingjefftroy100% (1)

- Manufactured StructuresDocumento108 páginasManufactured StructuresjefftroyAinda não há avaliações

- PwC-Internal Audit 2012Documento68 páginasPwC-Internal Audit 2012Sasono Adi100% (2)

- Commonwealth Risk Management PolicyDocumento7 páginasCommonwealth Risk Management PolicyjefftroyAinda não há avaliações

- Annotated Math HWDocumento8 páginasAnnotated Math HWjefftroyAinda não há avaliações

- General Paper Sample PDFDocumento2 páginasGeneral Paper Sample PDFcamilapatiAinda não há avaliações

- IMRAD - G1 PepperDocumento13 páginasIMRAD - G1 PepperRomero, Ken Angelo B.Ainda não há avaliações

- 4608 Eed 01Documento29 páginas4608 Eed 01NickAinda não há avaliações

- Chapter 7 (Additional Notes) Thermodynamics Review (Power Plant Technology by M Wakil)Documento29 páginasChapter 7 (Additional Notes) Thermodynamics Review (Power Plant Technology by M Wakil)Aries SattiAinda não há avaliações

- Forecasting ExercisesDocumento2 páginasForecasting ExercisesAsh VinaAinda não há avaliações

- Crimson Holdings Fact Sheet As of April 14Documento3 páginasCrimson Holdings Fact Sheet As of April 14WDIV/ClickOnDetroitAinda não há avaliações

- Tap Yourself FreeDocumento134 páginasTap Yourself Freenguyenhavn100% (2)

- Adeptus Evangelion 2.5 - Operations ManualDocumento262 páginasAdeptus Evangelion 2.5 - Operations ManualGhostwheel50% (2)

- Art-App-Module-12 Soulmaking, Improvisation, Installation, & TranscreationDocumento4 páginasArt-App-Module-12 Soulmaking, Improvisation, Installation, & TranscreationJohn Mark D. RoaAinda não há avaliações

- Termites and Microbial Biological Control StrategiesDocumento30 páginasTermites and Microbial Biological Control StrategiesMuhammad QasimAinda não há avaliações

- Nakshatra Exaltation DebilitationDocumento3 páginasNakshatra Exaltation DebilitationBhanu Pinnamaneni100% (1)

- LOD Spec 2016 Part I 2016-10-19 PDFDocumento207 páginasLOD Spec 2016 Part I 2016-10-19 PDFzakariazulkifli92Ainda não há avaliações

- Gerovital anti-aging skin care product guideDocumento10 páginasGerovital anti-aging skin care product guideכרמן גאורגיהAinda não há avaliações

- Pentecostal Ecclesiology: Simon K.H. Chan - 978-90-04-39714-9 Via Free AccessDocumento156 páginasPentecostal Ecclesiology: Simon K.H. Chan - 978-90-04-39714-9 Via Free AccessStanley JohnsonAinda não há avaliações

- 10risk Assessment and ComahDocumento25 páginas10risk Assessment and ComahHansraj RahulAinda não há avaliações

- 5s OfficeDocumento10 páginas5s OfficeTechie InblueAinda não há avaliações

- BiologyDocumento21 páginasBiologyHrituraj banikAinda não há avaliações

- BELL B40C - 872071-01 Section 2 EngineDocumento38 páginasBELL B40C - 872071-01 Section 2 EngineALI AKBAR100% (1)

- Tipologie Break in OutDocumento17 páginasTipologie Break in OutGiorgio FantauzziAinda não há avaliações

- Product CataloguepityDocumento270 páginasProduct CataloguepityRaghuRags100% (1)

- Celiac DiseaseDocumento14 páginasCeliac Diseaseapi-355698448100% (1)

- Biology BIOL 1003 CH 1-3 QuizDocumento14 páginasBiology BIOL 1003 CH 1-3 QuizYummyWords100% (1)

- Print Date:: Container No NO Size Seal No Seal Party Supplier Status Movement TypeDocumento3 páginasPrint Date:: Container No NO Size Seal No Seal Party Supplier Status Movement TypeYudha PermanaAinda não há avaliações

- GSM Modernization Poster2Documento1 páginaGSM Modernization Poster2leonardomarinAinda não há avaliações

- Specs Mantilla UV BT8800 Oct 2014Documento2 páginasSpecs Mantilla UV BT8800 Oct 2014Julio MendezAinda não há avaliações

- Typhoon Ulysses Philippines Deadly StormDocumento2 páginasTyphoon Ulysses Philippines Deadly Stormjai mansosAinda não há avaliações

- Radar PPNDocumento5 páginasRadar PPNSawaf MfAinda não há avaliações

- Welcome To International Journal of Engineering Research and Development (IJERD)Documento9 páginasWelcome To International Journal of Engineering Research and Development (IJERD)IJERDAinda não há avaliações

- 37th APSDC Scientific PresentationsDocumento7 páginas37th APSDC Scientific PresentationsSatyendra KumarAinda não há avaliações

- Electrical EngineerDocumento3 páginasElectrical Engineer12343567890Ainda não há avaliações

- Porta by AmbarrukmoDocumento4 páginasPorta by AmbarrukmoRika AyuAinda não há avaliações

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNo EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaAinda não há avaliações

- Sully: The Untold Story Behind the Miracle on the HudsonNo EverandSully: The Untold Story Behind the Miracle on the HudsonNota: 4 de 5 estrelas4/5 (103)

- Highest Duty: My Search for What Really MattersNo EverandHighest Duty: My Search for What Really MattersAinda não há avaliações

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureNo EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureNota: 5 de 5 estrelas5/5 (124)

- Pale Blue Dot: A Vision of the Human Future in SpaceNo EverandPale Blue Dot: A Vision of the Human Future in SpaceNota: 4.5 de 5 estrelas4.5/5 (586)

- The Fabric of Civilization: How Textiles Made the WorldNo EverandThe Fabric of Civilization: How Textiles Made the WorldNota: 4.5 de 5 estrelas4.5/5 (57)

- A Place of My Own: The Architecture of DaydreamsNo EverandA Place of My Own: The Architecture of DaydreamsNota: 4 de 5 estrelas4/5 (241)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationNo EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationNota: 4.5 de 5 estrelas4.5/5 (46)

- 35 Miles From Shore: The Ditching and Rescue of ALM Flight 980No Everand35 Miles From Shore: The Ditching and Rescue of ALM Flight 980Nota: 4 de 5 estrelas4/5 (21)

- Data-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseNo EverandData-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseNota: 3.5 de 5 estrelas3.5/5 (12)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestNo EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestNota: 4 de 5 estrelas4/5 (28)

- Recording Unhinged: Creative and Unconventional Music Recording TechniquesNo EverandRecording Unhinged: Creative and Unconventional Music Recording TechniquesAinda não há avaliações

- Packing for Mars: The Curious Science of Life in the VoidNo EverandPacking for Mars: The Curious Science of Life in the VoidNota: 4 de 5 estrelas4/5 (1395)

- The Future of Geography: How the Competition in Space Will Change Our WorldNo EverandThe Future of Geography: How the Competition in Space Will Change Our WorldNota: 4.5 de 5 estrelas4.5/5 (4)

- Across the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsNo EverandAcross the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsAinda não há avaliações

- The Mushroom at the End of the World: On the Possibility of Life in Capitalist RuinsNo EverandThe Mushroom at the End of the World: On the Possibility of Life in Capitalist RuinsNota: 4 de 5 estrelas4/5 (139)

- The Big, Bad Book of Botany: The World's Most Fascinating FloraNo EverandThe Big, Bad Book of Botany: The World's Most Fascinating FloraNota: 3 de 5 estrelas3/5 (10)

- A Garden of Marvels: How We Discovered that Flowers Have Sex, Leaves Eat Air, and Other Secrets of PlantsNo EverandA Garden of Marvels: How We Discovered that Flowers Have Sex, Leaves Eat Air, and Other Secrets of PlantsAinda não há avaliações

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindAinda não há avaliações

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNo EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansAinda não há avaliações

- Inventor of the Future: The Visionary Life of Buckminster FullerNo EverandInventor of the Future: The Visionary Life of Buckminster FullerNota: 4 de 5 estrelas4/5 (10)

- Fallout: The Hiroshima Cover-up and the Reporter Who Revealed It to the WorldNo EverandFallout: The Hiroshima Cover-up and the Reporter Who Revealed It to the WorldNota: 4.5 de 5 estrelas4.5/5 (82)

- Reality+: Virtual Worlds and the Problems of PhilosophyNo EverandReality+: Virtual Worlds and the Problems of PhilosophyNota: 4 de 5 estrelas4/5 (24)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseNo EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseNota: 4.5 de 5 estrelas4.5/5 (50)

- The End of Craving: Recovering the Lost Wisdom of Eating WellNo EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellNota: 4.5 de 5 estrelas4.5/5 (80)