Escolar Documentos

Profissional Documentos

Cultura Documentos

3BHS 126124 RevD - Extended Automation Solutions - LR

Enviado por

Patran ValentinDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

3BHS 126124 RevD - Extended Automation Solutions - LR

Enviado por

Patran ValentinDireitos autorais:

Formatos disponíveis

Extended automation

Integrated solutions for

cement industries

2 Working together | Extended automation

Working together, every step of the way.

Qassim Cement Company (QCC), located 360 km north of Riyadh in the Kingdom of Saudi Arabia

Extended automation | Working together 3

The challenge

Youre under more pressure than ever before to run your

operation profitably to achieve greater results with fewer

resources. In the past, optimizing process control defined

excellent performance. However, with changing market

demands requiring faster turnarounds, greater customization,

smaller lot sizes and lower overall cost, production gains

through process control improvements are not enough to

guarantee success.

In todays fast paced global economy, competitive advantages

result when a company can tap into its assets unused pro-

ductivity, safely and effectively, to meet changing demands.

With the Industrial

IT

extended automation System 800xA,

ABB provides you with the technology and solutions needed

to achieve a sustainable competitive advantage by enabling

your plant to perform smarter, safer and better at substantial

cost savings.

Have you achieved operational excellence?

Operational excellence is achieved when continuous improve-

ment strategies, in conjunction with real-time feedback and

analysis tools, maximize production and asset availability

safely, optimize quality, and ensure predictable and appropri-

ate plant performance. You face daily operational issues:

How quickly do you react not only to process upsets, but also

changes in demand or product mix? Is the right information

available to the right people in a usable format, or must they

search several different systems to gather the data? Are you

overspending on preventive maintenance?

Are you constantly reacting to equipment failures rather than

proactively identifying poor performers? Does your end

product consistently meet quality standards? At ABB, our

tools provide more than a one-time improvement in perform-

ance, and continue to meet the challenges youre faced with

on a daily basis. With System 800xA, the result is ongoing

improvement in your overall productivity and profitability,

ultimately leading you to operational excellence.

Qassim Cement Company (QCC), located 360 km north of Riyadh in the Kingdom of Saudi Arabia

4 The gold standard | Extended automation

Setting the gold standard of automation.

Control room at Jura Cement plant, located in Wildegg, Switzerland

Extended automation | The gold standard 5

Industrial

IT

System 800xA extends the reach of traditional

automation systems beyond control of the process to

achieve the productivity gains necessary to succeed in todays

business markets. For the first time, this scope is accessible

from a single user interface that is configured to present

information and provide interaction in a context appropriate

to all user disciplines.

Extended automation objects created within the engineering

environment provide a foundation for the efficient develop-

ment, deployment, reuse, and continuous improvement of

production and safety applications with predictability unattain-

able from other automation solutions.

Compounding value throughout the enterprise

System 800xAs unique operating environment allows you to

incorporate best in class products, applications and services

from the worlds largest automation supplier. Built on the

Industrial

IT

Aspect Object technology platform and industry

specific expertise, ABBs automation portfolio provides the

seamless link between process, safety, and business manage-

ment to deliver knowledge based solutions.

Protecting your investments

System 800xA is the latest installment of ABBs 20+ year

commitment to our process control system users. Our pledge

of Evolution through Enhancement ensures that future

advances in systems technologies will enhance rather than

compromise your current investments. With System 800xA,

you have the ability to extend the automation reach of your

present system to enjoy new levels of productivity.

System 800xA provides the flexibility to implement the

functions you require today and the agility to add others

as needs evolve. Where others promote rip and replace

migration strategies, we deliver true system evolution,

allowing you to build on your strong process control system

foundation.

Control room at Jura Cement plant, located in Wildegg, Switzerland

6 Collaborative production management | Extended automation

Improve your cement

production with collaborative

production management.

Increase efficiency, reduce costs and document your

performance

Collaborative Production Management (CPM) solutions

integrate manufacturing systems providing visibility, exe-

cution, tracking, reporting and optimization of cement

industries.

This results in decreasing costs through better scheduling,

execution and performance management. Ultimately CPM

solutions support increasing revenues through improved

processes and product quality, increasing profits and enhanc-

ing shareholders value.

Integrated CPM solutions provide you with consolidated,

consistent and clean information

With ABBs CPM solutions all operation, control, optimization

and business systems are integrated as one. You are certain

to obtain true integration of process, business, quality and

energy data. The information is provided on a transparent

platform in which information is accessible to all users in a

consistent way and in clean, consolidated reports.

Take faster and more accurate business decisions based

on manufacturing information

You need Enterprise Resource Planning (ERP) systems to know

how your business is performing. In a similar way you need to

know how your plant is performing. With CPM solutions that

integrate business and manufacturing systems you will react

Enterprise Resource Planning (ERP) systems

Orders/Prices/Costs

Process control system

Process data/On-line analyzers/Alarms

Collaborative Production

Management (CPM) solutions

Optimization

Energy Manager

Expert Optimizer

Loop Performance Manager

Information

Smart Client

Enterprise Connectivity

Knowledge Manager

LIMS

Raw data

Optimal moves

Information

Raw data

Maximum process capacity

Optimized setpoint

Optimize

Manual setpoint

Benefits

due to

optimization

Time

P

r

o

c

e

s

s

t

h

r

o

u

g

h

p

u

t

Manual Automatic, using Expert Optimizer

Stabilize

Expert Optimizer stabilize then optimize

Extended automation | Collaborative production management 7

faster to changing manufacturing conditions, and take more

accurate decisions based on real-time information.

Make goal oriented decisions to meet your production

targets

You need to evaluate if you are on target to meet your

production, operational and quality objectives. With Know-

ledge Manager you will be making goal oriented decisions by

accessing the information you need at the right time, place

and format. You will get analytical insights to identify devia-

tions and best practices to keep your production on target.

Providing solutions suited to the cement industry, the Know-

ledge Manager system supports you with:

monitoring manufacturing performance indicators.

production accounting and inventory management.

process operations and energy reporting.

downtime management.

integration with ERP systems.

Enhance your material balancing and production reporting

processes

Material balancing is a time consuming routine activity which

is, at the same time, vital because your production reporting

must reflect the reality of the business.

With our solutions for production accounting you will have

less administration tasks while ensuring consistency across

consumption measurements, production measurements and

confirmed stock levels.

Optimize your laboratory operation

The Laboratory Information Management System (LIMS)

supports you in complying with your business processes.

Providing a standardized and simplified workflow LIMS allows

you to concentrate on the results and maintains laboratory

productivity at its best level. With seamless integration to the

production information system, quality results are promptly

provided to the plant operation, production and sales teams.

With LIMS you will obtain:

optimized laboratory workflows.

industry specific validation procedures.

support for collaboration among laboratories.

control of instrument calibration.

Increase with efficiency robot supported applications

for laboratories

Increasing consistency, efficiency and cost-effectiveness of

sampling and testing operations are key benefits of ABBs

robot supported applications for laboratories. The higher and

more reliable throughput and performance of an automated

laboratory not only guarantees quicker available results but

also increases the use of capital investment in expensive

analysis equipment.

Improve performance by using intelligent solutions for

complex problems

With the award winning Expert Optimizer you can implement

advanced process optimization to improve productivity,

energy efficiency and profitability. Expert Optimizer will

effectively manage process complexity to help you achieving

the best possible performance.

You will achieve better control and optimal operating points

for processes such as:

Raw materials grinding and blending

Pre-calciner, kiln and cooler

Handling of alternative fuels

Cement grinding and blending

Expert Optimizers graphical and intuitive engineering interface

combines technology such as Fuzzy Logic, Neural Network

and Model Predictive Control to deliver an optimal solution to

your problem.

Maintain product quality

ABBs optimization solutions will help you achieve minimum

quality fluctuations at the highest production rate.

Maximize energy efficiency

With the process stabilized through all operating regions

unseen level of energy efficiency and production will be

reached.

Minimize energy costs

Reduce electrical and thermal energy cost by including

consumption and market constraints in your optimization

strategies.

Tap the vast experience of ABBs process engineers

In addition to their own process knowledge, customers can

tap the vast experience of ABBs process engineers to

develop the strategy best suited to optimize their dynamic

process.

8 Modular, flexible solutions | Extended automation

Modular, flexible solutions based on ABBs System 800xA

Integration of power and automation

A reliable and dependable energy supply is vital for the

functioning of any industry. Monitoring and controlling the

power is just as important as monitoring and controlling

any other significant process automation parameter. But in

reality the two are worlds apart separated by a lack of

common communication and architectural standards as well

as organizational differences between departments.

Electrical integration means integrating process automation

and power automation into the same plant control system.

This creates a single automation environment that unifies the

control of process-related equipment as well as protection,

control and monitoring of substation equipment and power

transmission and distribution. Integrating the process auto-

mation system with the power automation system permits a

single strategy in the areas of engineering, operations and

maintenance. Whether you generate power or consume it, the

economic benefits of electrical integration can run into

millions of dollars gained in increased production or saved in

reduced operating costs.

Power distribution

There are many benefits of electrical and automation integra-

tion having typical SCADA functions in the automation

system. A single view of both electrical and automation

systems is provided without additional process system I/O,

complex software interfaces, and marshalling racks. It also

gives plant personnel greater flexibility in controlling the entire

facility. Unified operations reduce duplication of equipment,

make staff more effective, and reduce training costs.

Extended asset management capabilities enable both process

and electrical condition-based monitoring to be done with

one system.

Process electrification

MV and LV equipment supervised and controlled from one

single system.

Example use case: a medium voltage (MV) mill motor has

been inhibited and cannot be restarted from the process

display. The operator can immediately switch to the electrical

single line diagram (SLD) display and check the circuit breaker

status. He can also view the integrated CCTV (closed circuit

television) and review online design documents, all from a

single operator station. With the integrated information, plant

operators can make informed decisions quickly based on

good, relevant, known data.

Electrical energy management

The possibility of measuring the electrical power consumption

in each process department enables individual supervision

and optimization of energy consumption.

Optionally, the system can shut down process units according

to (predictive) power limits or financial constraints. The shut

down will be performed in a controlled manner using the

process control application.

Process instrumentation

System 800xA supports all the contemporary standard

interfaces to connect to process instrumentation.

Intelligent device management and asset monitoring function-

ality lowers life cycle costs through significant savings in the

design, implementation, operation, and maintenance costs of

field equipment.

Plant operations

The growing deployment of peripheral applications related to

productivity improvement vastly increases the amount of data

available to improve productivity in the plant. Yet, without the

proper context, plant personnel can be exposed to informa-

tion overload.

Unique to System 800xA is its ability to gather information

from multiple plant sources and transform it into relevant

information for a diverse set of users such as maintenance

technicians, process engineers, production managers, or

plant operators.

For example, operators require an environment that allows

them to run the plant in a safe way and produce products in

the required quantity and quality.

Operations managers require an environment that lets them

know the return on investment, risk, uptime, and production

and maintenance costs at any given time.

Engineers need an environment that will allow them to

implement a specification change to their running plant in the

shortest time with the lowest cost and at the lowest risk.

Maintenance and service personnel need information to

ensure the maximum availability of plants and applications.

9 Modular, flexible solutions | Extended automation

Production

Power distribution

SCADA

Process electrification

LV & MV

Process control

Instrumentation

AC drives

Operation Engineering

ERP & Business systems Communication link

Headquaters

Extended operator workplace

System

servers

ECS, ISA-95, OPC

Local

operation

I/O

Firewall

Router

Controller

AC 800M

3rd party

PLCs

Extended automation | Modular, flexible solutions 10

AC drives

Process

optimization

Mobile

units

Heat

recovery

Process optimization

Production management Mobile Remote

Maintenance

Operation Engineering

Messenger

LIMS, production accounting,

material management

Controller

AC 800M

Grinding

optimization

Material online

analysis,

Slurry online

measurement

Robot supported

applications for

laboratories

Kiln

optimization

Raw mix

optimization

Stockpile

optimization

Wireless

Controller

AC 800M

Extended automation | Modular, flexible solutions 11

State of the art large screen operator workplace

System 800xA extended operator workplace, based on the 800xA

process portal, projects a perfect picture of the industrial process

data on a contoured, large-screen overview. Unlike many large

displays that seem designed merely to impress control room visi-

tors, the extended operator workplace gives operators the

functions that matter most to them: an outstanding interactive,

high-resolution display, full and easy-to-read information, an intui-

tive interface, effective alarm and trend display management,

process interaction, and ergonomics that raise safety, comfort and

efciency to new levels.

Mobile and remote access

Use of commonly available IT and networking methods allows

access to practically any production and maintenance information

through to remote operation of the plant at virtually any place over

the globe.

Performing engineering actions in the system is also not limited to

the plant location but can be done remotely.

Integrating existing control systems

Native use of OPC and other current communication standards

provides the upmost exibility for integerating other control sys-

tems into 800xA. Interfaces with many commonly used systems

are already available to be used in a plug and play manner.

Enabling predictive and proactive maintenance

Asset optimization software exploits the wealth of plant resident

information to assess and report equipment conditions in real-

time, reduce costly corrective and preventive maintenance and

optimize maintenance and calibration work ows.

System 800xA maintenance management features make informa-

tion within the CMMS (computerized maintenance management

system), for example MRO Maximo

and SAP PM

, transparently

accessible to users in both the process control and maintenance

system environments. Seamless context-sensitive interaction is

provided through standard System 800xA CMMS displays, such

as active work orders, work order history, preventive maintenance

schedules and available spare parts.

System 800xA optimizes the work process and signicantly

reduces the latent time between problem identication and

resolution.

ABB Minerals Application Library

Modern object oriented system architecture enables the

structured application of software design with pre-defined and

tested functions. The ABB Minerals Library provides tools and

functions to cover typically 8090 % of the standard control

functions of a minerals process out of the box.

Material transport and routing

Grinding mill control

Weighing and feeding controls

The electrical control and power management functionality

The result is less engineering, commissioning and maintenance

time over the whole life cycle of the installation.

Engineering

Integrated engineering environment efciently supports the com-

plete life cycle of the automation project, from planning, through

conguration and library management, to commissioning and

operation to minimize system ownership costs.

Using dynamic documents, you can quickly navigate to the dis-

plays required for action. Documents based on Microsoft Excel

,

Word

, or AutoCAD

can be enhanced with live process values for

easier diagnostics.

Heat recovery

ABB is focusing on energy saving and environment care. There-

fore, we have designed the turnkey solution of a small power

station to use the waste heat of the industrial process in the range

of 150 to 350 C.

The increasing cost of energy and the requests to reduce the CO

content are the market drivers for this solution. ABB can produce

electrical energy without using additional fossil energy. In different

countries, our customers may get benets from governmental

organizations, like CO certicates etc. to support their invest-

ments. This small power station also gives the customer a partial

independence from the power supply of the utility board. Particu-

larly in areas where the permanent power delivery cannot be

guaranteed.

12 Engineering, commissioning, training | Extended automation

Capitalize on field-proven solutions.

Extended automation | Engineering, commissioning, training 13

Efficient installation and commissioning

The most professionally designed electrification and process

control application can be almost worthless, unless the

installation and commissioning is in experienced hands. With

ABBs professional engineering and commissioning team,

excellent project management and well-proven installation

supervision, we ensure that your plant is operational in the

shortest time and at lower cost. Installation and commission-

ing is always planned in fine detail and ABB expertise ensures

a quick response to any unforeseen issues. In ABB, you can

rely on a partner, which is able to provide the widest possible

range of services, experience and expertise.

Maximize personnel efficiency

ABB training programs are highly effective, with an optimized

mix of theory and practical hands-on exercises to guarantee

better knowledge transfer that will lead to increased produc-

tivity. Over 250 focused courses and curriculums are available

within the global ABB University network covering a wide

range of automation products, specific application solutions

and process related programs. More than 30 courses and

seminars are specially tailored for cement industry customers

and can be delivered at dedicated ABB training centers in

various locations or if requested, and for more flexibility at

customer sites

Typical course program:

Process control system

Industrial

IT

800xA applications with Minerals Library

Configuration and operation

Industrial

IT

800xA engineering with PDA tool and Control

Builder M

Industrial

IT

800xA maintenance and troubleshooting

Plant electrification

HV and MV switchgear

Intelligent low voltage power distribution system

Protection relays

Drives applications

Gearless mill drives

Variable speed drives

Low voltage AC drives

Low voltage DC drives

Solutions for plant optimization

Expert Optimizer

Knowledge Manager

Laboratory Information Management System

Raw Mix Preparation

SpectraFlow analyzer

Visit ABBs training homepage to obtain more information

on the current offering (course locator) and actual schedules

at www.abb.ch/abbuniversity or send us an e-mail:

minerals.training@ch.abb.com

14 Commitment | Extended automation

Commitment to the

cement industry.

ABB is committed to the cement industry. Since 1961, ABBs

dedicated Center of Excellence in Switzerland has continually

developed standards for the cement industry.

During the last 50 years, ABB has delivered successful

process control systems for more than 600 cement

plants worldwide. More than 200 of these applications are

complete plant installations in over 40 countries.

ABB is a leading global supplier of process control systems

to the mineral processing industry. Its engineering depart-

ments, with their industry-specific validation procedures,

ensure consistently high quality in automation technologies.

Cam Pha Cement plant, located in Cam Pha town in Vietnams northern Quang Ninh province

Extended automation | Never far away 15

Customer care

ABB is never far away.

Challenge us on support services

With offices in almost every country, ABB provides local

support and engineering facilities that are always close at

hand, for the fastest and most efficient backup possible.

You can count on ABBs long-term commitment to provide

ongoing service and support throughout the life cycle of your

plant. Our portfolio includes services such as:

Technical support and remote services

Service agreements

System upgrades

Maintenance and retuning services

Process optimization consultancy

Spare parts and repair services

On-site workshops

Training services

You receive fast responses to your specific requests by

contacting our SupportLine:

Phone: +41 (0)844 845 845, available 24 hours per day,

365 days per year

Telefax: +41 (0)58 586 73 08

E-Mail: minerals.supportline@ch.abb.com

ABB SolutionsBank homepage:

http://solutionsbank.abb.com

2

0

1

0

A

B

B

.

A

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

3

B

H

S

1

2

6

1

2

4

Z

A

B

E

0

1

R

E

V

.

D

(

0

9

.

1

0

5

0

0

K

p

f

l

i

&

P

a

r

t

n

e

r

)

Contact us

ABB Switzerland Ltd

Local Business Unit Minerals

Segelhofstrasse 9P

5405 Baden 5 Dttwil

Switzerland

Phone: +41 58 586 84 44

Fax: +41 58 586 73 33

E-mail: process.industries@ch.abb.com

ABBs Minerals business unit is represented in the following

countries:

Australia, Brazil, Canada, Chile, China, Egypt, Estonia, Germany,

Greece, India, Indonesia, Latvia, Lithuania, Malaysia, Mexico,

Norway, Oman, Peru, Poland, Saudi Arabia, South Africa, Spain,

Sweden, Switzerland, Thailand, USA and Vietnam.

For contact details, please visit our website:

www.abb.com/cement

Você também pode gostar

- 2 Wire-Run FWD REV-Enable-Aux Fault-Clear Fault PDFDocumento1 página2 Wire-Run FWD REV-Enable-Aux Fault-Clear Fault PDFPatran ValentinAinda não há avaliações

- Xl3-Configurable-Assemblies Tablou PDFDocumento20 páginasXl3-Configurable-Assemblies Tablou PDFPatran ValentinAinda não há avaliações

- Schneider LV Switchboard Inspection GuideDocumento59 páginasSchneider LV Switchboard Inspection GuideAlp Arslan Ok100% (1)

- Sace Tmax XT: Circuit-Breaker Terminals and ConnectionDocumento28 páginasSace Tmax XT: Circuit-Breaker Terminals and ConnectionPatran ValentinAinda não há avaliações

- Centrale HidroDocumento118 páginasCentrale HidroPatran ValentinAinda não há avaliações

- Drive Solutions For The Cement Industry: DrivesystemsDocumento12 páginasDrive Solutions For The Cement Industry: DrivesystemsPatran ValentinAinda não há avaliações

- TESAR Installation Use and Maintenance EngDocumento20 páginasTESAR Installation Use and Maintenance EngPatran ValentinAinda não há avaliações

- O G Power Dist Application GuideDocumento24 páginasO G Power Dist Application GuidePatran ValentinAinda não há avaliações

- 6 Low VoltageDocumento15 páginas6 Low VoltagePatran ValentinAinda não há avaliações

- 1LAC000003 DistTrHandbookDocumento92 páginas1LAC000003 DistTrHandbookkastanis_3Ainda não há avaliações

- Brushless Excitation Systems UpgradeDocumento26 páginasBrushless Excitation Systems UpgradePatran ValentinAinda não há avaliações

- 4-Hidroelectric Power Plants - Automation Using Iec 61850 - Experiences and Improvements For The UserDocumento23 páginas4-Hidroelectric Power Plants - Automation Using Iec 61850 - Experiences and Improvements For The UserPatran ValentinAinda não há avaliações

- Netzwerkloesungen Mit IEC 61850-3 - IEEE 1613 Von MoxaDocumento68 páginasNetzwerkloesungen Mit IEC 61850-3 - IEEE 1613 Von MoxaPatran ValentinAinda não há avaliações

- Sipol: Transistorized Excitation Systems For Synchronous GeneratorsDocumento12 páginasSipol: Transistorized Excitation Systems For Synchronous GeneratorsPatran Valentin100% (1)

- Hydro Turbine Speed Governing SystemDocumento12 páginasHydro Turbine Speed Governing SystemPatran ValentinAinda não há avaliações

- MELFA Works - Instruction Manual BFP-A8525-D (11.08)Documento95 páginasMELFA Works - Instruction Manual BFP-A8525-D (11.08)Patran Valentin100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Brochure Construction DG-GROW March2016Documento16 páginasBrochure Construction DG-GROW March2016johnAinda não há avaliações

- Topic 1 Plant Planning and Power DemandDocumento34 páginasTopic 1 Plant Planning and Power Demandblaze emberAinda não há avaliações

- Design of Air Pre Heater and EconomizerDocumento4 páginasDesign of Air Pre Heater and EconomizerRyan PerezAinda não há avaliações

- DNV Os 101Documento80 páginasDNV Os 101preceptiveinquirerAinda não há avaliações

- Catalog ABB 2018Documento42 páginasCatalog ABB 2018Razvan Pislaru0% (1)

- PP SK655 755 ENeDocumento64 páginasPP SK655 755 ENeAlexandar Davidov100% (1)

- Testing and CommissioningDocumento7 páginasTesting and CommissioningHussain ElboshyAinda não há avaliações

- En SUNLIGHT Reserve Power Batteries VRLA SPA Sales Web1Documento7 páginasEn SUNLIGHT Reserve Power Batteries VRLA SPA Sales Web1didier_oAinda não há avaliações

- NABCEP PV Installer Resource Guide Dec2011Documento162 páginasNABCEP PV Installer Resource Guide Dec2011amma_rmunir100% (3)

- BP Easington - Rolls Royce Avon Gas Generator For Sale - 38305Documento8 páginasBP Easington - Rolls Royce Avon Gas Generator For Sale - 38305gertodoAinda não há avaliações

- Masoneilan - 10000 Series Spec Data PDFDocumento20 páginasMasoneilan - 10000 Series Spec Data PDFFelixAvilaAinda não há avaliações

- The Trial Transcript Will Be Made Available To The Public Once It Has Been Certified and Distributed by The Official Court ReporterDocumento234 páginasThe Trial Transcript Will Be Made Available To The Public Once It Has Been Certified and Distributed by The Official Court ReporterOSDocs2012Ainda não há avaliações

- OXYGENATESDocumento4 páginasOXYGENATEStotpityiAinda não há avaliações

- Beyond The Plug - Finding Value in The Electric Vehicle Charging EcosystemDocumento44 páginasBeyond The Plug - Finding Value in The Electric Vehicle Charging EcosystemAlfredo González NaranjoAinda não há avaliações

- Heritage BrochureDocumento8 páginasHeritage BrochureIbrahim SahinAinda não há avaliações

- Pset 8Documento11 páginasPset 8anand p s0% (1)

- Contrato PetrobrasDocumento21 páginasContrato PetrobrasEveraldo LuizAinda não há avaliações

- Electrical Drives Paper April 11Documento2 páginasElectrical Drives Paper April 11vinxtremeAinda não há avaliações

- Chhattisgarh State Industrial Development Corporation LimitedDocumento43 páginasChhattisgarh State Industrial Development Corporation LimitedRinku MishraAinda não há avaliações

- Policy Theme Our Customers Effective April 14, 2008Documento28 páginasPolicy Theme Our Customers Effective April 14, 2008Roshan FarsiwanAinda não há avaliações

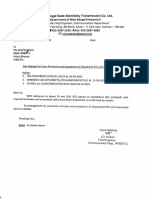

- Request Letter For Acceptance Dispatched RTU and Associated ItemsDocumento2 páginasRequest Letter For Acceptance Dispatched RTU and Associated ItemsGauravKumarAinda não há avaliações

- Parker Sporlan Refrigeration & Air Conditioning Catalogue 2015Documento320 páginasParker Sporlan Refrigeration & Air Conditioning Catalogue 2015Hnin PwintAinda não há avaliações

- Top 25 Grants and RebatesDocumento1 páginaTop 25 Grants and RebatesJoDueckAinda não há avaliações

- Fmea HXDocumento2 páginasFmea HXNora NaranjoAinda não há avaliações

- Chapter 3 - Externalities and Public PolicyDocumento36 páginasChapter 3 - Externalities and Public Policywatts1100% (5)

- Maintenance Patterns and Fmea AnalysisDocumento11 páginasMaintenance Patterns and Fmea AnalysisAdaaAinda não há avaliações

- FSW Patents ListDocumento231 páginasFSW Patents ListpatilsspAinda não há avaliações

- A. I Like To Play TennisDocumento7 páginasA. I Like To Play TennisUntung Edi SaputraAinda não há avaliações

- WM - Jiskoot Sampling OverviewDocumento4 páginasWM - Jiskoot Sampling OverviewSaravanakumar RajagopalAinda não há avaliações

- Cascade Refrigeration SystemsDocumento18 páginasCascade Refrigeration Systemscoc dhinesh100% (1)