Escolar Documentos

Profissional Documentos

Cultura Documentos

10 Steps Guide

Enviado por

Umair Haqqan AminurrahmanDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

10 Steps Guide

Enviado por

Umair Haqqan AminurrahmanDireitos autorais:

Formatos disponíveis

Steps To

Create A World-Class

Oil Analysis Program

InsightServices,Inc.|www.TESTOIL.com|@testoil1

2www.TESTOIL.com

TableofContents

#1IdentifyCriticalEquipment .................................................................................................................................................................. 4

#2DetermineTestPackages..................................................................................................................................................................... 5

#3ConsiderTestingOptions..................................................................................................................................................................... 6

#4ChooseanOilAnalysisLab................................................................................................................................................................... 7

#5InvestinTraining.................................................................................................................................................................................. 8

#6LearnHowtoInterpretanOilAnalysisReport.................................................................................................................................... 9

#7UseProperLubricationStorageandHandling .................................................................................................................................. 10

#8JustifyYourProgram.......................................................................................................................................................................... 11

#9EstablishandMaintainCredibility ..................................................................................................................................................... 12

#10ManageYourProgramUsingWebBasedTools.............................................................................................................................. 13

Conclusion................................................................................................................................................................................................. 14

ContactUs................................................................................................................................................................................................. 14

3www.TESTOIL.comInsightServices,Inc.|www.TESTOIL.com|@testoil1

WhyShouldIReadTenStepsToCreateAWorldClassOilAnalysisProgram?

Oilanalysiscanuncover,isolate,and

offersolutionsforabnormallubricant

andmachineconditionswhenusedas

apredictivemaintenancetool.These

abnormalitiescanresultinexpensive,

sometimescatastrophicdamage

causinglostproduction,extensive

repaircosts,andevenoperator

accidents.

Thegoalofaneffectiveoilanalysis

programistoincreasethereliability

andavailabilityofmachinerywhile

minimizingmaintenancecosts

associatedwithoilchangeouts,labor,

repairs,anddowntime.Accomplishing

thisgoaltakestime,training,and

patience.However,theresultsare

dramaticandthedocumentedsavings

andcostavoidancearesignificant.

Manyorganizationsthroughoutthe

worldhaveimplementedoilanalysis

programstohelpmanageequipment

reliability.Somehaveexperienced

substantialsavings,costreductions,

andincreasedproductivity,while

othershavereceivedonlymarginal

benefits.Asuccessfuloilanalysis

programrequiresadedicated

commitmenttounderstandingthe

equipment,thelubricant,the

operatingenvironment,andthe

relationshipbetweenthetestresults

andactionstobeperformed.

Themostsuccessfuloilanalysis

programsarethosethatare

thoughtfullydesignedaftercareful

evaluationanddevelopmentofclearly

definedgoals.Theemphasisshouldbe

ondesigningqualityandexcellencein

thebeginning,notforcefittingitin

alongtheway.

Thefollowing10stepswillprovidea

guidelineforimplementingan

effectiveoilanalysisprogram:a

programconsideredtobeoneofthe

criticaltechnologiestoincreasing

equipmentreliabilitywhile

maintainingasafeandcosteffective

plantoperation.

4www.TESTOIL.comInsightServices,Inc.|www.TESTOIL.com|@testoil1

#1IdentifyCriticalEquipment

Whenyoustartimplementinganoil

analysisprogram,youneedtodecidewhich

equipmentintheplanttosample.Thiscan

beadauntingtaskbutitcannotbe

overlooked.Supervisorsandmanagement

needtotakethetimetoidentifythe

targetedequipment,writedetailed

procedures,establishroutes,andsampling

schedules.

Equipmentcriticaltoplantoperations

shouldbeidentifiedfirst.Thisequipment

oftendoesnothaveabackupunitto

replaceitwhenitisnotinservice.In

addition,majorrepairsandoverhaulof

criticalequipmentoftenrequireacomplete

plantshutdown,substantialmanpowerand

subsequentlossofproductionactivities.

Criticalequipmentinplantstypicallyhave

thesecommoncharacteristics:

Theyrequireveryhighcapital

investmentandareexpensiveto

maintainandrepair.

Theyareengineeredforlongservice

liveswhenoperatedwithindesign

specificationsandinapredictable

environment.

Manyarequitelargeandaremadeup

ofseveralindividualcomponents.

Downtimeisquiteexpensive

sinceproductionisusually

haltedwhenunexpected

problemsorasystemfailure

isexperienced.

Appropriatetestingforcritical

equipmentincludes,butisnot

limitedto:

Wearmetalanalysis

Moisturecontent

Viscosity

Acidnumber

Analyticalferrography

Particlecounting

5www.TESTOIL.comInsightServices,Inc.|www.TESTOIL.com|@testoil1

#2DetermineTestPackages

Oilanalysistestpackagesshouldbe

carefullyconsidered.Differentequipment

havedifferenttestprofilerequirements.

Whendeterminingwhattestpackagesto

choose,theactualequipmentandthe

surroundingenvironmentshoulddictate

whattestsareappropriate.

Keepinmindthatwithoilanalysisyourgoal

istoincreasemachinereliabilitythrough

improvedfluidconditionandearly

detectionthatotherwisewouldnotbe

obviousunlessitcausesmachinefailures.

Havinganideaaboutwhatthevarioustests

are,whattheycanaccomplish,andtaking

intoaccountthemaintenancephilosophy

beingpracticed,testpackagescaneasilybe

drawnuptoaccomplishthedesiredresults.

Forexample,youmayknowthatsome

equipmentcanberuntofailuremuchless

expensivelythanthecostofperforminga

regularoilanalysis.Ontheotherhand,on

machineswithsmallerreservoirswhenoil

qualityisallthatwouldbemonitored,it

maybebesttocontinuewithregularor

evenincreasedfrequencyofoilchanges.

Ifyouarenotsurewhattestsarerightfor

yourequipment,itisbesttoconsulta

qualitylabforassistanceinthisarea.

Whendeterminingwhattest

packagesyouneed,askyourself

thefollowingquestions:

1. Whatisbeingmonitored,the

machine,thelubricant,or

both?Thesethreeitems

requireadifferentsetoftests.

Eachtypeofmachineshould

haveatestpackagetailoredto

itsneeds.Youshouldalsobegin

adialoguewithanoilanalysis

labtohelpyoudeterminewhat

testpackageswillhelpyou

reachyourgoals.

2. Howoftenwillsamplesbe

takenfromeachmachine?

Dependingonthecriticalityand

typeoftesting,frequencyof

samplingcouldrangefrom

onceaweektoannually.

6www.TESTOIL.comInsightServices,Inc.|www.TESTOIL.com|@testoil1

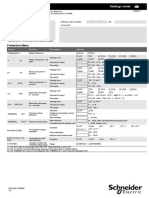

#3ConsiderTestingOptions

Whendesigninganoilanalysisprogram,youhaveafewchoicesonhowtohaveyouroilsamplestested.Thissectionoutlinesthese

optionsandhelpsyouseewhichoneisbestforyourorganization:

Pros Cons

Maintainanonsitelab

Turnaroundtimeforresultscanbecontrolledinhouse.

Notdependentonanoutsideresource.

Testingpackagescanbeeasilychanged.

Quickresponseforemergencysamples.

Costofpurchasingandmaintainlaboratory

instrumentation.

CostofLIMSsoftwareandupdates.

Labtechniciansmustbetrainedforeachtestprocedure

andinterpretationofresults.

Lackofcomprehensivetesting.

Useyourlubricationvendor

Theyhaveexpertiseinunderstandandknowing

lubricationformulations

Lubesuppliersoftenoffertoperformoilanalysisforfree

tolargevolumecustomers.

Convenienceofusingonesupplier.

Lubricantmanufacturersareinbusinesstoselllubricant,

notanalyzeit.

Noaccesstoanalyststodiscusstestresults.

Turnaroundisnotapriority.

Notabusinesstheynecessarilyinvestresourcesinto.

Contractanoutsidelab

Fullcomplementoftestingservices

MostlabsmaintainISOcertification

Highlytrainedlabstaffperformingthetestsina

controlledenvironment.

Experiencedanalystsavailabletodiscusstestresults.

Continualinvestmentinresourcestomaintainthe

highestqualityofservices.

Thecostpersample.

Eachtestperformedonanoilsamplecostsmoney,so

somelabsmaylookatwaystosavemoneyand

potentiallycutcorners.

Someoutsidelabscanbecostlyandslowtodeliver

results.

InsightServices,Inc.|www.TESTOIL.com|@testoil1

7www.TESTOIL.com

#4ChooseanOilAnalysisLab

Ifitisdeterminedthatcontractingan

outsidelabisthebestcourseforyouroil

analysisprogram,caremustbetakento

insurethatthelabisagoodfitforyour

company.Itisimportanttomatchalab

withthepredictivemaintenancestrategies

thatyourplantemploys.

Itshouldbeunderstoodthatsomelabs

catersolelytoindustrialapplicationswhile

othersareprimarilyfocusedonengineoils.

Youshouldbeawareofthis,asitisbestto

contractwithalabthatfocuses100%of

theirtimeservingtheindustrialsector.The

labthatfocusessolelyonindustrial

applicationswillbefamiliarwithyourtype

ofequipmentandtheanalystswillhave

muchmoreexpertiseinanalyzingyourtest

results.Whileanylabwillagreetoperform

yourtesting,thequestionthatmustbe

askedisDoesthelabhavetheexperience

requiredtobemyoilanalysisproviderand

willIreceivethecorrecttests?

Customerserviceisanotherimportant

aspecttoconsiderwhenchoosingalab.In

ordertoresolveissuesquicklyyourlab

shouldbeavailableonyourfirstcall.Itis

importanttonotethatsomelabshave

limitedaccesstoanalystandrelyheavilyon

voicemailservices.

Whenevaluatingalab,consider

thefollowingquestions.

Whatisturnaroundtimeon

samples?

Whatdoespricinginclude?

shippingcost

sitevisitsfromlab

training

rushsamples

supplies

lubeaudits

Willtechnicalhelpbe

available?Doesitcostextra?

Howlongwillthecontract

last?Isthereachargetobreak

thecontract?

Howwillmyresultsbe

communicatedtome?

Doesthelabofferunlimited,

onlineaccesstomydata?

8www.TESTOIL.comInsightServices,Inc.|www.TESTOIL.com|@testoil1

#5InvestinTraining

Oneaspectofareputable,selfsufficientoil

analysisprogramthatisoftenoverlookedis

training.Trainedtechniciansthat

understandhowimportantquality

lubricationproceduresarewillbekeyin

maintainingaprogram.

Staffingofalubricationprogramis

extremelyimportant.Youmayconsider

hiringsomeonewithaproventrackrecord

ofsuccess,howeverdonotoverlookthe

talentyoualreadyhaveinyourplant.There

arelikelyseveralpeoplealreadyinyour

organizationthatwouldbegoodfits.

Onceyourstaffisinplaceyoucanlookat

outsideresourcestoassistwithtraining.

Thereareseveralcompaniesthatoffer

excellenttraininginlubrication

fundamentalsandpracticesandmostwill

bewillingtocometoyoursiteifyouhave

enoughpeopletofillaclass.Donotforget

toincludesupervisorsandmanagers.They

needtobeonboardandbeawareofwhat

isrequiredandthebenefitsthatcanbe

achievedbyimplementinganoilanalysis

program.

Oilanalysisisaneverchangingtechnology

andtoreapitsbenefits,onemust

continuallyreceivequalitytraining.

Trainingoptionsmayinclude:

Classesand/orcertifications.

Tradeshowsandconferences

areanotherwaytohelp

personnelstayontopof

recentadvancesintheirfield.

Departmentbudgetshould

reflecttheseeducational

opportunitiesfromyearto

year.

Foroilanalysistrainingoptions

visit:www.testoil.com

9www.TESTOIL.comInsightServices,Inc.|www.TESTOIL.com|@testoil1

#6LearnHowtoInterpretanOilAnalysisReport

Theoilanalysisreportisavitaltoolfora

smoothrunningoperation.Goingdeeper

thanthereportsummariesandknowing

howtoanalyzetheoilanalysisreportcan

helppreventequipmentbreakdownand

unnecessaryequipmentteardowns.

Typicaloilanalysisreportsfeatureproblem

summaries,lubricantandmachine

conditionstatus,andcriticalalerts.They

shouldalsoincludegraphicaldepictionof

varioustests,aswellasothervisual

elementstoassistintheinterpretationof

thetestresults.

Readinganoilanalysisreportcanbe

overwhelmingunlessyouknowwhatyou

arereading.Tooofteninlubeanalysisthe

failureofaprogramcanbeattributedto

thelackofinterpretationoftheconditions

reportandaninappropriateresponsetothe

results.Whenthishappens,valuable

informationislost.Thereasonforthiscan

largelybeattributedtothelackoftraining

ofyourmaintenanceprofessionals.

Withoutasolidunderstandingofthe

purposeoflubeanalysisandtheabilityto

interprettestresultstheycannotbe

expectedtocarryoutthisduty.

Maintenanceprofessionalsshouldreceive

trainingandeducationinlubeanalysis.In

fact,trainingandeducationshouldoccurat

severaldifferentlevelsandwitheveryone

whocontributestomachinereliability,from

managementallthewaytocraftsmen.

YourLabsResponsibilities

Yourlabshouldalsobeadeptat

interpretingresults.Manylabs

advertisethattheiranalystshave

degrees,butwhenitcomesto

analyzingtestresults,experience

inthefieldisparamount.Make

suretheanalystseducationis

relevantandnotetheexperience

ofthetechnicalpeopleinthelab

aswell.

10www.TESTOIL.comInsightServices,Inc.|www.TESTOIL.com|@testoil1

IFHgroup.com

#7UseProperLubricationStorageandHandling

Havinglubricationstorageandhandling

systemsinplaceisimportantaswell.

Lubricationproductsareexpensive,sothey

needtobehandledinafashionthat

maximizesthereturnoninvestment.

Makesureyourstorageandhandlingareas

areclean,wellorganized,andclimate

controlled.Youareresponsibleforensuring

thenewoilandgreaseplacedinyour

equipmentiscleananddry,andhasnot

beenexposedtoextremetemperature

variations.

Ifyouhaveoilstorageracks,consider

separatepumpsandfiltersforeach

differentlubricant.Furthermore,makesure

yourtransfercontainersarecleanandbe

surenottoexposelubricantsto

contaminationinroutetotheequipment.

Testallyouroilforacceptancebefore

placingitintoyoursystemforuse.Doingso

isespeciallyvaluablewithbulkshipments,

becauseyouneverknowwhatwasinthe

tankerbeforeyourloadofoil.

Reasonsforusingproper

lubricationhandlingandstorage:

Protectlubeproductsfrom

environment

Protectfromplant

dirt/moisture/sunlight

Filternewlubesorlubesas

youusethem

Keeplubesseparatefrom

otherplantchemical/products

11www.TESTOIL.comInsightServices,Inc.|www.TESTOIL.com|@testoil1

#8JustifyYourProgram

Asyouputtogetheranytypeofpredictive

maintenancetechnology,likeanoilanalysis

program,youneedtojustifytheprogram.

Onecommonwayofjustifyingoilanalysisis

keepingrecordsofallpredictiveoilchanges,

filtrationrequests,dehydrationrequests,

andsoon.Forexample,thegoalmaybeto

improvetheoverallfluidcleanlinesslevels

intheplantshydraulicpressbyusing

improvedfiltration.Inthiscase,oilanalysis

andspecificallytheparticlecountdata

becomesaperformancemetricthatcanbe

usedtomeasurecompliancewiththe

statedreliabilitygoals.

Themetricsprovidejustificationand

accountability,notjustforthosedirectly

involvedwiththeoilanalysisprogram,but

alsoforthewholeplant,sendingaclear

messagethatlubricationandoilanalysisare

animportantpartoftheplantsstrategyfor

achievingbothmaintenanceandproduction

objectives.

Youalsoneedtoannuallyevaluateyouroil

analysisprogramseffectiveness,which

includesacostbenefitevaluationofmoney

savedbyavoidingmaintenanceissuesor

machinedowntimeduetooilanalysis.

Evaluationallowsforcontinuous

improvementoftheprogrambyrealigning

theprogramwitheitherpreexistingornew

reliabilityobjectives.

Considerthefollowing

justificationsforoilanalysis

Somereasonstouseoilanalysis

are:toavoidcatastrophic

failures,extendlubricantlifeand

toextendequipmentlife.

Agoodoilanalysisprogramcan

savebigdollarsforareallysmall

investment.Youcanlearnto

predictconditionsthatarethe

precursoroffailurethroughoil

analysisandtrending.

Asolidanalysisprogramresults

inmakingconditionbased

decisionsbothonthestateof

theequipmentandthelubricant.

12www.TESTOIL.comInsightServices,Inc.|www.TESTOIL.com|@testoil1

1

1

2

2

3

3

#9EstablishandMaintainCredibility

Probablyoneofthemostessentialelementstoanysuccessfuloilanalysisprogramiscredibility.Afteryouestablishcredibilityina

program,youmustmaintainthecredibility.Anyknowledgeablepredictivemaintenancepersonwillagreethathowinternal

customersviewtheprogramcandetermineiftheprogramisaheroorazero.Whenestablishingcredibilityinanyoilanalysis

program,considerthesepoints:

Credibilityinanyoilanalysis

programissomewhatpolitical.

Oneofthebestwaystoavoidthis

phenomenoniseducation.Management,

operations,maintenance,andothersmay

viewtheprogramdifferently.Theoil

analysisprogrammaybeforcedonthem

justbecauseitspartofthecurrent

maintenancestrategy.Asaresult,you

wanttoeducateeveryoneonwhatoil

analysisisandisnt.Tailoryourmessage

toeachlevelwithinthecompanyto

reduceanypoliticalissues.

Havingpersonnelwhocan

communicateclearlyisofutmost

importance.

Whensomeoneasksaquestion

concerningtheprogram,givetheman

answerthattheycanunderstand.Most

managersdontwantalessoninoil

analysis,theyjustwanttoknowiftheiroil

isgoodandiftheirequipmentisgoingto

failorbereliableuntilthenextsample

frequency.Forexample,simplystating,

Contaminationlevelofforeign

particulatesexceedsourdesiredleveland

oxidationhascausedtheviscosityofthe

oiltoraisepastasafelevelforthis

machineismucheasiertounderstand

thanatechnicalexplanation,suchas,The

PCis21/19/16andtheVIShasraised20

percent.

Youearncredibilitybyhavinga

programthataddsvaluetothe

companyanditsusers.

Youwanttoensurethatbenefitsare

ongoing.Iftoomuchtimelapsesbeforea

managerseesvaluefromoilanalysis,trust

intheprogrammaydecline.Ontheflip

side,makesurethateverymaintenance

actionrequestedfromoilanalysisresults

bebackedupwithdata.

Theprogramneedstostandonitsown

merit.Theprogramsmanagermustalso

havemeritofbeingknowledgeable,

truthful,andeasytoworkwith.Without

this,theprogrammanagerisnomore

thananoutsideconsultanttryingtosella

solutiontoaproblemthatmayormaynot

exist.

13www.TESTOIL.comInsightServices,Inc.|www.TESTOIL.com|@testoil1

#10ManageYourProgramUsingWebBasedTools

Onceasampleistestedandthedataisin

placetheremustbeawayforthelabto

communicatethedatatoyou.

Manylabsnowofferwebbasedtoolsthat

enablecustomerstoeasilyprocessthe

informationcontainedintheiroilanalysis

reports.

Webbasedprogrammanagementcanhelp

yourstaffmakebetter,moreinformed

decisionsaboutyouroilanalysisprogram

andtakenecessarystepsrequiredtoavoid

catastrophes.

Byusingawebbasedmanagementtool,

youandyourmaintenancestaffcan

collaborateandmanagereportsbecauseall

thedataisinoneeasytouseinterface,

whichallpartiescanaccessatalltimes.

Ideally,thewebbasedprogram

shouldoffertoolstoquickly

managesampleresultsand

monitorequipmentinthese

importantways:

Reviewequipmentsampling

history

Analyzemachinecondition

Accessandreviewrecentand

pastreports

Graphtrendsand

inconsistenciesthrough

interactivegraphs

Formoreinformationonwebtools

goto:www.testoil.com/datasight

14www.TESTOIL.comInsightServices,Inc.|www.TESTOIL.com|@testoil1

Conclusion

JustsendinganoilsampletothefirstlabfoundontheInternetmaynotguaranteeaqualityoilanalysisprogram.Simplytakingafew

precautionary,wellplannedstepsshouldminimizeanyunforeseenproblems.Withagoodvision,correctcommunication,andan

understandingofwhattoexpectfromoilanalysis,aprogramcanbeestablishedthatwillbecredibleandamerittothereliabilityof

anycompany.

ContactUs

Call:2162512510

Email:info@testoil.com

VisitourWebsite:www.testoil.com

Visitourblog:http://oilanalysis.testoil.com/

Tweetusat:@testoil1

AboutTESTOIL

TESTOILisafullserviceoiltestinglaboratoryownedby

InsightServices.Since1988thelaboratoryhasbeen

providingfastandreliableoilanalysisresultsacrossall

industriesthroughouttheAmericas.

Thefirmscomprehensiverangeofoilanalysisservices

assistsreliabilityengineerswithconditionmonitoring

andidentificationofmachinewear.

TESTOILemploysasophisticateddiagnostictechnology

thatassiststheirMachineConditionAnalystsinmaking

equipmentandlubricationconditionassessments.

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- General: Transport Format, Transport Format Combination (Set) TS 25.302Documento5 páginasGeneral: Transport Format, Transport Format Combination (Set) TS 25.302Sowmya JayanandaAinda não há avaliações

- VCB$SF 6Documento3 páginasVCB$SF 6karthikumarAinda não há avaliações

- SD6109Documento10 páginasSD6109Alonso Corado100% (1)

- Determine HWM and Reduce It by Shrink SpaceDocumento6 páginasDetermine HWM and Reduce It by Shrink SpaceSiva KumarAinda não há avaliações

- 5G Smart Port Whitepaper enDocumento27 páginas5G Smart Port Whitepaper enWan Zulkifli Wan Idris100% (1)

- Creating Delegate NodeDocumento26 páginasCreating Delegate NodeRama Krishna BAinda não há avaliações

- Read MeDocumento4 páginasRead MeSticle ArtizanaleAinda não há avaliações

- Youth and Social MediaDocumento9 páginasYouth and Social MediaShreyas ShahaAinda não há avaliações

- Edustack Ruff FinDocumento12 páginasEdustack Ruff Finsanjoo1786Ainda não há avaliações

- Chattr ManualDocumento3 páginasChattr ManualgtirnanicAinda não há avaliações

- Seminar Report On CyberneticsDocumento67 páginasSeminar Report On CyberneticsSimmi JoshiAinda não há avaliações

- ADAM-5000 IO Module Manual Ed 2.3Documento88 páginasADAM-5000 IO Module Manual Ed 2.3Pham SangAinda não há avaliações

- My AadharDocumento1 páginaMy Aadharsales2.hydakbartravelsonline.com BackupAinda não há avaliações

- Error Messages Guide EnglishDocumento226 páginasError Messages Guide EnglishSandeep PariharAinda não há avaliações

- Simple 4k Wallpaper - Google SearchDocumento1 páginaSimple 4k Wallpaper - Google SearchElix3rAinda não há avaliações

- Psi PopDocumento31 páginasPsi PopRebecca Monzon0% (1)

- Ahb7816t ElDocumento3 páginasAhb7816t ElcjtrybiecAinda não há avaliações

- Questions On LaplaceDocumento4 páginasQuestions On LaplaceApam BenjaminAinda não há avaliações

- Manuals For Cars: Autosoft Catalog:: Chip Tuning FolderDocumento165 páginasManuals For Cars: Autosoft Catalog:: Chip Tuning FolderKamyl AzariAinda não há avaliações

- Solid PrincipalDocumento66 páginasSolid Principalkris2tmgAinda não há avaliações

- Mine Ventilation Using CFDDocumento5 páginasMine Ventilation Using CFDmitevAinda não há avaliações

- 2010-10-31 Chet Ramey Early Bash DatesDocumento2 páginas2010-10-31 Chet Ramey Early Bash Datesmsnicki100% (2)

- Data Security in Cloud ComputingDocumento324 páginasData Security in Cloud Computingprince2venkatAinda não há avaliações

- 82-P01.91.300481-01 GS100 Operation ManualDocumento137 páginas82-P01.91.300481-01 GS100 Operation ManualWolaé Mathurin Edmond Amegandjin100% (2)

- Case 06 RPA WALT Robotic Process AutomationDocumento13 páginasCase 06 RPA WALT Robotic Process AutomationPragya JoshiAinda não há avaliações

- Gemini AS Operator GuideDocumento149 páginasGemini AS Operator GuideThesa Grace OrnoAinda não há avaliações

- 12 PandasDocumento21 páginas12 PandasArshpreet SinghAinda não há avaliações

- VIP400 Settings Sheet NRJED311208ENDocumento2 páginasVIP400 Settings Sheet NRJED311208ENVăn NguyễnAinda não há avaliações

- A Bubble Text EffectDocumento16 páginasA Bubble Text EffectvermaxeroxAinda não há avaliações

- SokkiaioDocumento24 páginasSokkiaioUlisesRiveraUrbanoAinda não há avaliações