Escolar Documentos

Profissional Documentos

Cultura Documentos

Level 1

Enviado por

jeyanbass0 notas0% acharam este documento útil (0 voto)

411 visualizações5 páginasVibration Practitioner Specialist Level 1

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoVibration Practitioner Specialist Level 1

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

411 visualizações5 páginasLevel 1

Enviado por

jeyanbassVibration Practitioner Specialist Level 1

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 5

VIBRATION PRACTITIONER / SPECIALIST

CERTIFICATION PROGRAM BASED ON

VIBRATION PRACTITIONER / SPECIALIST

CERTIFICATION PROGRAM BASED ON

LEVEL LEVEL

ISO 18436

1

Certification Body

Training Institution

MATERIALS TECHNOLOGY EDUCATION

Approved Training Provider

SERBA DINAMIK SDN. BHD.

A Joint Program by :

INTRODUCTION

The quality of vibration analysis and condition monitoring depends to very large extent on the quality of the

people who carry it out. It does not matter how good the monitoring equipment is or even how committed

management is, the program will fall unless it is run by capable and dedicated people. What can be done to

ensure the availability of capable and dedicated people? Professional certicate with performance objectives

will be the answer.

THE NEED

2.1 Plant requirement

Nowadays, no one questions the benets of a good predictive maintenance system. Plenty of evidence from a

wide variety of sources has demonstrated the benets time and time again. Three factors, primarily, govern

the quality of the program.

Management understanding and commitment

Suitable and quality of equipment for the identied tasks

Quality, dedication and competency of the personnel who will run the program

Of these, the rst two are beyond the scope of this paper and helping ensure the third is our focus by way of

creating a certication program in compliance to international industrial standards and practices.

2.2 Personal/Personnel Requirements

Individuals need to know their tasks and they need to be able to demonstrate that they know them. This

statement is true particularly in the vibration jobs, since the diversity of educational background, training and

experience is so broad.

Similar problems exist for companies who need to hire the appropriate expertise. How can they know what

type of individual is required for their particular job? How can they even write the job description, since the

specialty is so narrow? A certication program will be a solution.

CERTIFICATION INSTITUTION

IMM is an certication institution recognized by PETRONAS and other PSC contractors in Malaysia and this

Vibration Specialist Certication Program is done strictly in accordance to ISO18436 requirements which shall

be recognized worldwide.

IMM recognized Vibration Technology as a proven tool to troubleshoot and analyse problem related to various

failure in material of machines, structure etc.

WHY CERTIFICATION?

Certication gives academic recognition to you technical staff which is increasingly important in a competitive

global market that heavy emphasis on standards of excellence that is traceable to documented systems and

work practices. This IMM Vibration Specialist Certication program fullls the need for such a standard of

excellence.

THE PROGRAM CONTENT

Training course requirements for personnel involved in vibration condition monitoring and diagnostics of

machines

Vibration Practitioner / Specialist Certication

Program Based On Iso18436

The Course Examination Fee

Vibration Practitioner Level I

2,610

00

RM 500

00

RM

Course fee/pax Exam fee/pax

SERBA DINAMIK SDN. BHD.(266724-K)

(A member of SERBA DINAMIK Group)

5 - 8 May 2014

5 - 8 May 2014

2

.

LEVEL 1

The Program Content

Pinciples of Vibration

Basic Motion

Period

Frequency Amplitude

Peak

Peak-to-peak

R.M.S

Parameters

Displacement

Velocity

Acceleration units

Unit conversions

Times and frequency domains

Natural Frequency

Resonance

Critical speeds

Data Acquisition

Instrumentation

Transducer

Sensor mounting

Mounted natural frequency

Test planning

Data formats

Computer database upload/download

Signal Processing

FFT Application

Condition Monitoring

Fault condition recognition

Fault Analysis

General fault recognition

Correction Action

Basic maintenance action

Equipment Knowledge

Electric motors

Generators and drives

Pumps, Fans

Compressors

Equipment Knowledge

Rolling mills

Paper machines

Other process equipment

Machine tools

Structure, piping

Gearboxes

Acceptance Testing

Test procedure

DAY 1 DAY 3

DAY 4

DAY 2

23

List of Approved Trainers

Dr. Ir. Mohd Abdul Karim Abdullah

The Managing Consultant of Serba Dinamik Resource & Development Sdn. Bhd. (SDRD) who has acquired more than 25 years of hands-on experience in managing, supervising,

lecturing and carrying out various tasks related to turbomachinery maintenance nation-wide and internationally. Among other experience but not least is as follows: -

Conducting public and in-house training course covering topics on precision alignment and balancing, maintenance & inspection of steam turbines, compressors and pumps,

predictive / preventive maintenance and turbomachinery protection system.

Involved in eld management and supervision for overhauling of steam turbines, gas turbines, reciprocating & centrifugal compressors and pumps of various made / brand.

Executing project control function in the job planning and work scheduling to maintain the planned work and production schedule. Analyse schedule impacts resulting from

design alternatives, eld change and site condition encountered and revising the project schedule when necessary to incorporate any changes.

Planning, recruiting and managing human resources for various plant shutdown & maintenance representing company management and other construction & fabrication

projects.

Miscellaneous experience on construction & fabrication for various projects under the company involving civil activities & mechanical such as checking fabrication drawings,

erection drawings, interprets engineering drawings for tender proposal, recheck piping spool isometric drawings for dimensional accuracy and conformity with plans,

elevations and specication.

Involved actively and executively as a CEO of Serba Dinamik Group.

Profesional engineer contribution

-Mentor for the IEM Training Scheme (Mechanical discipline)

-Personal campaign for recruitment of more graduate engineer into being active member of IEM

En. Mokhtar Mohd. Tahir

The Reliability Manager with Serba Dinamik Sdn. Bhd. who has 23 years of experience in the oil and gas industry including constructions, commissioning, troubleshooting and

maintenance. Comprehensive knowledge of static and rotating equipment with particular expertise in condition monitoring, vibration analysis, troubleshooting and overhaul for

rotating equipment

Actively perform maintenance and repair of rotating equipment during planned and unplanned shutdown, and assist instrumentation calibrate and setting vibration probe

during turnaround

Lead troubleshooting activities on turbomachineries nationwide in Malaysia inclusive of rectication machine problem such as in situ balancing

Collection of condition maintenance data and analysis work on it thereafter

En. Afandi Abd Hamid

Vice President Operation and Maintenance Business Unit of Serba Dinamik Group berhad. Having more than 19 years of consultancy and hands on experience in analysing and

troubleshooting various problems related to rotating equipment. Among others but not least as below :-

In-depth experience in principles and fundamentals of Vibrations of Rotating Equipment (RE) with analysis for suitable remedy and mitigation applications

Signicant involvement in projects by major oil and gas operators in Malaysia i.e. Petronas, Shell and ExxonMobil, as well as Middle-East especially the Gulf Corporation Council

(GCC) Countries for Rotating Equipment in Vibrations

Have resolved substantial Vibrations problems with adequate study and research of RE defects on parts as well as assembly

Highly skillful in plant equipment and machineries especially Rotating Equipment activities for planned and unplanned TurnAround Outage & Shutdown

Contributed effectively in advising Clients for solutions toward Vibration symptom detection and corrective action

Support substantially in Condition Base Monitoring (CBM) team with emphasis to Vibrations and related factors

4

Dr. Rahizar Bin Ramli

Senior lecturer with University Malaya. Having more than 23 years in areas of vibration and acoustics technology involvement, both consultancy and lecturing

Massive teaching and training experience in principles and fundamentals of Vibrations of Rotating Equipment (RE) with analysis for remedy and mitigation

Wide coverage of research and development for Vibrations on simulation as well as on real actual physical machineries in the industry

Responsible on implementing Vibration Condition Monitoring for many processing plants, power plants, and oil and gas industries throughout South East Asia

Numerous experience in machinery diagnostics using vibration analysis whilst regularly conducting training on vibration analysis for engineers and technicians

Involved in various consultation works related to vibration and structural dynamics, focussing on offshore and offshore applications

Conducted exploratory research works related to piping vibrations, active noise control, and evaluating experimental modal analysis with nite element analysis for large

structures

Produced signicant number of internal reports on vibration analysis and diagnostics to clients and has published several technical papers and conference for the same

Prof. Dr. Ir. Mohd Salman Leong

Professor with University Technology Malaysia specialising in Vibration & Acoustic. Having more than 35 years of lecturing, consulting and hands on research, development and

analytical works in various aspects of plant engineering.

Prominent speaker in Vibrations with wide coverage for all types of vibrations and factors related from troubleshooting, mitigation and monitoring

Have undertaken major position in Research and Development Projects on Vibrations at other tertiary institution i.e. Heriot Watt.

Actively involved in industries for giant Government Agencies as well as Private sectors including Petronas Research & Scientic Services,

Tenaga Nasional Berhad and Proton Berhad

Vast background experience in Teaching and Training for the industry locally and worldwide on Vibrations for building structures and machineries movement

Major involvement in relevant Vibrations Projects with successful track record; among others are :

1. Klang Valley MRT Noise & Vibration Analysis and Mitigation Measures 3,530.000.00

2. New LCC Terminal: Main Terminal & Satellite Buildings, Contact Piers 895,000.00 and Sky Bridge: Acoustics and Vibration Design (including vibration acceleration analysis for

human inducedvibration and tuned mass dampers design for Skybridge).

3. BP-Petronas Polyethylene Malaysia, Strutural Vibrations from Reactor 428,400.00 Investigations and Finite Element Analysis

4. Petronas Carigali Tukau Compressors, Piping & Structure Vibrations 365,758.00 Investigations and Finite Element Analysis

5. Kuala Lumpur Convention Centre Acoustics & Vibration Design. 540,000.00

Secured vital grants and funds from Government and Private Universities leading to awards in carrying-out research, publications and supervision to the societies and public

at large

Secured extensive amount of various Contracts on Consultation and Advisory services on Vibrations Projects by Plant Operators among others were Brunei LNG and MMC

Gamuda MRT Project. The same achievement also for Original Equipment Manufacturer (OEM) for equipment i.e. Gas Turbine (Rolls Royce), Steam Turbine,

Compressors and Gearbox

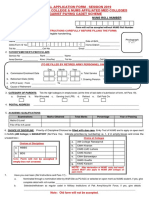

Registration Form

Yes! Please register the following participants for course

I am unable to attend but please put me on your mailing list

No.

Name (Dr/Mr/Mrs/Ms) Designation

Approving Manager/Contact Person:

Designation:

Company Stamp:

Kindly send your cheque or bank draft,

payable to:-

MATERIALS TECHNOLOGY

EDUCATION

No. 10-1, Jalan Bandar 3,

Pusat Bandar Puchong,

47160 Selangor, Malaysia

Registration is on receipt of payment.

Kindly ensure early booking for the

limited seats to avoid any inconvenience

If you are unable to attend, a substitute

participant is welcome to attend in your

place at no additional charge. A full refund,

less 10% administrative charge, will be

given if cancellation is received in writing at

least 14 working days prior to the course. A

50% refund and documentation will be

given if cancellation is received less than 7

days prior to the course.

Cancellation & Transfer

How To Register

SERBA DINAMIK SDN. BHD.

7-5, PUSAT DAGANGAN UMNO SHAH ALAM,

LOT 8, PERSIARAN DAMAI, SEKSYEN 11,

40100 SHAH ALAM,

SELANGOR, MALAYSIA

: +603 5511 3213 : +603 5511 3212

: serbadk@e-serbadk.com

(266724-K)

Dr. Ir. Mohd Abdul Karim Abdullah

Prof Dr. Ir. Salman Leong

Dr. Rahizar Ramli

En. Afandi Abd Hamid

En. Mokhtar Mohd. Tahir

The Instructors

5

MATERIALS TECHNOLOGY EDUCATION

NO. 10-1, JALAN BANDAR 3,

PUSAT BANDAR PUCHONG,

47160 SELANGOR, MALAYSIA

: +603 5882 3574 : +603 5882 3524

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Writing - Free Writing Short NarrativeDocumento11 páginasWriting - Free Writing Short NarrativeSaravana SelvakumarAinda não há avaliações

- Part Iv: Development PlansDocumento4 páginasPart Iv: Development Plansjean monsalud100% (1)

- Monitoring and EvaluationDocumento2 páginasMonitoring and EvaluationChelsea Macalia YumulAinda não há avaliações

- Professional Learning Tool ps3 2Documento18 páginasProfessional Learning Tool ps3 2api-488407762Ainda não há avaliações

- The Ielts Academic Speaking Test TutorialDocumento5 páginasThe Ielts Academic Speaking Test TutorialNadeemShahAinda não há avaliações

- Nature Deficit DisorderDocumento9 páginasNature Deficit Disorderapi-302555293Ainda não há avaliações

- DLL Precalculus Week 1Documento3 páginasDLL Precalculus Week 1Elswhere Cu PidAinda não há avaliações

- Lesson PlanDocumento4 páginasLesson Planzanderhero30100% (1)

- A Survey Study On Study Habits That Affects Reading Comprehension of Grade 7 Students of Eastern Quezon CollegeDocumento31 páginasA Survey Study On Study Habits That Affects Reading Comprehension of Grade 7 Students of Eastern Quezon Collegefillesaintmerced75% (8)

- Active Directory Troubleshooting WorkshopPLUS (4 Days)Documento2 páginasActive Directory Troubleshooting WorkshopPLUS (4 Days)kapil gautamAinda não há avaliações

- Vii. Session 7: Code of Ethics: Pre-TestDocumento9 páginasVii. Session 7: Code of Ethics: Pre-TestImee Joy DayaanAinda não há avaliações

- BibliografiDocumento5 páginasBibliografiuncle crazy0% (1)

- Self Assessment PPT - PPSXDocumento17 páginasSelf Assessment PPT - PPSXKavita PatelAinda não há avaliações

- Shine Awards Edition 2012Documento16 páginasShine Awards Edition 2012Liam PapeAinda não há avaliações

- Lesson Plan 3rd Grade OldenburgDocumento4 páginasLesson Plan 3rd Grade Oldenburgapi-243788225100% (1)

- Multigrade Teaching InsightsDocumento4 páginasMultigrade Teaching InsightsCyrill Gabunilas FaustoAinda não há avaliações

- Self Study Report 2015Documento623 páginasSelf Study Report 2015Yashwant SahaiAinda não há avaliações

- 2013 Regional Summit CommuniqueDocumento24 páginas2013 Regional Summit CommuniqueIbukun Olagbemiro100% (3)

- Ummer: Munich International Summer UniversityDocumento66 páginasUmmer: Munich International Summer UniversityEduardo IparraldeAinda não há avaliações

- IRSSM5 - Call For PapersDocumento6 páginasIRSSM5 - Call For PapersgeorgejosephAinda não há avaliações

- Shifting From Modular To F2F PR1 G1Documento7 páginasShifting From Modular To F2F PR1 G1Je-ann ValerianoAinda não há avaliações

- Syllabus NWU - ACA - 010Documento12 páginasSyllabus NWU - ACA - 010Mariecris Barayuga Duldulao-AbelaAinda não há avaliações

- Med 2019 NumsDocumento6 páginasMed 2019 NumsTalha GulAinda não há avaliações

- Reading Lesson Plan 1Documento5 páginasReading Lesson Plan 1api-541765085Ainda não há avaliações

- Nota Chapter 4 Perception Attribution and Management of DiversityDocumento17 páginasNota Chapter 4 Perception Attribution and Management of DiversitySue AhmadAinda não há avaliações

- Introduction To Nursing TheoriesDocumento68 páginasIntroduction To Nursing TheoriesRahman LuthfiaAinda não há avaliações

- Syllabus: Cambridge IGCSE EconomicsDocumento20 páginasSyllabus: Cambridge IGCSE EconomicsnewtonokewoyeAinda não há avaliações

- Automotive Systems: Graduate ProgramDocumento2 páginasAutomotive Systems: Graduate ProgramVicentiu Iulian SavuAinda não há avaliações

- Multicultural Teacher Education For The 21st CenturyDocumento17 páginasMulticultural Teacher Education For The 21st CenturyArlene AlmaydaAinda não há avaliações

- UT Dallas Syllabus For Huma7323.001.07s Taught by Elke Matijevich (Exm017100)Documento4 páginasUT Dallas Syllabus For Huma7323.001.07s Taught by Elke Matijevich (Exm017100)UT Dallas Provost's Technology GroupAinda não há avaliações