Escolar Documentos

Profissional Documentos

Cultura Documentos

Lube Oil Requirements For Diesel Engines

Enviado por

Jitendra KumarDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Lube Oil Requirements For Diesel Engines

Enviado por

Jitendra KumarDireitos autorais:

Formatos disponíveis

Lube Oil requirements for Diesel Engines

Crankcase

The oil has to serve two purposes;

1. reduce friction

2. Cool bearings

A good quality mineral oil will serve the purpose of reducing friction to an acceptable level

depending upon the metals involved and other conditions such as temperature. All oils will oxidise and this

reduces its effectiveness as a lubricant. Oxidation will also cause deposits which can block passage ways

and coat working parts. The rate of oxidation will depend upon temperature, the higher the temperature

the more rapid the rate. Anti oxidants are available which reduce the rate, also additional properties can

be achieved by the use of additives.

Under high temperatures an oil is liable to thermal degradation which causes discoloration and

changes the viscosity. Additives cannot change an oils susceptibility to this degradation. The refining

process can remove compounds which effect the thermal stability of the oil and also those that lower

oxidation resistance. ost of the chemicals found in an oil will react more or less with oxygen, The effects

of this oxidation is always undesirable. !ence, a ma"or ob"ective of the refining process of a mineral oil is

to remove those hydrocarbons i.e. the aromatics, the small amount of unsaturates together with

molecules containing sulphur, oxygen and nitrogen.

Unfortunately these same molecules are those that improve the boundary lubrication

performance. !ence, a careful balance must be struck. The use of anti#oxidants make a slightly better

balance although there usefulness is limited.

Tin based whitemetal is susceptible to hardening as an oxide layers from on the surface.

These tin oxides are a grey#black in appearance and are extremely hard. There formation

reduces the bearing clearance as the oxide layer is thicker than the original white metal material from

which it formed. The oxide has a lower coefficient of friction than the original white metal but it will cause

problems if it brakes up as fragments will become embedded edge on in the white metal and can score

the pin.

Contamination

Water

Water from,

1. bilge's

2. Jackets

3. Sea via coolers

4. leaky seals or washing in purifiers

. Condensation

Problems caused by water contamination,

Water leads to corrosion especially if there is sulphur present due to fuel contamination

forms emulsions which are not capable of withstanding high loads

removes water soluble additives when centrifuged out

leads to possible bacterial attack

Fuel

ay be heavy residual or light diesel$gas oil and can be sourced to faulty to cylinder combustion or faulty

seals on fuel p$ps.

Problems

Increases viscosity for hfo, reduces viscosity for D..

reduces flashpoint

Introduces impurities such as sulphur

dilutes lub oil when in large !uantities

Solid impurities

i.e. carbon from the cylinder combustion process, particularly of importance with trunk piston engines but

also for crosshead engines with inefficient diaphragm. The carbon can lead to restrictions and blockages of

oil ways causing bearing failure. %traight mineral oils hold &' carbon in suspension, dispersant oils hold

about ('.

Bacterial attack

)ertain bacteria will attack oil but water must be present. The bacteria may exist in a dormant state in the

oil but water is required if they are to reproduce.. The bacteria digest the oil causing breakdown

emulsions to be formed, acidity increases, dead bacteria block filters and corrosive films form on working

surfaces.

In summary their must be three essential conditions for microbiological growth;

There must be a source of carbon" present in the oil

There must be some bacteria or fungal spores present"these are almost universally present in

the atmosphere

There must be free water present

Two other factors which encourage the growth are a slight acidity in the water *p! ( or +, and a slightly

raised temperature *-. to /.

o

), which can lead to rapid growth.

0iocide additives are available but they are not always compatible with other desired additives

and can lead to large organic blockages if treated in the machinery. The best solution is to avoid the

presence of water. 1f mild attack takes place the oil may be heated in the renovating tank to above 2.

o

)

for -/hrs before being returned to the sump via the centrifugal separator. 3or a severe attack the only

solution is complete replacement of the charge followed by sterilisation of the system. 1t may be noted

that on replenishment the bacteria may be present in a dormant state in the new charge.

Test results of crankcase oils

#iscosity#1ncreases due to thermal degradation or hfo contamination, reduces with diesel oil

contamination, corrective action needed if it increases by -(' from new oil.

Water content#)orrective action required at &'

Insoluble $ediments#basically the result of wear and oxidation, corrective action at &' by weight

%sh#a measure of incombustibles in the oil sample, corrective action at ..&4' by weight

T%&#Total acid number consists of the strong acids *mainly sulphuric acid, formed in the combustion

process and weak acids resulting form oxidation of the lub oil.

$%&#%trong acid number, the oil should be renewed if any is detected

T'&#Total base number indicates the alkaline reserve particulary important for trunk piston engines

(losed flash point#highlightd fuel contamination, corrective action if reduces by 4.

o

) from new

Cylinder lub oil

The type of cyl l.o. required will depend upon the cylinder conditions and the engine design e.g crosshead

or trunk piston. !owever, the property requirements are basically the same but will vary in degree

depending upon the fuel and operating conditions.

&ormal properties re!uired are;

a. ade!uate viscosity at working temperature so that the oil spreads over the liner surface to

provide a tough film which resists the scrapper action of the piston rings

b. the oil must provide an effective seal between the rings and liner

c. only a soft deposit must be formed when the oil burns

d. alkalintiy level )total base number or T'&* must match the acidity of the oil being burnt

e. detergent and dispersant properties are re!uired in order to hold deposits in suspension and

thus keep surfaces clean

Addities

All oils for all purposes can be designed to give particular properties through the careful use of additives to

the base mineral oil stock.

(ommon additives are;

%ntio+idants"these are used in all oils to reduce the rate at which o+idation occurs and are

especially useful were the lub oil cools the piston

,+treme pressure agents these are compounds of phosphorus, $ulphur or (hlorine which

increase the strength of the oil film under conditions of high temperature or pressure.

,Dispersants or detergents"found in trunk piston engine oils and cyl l.o. these keep surfaces

clean by holding deposits in suspension.

#iscosity inde+ improvers" these prevent e+cessive changes in viscosity with change in

temperature

ther additives can be defined by name such as anti"wear, anti"corrosion, anti"bacteria, anti"

foaming etc.

5hen running in, the cylinder lube oil in"ector pumps may be filled with a a straight mineral

oil without anti#wear properties# typically the crankcase oil# once this small reserve of oil is exhauted,

running in carries on with normal cylinder lube oil. The flow of oil is increased to carry away metallic

particles.

!roblems caused by stuffing bo" leakage oil entering crankcase

6ow speed engines are particularly at risk from crankcase lubricant contamination caused by cylinder oil

drainage past the piston rod gland and combustion products. This can lead to severe damage of engine

crankcase components and reduction of life of oil which is normally expected to last the lifetime.

There has been a general increase in the viscosity and 0ase number of crankcase oils over recent years

particularly for engines built since the early &27.8s. 1ncreased alkalinity, viscosity and insolubles, fuel

derived elements such as vanadium and oil additive derived elements such as calcium, suggest that the

contamination is from the cylinder oil drainage.

9eterioration of the crankcase oil has led to the expensive necessity of replacing up to (.' of the sump,

this is particularly of concern as it is often only a temporary measure.

-our causes are put forward,

1. !ew crankcase oil conta"inated with new cylinder oil#unlikely

2. Cylinder oil drainings being recycled and returned to the su"p#very likely as it is a co""on

practice to purify oil leaking through the gland$ tests done on this purified oil found high

a"ounts of insolubles

3. %eakage past rod gland# very likely$ high pressure scavenge air can blow cylinder oil and dirt

past the top scrapper ring and sealing rings into the piston rod drain tank$ and even possibly

directly into the su"p. & proble" that worsens with age and wear.

4. leakage of e'haust valve lubrication syste"#unlikely

3rom above the suggestion is the most likely cause for contamination is leakage past the

piston rod. 1t is seen that maintenance of the stuffing box is of the utmost importance. Tell tales and

drainage lines should be proved free and use of oil drained from the uppermost drain should not be

allowed even after purification due to the high level of contamination which can destroy the properties of

the oil in the sump

I know of a case where due to the increased viscosity of the oil a 50% charge of hydraulic oil was

added to the sump of a very large slow speed engine under advice from the manufacturer

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- Pilgrim NutDocumento2 páginasPilgrim NutJitendra KumarAinda não há avaliações

- Overall Arrangement: Description of The Salient PartsDocumento6 páginasOverall Arrangement: Description of The Salient PartsJitendra KumarAinda não há avaliações

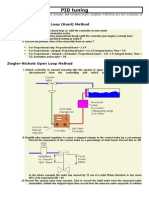

- PID TuningDocumento4 páginasPID TuningJitendra Kumar100% (1)

- Oxygen AnalysersDocumento2 páginasOxygen AnalysersJitendra KumarAinda não há avaliações

- Oil WhirlDocumento2 páginasOil WhirlJitendra KumarAinda não há avaliações

- Increasing Propulsive EfficiencyDocumento6 páginasIncreasing Propulsive EfficiencyJitendra KumarAinda não há avaliações

- Motor Ship Steam Plan1Documento3 páginasMotor Ship Steam Plan1Jitendra KumarAinda não há avaliações

- Lifting Using Accessories: Calculation of LoadDocumento2 páginasLifting Using Accessories: Calculation of LoadJitendra KumarAinda não há avaliações

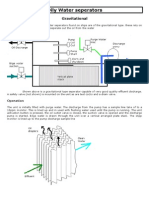

- Oily Water SeperatorsDocumento2 páginasOily Water SeperatorsJitendra KumarAinda não há avaliações

- Navigation LightingDocumento1 páginaNavigation LightingJitendra KumarAinda não há avaliações

- Motor Ship Steam Plant ControlDocumento1 páginaMotor Ship Steam Plant ControlJitendra KumarAinda não há avaliações

- Tooth Design: Forces Acting On Spur GearsDocumento77 páginasTooth Design: Forces Acting On Spur GearsJitendra KumarAinda não há avaliações

- Mechanical GovernorsDocumento1 páginaMechanical GovernorsJitendra KumarAinda não há avaliações

- LNG Containment DesignsDocumento3 páginasLNG Containment DesignsJitendra KumarAinda não há avaliações

- Liquified Gas CargoesDocumento2 páginasLiquified Gas CargoesJitendra KumarAinda não há avaliações

- LiftingDocumento5 páginasLiftingJitendra KumarAinda não há avaliações

- Jacket Water SystemDocumento2 páginasJacket Water SystemJitendra KumarAinda não há avaliações

- Hydraulic SystemsDocumento4 páginasHydraulic SystemsJitendra KumarAinda não há avaliações

- Halon 1301 Bromotrichlhoromethane CF3BrDocumento2 páginasHalon 1301 Bromotrichlhoromethane CF3BrJitendra Kumar0% (1)

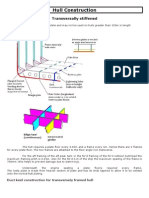

- Hull ConstructionDocumento4 páginasHull ConstructionJitendra KumarAinda não há avaliações

- Hydraulic GovernorsDocumento6 páginasHydraulic GovernorsJitendra KumarAinda não há avaliações

- Holding Down ArrangementsDocumento3 páginasHolding Down ArrangementsJitendra KumarAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Positioning Techniques - Horizontal Vertical PDFDocumento34 páginasPositioning Techniques - Horizontal Vertical PDFMuhd Zuhairi100% (1)

- Chap - 04 (Basic Chemistry) PDFDocumento73 páginasChap - 04 (Basic Chemistry) PDFDewi RahayuAinda não há avaliações

- Correlation of Free Fall Drop To Instrumented ShockDocumento14 páginasCorrelation of Free Fall Drop To Instrumented Shockpyuen1976Ainda não há avaliações

- Using Empower Systemsqt Qualification Tool For Waters Modular HPLC SystemsDocumento8 páginasUsing Empower Systemsqt Qualification Tool For Waters Modular HPLC SystemsПетр КрасновAinda não há avaliações

- Thermodynamics of Natural Systems-137-140Documento4 páginasThermodynamics of Natural Systems-137-140Asep IrawanAinda não há avaliações

- Water Requirement in Chemical Process IndustriesDocumento145 páginasWater Requirement in Chemical Process IndustriesKAUSTAV ROYAinda não há avaliações

- Cape - Mass SpectrosDocumento8 páginasCape - Mass Spectrosasjawolverine0% (1)

- Lange (2007)Documento10 páginasLange (2007)Ally BAinda não há avaliações

- 4RA34RB3 Lecture Note 7 Semiconductor DetectorsDocumento18 páginas4RA34RB3 Lecture Note 7 Semiconductor Detectorstarek mahmoudAinda não há avaliações

- Design of Industrial Gravity Type Separators For The Hydrocarbons and Heavy Oil-Water SeparationsDocumento5 páginasDesign of Industrial Gravity Type Separators For The Hydrocarbons and Heavy Oil-Water SeparationsCandraAinda não há avaliações

- The Information Contained in This Document Supersedes All Similar Information That May Be Found Elsewhere in This ManualDocumento11 páginasThe Information Contained in This Document Supersedes All Similar Information That May Be Found Elsewhere in This Manual林苏文Ainda não há avaliações

- January 2006 QP M1 EdexcelDocumento13 páginasJanuary 2006 QP M1 EdexcelOmar HashemAinda não há avaliações

- Grade 7 2nd Parallel Assessment SampleDocumento3 páginasGrade 7 2nd Parallel Assessment SampleElaiza TauthoAinda não há avaliações

- ASTM D2281-10 Standard Test Method For Evaluation of Wetting Agents by Skein TestDocumento3 páginasASTM D2281-10 Standard Test Method For Evaluation of Wetting Agents by Skein TestDerek Vaughn100% (1)

- Patrick Lee - Fermions and Spin LiquidDocumento58 páginasPatrick Lee - Fermions and Spin LiquidKonnasderAinda não há avaliações

- Ch-19 Gas Welding, Gas Cutting & Arc WeldingDocumento30 páginasCh-19 Gas Welding, Gas Cutting & Arc WeldingJAYANT KUMARAinda não há avaliações

- SS1 Chemistry 2nd Term Lesson Note PDFDocumento58 páginasSS1 Chemistry 2nd Term Lesson Note PDFKelly Isaac100% (3)

- Total Carbon and Nitrogen Determination in Soil: Application NoteDocumento3 páginasTotal Carbon and Nitrogen Determination in Soil: Application Notelaoying qdAinda não há avaliações

- Visualization of Magnetic Field Generated by PortaDocumento6 páginasVisualization of Magnetic Field Generated by PortajuanAinda não há avaliações

- Color: A Coloring Book byDocumento19 páginasColor: A Coloring Book byMarta Pérez Madrid50% (2)

- 11 Physics Kinematics Test 01Documento1 página11 Physics Kinematics Test 01Nikhil SahuAinda não há avaliações

- Aplikasi Metode Geomagnet Dalam Eksplorasi Panas BumiDocumento10 páginasAplikasi Metode Geomagnet Dalam Eksplorasi Panas Bumijalu sri nugrahaAinda não há avaliações

- A New Synthetic Method For The Preparation of 5-Deazaflavins and 5-Deaza-10-OxaflavinsDocumento2 páginasA New Synthetic Method For The Preparation of 5-Deazaflavins and 5-Deaza-10-OxaflavinsThéoAinda não há avaliações

- Kollicoat Smartseal 30 D ShortDocumento39 páginasKollicoat Smartseal 30 D ShortniknenadAinda não há avaliações

- DTR Rampa Amtrv-Pro 2022 - enDocumento19 páginasDTR Rampa Amtrv-Pro 2022 - enEglė STAinda não há avaliações

- Tabalbag Leonor ScienceDocumento9 páginasTabalbag Leonor Scienceemo mHAYAinda não há avaliações

- Potential Measurement of Jackets / Platform Legs: 5.cathodic ProtectionDocumento35 páginasPotential Measurement of Jackets / Platform Legs: 5.cathodic ProtectionyouplaiAinda não há avaliações

- Propagating Scalar Modes in (2+1) - CDT Quantum GravityDocumento60 páginasPropagating Scalar Modes in (2+1) - CDT Quantum GravityAdam BruceAinda não há avaliações

- Factor Affecting Rate of Reaction ExerciseDocumento3 páginasFactor Affecting Rate of Reaction ExerciseRafiq IrdhinaAinda não há avaliações

- Structures of AlkanesDocumento23 páginasStructures of Alkanesbrenda4cerme4oAinda não há avaliações