Escolar Documentos

Profissional Documentos

Cultura Documentos

1 2014+19 12 36 775

Enviado por

lumydee_887697Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

1 2014+19 12 36 775

Enviado por

lumydee_887697Direitos autorais:

Formatos disponíveis

The best solution

for advanced industrial

applications

DGT-BATCH

MULTI-PRODUCT DOSAGE FUNCTIONING

Configuration which allows the dosage of

various products, in loading or unloading,

as well as mixing and formulation, with the

possibility of managing mixers, burners or

vibrators using dedicated contacts.

DATABASES

Database of 16 selectable products/ phases which may be:

- Automatic dosage;

- Manual dosage, with possibility of managing a control light;

- Complete or partial unloading;

- Fractioned unloading, for dividing all the dosed material in equal quantities;

- Timer, for enabling mixers, burners, or stirrers for a preestablished time period;

- Pause, for allowing the manual operations of the operator;

- Manual weight, for adding pre-weighed quantities to the dosage.

Database of 15 formulas, each one can contain:

- up to 8 products/phases with target, speed change threshold, flight, +/- tolerance;

- minimum tare and maximum tare values.

KEYBOARD FUNCTIONS

START / RESTART dosage, PAUSE / RESET cycle and introduction / selection formula.

Automatic recalculation of the formula targets, by entering the total weight to be dosed.

Quick introduction and selection of the dosage data, in the numeric keyboard models.

I/O FUNCTIONS

Serial communication protocol for programming the formulas, the products and managing the cycle.

START / RESTART dosage, PAUSE / RESET cycle through external inputs.

Formula selection through 2 external inputs (only for models with 4 inputs).

Dual dosage speed (approximate and fine), through any available contacts or analogue output (in the AN models).

One may assign to each product/phase a direct contact, for "fine" dosage, or a binary combination of contacts to codify up to 15

products/phases (only for models with 6 outputs).

Fine dosage contact active either constantly or intermittently (jogging).

I ndication of weight within tolerance, out of tolerance, finished dosage, or alarm through any dedicated contacts

Analogue output (only for "AN" models) proportional to the weight or to the dosage speed.

DOSAGE FUNCTIONS

Checking the presence of the tare at the dosage start.

Automatic printing of the dosage data.

Storage and printing of the consumptions. Printouts may be quickly recalled from the keyboard.

Automatic correction of the flight weight.

Repetitions of the programmable dosage cycles; infinite cycle function.

Tolerance test on the dosed weight, with guided correction on display.

Check of the maximum dosage time.

Alarms indication on display.

BASIC FUNCTIONING OF THE MULTICOMPONENT DOSAGE

Once the dosage start command has been received, the following takes place:

- the presence of the tare and weight stability is verified,

- the execution of the automatic tare and the enabling of the automation through the dedicated outputs: the instrument executes the first

phase of the formula;

Once the first phase is finished, the instrument automatically passes to the following phase, executing the automatic tare;

At the end of the last configured phase, the instrument enables the fine cycle contact and waits for the start of the new dosage, or

automatically restarts with the following cycle.

DETAIL 1

Example of dosage system using the DGTQF for loading routine

SALES AND TECHNICAL ASSISTANCE SERVICE

Você também pode gostar

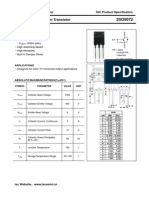

- Isc 2SD5072: Isc Silicon NPN Power TransistorDocumento3 páginasIsc 2SD5072: Isc Silicon NPN Power Transistorlumydee_887697Ainda não há avaliações

- Id Nume Datan Profesia Orasul Stciv SalariulDocumento2 páginasId Nume Datan Profesia Orasul Stciv Salariullumydee_887697Ainda não há avaliações

- Tutorial - Desenare Piesa Autocad PDFDocumento0 páginaTutorial - Desenare Piesa Autocad PDFlumydee_887697Ainda não há avaliações

- Id Nume Datan Profesia Orasul Stciv Salariul Majorare, %Documento2 páginasId Nume Datan Profesia Orasul Stciv Salariul Majorare, %lumydee_887697Ainda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Thông Số Cài Đặt VFD CTK3Documento84 páginasThông Số Cài Đặt VFD CTK3Nguyen Hai DangAinda não há avaliações

- Santhosh S. Design & Development of Solar Electric Boat, 2021Documento43 páginasSanthosh S. Design & Development of Solar Electric Boat, 2021VitBarAinda não há avaliações

- Kenwood-KAF1010 - 3010 AmpDocumento17 páginasKenwood-KAF1010 - 3010 AmpmikisdAinda não há avaliações

- AC SPINDLE MOTOR Paramete PDFDocumento750 páginasAC SPINDLE MOTOR Paramete PDFJosh NhânAinda não há avaliações

- PSU CalculatorDocumento10 páginasPSU CalculatorVíctor RojasAinda não há avaliações

- ETSDocumento4 páginasETSGiorgos PapadopoulosAinda não há avaliações

- Load Cells Types, How It Works, and ApplicationsDocumento21 páginasLoad Cells Types, How It Works, and ApplicationsEncardio RiteAinda não há avaliações

- Elec 3404 Lab Note 2011Documento15 páginasElec 3404 Lab Note 2011Mrinal MitraAinda não há avaliações

- John Newlands,-WPS OfficeDocumento3 páginasJohn Newlands,-WPS OfficeDeleteafter ThismlbbAinda não há avaliações

- Acer Aspire ES1-572 Compal B5W1S LA-D671P r1.0Documento43 páginasAcer Aspire ES1-572 Compal B5W1S LA-D671P r1.0Fc LicoAinda não há avaliações

- Effect of Heater Geometry On The High Temperature Distribution On A MEMS Micro-HotplateDocumento6 páginasEffect of Heater Geometry On The High Temperature Distribution On A MEMS Micro-HotplateJorge GuerreroAinda não há avaliações

- Bulletin 800F 22.5 MM Push ButtonsDocumento3 páginasBulletin 800F 22.5 MM Push ButtonsRex BernedoAinda não há avaliações

- Automatic Cocktail Mixer DispenserDocumento15 páginasAutomatic Cocktail Mixer DispenserAj CruzAinda não há avaliações

- L Completely Fair Scheduler PDFDocumento10 páginasL Completely Fair Scheduler PDFpelao321Ainda não há avaliações

- Engine Control System 1. General: 37 Engine-4A-Fe and 7A-Fe EnginesDocumento10 páginasEngine Control System 1. General: 37 Engine-4A-Fe and 7A-Fe EnginesDavid R PaucaraAinda não há avaliações

- Woodward L Series Application NoteDocumento17 páginasWoodward L Series Application NoteDave WallaceAinda não há avaliações

- Das Audio Altavoces Catalogo 2010Documento20 páginasDas Audio Altavoces Catalogo 2010Jorge RedonAinda não há avaliações

- Radioactivity UitmDocumento25 páginasRadioactivity UitmMoody6861Ainda não há avaliações

- Science 8Documento2 páginasScience 8Karena WahimanAinda não há avaliações

- Preliminary Information: B-MAC-B69 Model Cp-2HbDocumento1 páginaPreliminary Information: B-MAC-B69 Model Cp-2HbCykhong KhongAinda não há avaliações

- RF Amplifier Design Using HFA3046, HFA3096, HFA3127, HFA3128 Transistor ArraysDocumento4 páginasRF Amplifier Design Using HFA3046, HFA3096, HFA3127, HFA3128 Transistor ArraysbezasamiAinda não há avaliações

- Data SheetDocumento2 páginasData SheetIsrael GavilanesAinda não há avaliações

- Woodward 2301A 9905 9907 Series Technical ManualDocumento52 páginasWoodward 2301A 9905 9907 Series Technical Manualtimipl2100% (5)

- 5 DC GridsDocumento75 páginas5 DC GridsNamiraAinda não há avaliações

- Vs-Vsk.230..Pbf Series: Vishay SemiconductorsDocumento9 páginasVs-Vsk.230..Pbf Series: Vishay SemiconductorsrenidwilAinda não há avaliações

- High Performance FSK/ASK Transceiver IC: Data SheetDocumento45 páginasHigh Performance FSK/ASK Transceiver IC: Data Sheetআশিক পালোয়ানAinda não há avaliações

- Basic DfwmacDocumento6 páginasBasic DfwmacDinesh Kumar PAinda não há avaliações

- 85TO3GHDocumento6 páginas85TO3GHVictor BondarenkoAinda não há avaliações

- Design of Power System Stabilizer Using Power Rate Reaching Law Based Sliding Mode Control TechniqueDocumento6 páginasDesign of Power System Stabilizer Using Power Rate Reaching Law Based Sliding Mode Control TechniqueIrfan QureshiAinda não há avaliações

- 2SC3987 NPN Planar Silicon Darlington TransistorDocumento5 páginas2SC3987 NPN Planar Silicon Darlington Transistoradda chariAinda não há avaliações