Escolar Documentos

Profissional Documentos

Cultura Documentos

Non-Crimp: Composites

Enviado por

abthakurTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Non-Crimp: Composites

Enviado por

abthakurDireitos autorais:

Formatos disponíveis

Non-crimp

fabric

composites

Manufacturing,

properties

and

applications

Edited

by

Stepan

V. Lomov

WP

WOODHEAD

PUBLISHING

Oxford

Cambridge

Philadelphia

New Delhi

Contents

Contributor contact details xiii

Introduction

xvi

Part I

Manufacturing

of

non-crimp

fabrics 1

1 Production of

non-crimp

fabrics for

composites

3

A. Schnabel and T,

Gries, Institut

fur

Textiltechnik

(ITA)

of RWTH Aachen

University, Germany

1.1 Introduction

3

1.2

Warp-knitted non-crimp

fabric

(NCF)

5

1.3 Weft-knitted NCF

22

1.4

Non-crimp

woven fabrics

23

1.5 3D woven and non-interlaced NCF 27

1.6 Fixation

by

adhesion 30

1.7

Comparison

of

production technologies

33

1.8 Future trends 35

1.9

Acknowledgements

37

1.10 References 37

2 Standardisation of

production technologies

for

non-crimp

fabric

composites 42

F. Kruse and T. Gries, Institut

fUrTextiltechnik

(ITA)

of

RWTH

Aachen

University, Germany

2.1 Introduction 42

2.2 Classification and standardisation of

non-crimp

fabric

(NCF)

production

methods 42

2.3

Outstanding patents

of

existing

machines for the

production

of NCFs 47

2.4 The 'Hexcel

patent'

-

EP

0972102

B1

59

2.5 Product

patents

in the

production

of NCFs 61

2.6

Immobilisation of

adhesive on the surface of semi-finished

textile

products

(DE

102008004112

A1)

64

2.7

References

65

3 Structural

stitching

of

non-crimp

fabric

preforms

for

composites

67

P.

Mitschang,

Institut

fur

Verbundwerkstoffe

GmbH, Germany

3.1 Introduction 67

3.2 Threads for structural

stitching technology

68

3.3

Stitching technology

and

sewing

machines 70

3.4

Quality

aspects

for

structural

stitching

74

3.5

Applications

and future trends

81

3.6 References 82

4

Understanding

and modelling the effect of

stitching

on the

geometry

of

non-crimp

fabrics 84

S. V. Lomov, Katholieke Universiteit

Leuven, Belgium

4.1

Introduction 84

4.2 General

parameters

of the fibrous

plies

85

4.3

Geometry

of the

stitching

86

4.4 Distortions of fibres in the

plies

92

4.5

Change

of the

geometry

after shear 98

4.6 A

geometrical

model of NCF 100

4.7 Conclusion

100

4.8

References 102

5 Automated

analysis

of defects in

non-crimp

fabrics for

composites

103

M.

Schneider,

Toho

Tenax

Europe GmbH,

Germany

5.1

Motivation 103

5.2

Quality

characteristics of

non-crimp

fabric

(NCF)

104

5.3

Quality analysis

of NCF

by digital image

analysis

106

5.4 Future trends 111

5.5 References 114

Part II

Manufacturing

of

non-crimp

fabric

composites

115

6

Deformability

of

textile

preforms

in

the

manufacture

of

non-crimp

fabric

composites

117

S. V.

Lomov,

Katholieke

Universiteit

Leuven, Belgium

6.1 Introduction

117

6.2 Shear

118

6.3 Biaxial

tension 128

6.4

Compression 132

6.5

Bending 136

6.6 Conclusion

139

6.7 References 141

7

Modelling the

deformability

of biaxial

non-crimp

fabric

composites

144

P.

Harrison,

University

of

Glasgow,

UK, W-R.

Yu,

Seoul

National

University,

Korea and A. C. Long,

University

of

Nottingham, UK

7.1 Introduction 144

7.2 Behaviour of fabric architecture on the shear and

draping

behaviour of

non-crimp

fabrics

(NCFs)

145

7.3

Modelling strategies

for NCF

forming

148

7.4

Energy-based

kinematic

mapping

149

7.5 Finite

element

modelling

of

forming

for

NCFs 156

7.6 Future trends 161

7.7 Further information and advice

162

7.8 References 162

8

Permeability

of

non-crimp

fabric

preforms

166

R.

Loendersloot,

University

of

Twente,

The Netherlands

8.1 Introduction 166

8.2

Experimental permeability

results 168

8.3 Geometric effects 187

8.4 Deformation and

permeability

196

8.5 Conclusions 208

8.6

Acknowledgements

209

8.7

References 210

8.8

Appendix:

nomenclature 214

9 Understanding variability

in the

permeability

of

non-crimp

fabric

composite

reinforcements 216

A.

Endruweit

and A. C.

Long, University

of

Nottingham,

UK

9.1

Introduction

216

9.2 Material characterisation

217

9.3

Permeability

measurement

222

9.4 Modelling

and simulation

233

9.5

Future trends

239

9.6

References

239

10

Modelling

of the

permeability

of

non-crimp

fabrics

for

composites 242

B.

Verleye,

S. V.

Lomov and

D.

Roose,

Katholieke Universiteit

Leuven,

Belgium

10.1

Introduction 242

10.2

Numerical simulation 246

10.3

Experimental

validation 251

10.4

Parametric

study

253

10.5

Influence of shear 256

10.6 Conclusion

257

10.7

Acknowledgements 257

10.8 References

258

Part

III

Properties

of

non-crimp

fabric

composites

261

11 Mechanical

properties

of

non-crimp

fabric

(NCF)

based

composites:

stiffness and

strength

263

S. V.

Lomov, T. Truonq Chi and I.

Verpoest,

Katholieke

Universiteit

Leuven,

Belgium

11.1 Introduction

263

11.2 Materials and

composite production

264

11.3

Test

procedures

265

11.4

Mechanical

properties

of

non-crimp

fabric

(NCF)

composites

266

11.5 Mechanical

properties

of

composites

based on

sheared MMCF 274

11.6

Damage development

in B2

(0790)

laminates 279

11.7

X-ray radiography

283

11.8

Damage

initiation in non-sheared

and sheared materials 285

11.9 Conclusions

286

11.10 References

287

12

Damage progression

in

non-crimp

fabric

composites

289

L.

E.

Asp,

J.

Varna and E.

Marklund,

Swerea SICOMP and

Lulea

University

of

Technology,

Sweden

12.1 Introduction 289

12.2

Damage progression

in

non-crimp

fabric

(NCF)

composites

due to

in-plane loading

290

12.3

Damage progression

in

impacted

NCF

composites

300

12.4 Conclusions 308

12.5 References 308

13

Fatigue

in

non-crimp

fabric

composites 310

K.

Vallons, Katholieke Universiteit

Leuven, Belgium

13.1

Introduction

310

13.2

Fatigue

in

non-crimp

fabric

(NCF)

composites

311

13.3

Post-fatigue

residual

properties

330

13.4 Conclusions and

open questions

332

13.5 References

332

13.6

Appendix 333

14 Mechanical

properties

of

structurally

stitched

non-crimp

fabric

composites

335

N.

Himmel,

Institut ftir Verbundwerkstoffe

GmbH,

Germany

and

H.

HeB,

BASF

Engineering

Plastics

Europe, Germany

14.1 Introduction

335

14.2 Materials and

stitching

configurations

337

14.3

Characterisation of

structurally

stitched

NCF laminates

341

14.4

Simulation of mechanical behaviour of

structurally

stitched laminates 348

14.5 Conclusions and future trends 354

14.6 References 355

15

Predicting

the effect of

stitching

on the

mechanical

properties

and

damage

of

non-crimp

fabric

composites:

finite element

analysis

360

D. S.

Ivanov,

S. V. Lomov and I.

Verpoest,

Katholieke

Universiteit

Leuven,

Belgium

15.1 Introduction

360

15.2

Representative

volume element

(RVE)

of

non-crimp

fabric

(NCF)

composites

363

15.3 Elastic

analysis

369

15.4

Damage

accumulation in

NCF

composites

372

15.5 Conclusions

383

15.6 References

384

16

Modelling drape,

stress and

impact

behaviour

of

non-crimp

fabric

composites

386

A.

K.

Pickett, University

of

Stuttgart, Germany

16.1 Finite

element

(FE)

methods for

drape,

stress and

impact analysis

386

16.2 Laminate

analysis

and FE stiffness for

non-crimp

fabric

(NCF)

387

16.3

FE methods for infusion

analysis

389

16.4

Draping

and FE simulation

390

16.5

Infusion simulation 394

16.6

Stiffness and failure

394

16.7

Impact

and failure

396

16.8 References

400

17

Modelling

stiffness and

strength

of

non-crimp

fabric

composites:

semi-laminar

analysis

402

E.

Marklund, J.

Varna and L. E. Asp, Swerea SICOMPand

Lulea

University

of

Technology,

Sweden

17.1

Introduction 402

17.2

Stiffness models 405

17.3

Strength

models for

non-crimp

fabric

(NCF) composites

420

17.4 Conclusions

435

17.5 References

436

Part IV

Applications

of

non-crimp

fabric

composites

439

18

Aerospace applications

of

non-crimp

fabric

composites

441

P. Middendorf and C. Metzner, EADS Innovation

Works,

Germany

18.1 Introduction 441

18.2 Aeronautic

requirements

443

18.3

Application examples

445

18.4 Future trends

447

18.5

References 448

19

Non-crimp

fabric:

preforming analysis

for

helicopter applications

449

F. Dumont and C.

Weimer,

Eurocopter

Deutschland

GmbH,

Germany

19.1 Introduction 449

19.2 Preform

techniques

for

non-crimp

fabrics

(NCFs)

449

19.3 Main NCF deformation mechanism

observed

during preforming

454

19.4

Preforming

defect analysis

456

19.5 Conclusion and future trends

458

19.6 References 460

20 Automotive

applications

of

non-crimp

fabric

composites

461

B. SkOck-Hartmann and T.

Gries,

Institut ftirTextiltechnik

(ITA)

of RWTH Aachen

University,

Germany

20.1 Introduction

461

20.2

Applications

of

non-crimp

fabrics

(NCF)

in the

automotive

industry

466

20.3 Research and

development

for the use of

NCF in automotive

applications 469

20.4 Future trends

476

20.5 Conclusion

478

20.6 References

479

21

Non-crimp

fabric

composites

in wind turbines 481

G. Adolphs and C.

Skinner, OCV Technical

Fabrics,

Belgium

21.1 Introduction

481

21.2

Development

of

non-crimp

fabric

(NCF) composites

in wind

energy

483

21.3 NCF materials

used in nacelle construction 491

21.4

Future trends

492

21.5

References

493

22

Cost

analysis

in

using non-crimp

fabric

composites

in

engineering

applications

494

P.

Schubel,

University

of

Nottingham,

UK

22.1 Introduction 494

22.2

Costing methodologies: current

approaches

495

22.3 Technical cost

modelling

496

22.4 Case

study:

40 m wind turbine blade shell

504

22.5

Acknowledgements

509

22.6 References 509

Index

511

Você também pode gostar

- Modeling Embedded Systems and SoC's: Concurrency and Time in Models of ComputationNo EverandModeling Embedded Systems and SoC's: Concurrency and Time in Models of ComputationAinda não há avaliações

- Softening of Concrete Loaded in Compression: WWW - Tue.nl/taverneDocumento234 páginasSoftening of Concrete Loaded in Compression: WWW - Tue.nl/taverneYogesh YadavAinda não há avaliações

- Handbook of 3D Integration, Volume 1: Technology and Applications of 3D Integrated CircuitsNo EverandHandbook of 3D Integration, Volume 1: Technology and Applications of 3D Integrated CircuitsPhilip GarrouAinda não há avaliações

- Woven Fabric EngineeringDocumento436 páginasWoven Fabric Engineeringbrg_shekhar80% (5)

- ANN ThesisDocumento163 páginasANN ThesisSonal PanwarAinda não há avaliações

- Lecture1 ALLDocumento35 páginasLecture1 ALLadeelyjAinda não há avaliações

- Design of Composite Structures Against FatigueDocumento272 páginasDesign of Composite Structures Against Fatigueqasda100% (1)

- M.tech. Textile TechnologyDocumento26 páginasM.tech. Textile TechnologyNilesh Shingote100% (1)

- (Modern Concrete Technology) Alva Peled, Arnon Bentur, Barzin Mobasher-Textile Reinforced Concrete-CRC Press (2017) PDFDocumento490 páginas(Modern Concrete Technology) Alva Peled, Arnon Bentur, Barzin Mobasher-Textile Reinforced Concrete-CRC Press (2017) PDFLong Ct100% (3)

- National University of Sciences & Technology: Final Year Project Report TitleDocumento82 páginasNational University of Sciences & Technology: Final Year Project Report TitleAhsen IftikharAinda não há avaliações

- (Engin 1Documento444 páginas(Engin 1Esmael AdemAinda não há avaliações

- 2001 TB 194 Construction, Laying and Installation TDocumento145 páginas2001 TB 194 Construction, Laying and Installation Tculjak_i0% (1)

- Fatigue Testing of 3D-Printed Compliant Joints: An Experimental StudyDocumento73 páginasFatigue Testing of 3D-Printed Compliant Joints: An Experimental StudyCamilo TorresAinda não há avaliações

- Ali Elkamel, Hesham Alhumade, Navid Omidbakhsh, Keyvan Nowruzi, Thomas Duever - Chemical Product Formulation Design and Optimization. Methods, Techniques, and Case Studies-Wiley (2023)Documento227 páginasAli Elkamel, Hesham Alhumade, Navid Omidbakhsh, Keyvan Nowruzi, Thomas Duever - Chemical Product Formulation Design and Optimization. Methods, Techniques, and Case Studies-Wiley (2023)Ömer CanAinda não há avaliações

- Handbook of Polymeric Foams and Foam Technology: HanserDocumento10 páginasHandbook of Polymeric Foams and Foam Technology: Hanserfreidor0% (2)

- Report v6Documento28 páginasReport v6Farukh AzizzAinda não há avaliações

- Finite-Element Plasticity and Metalforming AnalysisDocumento323 páginasFinite-Element Plasticity and Metalforming AnalysisHassan DM100% (1)

- Annex - 6 IndutechDocumento16 páginasAnnex - 6 IndutechSiddharthBhasneyAinda não há avaliações

- M.Tech Mini Project ReportDocumento37 páginasM.Tech Mini Project Reportjuned shaikhAinda não há avaliações

- M. Rades - Dynamics of Machinery 3Documento300 páginasM. Rades - Dynamics of Machinery 3Alex IordacheAinda não há avaliações

- Polymers 13 04126 v2Documento21 páginasPolymers 13 04126 v2moraleslaureanoAinda não há avaliações

- 3D Printing For Energy Applications Vincenzo Esposito Full ChapterDocumento51 páginas3D Printing For Energy Applications Vincenzo Esposito Full Chapteryvonne.bowling742100% (14)

- Preforming: Test and Simulation MethodsDocumento35 páginasPreforming: Test and Simulation MethodsadeelyjAinda não há avaliações

- Hakemlik MakaleDocumento22 páginasHakemlik MakaleTuran ÇetinAinda não há avaliações

- The Effect of Residual Stress and Crack Closure On Fatigue CrackDocumento304 páginasThe Effect of Residual Stress and Crack Closure On Fatigue CrackTácito PicançoAinda não há avaliações

- Analysis of Membrane StructuresDocumento104 páginasAnalysis of Membrane StructuresRuperto Bravo100% (2)

- Ibtesam' ThesisDocumento126 páginasIbtesam' Thesishasanmt23Ainda não há avaliações

- Prevention Pave CrackingDocumento136 páginasPrevention Pave Crackingbloomdido100% (2)

- PHD Thesis Ana GiraoDocumento370 páginasPHD Thesis Ana GiraoMassimo LatourAinda não há avaliações

- 10 - A Surrogate Modelling Strategy To Improve The Surface Morphology Quality 2023Documento14 páginas10 - A Surrogate Modelling Strategy To Improve The Surface Morphology Quality 2023yasin yapiciAinda não há avaliações

- Dassa PHD Thesis CensDocumento133 páginasDassa PHD Thesis CenstonisugusAinda não há avaliações

- TT IIIDocumento21 páginasTT IIIVedha ThangavelAinda não há avaliações

- Bruno 2021Documento156 páginasBruno 2021Yash MittalAinda não há avaliações

- Processes and Properties of Polymer Composites Used For Additive ManufacturingDocumento4 páginasProcesses and Properties of Polymer Composites Used For Additive ManufacturingSantiago OrtizAinda não há avaliações

- Proceedings 02 00425 v2Documento7 páginasProceedings 02 00425 v2abthakurAinda não há avaliações

- Battery ReconditioningDocumento26 páginasBattery ReconditioningJamesTimAinda não há avaliações

- A5 Manual Welding Product Guide Feb 2016 Low Res Final 1379066 SnapshotDocumento40 páginasA5 Manual Welding Product Guide Feb 2016 Low Res Final 1379066 SnapshotRaron1Ainda não há avaliações

- ASTM B 211 StandardDocumento10 páginasASTM B 211 StandardalbertAinda não há avaliações

- Battery Bank App Note ADocumento22 páginasBattery Bank App Note Aamorosoy100% (3)

- Lead Acid Battery Instruction Sheet (f5)Documento4 páginasLead Acid Battery Instruction Sheet (f5)FaycelmekadminiAinda não há avaliações

- ASTM B 211 StandardDocumento10 páginasASTM B 211 StandardalbertAinda não há avaliações

- Application Note: Measurements On FM Transmitters For Acceptance, Commissioning and MaintenanceDocumento89 páginasApplication Note: Measurements On FM Transmitters For Acceptance, Commissioning and MaintenanceabthakurAinda não há avaliações

- Beamex White Paper - Weighing Scale Calibration ENGDocumento8 páginasBeamex White Paper - Weighing Scale Calibration ENGabthakurAinda não há avaliações

- Calibration WeightsDocumento5 páginasCalibration WeightsabthakurAinda não há avaliações

- Adhesion Test SpecDocumento3 páginasAdhesion Test SpecdcevipinAinda não há avaliações

- Sony BDP 1100Documento36 páginasSony BDP 1100abthakurAinda não há avaliações

- 230S 1 PDFDocumento21 páginas230S 1 PDFabthakurAinda não há avaliações

- Aluminum Reference GuideDocumento6 páginasAluminum Reference GuideAravind BaskerAinda não há avaliações

- An5030 PDFDocumento20 páginasAn5030 PDFCanh LuongtienAinda não há avaliações

- An 15Documento2 páginasAn 15abthakurAinda não há avaliações

- Byv26a Byv26cDocumento2 páginasByv26a Byv26cabthakurAinda não há avaliações

- Data SheetDocumento2 páginasData SheetabthakurAinda não há avaliações

- An 15Documento2 páginasAn 15abthakurAinda não há avaliações

- Icl7106 Icl7107Documento14 páginasIcl7106 Icl7107José AdelinoAinda não há avaliações

- E4329 QuickGuideDocumento52 páginasE4329 QuickGuidelumasAinda não há avaliações

- Byv26a Byv26cDocumento2 páginasByv26a Byv26cabthakurAinda não há avaliações

- Aluminium TemperDocumento4 páginasAluminium TemperSinan YıldızAinda não há avaliações

- Datasheet - HK Cxa1213bs 194518Documento26 páginasDatasheet - HK Cxa1213bs 194518abthakurAinda não há avaliações

- Company Profile - Shubh CastingsDocumento5 páginasCompany Profile - Shubh CastingsabthakurAinda não há avaliações

- Vernier CalipersDocumento32 páginasVernier CalipersabthakurAinda não há avaliações

- Display Pixel Defect InformationDocumento3 páginasDisplay Pixel Defect InformationabthakurAinda não há avaliações

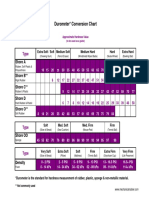

- Durometer Conversion Table PDFDocumento1 páginaDurometer Conversion Table PDFabthakurAinda não há avaliações

- Chopped Strand Mat For Hand-Lay Up: Product DescriptionDocumento2 páginasChopped Strand Mat For Hand-Lay Up: Product DescriptionabthakurAinda não há avaliações

- Gap Analysis ChecklistDocumento5 páginasGap Analysis ChecklistabthakurAinda não há avaliações

- ICSECM-2017 Chameera UdawatthaDocumento11 páginasICSECM-2017 Chameera UdawatthaSavinda SenevirathneAinda não há avaliações

- Paper Hanoi Metro ToSEAGS-AGSSEA VDDDocumento7 páginasPaper Hanoi Metro ToSEAGS-AGSSEA VDDIngrid Irreño PalomoAinda não há avaliações

- 3D ExerciseDocumento1 página3D ExerciseRashiqah RazlanAinda não há avaliações

- Catalogo General TeleH ESPDocumento156 páginasCatalogo General TeleH ESPAnonymous MbqTZHLNR9Ainda não há avaliações

- Question Bank Chemistry 1Documento34 páginasQuestion Bank Chemistry 1Karanam.Ramakumar100% (3)

- Session 11 Physical Vapour DepositionDocumento26 páginasSession 11 Physical Vapour DepositionMurali DontuAinda não há avaliações

- Point Group PDFDocumento46 páginasPoint Group PDFDharamsingh WaskaleAinda não há avaliações

- NIRMAL-Guidelines-Mini Project or Internship Assessment Report (KEE-354)Documento7 páginasNIRMAL-Guidelines-Mini Project or Internship Assessment Report (KEE-354)anurudhAinda não há avaliações

- Fast Numerical Methods For Mixed-Integer Nonlinear Model-Predictive ControlDocumento380 páginasFast Numerical Methods For Mixed-Integer Nonlinear Model-Predictive ControlDaniel Suarez ReyesAinda não há avaliações

- Quantitative Analysis of A Sulfate: I. RationaleDocumento5 páginasQuantitative Analysis of A Sulfate: I. RationaleBhupesh MulikAinda não há avaliações

- 10ME82 16-17 (Control Engg.)Documento30 páginas10ME82 16-17 (Control Engg.)Sharanabasappa SajjanAinda não há avaliações

- Solving Equilibrium Problems FDocumento16 páginasSolving Equilibrium Problems FAntonyAinda não há avaliações

- Home Assignment DC Motor Control1Documento7 páginasHome Assignment DC Motor Control1jegjegtAinda não há avaliações

- Ferroelectricity in HfO2Documento6 páginasFerroelectricity in HfO2Basharat AhmadAinda não há avaliações

- Final Exam 2010 SolnDocumento7 páginasFinal Exam 2010 SolnSimon AlmeidaAinda não há avaliações

- Module 3: Mass Transfer Coefficients: Lecture No. 5Documento3 páginasModule 3: Mass Transfer Coefficients: Lecture No. 5walisyhAinda não há avaliações

- Marksheet PDFDocumento1 páginaMarksheet PDFDurjoy DasAinda não há avaliações

- Experiment 5Documento6 páginasExperiment 5Vinicius GuimarãesAinda não há avaliações

- Drying Shrinkage C596.22657 PDFDocumento4 páginasDrying Shrinkage C596.22657 PDFSARAH ABRAHAM0% (1)

- InterferenceDocumento8 páginasInterferencerajesh.v.v.kAinda não há avaliações

- Chapter13 PDFDocumento34 páginasChapter13 PDFAnastasia BulavinovAinda não há avaliações

- A Comparative Ion Chemistry Study of Acetone, Diacetone Alcohol, and Mesityl OxideDocumento10 páginasA Comparative Ion Chemistry Study of Acetone, Diacetone Alcohol, and Mesityl OxidevasucristalAinda não há avaliações

- 53206-mt - Computational Fluid DynamicsDocumento2 páginas53206-mt - Computational Fluid DynamicsSRINIVASA RAO GANTAAinda não há avaliações

- 3 Rekayasa Reaksi PolimerisasiDocumento86 páginas3 Rekayasa Reaksi Polimerisasirudy_423522658Ainda não há avaliações

- Experiment No 7-MQCDocumento7 páginasExperiment No 7-MQCArvind Bhosale100% (1)

- 1006 1009Documento4 páginas1006 1009SinhrooAinda não há avaliações

- AIChE - Integrate Compressor Performance Maps Into Process SimulationDocumento6 páginasAIChE - Integrate Compressor Performance Maps Into Process SimulationMuhammad ImranAinda não há avaliações

- Chapt-17 Compass ErrorDocumento4 páginasChapt-17 Compass ErrorShubham SinghAinda não há avaliações

- Chapter 21Documento26 páginasChapter 21Sabeeh HasnainAinda não há avaliações

- Gantry GirderDocumento39 páginasGantry GirderolomizanaAinda não há avaliações

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisNo EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisNota: 5 de 5 estrelas5/5 (1)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tNo EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tNota: 4.5 de 5 estrelas4.5/5 (27)

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceNo EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceNota: 4 de 5 estrelas4/5 (19)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureNo EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureNota: 4.5 de 5 estrelas4.5/5 (2)

- Analog Design and Simulation Using OrCAD Capture and PSpiceNo EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceAinda não há avaliações

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsAinda não há avaliações

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneNo EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneNota: 4.5 de 5 estrelas4.5/5 (5)

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsNo EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsNota: 5 de 5 estrelas5/5 (1)

- Design for How People Think: Using Brain Science to Build Better ProductsNo EverandDesign for How People Think: Using Brain Science to Build Better ProductsNota: 4 de 5 estrelas4/5 (8)

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersNo EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersNota: 4 de 5 estrelas4/5 (13)

- Laws of UX: Using Psychology to Design Better Products & ServicesNo EverandLaws of UX: Using Psychology to Design Better Products & ServicesNota: 5 de 5 estrelas5/5 (9)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsAinda não há avaliações

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchNo EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchNota: 4 de 5 estrelas4/5 (10)

- Guidelines for Auditing Process Safety Management SystemsNo EverandGuidelines for Auditing Process Safety Management SystemsAinda não há avaliações

- A Complete Guide to Safety Officer Interview Questions and AnswersNo EverandA Complete Guide to Safety Officer Interview Questions and AnswersNota: 4 de 5 estrelas4/5 (1)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableNo EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableAinda não há avaliações

- Lean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsNo EverandLean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsNota: 4 de 5 estrelas4/5 (2)

- Rules of Thumb for Maintenance and Reliability EngineersNo EverandRules of Thumb for Maintenance and Reliability EngineersNota: 4.5 de 5 estrelas4.5/5 (12)