Escolar Documentos

Profissional Documentos

Cultura Documentos

Supplier Scorecards

Enviado por

meetsarkar0 notas0% acharam este documento útil (0 voto)

64 visualizações7 páginassupplier scorecard

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentosupplier scorecard

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

64 visualizações7 páginasSupplier Scorecards

Enviado por

meetsarkarsupplier scorecard

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 7

Directworks Case Study

Directworks Case Study

Supplier scorecards have been a critical piece of any supplier relationship

management program for decades. They can be a very effective tool

for virtually any industry and every type of spend. When done well,

they can drive supplier performance to levels that truly impact your

companys bottom line.

So heres a question: Why is it that everywhere you look, e.g., industry

conferences, LinkedIn discussions, community portals, and blogs and

such, people are still asking questions about how to fix their supplier

scorecards? This practice should not be that difficult, so what is the

source of frustration? Following are two articles that shed some light

on the issue as well as some best practices to overcome the challenges

of supplier scorecarding.

1

2014 Directworks

Supplier scorecards

Supplier scorecards www.directworks.com

Metrics are incomplete or not timely

For anyone who ever had to pull metrics, the first source of frustration is easy to identify. Accurate metrics are

rarely at ones fingertips. The data exists in multiple systems and lack of data standardization can make it difficult

to roll up to an individual supplier. Also, the time frame or event period that the data represents may be difficult

to align. Its pure frustration right out of the gate. Thus, instead of focusing on capturing the right information

needed to meaningfully measure supplier performance, companies often find themselves measuring what is most

convenient and easy to report on. This results in a scorecard that is ineffective at driving true supplier performance.

Creating an effective supplier scorecard has proven to be much

more difficult than one would think. While there are many

potholes and roadblocks that need to be overcome, a number

of leading manufacturers have clearly identified and prioritized

the key issues that need to be addressed. Lets examine these.

Its the same scorecard for every type of supplier

All suppliers are not the same. As an example, the Kraljic Model classies suppliers as commodity, transactional,

bottleneck, or strategic. Each segment represents diferent levels of prot impact, sourcing risk, and complexity to

replace. Each segment also requires very diferent supplier management strategies and action plans. So why do so many

companies have just one type of supplier scorecard or choose to only use scorecards with select segments? Customizing

your scorecard by segment will enable you to enhance the value each segment can provide to your organization.

2

2014 Directworks

So how do you address the many frustrations related to supplier scorecards? First, focus your scorecard around

improving the end-game, such as margin enhancement for a division or product line. Second, you will need to

understand the interrelationships between supplier metrics and how changing one can adversely change another.

For example, optimizing shipping costs for Supplier ABC may save you money in logistics, but drive up inventory

and storage expenses. Third, make sure your supplier scorecard is appropriate for the role or value that the supplier

serves for your company. Finally, and most challenging of all, you need to get accurate, timely data that can be

relied upon. If you can do these things, you should be able to quickly discover issues to address which will truly

improve your companys bottom line.

Too much qualitative, not enough quantitative

Misaligned department objectives

A one-sided view of the relationship

One sure-fire way of judging a scorecard quickly is to examine the type of individual

metrics. How many are quantitative versus qualitative (yes/no, excellent/average/

poor). For the quantitative ones, how many are actual calculations, preferably

fed in and verified? A good scorecard utilizes quantitative metrics with little

subjectivity. Using too many metrics that are opinion- and judgment-based yields

great debate and significant frustration.

There are many stakeholders in the sourcing and supplier management arena

including executives, process owners, functional partners, commodity managers,

and so on. Each stakeholder views supplier performance a bit differently and may

have conflicting goals. Too many times, the overall company business objectives

get lost in the shuffle with one departments gains being offset by anothers

losses. Scorecards need to be built so they show the true impact on overarching

company objectives. It takes a collaborative process that is driven by the C-suite.

Finally, many scorecards today are very one-sided with the buyer scoring the supplier

and asking what are you going to do to make this better? The reality is that the

buyer and supplier are interrelated, with each impacting the others performance.

In the manufacturing industry, best-in-class supplier managers have turned to

conducting 360 degree reviews and closely examining how their own processes

and performance impacts each of their suppliers. Manufacturers recognize that

changes on their side of the equation can also improve supplier performance. So do

you have a scorecard that tracks internal performance?

Conclusion

Scorecard data not integrated into sourcing and supplier management tools

The next source of frustration centers on how scorecard templates and data

often function outside of ones existing sourcing and supplier management tools.

Many scorecards are spreadsheet-based with a lot of manual processing and data

cleansing needed. Without integration, purchasing and sourcing specialists may

be acting on old data including bringing suppliers into the fold who should be on

a block or watch list. Gathering and analyzing data from multiple places can be

time consuming and fraught with error. Outbound integration is also needed to

push supplier data collected during a sourcing event into the scorecard process.

3

Directworks Case Study

The ABCs to building an

efective scorecard

I. Establish the right purpose for your scorecard

A truly effective scorecard is one that successfully identifies supplier risk and performance issues allowing ample

time to correct the issues before they impact financial performance. The metrics monitored should be linked to

root causes and be easily verifiable by the supplier. It is a communication tool that all parties have helped to build

and act upon. Each involved party should be motivated to get the most effective scorecard system in place. A

scorecard should be viewed as a tool that helps create long-term, successful relationships.

In nearly every industry, supplier scorecards are viewed as an important part of

managing supplier relationships. Scorecards help keep both parties on the same

page. They are used to identify areas of improvement, to justify change, or to add

extra incentive when pushing good suppliers to take performance to the next level.

Unfortunately, many will tell you that while they believe in the scorecard process,

they struggle to build a scorecard that is truly efective. Data can be inaccurate,

not timely, out of sync, too hard to measure, or not provide enough direction on

how to address a particular issue. Manufacturers have been wrestling with this

challenge for years and many have made signicant progress. Lets look at some key

practices that have made a diference.

4

2014 Directworks

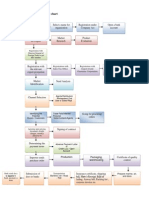

II. Build it backwards

The best way to build a truly effective scorecard is to

start at the end of the process and work your way back

to the metrics you need to capture. The end of the

process can be defined as the final action you need to

take because of the storyline that the scorecard metrics

are telling. Lets look at the following example.

Suppliers need to be able to deliver the right amount

of components or direct materials in the timeframe

required. Those who fail may ultimately be replaced,

even if they have the best price. In this situation, this

action marks the end of the process. So lets continue to

build the story backwards, identifying measurements

and data needed to identify the problems.

Working backwards allows you to identify various storylines that need to be tracked so you never experience a

production line stoppage due to a component shortage. Its the metrics along the way that help identify root

causes and potential solutions. In the example above, shipments from Asia to the US were being held up in Customs

much longer than expected. The supplier agreed to provide additional lead time to help address the problem.

1. A manufacturer has identified that if it should run out of component XYZ, production lines will stop

completely resulting in significant costs and a potential loss of sales. The component is a critical part

of the final product and is hard to source at a reasonable price.

2. For such strategic components, a policy is created stating that every supplier who misses their

delivery commitments, on average, 20% of the time or more be reviewed for corrective action or

possible replacement.

3. A dashboard indicator is created that turns red when 15% of components provided by a supplier

arrive beyond the promised delivery date. A three month rolling average is used to calculate the metric.

4. Any supplier receiving a red flag on this issue must immediately review its production floor metrics

to determine if the agreed upon quantity is being produced in the agreed upon timeframe, as well

as metrics around how long it takes to move the finished product to port.

5. Simultaneously, the logistics group reviews the metrics that show the amount of time it takes for

products delivered to the port to reach their final destination, the plant floor.

6. Finally, metrics are created showing the number of components in stock, as well as the number needed

for the week or month of production.

5

2014 Directworks

To learn more

Call 724.933.1180 or Visit www.directworks.com

.

About Directworks

Directworks provides cloud-based software solutions purpose-built for

manufacturers to improve supplier collaboration, total cost visibility, and the

efciency of sourcing and supplier management activities. Leading manufacturers

use Directworks to accelerate product launches, expand margins, and optimize

their direct materials supply chain for cost, performance, and risk.

To learn more about

our sourcing and

supplier management

software, call

724.933.1180

Conclusion

When done well, scorecards can be a powerful tool that not only reduce risk and enable better supplier performance,

but improve product profitability. Scorecards are worth the investment they take to set up. Those that excel

at building effective scorecards will achieve a competitive advantage by ensuring that the right suppliers are

delivering the right materials at the right time.

1. Make sure the data collected for each metric is from the same time period.

2. Rely on data that is system generated and less subject to human error.

3. Audit key data elements to ensure quality, including supplier-provided data.

4. Only pull the data you need, as it is easier to manage, maintain, and keep clean.

III. Address the roadblocks

Building a scorecard backwards allows you to create a path from metric to action enabling you to identify root

causes and correct deficiencies before they impact your profits. But you still must pay attention to the finer details

of data collection, which, if ignored, can truly derail a good scorecard. Here are some tips:

6

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- AI - Playbook Executive Briefing Artificial IntelligenceDocumento27 páginasAI - Playbook Executive Briefing Artificial IntelligencemeetsarkarAinda não há avaliações

- Export ProcedureDocumento42 páginasExport Procedurevenkataswamynath channa85% (13)

- EyDocumento2 páginasEymeetsarkarAinda não há avaliações

- Cost Reduction StrategiesDocumento10 páginasCost Reduction StrategiesmeetsarkarAinda não há avaliações

- American Tower ReportDocumento13 páginasAmerican Tower ReportmeetsarkarAinda não há avaliações

- Tutorial On Exposure MeteringDocumento10 páginasTutorial On Exposure MeteringmeetsarkarAinda não há avaliações

- BASF in India Manufactures PolymersDocumento3 páginasBASF in India Manufactures PolymersmeetsarkarAinda não há avaliações

- BASF India LTDDocumento6 páginasBASF India LTDmeetsarkarAinda não há avaliações

- How To Photograph ArchitectureDocumento29 páginasHow To Photograph ArchitecturemeetsarkarAinda não há avaliações

- PMI Procedure Rev.00Documento13 páginasPMI Procedure Rev.00Abdul Khaliq40% (5)

- NegotiationSkills FreeReportDocumento19 páginasNegotiationSkills FreeReportmeetsarkarAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- PPS User ManualDocumento294 páginasPPS User ManualVincent Grondin100% (1)

- Software Requirements Specification: Version 1.1 ApprovedDocumento19 páginasSoftware Requirements Specification: Version 1.1 ApprovedaslamAinda não há avaliações

- Basic Data: Consent of Otis GMBHDocumento30 páginasBasic Data: Consent of Otis GMBHRafael Bruno100% (5)

- WASv7 Tuning Script Templates v1 1Documento12 páginasWASv7 Tuning Script Templates v1 1Pardhasaradhi KogantiAinda não há avaliações

- SOAS and Ministry of Defence, Freedom of Information ResponsesDocumento2 páginasSOAS and Ministry of Defence, Freedom of Information ResponsesDemilitarise SOASAinda não há avaliações

- GCC Mid-2 For Students Question BankDocumento2 páginasGCC Mid-2 For Students Question BankJayakanthAinda não há avaliações

- BibType GuideDocumento3 páginasBibType GuidewankbassAinda não há avaliações

- Ibm DatastageDocumento74 páginasIbm Datastagezipzapdhoom100% (1)

- Simatic Communication With SIMATIC: The Following Supplement Is Part of This DocumentationDocumento220 páginasSimatic Communication With SIMATIC: The Following Supplement Is Part of This DocumentationRMK BrothersAinda não há avaliações

- 1850 TSS-320 R3-4 DSDocumento3 páginas1850 TSS-320 R3-4 DSbaratepaAinda não há avaliações

- DSP FFT - Codigo en MatlabDocumento2 páginasDSP FFT - Codigo en MatlabmickvillacisAinda não há avaliações

- Introduction To Programming Expert Advisors in MQL4Documento89 páginasIntroduction To Programming Expert Advisors in MQL4abdulrazakyunus100% (2)

- Mis Pepsico Project ReportDocumento63 páginasMis Pepsico Project ReportSheenam BhallaAinda não há avaliações

- PIP For Oracle Product Hub DataSheetDocumento3 páginasPIP For Oracle Product Hub DataSheetaliAinda não há avaliações

- (Live) NUET Syllabus DetailsDocumento5 páginas(Live) NUET Syllabus DetailsVestineo100% (1)

- Data Analytics With Spark PDFDocumento29 páginasData Analytics With Spark PDFBesmirSejdiuAinda não há avaliações

- Genmath Quiz 1Documento1 páginaGenmath Quiz 1Genelle Mae MadrigalAinda não há avaliações

- Transport DocumentDocumento7 páginasTransport DocumentSatish KumarAinda não há avaliações

- Latest Trends in Test Automation 2018Documento9 páginasLatest Trends in Test Automation 2018Harsh Murari100% (1)

- Scan Path DesignDocumento54 páginasScan Path DesignaguohaqdoAinda não há avaliações

- Archmodels 06Documento5 páginasArchmodels 06Ahmed SamiAinda não há avaliações

- Sapience AgentDocumento26 páginasSapience AgentSimin GeorgeAinda não há avaliações

- Fundamentals of Instrumentation and More by NJATC PDFDocumento195 páginasFundamentals of Instrumentation and More by NJATC PDFfarhanishaque616100% (8)

- Ir Shell 3 9 User GuideDocumento35 páginasIr Shell 3 9 User Guidestranno100% (8)

- Computer System Overview (Review) : Operating SystemsDocumento50 páginasComputer System Overview (Review) : Operating SystemsLộc Khang PhúcAinda não há avaliações

- Altair's Student Guides - Instructor's Manual - CAE and Multi Body DynamicsDocumento18 páginasAltair's Student Guides - Instructor's Manual - CAE and Multi Body DynamicsKFourMetrics100% (5)

- Rock Classification (Group Activity)Documento1 páginaRock Classification (Group Activity)Pocholo GarciaAinda não há avaliações

- How To Create A Project For A Simple UClinux Ready MicroBlaze 4.0 Design On XPS (Xilinx Platform Studio) For Spartan-3EDocumento13 páginasHow To Create A Project For A Simple UClinux Ready MicroBlaze 4.0 Design On XPS (Xilinx Platform Studio) For Spartan-3EIvan RomoAinda não há avaliações

- Gitlab Basics: Common TerminologiesDocumento4 páginasGitlab Basics: Common Terminologiesali razaAinda não há avaliações

- Code Division DuplexingDocumento39 páginasCode Division DuplexingVinayKumarSingh100% (5)