Escolar Documentos

Profissional Documentos

Cultura Documentos

Investigation and Analysis of Metallurgical and Mechanical Properties of AA1100 Using FSW by P.vijayasarathi, D.christopher Selvam

Enviado por

ijr_journalDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Investigation and Analysis of Metallurgical and Mechanical Properties of AA1100 Using FSW by P.vijayasarathi, D.christopher Selvam

Enviado por

ijr_journalDireitos autorais:

Formatos disponíveis

International Journal of Research (IJR) Vol-1, Issue-7, August 2014 ISSN 2348-6848

INVE!I"A!I#N AN$ ANA%&I #' (E!A%%)R"I*A% AN$ (E*+ANI*A% ,R#,ER!IE #' AA1100 )IN" '-

,.VIJA&AARA!+I, $.*+RI!#,+ER E%VA(

, a g e / 1221

P.Vijayasarathi

1

, D.Christopher Selvam

2

1

(Mechanical Department, Anna university Research scholar, Chennai, India)

2

(Asst. Prof., Mechanical Department, Jeppiaar Institute Of Technology, Kunnam, Chennai,

India)

ABSTRACT:

The effect of processing parameters on the

mechanical and metallurgical properties

of two similar joints of AA1100 produced

by friction stir welding was analysed in

this investigated. Different FSW samples

were produced by varying the rotating

spindle speed of the tool as 800 and

1400rpm and by varying the alloy

positioned on the advancing side of the

tool. In all the experiments the horizontal

feed rate is fixed at 75m/min. All the welds

were produced perpendicularly to the

rolling direction for both the alloys. Micro

hardness (HV) and tensile tests performed

at room temperature were used to evaluate

the mechanical properties of the joints. In

order to analyse the micro structural

evolution of the material, the welds cross-

sections were observed optically and SEM

observations were made of the fracture

surfaces.

Keywords

FSW; Aluminium alloys AA110;

Mechanical and metallurgical

characterization.

I. INTRODUCTION

Modern aerospace concepts

demand reductions in both the weight as

well as cost of production of materials.

Under such conditions, welding processes

have proven most attractive, and programs

have been set up to study their potential.

Car manufacturers and shipyards are also

evaluating new production methods.

Increasing operating expenses are driving

manufacturers to reduce weight in many

manufacturing applications, particularly in

aerospace sector. The goal is to reduce the

costs associated with manufacturing

techniques to result in considerable cost

and weight savings by reducing

riveted/fastened joints and part count. One

way of achieving this goal is by utilising a

novel welding technology known as

Friction Stir Welding (FSW). Friction stir

welding is a solid-state joining process

developed and patented by the Welding

Institute (TWI) in 1991 by Thomas et al

and it is emerged as a welding technique to

be used in high strength alloys (2xxx,

6xxx, 7xxx and 8xxx series) for aerospace,

automotive and marine applications that

were difficult to join with conventional

techniques[1,2]. This technique is

attractive for joining high strength

aluminium alloys since there is far lower

heat input during the process compared

with conventional welding methods such

as Tungsten Inert Gas (TIG) or Metal Inert

Gas (MIG). This solid state process leads

to low distortion in long welds, excellent

Investigation and Analysis of Metallurgical and

Mechanical Properties of AA1100 using FSW

Investigation and Analysis of Metallurgical and Mechanical Properties of AA1100 using FSW

1222 | Page

mechanical properties in the weld and

heat-affected zone, no fumes or spatters,

low shrinkage, as well as being energy

efficient. Furthermore, other cost

reductions are realized in that the process

uses a non-consumable welding tool. The

process was developed initially for

aluminium alloys, but since then FSW was

found suitable for joining a large number

of materials.

In FSW a non-consumable rotating

tool with a specially designed pin and

shoulder is inserted into the abutting edges

of sheets or plates to be joined and

traversed along the line of joint. The tool

serves two primary functions: (a) heating

of work piece, and (b) movement of

material to produce the joint. The heating

is accomplished by friction between the

tool and the work piece and plastic

deformation of work piece. The localized

heating softens the material around the pin

and combination of tool rotation and

translation leads to movement of material

from the front of the pin to the back of the

pin. As a result of this process a joint is

produced in solid state. During FSW

process, the material undergoes intense

plastic deformation at elevated

temperature, resulting in generation of fine

and equiaxed recrystallized grains. The

fine microstructure in friction stir welds

produces good mechanical properties. Fig.

1 shows a schematic diagram of the FSW

process.

Figure 1: Schematic diagram of the FSW process.

Many papers are present in the literature

regarding this field. Further to joints of

similar alloys, FSW is being studied for

welding dissimilar alloys which can be of

particular interest in some industrial

applications. Some works can be found in

the literature [37], but data is still scarce

on the characterisation of 1100 joint type.

Some authors have demonstrated that the

microstructure of the weld nugget of

strongly different aluminium alloys is

mainly fixed at the retreating side of the

Investigation and Analysis of Metallurgical and Mechanical Properties of AA1100 using FSW

1223 | Page

material [3]. Murr et al. [8] showed the

properties of dissimilar casting alloys by

FSW. The micro structural evolution of

dissimilar welds as a function of

processing parameters has been widely

studied in [9], showing the behaviour of

AA6061AA2024 materials. Dickerson et

al. [10] found that friction-stir-welded butt

joints are generally defect free if welding

process conditions (welding speed and

sheet thickness) are properly tuned within

a tolerance box for a particular alloy. It is

not possible to assume that FSW will be

free of flaws, however, because

manufacturers may want to run FSW

outside the tolerance box in order to

increase productivity. The weld zones are

more susceptible to corrosion than the

parent metal [11-16]. Generally, it has

been found that Friction stir (FS) welds of

aluminium alloys such as 2219, 2195,

2024, 7075 and 6013 did not exhibit

enhanced corrosion of the weld zones.

FSW of aluminium alloys exhibit inter

granular corrosion mainly located along

the nuggets heat-affected zone (HAZ) and

enhanced by the coarsening of the grain

boundary precipitates. Coarse precipitates

and wide precipitate-free zones promoted

by the thermal excursion during the

welding are correlated with the

intergranular corrosion. The effect of FSW

parameters on corrosion behaviour of

friction stir welded joints was reported by

many workers [14, 16]. The effect of

processing parameters such as rotation

speed and traverse speed on corrosion

behaviour of friction stir processed high

strength precipitation harden able

AA2219-T87 alloy was investigated by

Surekha et al. [16]. However, researchers

have nevertheless been strained to study

competent study of the mechanical

properties in terms of UTS, YS and %

elongation, micro hardness test,

fractography analysis, and metallurgical

properties, and the main causes of

developing defects with changing FSW

parameters for a two similar aluminium

joint of AA1100. Selection of process

parameters is an important issue in the

FSW process. Present paper, the effect of

different welding speeds on the weld

characteristics of advancing and retreating

side of AA110 and retreating side of

AA1100 fabricated by a cylindrical-

shouldered tool pin profile is investigated.

2. EXPERIMENTAL PROCEDURE

The experiments were

conducted on the aluminium alloy AA110,

its chemical composition and mechanical

properties are respectively presented in

Tabs. 1.The rolled plates of 6.35mm

thickness were cut into the required size

(100mm100 mm) by power hacksaw

cutting and grinding. Square butt joint

configuration was prepared to fabricate

FSW joints. The initial joint configuration

was obtained by securing the plates in

position using mechanical clamps. The

direction of welding was normal to the

rolling direction. Single pass welding

procedure was used to fabricate the joints.

In present work cylindrical- shouldered

tool pin profile was used for the welds,

made of high carbon high chromium steel.

The tool dimensions are shown in Fig. 2.

The machine used for the production of the

joints was vertical machining centre.

Different materials positioned on the

advancing side of the tool allowed four

Investigation and Analysis of Metallurgical and Mechanical Properties of AA1100 using FSW

1224 | Page

different welding conditions described in Tab.2.

General Properties of AA1100

ALLOY

ULTIMATE

TENSILE

STRENGTH

(PSI)

THERMAL

EXPANSION

COEFFICIENT

DENSITY

KG/M

3

ELASTIC

MODULUS MELTING

POINT

AA100 13,000 20.4-25.010

-6

/K 2600-2800

70-79 GPa 660 C

Mechanical Properties of AA1100

Tensile Strength (M Pa) Yield Strength (M Pa) Elongation % Hardness (HV)

Min Max Min Max Min Max

230 570 215 505 8 25 90

Table 1: Chemical composition and mechanical properties AA1100.

OVER ALL PROCESS PARAMETERS

Materials of Rotational Speed

Vertical Force

Vertical Feed Horizontal

Chemical Compositions of AA1100

ELEME

NTS

Si & Fe Cu Mn

M

g

C

r

Zn Ti others Al

REQUI

RED

Mi

n

Ma

x

Mi

n

Ma

x

Mi

n

M

ax

- -

Mi

n

M

ax

M

ax

Eac

h

Tot

al

Si +

Fe

0.95

0.0

5

0.20 -

0.0

50

- - -

0.1

0

-

0-

0.0

5

0-

0.1

5

Bala

nce

CONTE

NTS

0.20 0.050

- -

0.10

- Bala

nce

Investigation and Analysis of Metallurgical and Mechanical Properties of AA1100 using FSW

1225 | Page

Joints (rpm) (Kg) Rate

(m/s)

Feed Rate

(mm/min)

AA1100 AA1100

800 6000 0.6 75

1000 7000 1.2 75

1200 8000 1.5 75

1400 8000 1.8 75

Table 2: Welding conditions employed to join the AA1100 plates.

Figure 2: Geometry of the cylindrical-shouldered tool pin profile used in the present study.

The design of the tool is a critical factor as

a good tool can improve both the quality

of the weld and the maximum possible

welding speed. The D3-type steel has High

carbon High chromium steel tool is

selected for welding[8]. The chemical

composition of the tool material described

in Tab.3.

All welded samples were visually

inspected in order to verify the presence of

possible macroscopic external defects,

such as surface irregularities, excessive

flash, and surface-open tunnels. By using

Radiographic unit, X-Ray radiographic

inspection was carried out on FSW

samples. The test is carried out in

Investigation and Analysis of Metallurgical and Mechanical Properties of AA1100 using FSW

1226 | Page

Metallurgical microscope- METOSCOPE-

1 equipment.

Mechanical properties of the test

welds were assessed by means of tensile

tests and the ultimate tensile stress (UTS)

yield strength (YS) and % elongation were

measured in the tensile test. Micro

indentation hardness test as per ASTM E-

384:2006 has been used to measure the

Vickers hardness of FSW joints. The

Vickers micro hardness indenter is made

of diamond in the form of a square-base

pyramid. The test load applied was 1Kg

and the dwell time was 15 seconds. The

indentations were made at midsection of

the thickness of the plates across the joint.

The tensile fractured surfaces were

analyzed by using scanning electron

microscopy (SEM).

Metallographic specimens were

cut mechanically from the welds,

embedded in resin and mechanically

ground and polished using abrasive disks

and cloths with water suspension of

diamond particles. The chemical etchant

was the Kellers reagent. The

microstructures were observed on optical

microscope.

Thermal and Physical Properties of the Tool material

TOOL

THERMAL

EXPANSION

COEFFICIENT

DENSITY

KG/M

3

ELASTIC

MODULUS

MELTING

POINT

D3 STEEL 1210

-6

/C 7.7x1000

190-210 GPa 1421C

Chemical Compositions of AA1100

ELEMEN

TS

C Mn Si Cr Ni W V P S Cu

CONTENT

S

2.00-

2.35

0.60 0.60

11.00

-

13.50

0.30 1.00 1.00

0.0

3

0.03 0.25

Table 3: Thermal Properties, Physical Properties and Chemical composition of D3 steel

tool.

Investigation and Analysis of Metallurgical and Mechanical Properties of AA1100 using FSW

1227 | Page

3. RESULT AND DISCUSSION

The mechanical and

metallurgical behaviour of two similar

FSW AA110 was studied in this research.

Transverse tensile properties of FSW

joints such as yield strength, tensile

strength, and percentage of elongation on

transverse tensile specimens are presented

in Tab. 4.

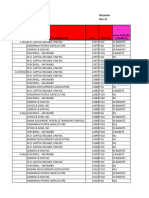

Material of FSW

Joint

Spindle Speed

in RPM

YS

(N/mm2)

UTS

(N/mm2)

% Elongation

AA1100

(TEST PIECE I)

800 105.44

110.57 8.00

AA1100

(TEST PIECE II)

1000 104.89

113.71 16.40

AA1100

(TEST PIECE III)

1200 87.94

93.37 12.40

AA1100

(TEST PIECE IV)

1400 91.82

98.62 9.20

Table 4: Mechanical properties of two similar FSW joints.

AA1100 (TEST PIECE I) is welded by

800 rpm tool rotation with vertical force of

6000Kg and the entire tool tip is inserted

in to the work piece with vertical feed rate

0.6m/s. At this condition the tool moves

entire length of the work piece with

horizontal feed rate of 75m/min on the

weld path between the weld plates. The

onion ring portion of the weld joints looks

very rough with excess of materials at the

edges of the weld part.

AA1100 (TEST PIECE II) is welded by

1000 rpm tool rotation with vertical force

of 7000Kg and the entire tool tip is

inserted in to the work piece with vertical

feed rate 1.2m/s. At this condition the tool

moves entire length of the work piece with

horizontal feed rate of 75m/min on the

weld path between the weld plates. The

onion ring portion of the weld joints looks

little bit improvement on smoothness with

less amount of material at the edge of the

weld part.

AA1100 (TEST PIECE III) is welded

by 1200 rpm tool rotation with vertical

force of 8000Kg and the entire tool tip is

Investigation and Analysis of Metallurgical and Mechanical Properties of AA1100 using FSW

1228 | Page

inserted in to the work piece with vertical

feed rate 1.5 m/s. At this condition the tool

moves entire length of the work piece with

horizontal feed rate of 75m/min on the

weld path between the weld plates. The

onion ring portion of the weld joints looks

smooth surface with less amount of

material at the edges of the weld part.

AA1100 (TEST PIECE IV) is welded

by 1400 rpm tool rotation with vertical

force of 8000Kg and the entire tool tip is

inserted in to the work piece with vertical

feed rate 1.8 m/s. At this condition the tool

moves entire length of the work piece with

horizontal feed rate of 75m/min on the

weld path between the weld plates. The

onion ring portion of the weld joints looks

very fine smooth surface with less amount

of material at the edges of the weld part.

Fig.3. shows the Effect of welding speed

on mechanical properties for two similar

alloys AA1100

Figure 3 : Effect of welding speed on mechanical properties for two similar alloys AA1100-

AA1100.

3.1. Microstructure and Hardness Test:

This test is carried out

in Metallurgical microscope-

METOSCOPE-1 equipment. The

microstructure at the FSW joints shows

fine Al-Fe-Si and MgSi particles and at the

base shows elongated Al-Fe-Si and MgSi

particles in a matrix of aluminum solid

solution. The fig. 4.shows the

microstructure of the FSW joints. The

hardness test is carried out in Vickers

hardness test machine at FSW joints in

weld region. Heat affected zone (HAZ)

and base metal with 1Kg load. The various

values are obtained from the FSW joints.

Fig.5. shows the Effect of welding speed

on micro hardness for similar alloys

AA1100

International Journal of Research (IJR) Vol-1, Issue-7, August 2014 ISSN 2348-6848

INVE!I"A!I#N AN$ ANA%&I #' (E!A%%)R"I*A% AN$ (E*+ANI*A% ,R#,ER!IE #' AA1100 )IN" '-

,.VIJA&AARA!+I, $.*+RI!#,+ER E%VA(

, a g e / 1229

Figure 4: SEM images of FSW joints of AA1100

Figure 5 :Effect of welding speed on micro hardness for similar alloys AA1100

3.2. Macro Examination Test

This test is carried

out in Stereomicroscope in 10X zoom

level observation, in this test the samples

was macro etched and examined visually

reveals complete fusion between weld and

base metal. So, its concluded there is no

presence of any weld defects like lack of

fusion, lack of penetration or excess

penetration, porosity, inclusions, cracking,

undercut, lamellar tearing, etc. The macro

structure is shown in following fig.6.

Figure 6:Macro structure of FSW joints

International Journal of Research (IJR) Vol-1, Issue-7, August 2014 ISSN 2348-6848

INVE!I"A!I#N AN$ ANA%&I #' (E!A%%)R"I*A% AN$ (E*+ANI*A% ,R#,ER!IE #' AA1100 )IN" '-

,.VIJA&AARA!+I, $.*+RI!#,+ER E%VA(

, a g e / 1230

4. CONCLUSION

The mechanical and

metallurgical behaviour of two similar

FSW AA1100 was studied in this paper.

The joints were produced with same alloy

positioned on the advancing side of the

tool. The joints were realized by changing

with a rotation speed from 800 to 1600

rpm and the horizontal feed rate is fixed at

75 mm/min. The downward force was

observed to be constant as the horizontal

feed rate for all the produced joints

increases. The tensile strength of the

similar joint is lower than that of the

parent metal. The similar joints exhibited

good mechanical properties and Micro

structural changes induced by the friction

stir welding process were clearly identified

in this study. A softened region has clearly

occurred in the friction stir welded joints,

due to dissolution of strengthening

precipitates.

REFERENCES

[1] W. M. Thomas, E. D. Nicholas,

Materials & Design, 18 (1997) 269.

[2] W. M. Thomas, E. D. Nicholas, J. C.

Needham, M. G. Nurch, P. Temple-Smith,

C. Dawes, Patents on Friction Stir Butt

Welding, International: PCT/GB92/02203;

British: 9125978.8; USA: 5460317, (1991-

1995).

[3] W. B. Lee, Y. M. Yeon, S. B. Jung, J.

Mater. Sci., 38 (2003) 4183.

[4] W. B. Lee, Y. M. Yeon, S. B. Jung,

Scripta Materialia, 49 (2003) 423.

[5] P. Cavaliere, R. Nobile, F.W. Panella,

A. Squillace, Int. J. Machine Tools

Manufacturing, 46 (2006) 588.

[6] P. Cavaliere, A. De Santis, F. Panella,

A. Squillace, Material & Design, 30

(2008) 609.

[7] A. Scialpi, M. de Giorgi, L. A. C. de

Filippis, R. Nobile, F.W. Panella,

Material & Design, 29 (2008) 928.

[8] L. E. Murr, N. A. Rodriguez, E.

Almanza, C. J. Alvarez, J. of Material

Science, 40 (2005) 4307.

[9] J. H. Ouyang, R. Kovacevic, J.

Material Engineering, 11 (2002) 51.

[10] T. L. Dickerson, J. Przydatek, Int. J.

Fatigue, 25 (2003) 1399.

[11] C.S. Paglia, K.V. Jata, R.G. Buchheit,

Material Science Engineering A, 424

(2006) 196.

[12] R.W. Fonda, P.S. Pao, H.N. Jones,

C.R. Feng, B.J. Connolly, A.J. Davenport,

Material Science Engineering A, 519

(2009) 1.

[13] D.A. Wadeson, X. Zhou, G.E.

Thompson, P. Skeldon, L. Djapic

Oosterkamp, G. Scamans, Corrosion

Science, 48(2006) 887.

[14] M. Jariyaboon, A.J. Davenport, R.

Ambat, B.J. Connolly, S.W. Williams,

D.A. Price, Corrosion Science, 49 (2007)

877.

[15] P. S. Pao, S. J. Gill, C. R. Feng, K. K.

Sankaran, Scripta Materiala, 45 (2001)

605.

[16] K. Surekha, B. S. Murty, K. Prasad

Rao, Solid State Sciences, 11 (2009) 907.

Você também pode gostar

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- H15B PLUS-2 Parts ManualDocumento158 páginasH15B PLUS-2 Parts ManualАлексей50% (2)

- Design of Weirs and BarragesDocumento42 páginasDesign of Weirs and BarragesDivyaSlp100% (2)

- Rigid PavementDocumento100 páginasRigid PavementJAY GANDHI100% (1)

- Malpresentation and MalpositionDocumento33 páginasMalpresentation and MalpositionPeprah Ondiba100% (1)

- Alkali Boil Out ProcedureDocumento7 páginasAlkali Boil Out Procedureismail karmanaAinda não há avaliações

- VeEX OTN Quick Reference GuideDocumento12 páginasVeEX OTN Quick Reference GuideDewan H S SalehinAinda não há avaliações

- WPS PQR CompressedDocumento5 páginasWPS PQR CompressedBalaje MantravadiAinda não há avaliações

- QR Code Attendance Monitoring SystemDocumento6 páginasQR Code Attendance Monitoring Systemjenny adlaoAinda não há avaliações

- LsApi PDFDocumento347 páginasLsApi PDFEduardo Martin Vega100% (2)

- "The Girl" Who Spoke Less in The Class by Sadia RashidDocumento1 página"The Girl" Who Spoke Less in The Class by Sadia Rashidijr_journalAinda não há avaliações

- Sales Promotion - A Changing Trend From Expensiveness To Effectiveness by Kavleen BharejDocumento4 páginasSales Promotion - A Changing Trend From Expensiveness To Effectiveness by Kavleen Bharejijr_journalAinda não há avaliações

- Public Libraries and Budget Costs - A Case Study of Osun State Library Services in Ife Central and Ife South Local Government AreasDocumento10 páginasPublic Libraries and Budget Costs - A Case Study of Osun State Library Services in Ife Central and Ife South Local Government Areasijr_journalAinda não há avaliações

- Prospero As An Analogy For God and The Creative Process in The TempestDocumento3 páginasProspero As An Analogy For God and The Creative Process in The Tempestijr_journalAinda não há avaliações

- Role of Online Banking in Economy by Anita Bindal Phulia, Monika Sharma, Deepak KumarDocumento6 páginasRole of Online Banking in Economy by Anita Bindal Phulia, Monika Sharma, Deepak Kumarijr_journalAinda não há avaliações

- PIG Based Water Quality Assessment in West Suvarnamukhi River Basin, Karnataka, India by Manjunath H. N. and Suresh T.S.Documento6 páginasPIG Based Water Quality Assessment in West Suvarnamukhi River Basin, Karnataka, India by Manjunath H. N. and Suresh T.S.ijr_journalAinda não há avaliações

- Relationship Marketing - A New Dimension of Marketing by Deepak KumarDocumento5 páginasRelationship Marketing - A New Dimension of Marketing by Deepak Kumarijr_journalAinda não há avaliações

- SAARC Dawn of New Hope by Mrs. Suman GuptaDocumento10 páginasSAARC Dawn of New Hope by Mrs. Suman Guptaijr_journalAinda não há avaliações

- Rural Marketing in India by Pooja Rani & Neha ShrivastavDocumento4 páginasRural Marketing in India by Pooja Rani & Neha Shrivastavijr_journalAinda não há avaliações

- Quality of Work Life of Employees in An Organization by Namita and Kritika WaliaDocumento11 páginasQuality of Work Life of Employees in An Organization by Namita and Kritika Waliaijr_journalAinda não há avaliações

- Pseudo-Dementia - An Artefact or A Grey Area of GeropsychiatryDocumento4 páginasPseudo-Dementia - An Artefact or A Grey Area of Geropsychiatryijr_journalAinda não há avaliações

- Psycho-Social Problems Among Working Women by Dr. Nimisha Beri & Mhonbeni MurryDocumento5 páginasPsycho-Social Problems Among Working Women by Dr. Nimisha Beri & Mhonbeni Murryijr_journalAinda não há avaliações

- Pathological Pattern of Atypical Meningioma-Diagnostic Criteria and Tumor Recurrence Predictors by Mohamed A.R ArbabDocumento8 páginasPathological Pattern of Atypical Meningioma-Diagnostic Criteria and Tumor Recurrence Predictors by Mohamed A.R Arbabijr_journalAinda não há avaliações

- Processing Fee and Subscription ChargesDocumento3 páginasProcessing Fee and Subscription Chargesijr_journalAinda não há avaliações

- Novel Method For Student Authentication in Online Examination by V.bhagat & V.katankarDocumento6 páginasNovel Method For Student Authentication in Online Examination by V.bhagat & V.katankarijr_journalAinda não há avaliações

- Online Court-Case Management - Need of The Hour (Suggested Method For Subordinate Civil Courts)Documento28 páginasOnline Court-Case Management - Need of The Hour (Suggested Method For Subordinate Civil Courts)ijr_journalAinda não há avaliações

- Motivation As An Instruments of Performance in Edo State Civil Service by Ajayi AdeolaDocumento43 páginasMotivation As An Instruments of Performance in Edo State Civil Service by Ajayi Adeolaijr_journalAinda não há avaliações

- Operating Systems For Multitasking Sensor Networks - A Survey by Pavitha N.Documento7 páginasOperating Systems For Multitasking Sensor Networks - A Survey by Pavitha N.ijr_journalAinda não há avaliações

- Multimode Monitoring of Electromyographic Signals With USB Interface by Sushil KumarDocumento7 páginasMultimode Monitoring of Electromyographic Signals With USB Interface by Sushil Kumarijr_journalAinda não há avaliações

- Mobile - Commerce by Pooja Rani, Neha Shri Vastav & Deepak KumarDocumento9 páginasMobile - Commerce by Pooja Rani, Neha Shri Vastav & Deepak Kumarijr_journalAinda não há avaliações

- Mahesh Dattani's Thirty Days in September in The Light of Rasa Theory by Manu SharmaDocumento6 páginasMahesh Dattani's Thirty Days in September in The Light of Rasa Theory by Manu Sharmaijr_journal0% (1)

- Merleau-Ponty and Blanchot's Negative Phenomenology by DR Chung Chin-YiDocumento13 páginasMerleau-Ponty and Blanchot's Negative Phenomenology by DR Chung Chin-Yiijr_journalAinda não há avaliações

- Influence of Rootstock Age and Pre-Defoliation of Scion On The Success of Epicotyl Grafting of MangoDocumento11 páginasInfluence of Rootstock Age and Pre-Defoliation of Scion On The Success of Epicotyl Grafting of Mangoijr_journalAinda não há avaliações

- Meningioma in Sudanese Patients Arbab Et Al.Documento10 páginasMeningioma in Sudanese Patients Arbab Et Al.ijr_journalAinda não há avaliações

- Language Teachers' Beliefs About Curriculum Innovation - Perspectives From AlgeriaDocumento15 páginasLanguage Teachers' Beliefs About Curriculum Innovation - Perspectives From Algeriaijr_journalAinda não há avaliações

- Improvement of Voltage Stability of Multi - Machine System Using FACTS by Prof. Sushil KumarDocumento6 páginasImprovement of Voltage Stability of Multi - Machine System Using FACTS by Prof. Sushil Kumarijr_journalAinda não há avaliações

- Matriarchal Assertiveness in Jane Austen's Persuasion by Dr. v. AsokkumarDocumento8 páginasMatriarchal Assertiveness in Jane Austen's Persuasion by Dr. v. Asokkumarijr_journalAinda não há avaliações

- Influence of Information and Communication Technology On Family Values Among The Staff of Ogun State University Teaching HospitalDocumento14 páginasInfluence of Information and Communication Technology On Family Values Among The Staff of Ogun State University Teaching Hospitalijr_journalAinda não há avaliações

- Indian Retailing Sector - Prospects and ChallengesDocumento4 páginasIndian Retailing Sector - Prospects and Challengesijr_journalAinda não há avaliações

- 11.numerical DifferentiationDocumento20 páginas11.numerical DifferentiationAbdulselam AbdurahmanAinda não há avaliações

- Acid-Base Equilibrium PPT UPDATED 2022Documento96 páginasAcid-Base Equilibrium PPT UPDATED 2022Sara Molinaro100% (1)

- Python Notes - 1Documento364 páginasPython Notes - 1hopefulantonelliAinda não há avaliações

- Shot CokeDocumento9 páginasShot CokeaminAinda não há avaliações

- Thermocouple Wire Reference Guide: WWW - Omega.co - Uk +44 (0) 161 777 6611 WWW - Omega.co - Uk +44 (0) 161 777 6611Documento1 páginaThermocouple Wire Reference Guide: WWW - Omega.co - Uk +44 (0) 161 777 6611 WWW - Omega.co - Uk +44 (0) 161 777 6611Mohamed MaltiAinda não há avaliações

- NCERT: Why Is Steel More Elastic Than Rubber?Documento7 páginasNCERT: Why Is Steel More Elastic Than Rubber?Satyam RaiAinda não há avaliações

- Smart Card/Proximity Based Vehicle Identification & Access Control SystemDocumento4 páginasSmart Card/Proximity Based Vehicle Identification & Access Control SystemkarunamoorthiAinda não há avaliações

- NEO PGM 'AND'/'OR' FunctionalityDocumento5 páginasNEO PGM 'AND'/'OR' FunctionalityAndre EinsteinAinda não há avaliações

- Applications and Interpretation Standard SpecimensDocumento56 páginasApplications and Interpretation Standard SpecimensNahir ClaraAinda não há avaliações

- Alkali MetalsDocumento12 páginasAlkali MetalsSaki Sultana LizaAinda não há avaliações

- AC Assingment 2Documento3 páginasAC Assingment 2Levi Deo BatuigasAinda não há avaliações

- IOP Conference Series: Materials Science and EngineeringDocumento9 páginasIOP Conference Series: Materials Science and EngineeringMahesh MAinda não há avaliações

- EWDLEWML Servo Motor DriverDocumento14 páginasEWDLEWML Servo Motor DriverWaleed LemsilkhiAinda não há avaliações

- Compact GSM II: Installation and Application ManualDocumento22 páginasCompact GSM II: Installation and Application ManualleonardseniorAinda não há avaliações

- Speedrunfile 1Documento26 páginasSpeedrunfile 1Adrian AquinoAinda não há avaliações

- Booklet Momentum BWFDocumento22 páginasBooklet Momentum BWFReem AshrafAinda não há avaliações

- (It Bus) Computer HistoryDocumento6 páginas(It Bus) Computer HistoryRica Elaine LubasanAinda não há avaliações

- Nov. AbwDocumento50 páginasNov. Abwjbyarkpawolo70Ainda não há avaliações

- Inductive TransducersDocumento12 páginasInductive TransducersMUKESH SUNDARARAJANAinda não há avaliações

- Ansoff Matrix Template User GuideDocumento6 páginasAnsoff Matrix Template User Guidebernardo95Ainda não há avaliações

- Live load and wind pressure on sloping roofsDocumento11 páginasLive load and wind pressure on sloping roofsAbel BerhanemeskelAinda não há avaliações