Escolar Documentos

Profissional Documentos

Cultura Documentos

Superjunction MOS

Enviado por

1balamanianDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Superjunction MOS

Enviado por

1balamanianDireitos autorais:

Formatos disponíveis

Appl i cat i on Not e, V1.

0, Febr uar y 2008

Power Management & Suppl y

CoolMOS

TM

900V

New 900V cl ass for superj uncti on devi ces

A new hori zon for SMPS and renewabl e energy

appl i cati ons

Edition 2008-02-10

Published by

Infineon Technologies AG

81726 Munich, Germany

2007 Infineon Technologies AG

All Rights Reserved.

LEGAL DISCLAIMER

The information given in this document shall in no event be regarded as a guarantee of

conditions or characteristics. With respect to any examples or hints given herein, any typical

values stated herein and/or any information regarding the application of the device,

Infineon Technologies hereby disclaims any and all warranties and liabilities of any kind,

including without limitation, warranties of non-infringement of intellectual property rights

of any third party.

Information

For further information on technology, delivery terms and conditions and prices, please

contact the nearest Infineon Technologies Office (www.infineon.com).

Warnings

Due to technical requirements, components may contain dangerous substances. For information

on the types in question, please contact the nearest Infineon Technologies Office.

Infineon Technologies components may be used in life-support devices or systems only with

the express written approval of Infineon Technologies, if a failure of such components can

reasonably be expected to cause the failure of that life-support device or system or to affect

the safety or effectiveness of that device or system. Life support devices or systems are

intended to be implanted in the human body or to support and/or maintain and sustain

and/or protect human life. If they fail, it is reasonable to assume that the health of the user

or other persons may be endangered.

CoolMOS

900V

New 900V class for superjunction devices

A new horizon for SMPS and renewable energy applictions

Application Note V1.0, 2007-05

3

CoolMOS

TM

900V

Revision History: 2008-02 V1.0

Previous Version:

We Listen to Your Comments

Any information within this document that you feel is wrong, unclear or missing at all?

Your feedback will help us to continuously improve the quality of this document.

Please send your proposal (including a reference to this document) to:

comments@infineon.com

CoolMOS

900V

New 900V class for superjunction devices

A new horizon for SMPS and renewable energy applictions

Application Note V1.1, 2007-05

4

Table of Contents Page

1 Introduction...............................................................................................................................................5

1.1 The Superjunction Principle........................................................................................................................6

2 Device characteristics..............................................................................................................................8

3 Target applications CoolMOS

TM

900V ...................................................................................................10

3.1 Wide range designs (90270Vac) with their typical 400Vdc bulk voltage................................................10

3.2 Replacement of IGBTs by CoolMOS 900V Series.................................................................................14

3.3 Lighting applications .................................................................................................................................16

3.4 Auxiliary power supplies in 3-phase systems............................................................................................16

4 Product Portfolio ....................................................................................................................................17

5 Circuit Design and Layout Recommendations.....................................................................................18

5.1 Control dv/dt and di/dt by Proper Selection of Gate Resistor ....................................................................18

5.2 Minimize Parasitic Gate-Drain Board Capacitance ...................................................................................18

5.3 Locate Gate Drivers and Gate Turn-Off Components as Close as Possible to the Gate...........................19

5.4 Use Symmetrical Layout for Paralleling MOSFETs, and Good Isolation of Gate Drive between FETs .....19

5.5 Summary ..................................................................................................................................................19

References ........................................................................................................................................................20

CoolMOS

900V

New 900V class for superjunction devices

A new horizon for SMPS and renewable energy applictions

Application Note V1.0, 2008-02

5

1 Introduction

Infineon introduces a new 900V voltage class of energy-saving CoolMOS

TM

power MOSFETs for high efficiency

switch-mode power supply and renewable energy applications.

CoolMOS

TM

900V offers extremely low static and dynamic losses, which is the signature of super junction

MOSFET technology where the so-called silicon limit is overcome. The square-law dependency between on-

resistance and blocking voltage in conventional MOSFETs is amended by new CoolMOS

TM

900V, resulting in

an industry-best on-state resistance per package type being four times or even lower if compared to

conventional 900V MOSFETs: 0.12 Ohm in TO247, 0.34 Ohm in TO220, and 1.2 Ohm in DPAK packages. A

figure-of-merit (FOM) on-resistance times gate charge (R

DSon

*Q

G

) as low as 34 *nC is reached, which

translates into extremely low conduction, driving and switching losses.

Samples are available now and the complete product spectrum will be filled up during 2008.

Target applications for CoolMOS

TM

900V are ATX power supplies, solar converters, quasiresonant flyback

designs for LCD TV, active frontend 3-phase-systems and other designs, were high blocking voltage, low

conduction and switching losses combined with low gate charge are necessary.

Table 1 gives a quick overview of available CoolMOS

TM

series today.

Table 1 CoolMOS

TM

Series at a Glance

Market

Entry

Voltage

Class [V]

Special

Characteristic

V

gs,th

[V]

G

fs

[S]

Internal R

g

[]

CoolMOS

TM

S5 1998 600 Low R

DS(on)

, Switching speed

close to standard MOSFETs

4.5 Low High

CoolMOS

TM

C3 2001 500/600/

650/800

Fast switching speed

symmetrical rise/fall time

at V

GS

=10 V

3 High Low

CoolMOS

TM

CFD 2004 600 Fast body diode,

Q

rr

1/10

th

of C3 series

4 High Low

CoolMOS

TM

CP 2005 500/600 Ultra-low RDS(on),

ultra-low Qg,

very fast switching speed

3 High Low

CoolMOS

TM

C3 2008 900 low RDS(on),

low Qg,

fast switching speed

3 High Low

CoolMOS

900V

New 900V class for superjunction devices

A new horizon for SMPS and renewable energy applictions

Application Note V1.0, 2008-02

6

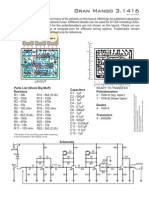

1.1 The Superjunction Principle

CoolMOS

TM

is a revolutionary technology for high voltage power MOSFETs and designed according to the

superjunction (SJ) principle [1], which in turn is based on the RESURF [2] ideas being successfully used for

decades in lateral power MOSFETs. Conventional power MOSFETs suffer from the limitation of the so-called

silicon limit [3], which means that doubling the voltage blocking capability typically leads to an increase in the

on-state resistance by a factor of five. The silicon limit is shown in Figure 1 where the area specific on-state

resistance of state-of-the-art standard MOSFETs as well are indicated. SJ technology may lower the on-state

resistance of a power MOSFET virtually towards zero. The basic idea is to allow the current to flow from top to

bottom of the MOSFET in very high doped vertically arranged regions. In other words, a lot more charge is

available for current conduction compared to what is the case in a standard MOSFET structure. In the blocking

state of the SJ MOSFET, the charge is counterbalanced by exactly the same amount of charge of the opposite

type. The two charges are separated locally in the device by a very refined technology, and the resulting

structure shows a laterally stacked fine-pitched pattern of alternating arranged p- and n-areas, see Figure 2.

The finer the pitch can be made, the lower the on-state resistance of the device will be.

0

10

20

30

40

500 600 700 800 900 1000

Blocking voltage [V]

A

r

e

a

s

p

e

c

i

f

i

c

r

e

s

i

s

t

a

n

c

e

[

O

h

m

*

m

m

2

]

CoolMOS

TM

State-of-the-art

conventional MOS

"Silicon Limit"

Figure 1 Area-specific on-resistance versus breakdown voltage comparison of standard MOSFET

and CoolMOS

TM

Technology

n

epi

D

p

-

n

+

sub

G

S

p

+

n

p

Superjunction MOSFET

-

-

-

-

-

-

D

G

S

Standard MOSFET

n

epi

D

p

-

n

+

sub

G

S

p

+

n

p

Superjunction MOSFET

-

-

-

-

-

-

n

epi

D

p

-

n

+

sub

G

S

p

+

n

p

Superjunction MOSFET

--

--

--

--

--

--

D

G

S

Standard MOSFET

D

G

S

Standard MOSFET

Figure 2 Schematic Cross-Section of a Standard Power MOSFET versus a Superjunction MOSFET

CoolMOS

900V

New 900V class for superjunction devices

A new horizon for SMPS and renewable energy applictions

Application Note V1.0, 2008-02

7

Another signature of SJ technology is the extremely fast switching speed. The turn off behavior of a

SJ MOSFET is not characterized by the relatively slow voltage driven vertical expansion of the space charge

layer but by a sudden nearly intrinsic depletion of the laterally stacked p-n structure. This unique behavior

makes the device very fast. The neutralization of these depletion layers is done via the MOS controlled turn-on

of the load current for the n-areas and via a voltage driven drift current for the p-areas. SJ devices reach

therefore theoretical rise and fall times in the range of few nanoseconds.

Figure 3 shows a comparison of R

DS(on),max

between todays most advanced available MOSFETs.

0.14

0.099

0.19

0.29

0.34

0.14

0.13

0.27

0.4

0.23

0.43

0.5

0.75

1.3

0

0.2

0.4

0.6

0.8

1

1.2

1.4

500V 600V 650V 800V 900V

R

D

S

(

o

n

)

[

O

h

m

]

Best in Class TO-220 CoolMOS Infineon

Best in Class TO-220 Superjunction Competitor

Best in Class TO-220 Standard Technology Competitor

Figure 3 Comparison of R

DS(on),max

for most advanced MOSFETs in TO220 package, available in the

market.

CoolMOS

900V

New 900V class for superjunction devices

A new horizon for SMPS and renewable energy applictions

Application Note V1.0, 2008-02

8

2 Device characteristics

CoolMOS

TM

900V is the next step towards THE IDEAL HIGH VOLTAGE SWITCH with key features:

Very low reduced conduction and switching losses

Lowest on-state-resistance per package @ 900 V blocking capability

Ultra-low gate charge and lowest figure-of-merit R

DS(on)

x Q

g

which gives the application benefits:

Extremely reduced heat generation

Reduced system size and weight

Very low gate drive power facilitating the use of low cost ICs and gate drivers

Reduced overall system cost

The most interesting circuit design aspect is the new dependence of R

DS(on)

on the breakdown voltage. The

more than square-law dependence of R

DS(on)

in the case of standard MOSFET has been broken and a more

linear voltage dependence has been achieved:

=

TM

) (

MOS Cool 1,3

MOS Standard 2,4...2,6

) ( n

n

V R

Br on DS

It follows from this that the on-state losses P

stat

present in the switch when transferring a particular power are:

2 2

) (

2

,

n

Br out on DS eff sw stat

V P R I P

Therefore, whereas the losses increase with the operating voltage when using a standard MOSFET(proportional

to V

0,40,6

), the losses are reduced using CoolMOS transistors proportionally to V

-0,7

.

CoolMOS

TM

900V series has the worlds lowest area-specific R

DS(on)

for 900V MOSFETs as shown Figure 4,

which results in lowest R

DS(on)

per package type. 120m in TO247 and 340m in TO220 result in low

conduction losses and high current handling capbility. Continuous drain currents up to 36A and pulse currents

up to 96A are possible (CoolMOS 900V 120m) . A comparison of available R

DS(on)

-values in DPak, TO220

and TO247 are given in Figure 4.

0

1

2

3

4

5

6

7

8

D-Pak TO-220 TO-247

R

D

S

o

n

[

O

h

m

]

Other 900V MOSFET 1

Other 900V MOSFET 2

Other 900V MOSFET 3

CoolMOS 900V

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

TO-220 TO-247

R

D

S

o

n

[

O

h

m

]

Other 900V MOSFET 1

Other 900V MOSFET 2

Other 900V MOSFET 3

CoolMOS 900V

Figure 4 Comparison of R

DS(on),max

for best-in-class 900V devices (Right: Zoom-in TO220/TO247)

CoolMOS

900V

New 900V class for superjunction devices

A new horizon for SMPS and renewable energy applictions

Application Note V1.0, 2008-02

9

The CoolMOS 900V cuts down the achievable R

DS(on)

in both packages by nearly a factor of four. By

introducing our new CoolMOS 900V technology we establish also a reduction of the total gate charge. The

new technology reduces the total gate charge Q

g

for similar R

DS(on)

types by 25% ( Figure 5) and offers the lowest

FOM (R

DS(on) x

Q

g

) in this voltage class. The FOM on the one hand a measure of the conduction losses attributed

to the switch, on the other hand it correlates with the Q

g

a parameter being related to the energy the driver

circuit has to offer to turn the switch on and off. A very low FOM stands therefore for low conduction losses,

easy driving and low switching losses.

0

10

20

30

40

50

60

70

80

900V, 1.3-1.4Ohm

Q

g

[

n

C

]

CoolMOS 900V

Other 900V MOSFET 1

Other 900V MOSFET 2

Other 900V MOSFET 3

Other 900V MOSFET 4

0

10

20

30

40

50

60

70

80

90

100

900V, 1.3-1.4Ohm

Q

g

*

R

D

S

o

n

[

O

h

m

*

n

C

]

CoolMOS 900V

Other 900V MOSFET 1

Other 900V MOSFET 2

Other 900V MOSFET 3

Other 900V MOSFET 4

Figure 5 Gate Charge Q

G

and Figute-of-merit (R

DS(on)

x Q

G

) values for 900V devices with nearly

same R

DS(on)

of 1.3-1.4

Not only has the new technology achieved breakthrough at reduced R

DS(on)

values, but new benchmarks have

also been set for the device capacitances. A second effect to be considered in the switching losses is the

energy being stored in the output capacitance. This energy E

oss

( Figure 6) is transfered into heat during hard

switched turn-on. Due to the strongly nonlinear voltage dependence of the output capacitance the 900V

CoolMOS compensation devices offer here a very good performance if switched to more than 150V (marked

in Figure 6).

Energy stored in the output capacitance of the MOSFETs is reduced by a factor of two or more at working

voltage.

0

1

2

3

4

5

6

7

8

0 100 200 300 400 500

V

DS

[V]

E

o

s

s

[

J

]

Other 900V MOSFET 1

Other 900V MOSFET 2

Other 900V MOSFET 3

Other 900V MOSFET 4

CoolMOS 900V

Figure 6 E

oss

values for different 900V MOSFETs

CoolMOS

900V

New 900V class for superjunction devices

A new horizon for SMPS and renewable energy applictions

Application Note V1.0, 2008-02

10

3 Target applications CoolMOS

TM

900V

The new CoolMOS

TM

900V serie offers more design flexibility and pushes the existing limits towards higher

power without significant disadvantages. Designers of power units benefit from the high blocking voltage, low

R

DS(on)

and low Gate charge of the new CoolMOS

TM

900V. Some examples are explained in the following

paragraphs.

3.1 Wide range designs (90270Vac) with their typical 400Vdc bulk voltage

Designs for standard grid voltages can benefit from the higher blocking voltage. Depending on the application

the efficiency can be increased and/or design can be simplified without additional costs or other disadvantages.

Example 1: 500W Single Transistor Forward (STF) Converter used in ATX power supplies

Major benefits with CoolMOS

TM

900V:

500W output power achievable with STF

higher efficiency (+0.7% with BiC TO220)

lower cost and part count

easier design (no high side control)

The output power benchmark for STF converters can be increased by using CoolMOS

TM

900V. Up to 500W is

achievable with a single MOSFET with increased performance and lower costs compared to standard Two-

Transistor-Forward (TTF) with 200m 500V MOSFETs. Figure 7 shows the schematics of both topologies. In

the STF we have only one transistor compared to the two transistors and the pulse transformer in a TTF.

Figure 7 ATX power supplies (secondary side schematic being simplified).

TTF STF

compared to TTF

CoolMOS

900V

New 900V class for superjunction devices

A new horizon for SMPS and renewable energy applictions

Application Note V1.0, 2008-02

11

Changing the topology from TTF to STF not only simplifies the design and adds layout benefits without the

disadvantages (like the need of high-side-switching) of TTF.

Table 2 shows a comparison of the primary side losses of TTF and STF. Working frequency is 100kHz.

Table 2 Losses comparison Two-Transistor-Forward vs. Single-Transistor-Forward Converter

Losses TTF with 200m STF with 500m STF with 340m

Conduction 6.5W 8.1W 5.5W

Output capacitance 2.8W 1.0W 2.1W

Switching 7.3W 4.7W 4.7W

Demagnetizing winding --- 0.5W 0.5W

Total losses 16.6W 14.3W 12.8W

Despite the higher R

DS(on)

of the CoolMOS

TM

900V it is possible to design a STF with a higher efficiency than a

TTF with 200m MOSFETs. This is due to the higher dynamic losses in a TTF because in every cycle two

transistors have to be switched compared to only one transistor in a STF.

Indeed the transformer in a STF needs an additional demagnetizing winding which causes a small amount of

losses which do not exist in TTF topology. But with careful design (bifilar winding) these losses can be very low

and dont influence the result significant.

Cost optimized designs use the 500m CoolMOS

TM

900V with slightly increased efficiency (compared to TTF

with 200m MOSFETs) and reducing losses up to 0.7% is possible using the 340m CoolMOS

TM

900V.

CoolMOS

900V

New 900V class for superjunction devices

A new horizon for SMPS and renewable energy applictions

Application Note V1.0, 2008-02

12

Example 2: 200W Quasiresonant Flyback converters for LCD-TV

Major benefits with CoolMOS

TM

900V:

more than 200W of output power achievable with Quasi-Resonant Flyback

improved EMI behavior due to true zero-voltage switching

higher efficiency (+0.7% compared to 600V or 650V parts, 0.2% compared to 800V parts)

lower voltage stress on secondary diodes or synchronous rectifiers

Modern LCD-TV require output power up to 200W with high efficieny of the power supply together with low

costs. The best topology for these requirements is the Quasi-Resonant Flyback Converter (QR-FB) and its

disadvantages (like the high peak voltage on primary switch) are easy to handle with CoolMOS

TM

900V.

Figure 8 Quasi-Resonant Flyback Converter for LCD-TV (schematic simplified on secondary)

MOSFETs with high blocking voltage allow optimized transformer design resulting in reduced semiconductor

losses and reduced voltage stress on secondary diode or synchronous rectifier.

Efficiency improvement of 0.2% compared to availabe 800V parts and even 0.7% compared to standard 650V

parts is possible using CoolMOS

TM

900V.

Table 3 shows the results of a 200W / 24V Quasiresonant Flyback design realized with 650V, 800V and 900V

MOSFETs, respectively at a switching frequeny of 100kHz

CoolMOS

900V

New 900V class for superjunction devices

A new horizon for SMPS and renewable energy applictions

Application Note V1.0, 2008-02

13

Table 3 200W / 24V Quasiresonant Flyback with different types of MOSFETs

650V

500m

CoolMOS

800V

500m

CoolMOS

900V

500m

CoolMOS

Benefit by using CoolMOS

900V

Duty Cycle

at V

in,min

and max load

18% 27% 32%

Longer DC tue to higher reflected

voltage

Peak current 4.8 A 3.1 A 2.7 A Reduced peak current

Conduction losses 1.35 W 0.90W 0.76 W Reduced conduction loss

Turn-on-losses 0.17 W 0.09 W 0 True zero-voltage switching!

Improved EMI behaviour!

Turn-off-losses 1.4 W 0.9 W 0.8 W Reduced turn-off loss due to lower peak

current

Voltage stress on

secondary side diode

91 V 57V 48V Reduced voltage stress on sec. side

diode or sync.rec MOSFET

Total losses 6.6 W 5.6 W 5.2 W

Efficiency loss 3.31 % 2.80 % 2.61 % Significant loss reduction!

0.7% vs. 650V

0.2% vs. 800V

CoolMOS

900V

New 900V class for superjunction devices

A new horizon for SMPS and renewable energy applictions

Application Note V1.0, 2008-02

14

3.2 Replacement of IGBTs by CoolMOS 900V Series

Using a MOSFET with its Ohmic forward characteristic allow a significant reduction of conduction losses below

the power dissipation of IGBTs where conduction losses can not fall below the on-set voltage times load current.

PFC and PWM stages are possible to up to 750V bulk voltage using CoolMOS

TM

900V without diminishing

safety margin.

Example 3: Renewable energy applications / solar converters

Major benefits with CoolMOS

TM

900V:

more panels in series possiblelower copper losses in wiring

higher overall efficiency

no Overvoltage Protection (OVP) necessary

smaller magnetic components due to higher switching frequency

Figure 9 Typical DC / AC Solar Converter (with Overvoltage Protection)

Renewable energy applications such as photovoltaic converters show very high efficiency requirements due to

system amortization via pay back of electricity fed back into the public network.

The use of MOSFETs instead of IGBTs enhances the efficiency especially in the mid range of output power - as

being characteristic especially for many days in central and Northern Europe by avoiding the characteristic

onset voltage of the IGBT. The clear disadvantage of the MOSFET, its limited blocking voltage range and its

more than square-law between R

DS(on)

and B

VDSS

is amended by the new MOS generation CoolMOS

TM

900 V.

This new product family allows to build converters with an enlarged input voltage range coming thus closer to

the upper limit of 1000 V as defined by the IEC 60364 for solar modules. Putting more panels in series instead

of paralleling reduces significantly cabling losses, efforts and costs. Alone the cabling losses can be cut by

factor of 2 when changing from 600 to 900 V voltage class.

Another factor in photovoltaic systems is size and cost of magnetic components. Offering a device with

improved R

DS(on)

x Q

g

and R

DS(on)

x E

oss

performance allows an increase of switching frequency without suffering

from the penalty of increased losses. Therefore reduction of system size is possible without losing energy

efficiency.

CoolMOS

900V

New 900V class for superjunction devices

A new horizon for SMPS and renewable energy applictions

Application Note V1.0, 2008-02

15

Example 4: Three Phase Active Frontend

Major benefits with CoolMOS

TM

900V:

lower losses / higher efficiency

peak power of up to 10kW is possible with just one TO247 BiC 120m (per position)

smaller input filter due to higher switching frequency

Designs using CoolMOS

TM

900V offer lower losses compared to solutions with IGBTs and allow much higher

switching frequencies with resulting smaller filter elements.

Figure 10 Three-Phase-Active-Frontend using MOSFETs

Without paralleling MOSFETs it is possible to handle output power levels of more than 10kW with the BiC

TO247 120m and compared to IGBTs the losses are lower up to 8kW.

Further lower losses or higher output power can easily be achieved by paralleling MOSFETs.

For example a 6kW-unit (3-phase 400Vac with 670V bulk voltage) assembled with CoolMOS

TM

900V 120m

dissipates only 26W instead of the 35W in an IGBT-design which results in more than 35% losses reduction in

the transistors. This is due to the ohmic forward characteristic of the MOSFET compared to the constant on-set

voltage of the IGBT.

Figure 11 shows the difference between the losses of MOSFET and IGBT in a Three-Phase-Active-Frontend

0

20

40

60

80

0 1 2 3 4 5 6 7 8 9 10

P

loss

/W

P

out

/kW

CoolMOS 900V

IGBT

Figure 11 Losses comparison between IGBT (IKW15N120T2) and MOSFET (IPW90R120C3)

CoolMOS

900V

New 900V class for superjunction devices

A new horizon for SMPS and renewable energy applictions

Application Note V1.0, 2008-02

16

3.3 Lighting applications

Using SEPIC topology as PFC converter eliminates high inrush current and improve surge current capability.

With CoolMOS

TM

900V the necessary higher blocking voltage compared to standard PFC boost topology can be

handled.

Figure 12 Lamp ballast with SEPIC preconverter

Additionally the 3-Phase-Supply of Lamp ballasts for street lighting and greenhouses requires a higher voltage

capability than is offered with 600V or 800V MOSFETs, and lower on-resistance than what is offered with

conventional 900V MOSFETs.

Ballasts for Flat Fluorescent Lamps require switches with a higher voltage capability due to the favored single

switch resonant topology.

3.4 Auxiliary power supplies in 3-phase systems

Using a 3-phase grid the blocking voltage of the MOSFETs in auxiliary power supplies needs to be higher than

800V. With CoolMOS

TM

900V Flyback converters even for higher output power levels are easy to design thanks

to low conduction, switching and driving losses.

Figure 13 Flyback Converter for auxiliary power supplies

CoolMOS

900V

New 900V class for superjunction devices

A new horizon for SMPS and renewable energy applictions

Application Note V1.0, 2008-02

17

4 Product Portfolio

CoolMOS

TM

900V portfolio in Figure 14 will be filled up during 2008.

Figure 14 CoolMOS

TM

900V Products.

Figure 15 Naming System for CoolMOS

TM

Products

CoolMOS

900V

New 900V class for superjunction devices

A new horizon for SMPS and renewable energy applictions

Application Note V1.0, 2008-02

18

5 Circuit Design and Layout Recommendations

There are a number of recommendations to make with respect to circuit design and layout practices which will

assure a combination of high performance and reliability. They can be recommended as if in order of

importance, but realistically all are important, both in contribution toward circuit stability and reliability as well as

overall efficiency and performance. They are not that dissimilar to recommendations made for the introduction of

MOSFETs compared to bipolar transistors, or CoolMOS

TM

compared with standard MOSFETs; it is a matter of

the degree of care.

5.1 Control dv/dt and di/dt by Proper Selection of Gate Resistor

In order to exert full R

g

control on the device maximum turn-off dv/dt we recommend the following procedure:

1) Check for highest peak current in the application

2) Choose R

g

accordingly not to exceed 50 V/ns (maximum rating in datasheet)

3) At normal operation condition quasi ZVS condition can be expected, which gives best efficiency results

5.2 Minimize Parasitic Gate-Drain Board Capacitance

Particularly care must be spent on the coupling capacitances between gate and drain traces on the PCB. As

fast switching MOSFETs are capable to reach extremely high dv/dt values any coupling of the voltage rise at the

drain into the gate circuit may disturb proper device control via the gate electrode. As the CoolMOS

TM

series

reaches extremely low values of the internal C

gd

capacitance (C

rss

in datasheet), we recommend keeping layout

coupling capacitances below the internal capacitance of the device to exert full device control via the gate

circuit. Figure 16 shows a good example, where the gate and drain traces are either perpendicular to each other

or go into different directions with virtually no overlap or paralleling to each other. A bad layout example is

shown as reference to the good layout in Figure 17.

If possible, use source foils or ground-plane to shield the gate from the drain connection.

Heatsink Heatsink

Two independent

Totem Pol Drivers

as close as

possible to the

MOSFET!

Separate and short

source inductance to

reference point for gate

drive!

Heatsink is connected to source (GND)!!

View Bottom Layer View Top Layer

Minimized couple

capacitance

between gate and

drain pin!

Figure 16 Good Layout Example Ensuring Clean Waveforms When Designing in CoolMOS

TM

CoolMOS

900V

New 900V class for superjunction devices

A new horizon for SMPS and renewable energy applictions

Application Note V1.0, 2008-02

19

Heatsink

High parasitic

capacitance between

gate and drain!

Decoupling

capacitor far away

from gate pin of

the MOSFET & ONLY

One Driver Stage

for two MOSFET

High source inductance

-

GND connection of the

decoupling capacitor C2

far away from the driver

stage

Figure 17 Bad Layout Example

5.3 Locate Gate Drivers and Gate Turn-Off Components as Close as Possible to

the Gate

Always locate the gate drive as close as possible to the driven MOSFET and the gate resistor in close proximity

of the gate pin. This prevents it acting as an antenna for capacitively coupled signals. The controller/IC driver

should be capable of providing a strong low level drive with voltage as near to ground as possible- MOS or

bipolar/MOS composite output stages work well in that regard, due to low output saturation voltages. While

some drivers may be deemed to have sufficient margin under static or DC conditions, with ground bounce,

source inductance drop, etc, the operating margin to assure off mode can quickly disappear.

5.4 Use Symmetrical Layout for Paralleling MOSFETs, and Good Isolation of

Gate Drive between FETs

We recommend the use of multi-channel gate drivers in order to have separate channels for each MOSFET.

Physical layout should be as symmetrical as possible, with the low impedance driver located as close as

possible to the MOSFETs and on a symmetric axis.

5.5 Summary

To summarize, below recommendations are important when designing in CoolMOS

TM

900V to reach highest

efficiency with clean waveforms and low EMI stress.

Control dv/dt and di/dt by proper selection of gate resistor

Minimize parasitic gate-drain capacitance on board

Locate gate drivers and gate turn-off components as close as possible to the gate

Use symmetrical layout for paralleling

CoolMOS

900V

New 900V class for superjunction devices

A new horizon for SMPS and renewable energy applictions

Application Note V1.0, 2008-02

20

References

[1] T. Fujihira: Theory of Semiconductor Superjunction Devices, Jpn.J.Appl.Phys., Vol. 36, pp. 6254-

6262, 1997.

[2] A.W. Ludikhuize, A review of the RESURF technology, Proc. ISPSD 2000, pp. 11-18.

[3] X. B. Chen and C. Hu, Optimum doping profile of power MOSFETs epitaxial Layer. IEEE Trans.

Electron Devices, vol. ED-29, pp. 985-987, 1982.

[4] G. Deboy, M. Mrz, J.-P. Stengl, H. Strack, J. Tihanyi, H. Weber, A new generation of high voltage

MOSFETs breaks the limit of silicon, pp. 683-685, Proc. IEDM 98, San Francisco, Dec. 1998.

www. i n f i n e o n . c o m

Published by Infineon Technologies AG

Você também pode gostar

- Embedded SystemsDocumento3 páginasEmbedded Systems1balamanianAinda não há avaliações

- Es Notes Unit 5Documento33 páginasEs Notes Unit 51balamanianAinda não há avaliações

- Microprocessors and Microcontrollers - Unit 15 - Week 12Documento5 páginasMicroprocessors and Microcontrollers - Unit 15 - Week 121balamanianAinda não há avaliações

- EE8711-PSS Lab: Mr. C.Venkatesh Kumar MR H Prasad DR A Jamna Ms.S.Gomathi Mr. A Sadeesh KumarDocumento3 páginasEE8711-PSS Lab: Mr. C.Venkatesh Kumar MR H Prasad DR A Jamna Ms.S.Gomathi Mr. A Sadeesh Kumar1balamanianAinda não há avaliações

- Pe1256 Iae4 Question PaperDocumento3 páginasPe1256 Iae4 Question Paper1balamanianAinda não há avaliações

- St. Joseph'S College of Engineering: Omr, Chennai-119 Department of Electrical and Electronics EngineeringDocumento14 páginasSt. Joseph'S College of Engineering: Omr, Chennai-119 Department of Electrical and Electronics Engineering1balamanianAinda não há avaliações

- Real-Time Visualization of Electromagnetic Waves Propagating in Air Using Live Electro-Optic Imaging TechniqueDocumento11 páginasReal-Time Visualization of Electromagnetic Waves Propagating in Air Using Live Electro-Optic Imaging Technique1balamanianAinda não há avaliações

- Laplace Table PDFDocumento2 páginasLaplace Table PDF1balamanianAinda não há avaliações

- Formula MasterDocumento11 páginasFormula Master1balamanianAinda não há avaliações

- Ee8712 - Ren Energy Systems LabDocumento17 páginasEe8712 - Ren Energy Systems Lab1balamanian0% (1)

- Reference Websites: WWW - Walter-Fendt - deDocumento10 páginasReference Websites: WWW - Walter-Fendt - de1balamanianAinda não há avaliações

- Unit Test 1 - Sem On 17.04.2020Documento2 páginasUnit Test 1 - Sem On 17.04.20201balamanianAinda não há avaliações

- St. Joseph'S College of Engineering: Department Circular Academic Year (2016-2017)Documento1 páginaSt. Joseph'S College of Engineering: Department Circular Academic Year (2016-2017)1balamanianAinda não há avaliações

- IV Eee A Vii Sem Result Analysis Results Before RV 6 March 2016Documento51 páginasIV Eee A Vii Sem Result Analysis Results Before RV 6 March 20161balamanianAinda não há avaliações

- Transfer Function Modeling For The Buck Converter: Sanda Lefteriu Cécile LabarreDocumento4 páginasTransfer Function Modeling For The Buck Converter: Sanda Lefteriu Cécile Labarre1balamanianAinda não há avaliações

- Implementation of Novel Three-Z Network DC-DC Converter With MPPT Technique For PV ApplicationDocumento6 páginasImplementation of Novel Three-Z Network DC-DC Converter With MPPT Technique For PV Application1balamanianAinda não há avaliações

- Ac Solar OutputDocumento2 páginasAc Solar Output1balamanianAinda não há avaliações

- Railway Gate ReportDocumento2 páginasRailway Gate Report1balamanianAinda não há avaliações

- Photographs - Inaugural Function & Lecture SessionsDocumento13 páginasPhotographs - Inaugural Function & Lecture Sessions1balamanianAinda não há avaliações

- Question Bank II Year III SEMESTER - B.E (Electrical and Electronics Engineering)Documento1 páginaQuestion Bank II Year III SEMESTER - B.E (Electrical and Electronics Engineering)1balamanianAinda não há avaliações

- Biomechanics of Bones: Warsaw University of TechnologyDocumento31 páginasBiomechanics of Bones: Warsaw University of Technology1balamanianAinda não há avaliações

- Difference Amplifier and ComparatorDocumento3 páginasDifference Amplifier and Comparator1balamanianAinda não há avaliações

- DQ TransformationDocumento51 páginasDQ TransformationAili LuggymixAinda não há avaliações

- Newton-Raphson UPFC Model For Power Ow Solution of Practical Power Networks With Sparse TechniquesDocumento8 páginasNewton-Raphson UPFC Model For Power Ow Solution of Practical Power Networks With Sparse Techniques1balamanianAinda não há avaliações

- Ideas of LeectricalDocumento1 páginaIdeas of Leectrical1balamanianAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- 00027646-C JB Wiring DiagramDocumento37 páginas00027646-C JB Wiring DiagramKarikalan JayAinda não há avaliações

- Antena Bibanda, OSJ146440Documento3 páginasAntena Bibanda, OSJ146440CarlosAgustoPinedaSanchezAinda não há avaliações

- TH420 Operating Manual EnglishDocumento64 páginasTH420 Operating Manual EnglishLeofler Laureta Aguinaldo0% (1)

- 8997 6956 00 Diagrams and DrawingsDocumento74 páginas8997 6956 00 Diagrams and DrawingseduamaAinda não há avaliações

- Bike Frames For Sale - EbayDocumento1 páginaBike Frames For Sale - EbayamirsharifiAinda não há avaliações

- EN - Ditec EL34 Control Panel Technical Manual PDFDocumento16 páginasEN - Ditec EL34 Control Panel Technical Manual PDFHildenira SousaAinda não há avaliações

- Sistema de Implemento Presentaciones PDFDocumento109 páginasSistema de Implemento Presentaciones PDFAbel Jairo Santos CabelloAinda não há avaliações

- Essotrans Extra, Multigrade 30, 10W, 30, 50 Essotrans Extra, Multigrade 30, 10W, 30, 50Documento2 páginasEssotrans Extra, Multigrade 30, 10W, 30, 50 Essotrans Extra, Multigrade 30, 10W, 30, 50Kaly7Ainda não há avaliações

- USA Standard Mesh Chart PDFDocumento4 páginasUSA Standard Mesh Chart PDFAnonymous EarAM2Ainda não há avaliações

- Hyundai Sonata L4-1997Documento1.194 páginasHyundai Sonata L4-1997Relcon Servicio AutomotrizAinda não há avaliações

- Haibike EBike Owner's Manual 2014Documento82 páginasHaibike EBike Owner's Manual 2014Yotta ByteAinda não há avaliações

- 15 Power Amplifier Class B ABDocumento16 páginas15 Power Amplifier Class B ABAnonymous 5kvqS5LAinda não há avaliações

- CG Power and Industrial Solutions Limited: LT Motors Division AhmednagarDocumento1 páginaCG Power and Industrial Solutions Limited: LT Motors Division Ahmednagaranurag dhyaniAinda não há avaliações

- Hydraulic System:: R. Qasim Abbas D Automatic Control I 4Documento5 páginasHydraulic System:: R. Qasim Abbas D Automatic Control I 4علي حسين علاوي ثوينيAinda não há avaliações

- Boss 332 545 551 Use - Maintenance ManualDocumento140 páginasBoss 332 545 551 Use - Maintenance ManualbadrezzineAinda não há avaliações

- Daikin Manual BookDocumento42 páginasDaikin Manual Bookamsal koto0% (2)

- Power Electronics & SCRDocumento55 páginasPower Electronics & SCRsoumyaranjan_kar34Ainda não há avaliações

- DAT500 Ver 1.3Documento50 páginasDAT500 Ver 1.3explorerakeshroshanAinda não há avaliações

- Ao2 PTB 18 10 Oxygen Sensor User ManualDocumento2 páginasAo2 PTB 18 10 Oxygen Sensor User ManualEdward BennettAinda não há avaliações

- Ad-R Series User ManualDocumento76 páginasAd-R Series User Manualzivkovic brankoAinda não há avaliações

- Tonepad BigmuffDocumento2 páginasTonepad BigmuffWasabiRockAinda não há avaliações

- Best Bosch Jigsaw PDFDocumento1 páginaBest Bosch Jigsaw PDFasad anwarAinda não há avaliações

- Ahu ManualDocumento15 páginasAhu ManualAlan LaundrdayAinda não há avaliações

- 952 - Comparative Statement - Electrical - Rev 00Documento8 páginas952 - Comparative Statement - Electrical - Rev 00clickanant4171Ainda não há avaliações

- Company Details ReepDocumento9 páginasCompany Details ReepDharshini NagalingamAinda não há avaliações

- Engine Disassembly Procedure: Step 2 Step 1Documento3 páginasEngine Disassembly Procedure: Step 2 Step 1lmjAinda não há avaliações

- Cordex DCDC Converter CXDF 24-482kWDocumento40 páginasCordex DCDC Converter CXDF 24-482kWGuillermo Ovelar0% (1)

- 315 D CaterpillarDocumento4 páginas315 D CaterpillarJose nildo lobato Mendes Mendes100% (1)

- Rope BergDocumento16 páginasRope BergsmsobhanAinda não há avaliações

- 6042 Parts 8990467 02-22-12 ANSI EnglishDocumento462 páginas6042 Parts 8990467 02-22-12 ANSI EnglishwalmadasanAinda não há avaliações