Escolar Documentos

Profissional Documentos

Cultura Documentos

Fire Protetion Alarm Check Valve

Enviado por

ambition1340cnDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Fire Protetion Alarm Check Valve

Enviado por

ambition1340cnDireitos autorais:

Formatos disponíveis

Project: WORLD TRADE CENTER DOHA QATAR

Title of the

Document

Method Statement for the

Installation of Alarm Check

Valve

Reference No. Revision No Date Page No.

QC-MS-FF-006 00 0 !CT "0#0 " of $

Table of Contents

Sr. No. Contents Page

0# Sco%e of &or' (

0" References (

0( Definitions (

0) Res%onsi*ilities+ Su%ervision (

0, Descri%tion of -or' )

06 Plant Re.uirement ,

0$ Man%o&er Re.uirement 6

0

Tem%orar/ &or's to *e 0esigne0 an0

1nstalle0

6

02 3ealth an0 Safet/ Re.uirements 6

#0 4nvironment re.uirements 6

## Securit/ arrangements 6

#"

S%ecial Contractual

5rrangements

$

#( Recor0s to *e %ro0uce0 $

#) 5ttachments $

Project: WORLD TRADE CENTER DOHA QATAR

Title of the

Document

Method Statement for the

Installation of Alarm Check

Valve

Reference No. Revision No Date Page No.

QC-MS-FF-006 00 0 !CT "0#0 ( of $

1.0. Scope & Objective

This method statement covers the detailed procedure for installation of Breeching Inlets & Cabinet.

This procedure defines the method used to ensure that the installation of Breeching Inlet is carried as

per the contract specification requirements and the approved drawings of Qatar World Trade Center

2.0. References

Contract Documents6

Specification !"#!$% &.$' ()*

+,-) !#% &$$. /dition Standard for the Installation of Sprin0ler S1stem

The 2ocal ,ire )uthorit1% Qatar Civil 3efence 3irectorate

Shop 3rawings 4ar0ed 5ISS6/3 ,78 C7+ST86CTI7+9

#.$. Definitions

Fire Protection System. )n1 fire alarm device or s1stem or fire e:tinguishing device or

s1stem% or their combination% that is designed and installed for detecting% controlling% or

e:tinguishing a fire or otherwise alerting occupants% or the fire department% or both% that a fire

has occurred

Automatic Sprinkler. ) fire suppression or control device that operates automaticall1

when its heat;activated element is heated to its thermal rating or above% allowing water to

discharge over a specified area.

4.0. Responsibilities Supervision

4.1 Pro<ect 4anager shall have the overall responsibilit1 of the pro<ect for e:ecution% qualit1

and safet1. =e shall maintain the planning progress and co;ordination of wor0s with

main contractor.

4.2 Pro<ect> Site 4echanical /ngineer(s* shall be responsible for monitoring of

the da1;to;da1 activities on site% for materials% drawings% allocation of resources to

wor0 areas on site and testing & commissioning. =e shall report to the -ro<ect

4anager.

4.3 Supervisor> Charge =and shall be directl1 responsible for the da1;to;da1 <ob

at site% for coordinating of wor0 with Technicians or an1 other staff assigned his area.

4.4 Q)>QC 3epartment will be overseeing the qualit1 requirements and qualit1 control

measures for the pro<ect in coordination with -ro<ect>Site /ngineer(s*.

4.5 Safet1 7fficer shall be responsible for the health & safet1 aspects on site as per the

)8)BT/C>/,/C7 safet1 4anual.

Project: WORLD TRADE CENTER DOHA QATAR

Title of the

Document

Method Statement for the

Installation of Alarm Check

Valve

Reference No. Revision No Date Page No.

QC-MS-FF-006 00 0 !CT "0#0 ) of $

".$ Description of !orks

".1 Pre #nstallation $%eck

5.1.1 4nsure that all safet1 requirements are in place in accordance with pro<ect

safet1 plan

5.1.2 4nsure that the latest revision of the approved wor0ing drawing is being

used.

".1.& 7n receipt of material on site% Q)>QC engineer> Site /ngineer shall inspect

the material internall1 and inspection shall be offered to the engineer for approval in

4I8 ( 4aterial inspection request form*

".1.4 /nsure that the all materials used have passed receiving inspection in

accordance with Q) procedures and are not damaged or defective. )n1 non;

conforming materials must be labeled b1 store 0eeper and returned to quarantine

area in accordance with procedure.

".1." /nsure that all the pipe fitters and helpers are aware of the correct materials

handling and installation procedure to ensure that best qualit1 of wor0manship.

Training shall be provided b1 site engineers > Supervisor as and when required.

".1.' /nsure space & access for installation is available and at correct location as

per the approved drawing and site conditions.

5.1.7 Chec0 the tools required to install the )larm Chec0 valve.

5.1.8 Supervisor shall ensure that correct tools and )larm chec0 valve with trim 0it

are available for installation and to achieve compliance with contract requirement.

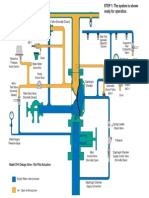

".& INSTALLATION OF ALARM CHECK VALVE

".2.1 The )larm Chec0 ?alve must be installed in an area not sub<ect to free@ing

temperatures or ph1sical damage. The )larm Chec0 ?alve ma1 be installed in the vertical

position with direction of flow up% or in the hori@ontal position with the access cover up.

5.2.2 ?erif1 that the appropriate trim chart and technical data for the )larm Chec0 ?alve

and associated equipment are available.

".2.& 8emove all plastic thread protectors from the openings of the )larm Chec0 ?alve.

5.2.4 )ppl1 a small amount of pipe;<oint compound or tape to the e:ternal threads of all

pipe connections required. Ta0e care not to allow an1 compound% tape% or other foreign matter

inside an1 nipples or openings of the valve or trim components. Trim the )larm Chec0 ?alve in

accordance trim chart provided along with the alarm chec0 valve

5.2.5 Install the )larm Chec0 ?alve and trim according to current Trim Charts for the valve

used. Trim charts are provided with trim pac0age and available with the pro<ect engineer or

Technical /ngineer. )fter installing the alarm chec0 valve% please unpac0 the water motor

gong and follow the instructions below to install as per the requirement.

Project: WORLD TRADE CENTER DOHA QATAR

Title of the

Document

Method Statement for the

Installation of Alarm Check

Valve

Reference No. Revision No Date Page No.

QC-MS-FF-006 00 0 !CT "0#0 , of $

5.2.6 For installation of water motor gong mark the through-wall locations for the

centerlines of the Sleeve and Drain Outlet. The Drain Outlet must be located at least 10 inches

(250mm)

5.2.7 Make 1-1/2 inch (38 mm) diameter holes straight through the wall at both locations.

5.2.8 Cut the non-threaded end of the Sleeve to a length equal to that of the wall thickness

plus 0 to 1/8 inch (0 to 3 mm). Thread the cut end to inch NPT per ANSI B1.20.1.

5.2.9 Install the alarm line piping up to and including the union half. Use thread sealant

sparingly on male threads only.

5.2.10 Prior to initiating installation of the Water Motor Alarm, mount the Drain Trim (less the

Wall Plate and 45 Elbow), as well as the balance of alarm line piping (including other union

half) to the Water Motor.

5.2.11 Tighten the NPT threaded end of the Sleeve into the Body hand tight plus 1/8 turn.

5.2.12 Slip the Support Washer over the Sleeve and place the assembly in position against

the wall.

5.2.13 Tighten the 3/4 inch Union. Install the Wall Plate and tighten the 45 Elbow.

5.2.14 Apply pressure against the outside edge of the Water Motor Body and verify

that the Body and Support

5.2.15 Washer sit square against the wall. If not, adjust the alarm line and/or drain piping to

suit.

5.2.16 From the outside wall, insert the Drive Shaft through the Sleeve and fully insert it into

the Impeller. (When fully inserted, the Shaft should protrude beyond the face of the wall by

approximately 20" minus 2" minus wall thickness.) Mark the Drive Shaft at a point of

approximately 1/8 to 1/4 inch inside the face of the wall; remove the Shaft; cut the Shaft where

previously marked; file off burrs from the cut end of the Drive Shaft; and, re-insert the Drive

Shaft through the Sleeve and fully insert it into the Impeller.

5.2.17 Hold the Gong Mount in position against the wall, engage the Coupling with

the Drive Shaft and then carefully thread the Striker Shaft Bearing onto the Sleeve. Securely

tighten the Striker Shaft Bearing using a pair of channel locks on the 1-1/2 inch (38 mm) hex

end.

Project: WORLD TRADE CENTER DOHA QATAR

Title of the

Document

Method Statement for the

Installation of Alarm Check

Valve

Reference No. Revision No Date Page No.

QC-MS-FF-006 00 0 !CT "0#0 6 of $

5.2.18 Spin the Striker by hand and verify that it spins freely (without any sign of binding). If

not, make the necessary adjustments.

5.2.19 Install the gong and securely tighten the Cap Nut. The identification sign

lettering must be orientated horizontally.

5.2.20 After installation, the alarm check valve must be tested in accordance with

the recognized installation standards. If a thread leak occurs or the groove joints leak, normally

the unit must be removed and the joints should be done again. This is due to the fact that

when the joint seal leaks, the sealing compound or tape is washed out of the joint or the

groove of the pipe might more or the groove fittings gasket might be damaged.

5.2.21 Ensure the alarm check valve is installed as per the procedure and the trim

connections are installed as per the trim chart.

".2.22 ?erif1 that all s1stem components are rated for the water wor0ing pressure of the

s1stem.

5.2.23 ,inal touch up of painting is to be done if required

A.$ P(A)* +,-.#+,/,)*

Special Wrench

Wrench

General tools

Protective clothing / equipment

/ngaged personnel on site will wear or use the following safet1 equipment as

appropriate

=ard hats% safet1 boots% overalls > wor0 wear% high visibilit1 clothing% safet1

goggles% gloves and 4as0s.

7.0 MA)PO0,+ +,-.#+,/,)*

4anpower requirement li0e Site /ngineer% Supervisor> ,oreman% and pipe fitters

depends upon the planning organi@ation chart and site progress of wor0s.

1.0. T,/PO+A+2 0O+3S *O 4, 5,S#6),5 & #)S*A((*,5

)ll the Safe Wor0ing Scaffolding -latforms will be installed in compliance to safet1

standard requirements.

Project: WORLD TRADE CENTER DOHA QATAR

Title of the

Document

Method Statement for the

Installation of Alarm Check

Valve

Reference No. Revision No Date Page No.

QC-MS-FF-006 00 0 !CT "0#0 $ of $

7.0. ,A(*8 A)5 SAF,* +,-.#+,/,)*S

Implementation of =ealth & Safet1 mechanisms and chec0s shall be done as

per contract agreement and the approved /,/C7 safet1 manual. The safet1 officer

shall carr1out the necessar1 routine inspections.

Safety (i9%tin9 Safet1 lights will be used in case of power failure ensuring good

illumination for the personnel. Breen color safet1 <ac0et shall be worn on site for all personnel who

are in site.

*ask (i9%tin9 )dequate lighting will be provided ensuring the good illumination of

the wor0ing area. Tas0 2ighting will be connected to the nearest site distribution board which is

8C3 protected.

,mer9ency Arran9ements : Site general safet1 procedure will be followed. In

case of emergenc1% the safet1 officer will stop the wor0. =e will put in to action the emergenc1

arrangements as described in /,/C7 safet1 4anual.

+isk $ontrol : 8is0 )ssessment and their controls are carried out for the

following activit1 > ha@ard and enclosed with this method statement.

Using Hand Tools

Disposal of Waste Material

Temporary Site Electrical Supply

The safet1 officer has the right to stop all the fire fighting wor0s activit1% if he is not satisfied

with the safet1 arrangement on site during installation and testing process.

10.0 4);#+O)/,)*A( +,-.#+,/,)*S

)ll remedial measures to control all the operations within the environmental legal limits

for Information and record.

!!.0 S,$.+#*2 A++A)6,/,)*S

+o additional securit1 arrangements over and above those alread1 in place at the site%

restricted access to the <ob site and the maintaining of the boundar1 fence securit1 guards will be

posted on all entrance points being used b1 vehicles during the camping out of this item of wor0 to

control and coordinate traffic movements.

12.0 SP,$#F#$ $O)*+A$*.A( O4(#6A*#O)S

We are e:ecuting all the wor0s b1 following the -ro<ect Specifications Section +o. !"#!$

and the related issued 5,or Construction9 drawings.

13. R,$O+5S *O 4, P+O5.$,5

Project: WORLD TRADE CENTER DOHA QATAR

Title of the

Document

Method Statement for the

Installation of Alarm Check

Valve

Reference No. Revision No Date Page No.

QC-MS-FF-006 00 0 !CT "0#0 of $

The following ,orm(s* > Chec0list(s* shall be prepared and raised to verif1 the above

activit1 to ensure that the activit1 is carried out as per the contract requirements.

nspection !e"uest #!$s% & !e'ision 0 shall (e raised along )ith *+ chec,list for

alarm chec, 'al'e installations

*+ +hec,list for nstallation of -larm chec, 'al'e

14. A**A$8/,)*S

The following documents are enclosed with this method statement

.orm T/&.0010nspection and Test plan for nstallation of .ire -larm chec,

2al'e

*+ +hec,list for nstallation of -larm chec, 'al'e

!is, -ssessment .orm & Using Hand Tools # *+0!-.003 %

!is, assessment .orm & Disposal of Waste Materials # *+0!-.004 %

!is, assessment .orm & Temporary Site Electrical Supply # *+0!-.001 %

777777777777777777777777777777

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- The Coca-Cola Company Struggles With Ethical CrisesDocumento16 páginasThe Coca-Cola Company Struggles With Ethical Crisesambition1340cnAinda não há avaliações

- Hodgson - Is Socialism Feasible (2019) - Pages-1,5,36-46Documento13 páginasHodgson - Is Socialism Feasible (2019) - Pages-1,5,36-46ambition1340cnAinda não há avaliações

- Inventory Management System: Arina Ramlee, Bruce Chhay, David HenryDocumento9 páginasInventory Management System: Arina Ramlee, Bruce Chhay, David Henryambition1340cnAinda não há avaliações

- Fomtec Foam Equipment BrochureDocumento7 páginasFomtec Foam Equipment Brochureambition1340cnAinda não há avaliações

- DV-5 Wet Step by Step PDFDocumento15 páginasDV-5 Wet Step by Step PDFambition1340cnAinda não há avaliações

- Fire Alarm Tal 1734 Electrical SpecificationDocumento11 páginasFire Alarm Tal 1734 Electrical Specificationambition1340cnAinda não há avaliações

- Waterflow Indicator PDFDocumento8 páginasWaterflow Indicator PDFambition1340cnAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Grease Fitting PDFDocumento20 páginasGrease Fitting PDFleonardsiregarAinda não há avaliações

- Go Oilfield MaterialDocumento165 páginasGo Oilfield Materialsnsengineering.metalAinda não há avaliações

- Standard Cable GlandsDocumento3 páginasStandard Cable Glandssml2001Ainda não há avaliações

- Ball Valve TFP600ADocumento1 páginaBall Valve TFP600AGustavo J. RafaelAinda não há avaliações

- Piping Engineering Note Nitrogen Purge SystemDocumento20 páginasPiping Engineering Note Nitrogen Purge SystemchrysanthiiiiiiAinda não há avaliações

- Solenoid Valves 3/2-5/2 551: Single/dual Solenoid (Mono/bistable Function) 1/4Documento10 páginasSolenoid Valves 3/2-5/2 551: Single/dual Solenoid (Mono/bistable Function) 1/4Dinesh ChouguleAinda não há avaliações

- WIKA Catalog800 Mechanical Temperature 042409 PDFDocumento67 páginasWIKA Catalog800 Mechanical Temperature 042409 PDFDidik RiswantoAinda não há avaliações

- Cameron Handbook - TA3000 Product Manual Rev 4Documento141 páginasCameron Handbook - TA3000 Product Manual Rev 4mongojerry75% (4)

- Metric Bolts - Minimum Ultimate Tensile & Proof LoadsDocumento4 páginasMetric Bolts - Minimum Ultimate Tensile & Proof LoadsBenjamin IndrawanAinda não há avaliações

- LOCTITE North American Product CatalogDocumento132 páginasLOCTITE North American Product CatalogOmri HamaniAinda não há avaliações

- Check Valves: CV, CH, CO, CA, COA, CL and CW SeriesDocumento17 páginasCheck Valves: CV, CH, CO, CA, COA, CL and CW SeriesEdwin ArguelloAinda não há avaliações

- Hose Reels CatalogueDocumento44 páginasHose Reels CatalogueAlfian ImaduddinAinda não há avaliações

- Insertos KYOCERA RoscadoDocumento3 páginasInsertos KYOCERA RoscadoCristian AlonsoAinda não há avaliações

- BKH / Bkhp420 2-Way Ball Valve Stainless Steel: Available Sizes ConnectionsDocumento4 páginasBKH / Bkhp420 2-Way Ball Valve Stainless Steel: Available Sizes ConnectionsManikandan MAinda não há avaliações

- "T" Type Air Process Heaters: For In-Line Air and Gas HeatingDocumento2 páginas"T" Type Air Process Heaters: For In-Line Air and Gas HeatingClaudia T.Ainda não há avaliações

- Arjay Engineering Level Sensor 9080 Users ManualDocumento15 páginasArjay Engineering Level Sensor 9080 Users ManualDan SomervilleAinda não há avaliações

- Presostat Electronic PDFDocumento128 páginasPresostat Electronic PDFMarius MariusAinda não há avaliações

- Teesing Type of ThreadDocumento13 páginasTeesing Type of ThreadVic Blázquez100% (1)

- Flomec CatalogDocumento72 páginasFlomec CatalogWilfredo MolinaAinda não há avaliações

- CMP Products Cable Gland Catalogue: E1X Double Seal Industrial Cable Gland For Braid & Steel Tape Armoured CablesDocumento1 páginaCMP Products Cable Gland Catalogue: E1X Double Seal Industrial Cable Gland For Braid & Steel Tape Armoured CablescrisraharjoAinda não há avaliações

- Quick Connectors: For Testing, Filling and PluggingDocumento64 páginasQuick Connectors: For Testing, Filling and PluggingJivendra KumarAinda não há avaliações

- AccessoriesDocumento64 páginasAccessoriesTcristomoradoAinda não há avaliações

- RS485 Resistive Level SensorsDocumento4 páginasRS485 Resistive Level SensorsshadyghanemAinda não há avaliações

- Parker Truck Pump CatalogDocumento12 páginasParker Truck Pump CatalogElias80Ainda não há avaliações

- EPR Paddle Wheel Flow MeterDocumento16 páginasEPR Paddle Wheel Flow MeterAndrés VargasAinda não há avaliações

- R-P-AP-0004 Rev01 Georg Fischer CATA SPEC Transfer Protocol PDFDocumento488 páginasR-P-AP-0004 Rev01 Georg Fischer CATA SPEC Transfer Protocol PDFdesai_tejasAinda não há avaliações

- Valvula SBSGDocumento4 páginasValvula SBSGReinaldo RuskeAinda não há avaliações

- R - 00 SeriesDocumento16 páginasR - 00 SeriesAdrian SetyadharmaAinda não há avaliações

- Eclipse Model 706 High Performance Guided Wave Radar Level TransmitterDocumento44 páginasEclipse Model 706 High Performance Guided Wave Radar Level TransmitterMohamed RafihAinda não há avaliações

- CATALOGO - DIXON VALVE Petrochemical - 1 - Exploration - 2017Documento24 páginasCATALOGO - DIXON VALVE Petrochemical - 1 - Exploration - 2017Hector Luis MejiaAinda não há avaliações