Escolar Documentos

Profissional Documentos

Cultura Documentos

Equation K-1, K-3 Calculation Spreadsheet

Enviado por

jowarDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Equation K-1, K-3 Calculation Spreadsheet

Enviado por

jowarDireitos autorais:

Formatos disponíveis

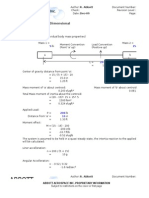

Subpart K - Ferroalloy Production - Calculating CO

2

Emissions Using Equation K-1 and Calculating CH

4

Emissions Using Equation K-3

OPTIONAL SPREADSHEET FOR FACILITY RECORDKEEPING PURPOSES

Version e-GGRT RY2010.R.02

Today's date 9/9/2014

Use one spreadsheet for each EAF. Make additional copies as needed.

Equation K-1:

Equation K-3:

Facility Name:

Reporter Name:

Unit Name/ ID:

Reporting Period:

Comments:

Unit Type:

Input Data for Reducing Agents

Space for up to five materials is provided.

This spreadsheet is protected and contains locked cells to ensure that you do not inadvertently alter any of the included formulas and/or calculations. To remove this protection and alter this

spreadsheet, right-click the "worksheet" tab near the bottom of the screen and select Unprotect Sheet. When prompted for the password, type GHG and click "OK." Please note that making

changes to an unprotected sheet could result in incorrect calculations and that you are responsible for the accuracy of the data you report to EPA. For additional help, visit the Microsoft Excel

Support website (http://office.microsoft.com/en-us/excel-help).

EAF

1

- -

1

1

1

1

1

2205

2000

12

44

-

2205

2000

12

44

-

2205

2000

12

44

2205

2000

12

44

2205

2000

12

44

2205

2000

12

44

l

l

outgoing product non

l

outgoing product non

k

k

outgoing product

k

outgoing product

j

h

ore ore

m

m electrode electrode

i

i

agent reducing

i

agent reducing

C M

C M

M

C M

C M

C M

h h

m

j flux j flux

CO2

C

E

)

2205

2000

(

1

4

i i

product

i

product CH

EF M E

Subpart K - Ferroalloy Production - Calculating CO

2

Emissions Using Equation K-1 and Calculating CH

4

Emissions Using Equation K-3

OPTIONAL SPREADSHEET FOR FACILITY RECORDKEEPING PURPOSES

Version e-GGRT RY2010.R.02

Today's date 9/9/2014

Use additional copies of this spreadsheet for additional materials (i.e, use multiple spreadsheets to calculate contributions to E

CO2

and E

CH4

, and add the contributions prior to entering in eGGRT).

i=1 i=2 i=3 i=4 i=5

[M

reducing agent i

] = Annual mass of reducing agent i

fed, charged, or otherwise introduced into the EAF

(tons)

[C

reducing agent i

] = Carbon content in reducing agent

i (percent by weight, expressed as a decimal

fraction)

Input Data for Electrodes

Space for up to five materials is provided. Use additional copies of this spreadsheet for additional materials.

Use additional copies of this spreadsheet for additional materials (i.e, use multiple spreadsheets to calculate contributions to E

CO2

and E

CH4

, and add the contributions prior to entering in eGGRT).

m=1 m=2 m=3 m=4 m=5

[M

electrode m

] = Annual mass of carbon electrode m

consumed in the EAF (tons)

[C

electrode m

] = Carbon content of the carbon

electrode m (percent by weight, expressed as a

decimal fraction)

Input Data for Ore

Space for up to five materials is provided. Use additional copies of this spreadsheet for additional materials.

Use additional copies of this spreadsheet for additional materials (i.e, use multiple spreadsheets to calculate contributions to E

CO2

and E

CH4

, and add the contributions prior to entering in eGGRT).

h=1 h=2 h=3 h=4 h=5

[M

ore h

] = Annual mass of ore h charged to the EAF

(tons)

[C

ore h

] = Carbon content in ore h (percent by

weight, expressed as a decimal fraction)

Input Data for Flux

Space for up to five materials is provided. Use additional copies of this spreadsheet for additional materials.

Use additional copies of this spreadsheet for additional materials (i.e, use multiple spreadsheets to calculate contributions to E

CO2

and E

CH4

, and add the contributions prior to entering in eGGRT).

j=1 j=2 j=3 j=4 j=5

[M

flux j

] = Annual mass of flux material j fed,

charged, or otherwise introduced into the EAF to

facilitate slag formation (tons)

[C

flux j

] = Carbon content in flux material j (percent

by weight, expressed as a decimal fraction)

Input Data for Product

Space for up to five materials is provided. Use additional copies of this spreadsheet for additional materials.

Use additional copies of this spreadsheet for additional materials (i.e, use multiple spreadsheets to calculate contributions to E

CO2

and E

CH4

, and add the contributions prior to entering in eGGRT).

Subpart K - Ferroalloy Production - Calculating CO

2

Emissions Using Equation K-1 and Calculating CH

4

Emissions Using Equation K-3

OPTIONAL SPREADSHEET FOR FACILITY RECORDKEEPING PURPOSES

Version e-GGRT RY2010.R.02

Today's date 9/9/2014

k=1 or i=1 k=2 or i=2 k=3 or i=3 k=4 or i=4 k=5 or i=5

[M

product k

] = Annual mass of alloy product k tapped

from EAF (tons)

[C

product k

] = Carbon content in alloy product k

(percent by weight, expressed as a decimal

fraction)

[EF

product i

] = CH

4

emission factor for alloy product i

from Table K-1 in this subpart (kg of CH4

emissions per metric ton of alloy product i)

Input Data for non-Product Outgoing Material

Space for up to five materials is provided. Use additional copies of this spreadsheet for additional materials.

Use additional copies of this spreadsheet for additional materials (i.e, use multiple spreadsheets to calculate contributions to E

CO2

and E

CH4

, and add the contributions prior to entering in eGGRT).

l=1 l=2 l=3 l=4 l=5

[M

non-product outgoing l

] = Annual mass of non-product

outgoing material l removed from EAF (tons)

[C

non-product outgoing l

] = Carbon content in non-

product outgoing material l (percent by weight,

expressed as a decimal fraction)

Constants

[44/12] = Ratio of molecular weights, CO

2

to

carbon

44/12

[2000/2205] = Conversion factor to convert tons to

metric tons

2000/2205

Annual CO

2

Emissions (metric tons) from Equation K-1

[E

CO2

] = Annual process CO

2

emissions from an

individual EAF (metric tons)

0.0

Enter this value in e-GGRT

Annual CH

4

Emissions (metric tons) from Equation K-3

[E

CH4

] = Annual process CH

4

emissions from an

individual EAF (metric tons)

0.00

Enter this value in e-GGRT

Table K-1 of Subpart KElectric Arc Furnace (EAF) CH

4

Emission Factors

Batch-

Charging

Sprinkle-

Charging

a

Sprinkle-Charging and

>750C

b

Silicon metal 1.5 1.2 0.7

Ferrosilicon 90% 1.4 1.1 0.6

Ferrosilicon 75% 1.3 1 0.5

Ferrosilicon 65% 1.3 1 0.5

a Sprinkle-charging is charging intermittently every minute.

b Temperature measured in off-gas channel downstream of the furnace hood.

Alloy product produced in EAF

CH

4

Emission Factor (kg CH

4

per metric ton product)

EAF Operation

Você também pode gostar

- LCA Spreadsheet 1 10Documento74 páginasLCA Spreadsheet 1 10St_LairAinda não há avaliações

- Load ScheduleDocumento16 páginasLoad ScheduleXander Delinya100% (1)

- Material Balance PDFDocumento5 páginasMaterial Balance PDFMayank VisalparaAinda não há avaliações

- 302 ProjectDocumento35 páginas302 Projectredpanda193Ainda não há avaliações

- Water CalculationDocumento41 páginasWater Calculationahmad aboulsoudAinda não há avaliações

- Isobutane Butane Fractionator PDFDocumento7 páginasIsobutane Butane Fractionator PDFhoustonmathAinda não há avaliações

- Wbs Project - IndriDocumento42 páginasWbs Project - Indrikere_hore007Ainda não há avaliações

- List EngDocumento60 páginasList EngtonnyAinda não há avaliações

- Insulated PipeDocumento54 páginasInsulated Pipedeion29Ainda não há avaliações

- FMC OffShore YZ Yard Weighting, Load Out, DeMobilization and Closing - Rev2Documento5 páginasFMC OffShore YZ Yard Weighting, Load Out, DeMobilization and Closing - Rev2HELIO SANTOS JUNIORAinda não há avaliações

- Fractionation SystemsDocumento8 páginasFractionation SystemsKha Damayantirika Tsf 'reall'Ainda não há avaliações

- Civil Spec Part-ADocumento118 páginasCivil Spec Part-AAnonymous nwByj9LAinda não há avaliações

- Lvgo Water Cooler Data Sheet E-0107Documento6 páginasLvgo Water Cooler Data Sheet E-0107mohsen ranjbarAinda não há avaliações

- New Gas Fired Power Plant at Ressano Garcia - CER - Calculation - v5Documento11 páginasNew Gas Fired Power Plant at Ressano Garcia - CER - Calculation - v5rym romdhanAinda não há avaliações

- Quick Response Area ReductionDocumento5 páginasQuick Response Area ReductionNaseer PashaAinda não há avaliações

- By Product Co2 Recovery Flow PDFDocumento1 páginaBy Product Co2 Recovery Flow PDFtejcd1234Ainda não há avaliações

- Code Ref.Documento155 páginasCode Ref.Selvakpm06Ainda não há avaliações

- Tank Weight CalculatorDocumento1 páginaTank Weight CalculatorRafael ReyesAinda não há avaliações

- Design of Welded Steel Storage Tanks in Accordance With API650 Job DataDocumento4 páginasDesign of Welded Steel Storage Tanks in Accordance With API650 Job DatamirzacogoAinda não há avaliações

- Gas Flow Calculation AGA3Documento1 páginaGas Flow Calculation AGA3ijaz ahmadAinda não há avaliações

- The Matlab Code Turab Word FileDocumento2 páginasThe Matlab Code Turab Word Filemuhammad saeedAinda não há avaliações

- Heat Load Estimation - Ac-Pump RoomDocumento3 páginasHeat Load Estimation - Ac-Pump RoomPranjoy MukherjeeAinda não há avaliações

- Beam DesignDocumento8 páginasBeam DesignGeorge GeorgianAinda não há avaliações

- PipeClass NG 11.08.09 PDFDocumento138 páginasPipeClass NG 11.08.09 PDFbadelitamariusAinda não há avaliações

- Piping CalculationDocumento19 páginasPiping CalculationYusri Fakhrizal100% (1)

- AWS A5.12: Material Safety Data Sheet (MSDS)Documento3 páginasAWS A5.12: Material Safety Data Sheet (MSDS)Mani VannanAinda não há avaliações

- Calculate Size of Anchor Fastener For Water Pipe Support (19.1.20)Documento4 páginasCalculate Size of Anchor Fastener For Water Pipe Support (19.1.20)jiguparmar1516Ainda não há avaliações

- Plasma Laser CuttingDocumento5 páginasPlasma Laser Cuttingibrahim syedAinda não há avaliações

- S/N Name Registration Number Sign: Group 2 MembersDocumento3 páginasS/N Name Registration Number Sign: Group 2 MembersAkankwasa RonaldAinda não há avaliações

- DEWA Infrastructure GuidelineDocumento819 páginasDEWA Infrastructure Guidelinenirmal mohanAinda não há avaliações

- Agitator SizingDocumento4 páginasAgitator SizingArbee AquinoAinda não há avaliações

- E PipeAlatorDocumento9 páginasE PipeAlatorselisenAinda não há avaliações

- Test Gas CalculationDocumento4 páginasTest Gas CalculationgrabettyAinda não há avaliações

- PowerTool Ver2.0 - 2015Documento44 páginasPowerTool Ver2.0 - 2015Tech ManagerAinda não há avaliações

- Design of Loose Type Flanges-Lap Joint-2Documento12 páginasDesign of Loose Type Flanges-Lap Joint-2Jose BijoyAinda não há avaliações

- Water Plant EstimateDocumento4 páginasWater Plant EstimateBalakrishna BedudooriAinda não há avaliações

- Freeboard Claculation For Stoarage Tanks As Per Api-650 12Th Edition V V D D H H K K Q Q I IDocumento2 páginasFreeboard Claculation For Stoarage Tanks As Per Api-650 12Th Edition V V D D H H K K Q Q I IAnonymous JWI6rqt100% (1)

- AFMC (Medical) Solved Paper 2013 PDFDocumento32 páginasAFMC (Medical) Solved Paper 2013 PDFAnkur BanerjeeAinda não há avaliações

- EDL Upgrading SPBG Bogor - ElectricalDocumento63 páginasEDL Upgrading SPBG Bogor - Electrical17crushAinda não há avaliações

- Actual Design Kaizen Pipe Sizing Air Cooled Condensing Unit 38ASB600AFDocumento26 páginasActual Design Kaizen Pipe Sizing Air Cooled Condensing Unit 38ASB600AFRocky James AsildoAinda não há avaliações

- Estimates Basic CALCULATEDDocumento49 páginasEstimates Basic CALCULATEDTarun ChopraAinda não há avaliações

- Reference: Chapter 2 Spread Sheet Made By: Himanshu Parikh Vadodara, Gujarat, IndiaDocumento5 páginasReference: Chapter 2 Spread Sheet Made By: Himanshu Parikh Vadodara, Gujarat, IndiaHimanshu ParikhAinda não há avaliações

- Calculation Tool Carbon Footprint Wastewater Treatment Plants To EurEau MembersDocumento105 páginasCalculation Tool Carbon Footprint Wastewater Treatment Plants To EurEau MembersAnca FajardoAinda não há avaliações

- Pump Selection: Examples of Centrifugal PumpsDocumento18 páginasPump Selection: Examples of Centrifugal PumpscsAinda não há avaliações

- American SteelBook 2Documento454 páginasAmerican SteelBook 2JesusAinda não há avaliações

- Silicon Compound Manufacturing (O'mara)Documento32 páginasSilicon Compound Manufacturing (O'mara)Arens Ong100% (1)

- Weather Conditions: Daily Progress ReportDocumento2 páginasWeather Conditions: Daily Progress Reportbishu70Ainda não há avaliações

- Discharge Capacity CheckDocumento14 páginasDischarge Capacity CheckkolioskiAinda não há avaliações

- Technical Data: 150x125 CNHA 5 18.5Documento5 páginasTechnical Data: 150x125 CNHA 5 18.5سمير البسيونىAinda não há avaliações

- Solid & Liquid Fuels:: Combustion CalculationsDocumento6 páginasSolid & Liquid Fuels:: Combustion Calculationshamid vahedil larijaniAinda não há avaliações

- Simple Economic Model - Household Solar + BatteryDocumento12 páginasSimple Economic Model - Household Solar + BatteryDynamic SaravananAinda não há avaliações

- 5642 Carbon Emission Factors Cvs 2012Documento10 páginas5642 Carbon Emission Factors Cvs 2012Gabriel AlvesAinda não há avaliações

- LC1 - C2001-33BQ-0000 - Pump Room - Rev01Documento111 páginasLC1 - C2001-33BQ-0000 - Pump Room - Rev01suheil samaraAinda não há avaliações

- Capacitor Bank Sizing ExamplesDocumento29 páginasCapacitor Bank Sizing ExamplesRobert OtimAinda não há avaliações

- Fire Jockey Pump. Rev B1Documento3 páginasFire Jockey Pump. Rev B1Pump SpesialistAinda não há avaliações

- Stability Verification of Thrust Blocks: Thrust Force From Piping System (TF)Documento6 páginasStability Verification of Thrust Blocks: Thrust Force From Piping System (TF)rubendcunoAinda não há avaliações

- Cone DevelopmentDocumento1 páginaCone DevelopmentrsubramaniAinda não há avaliações

- Biograce Excel Tool Version 4D For Compliance: Go To Sheet 'Warning'Documento38 páginasBiograce Excel Tool Version 4D For Compliance: Go To Sheet 'Warning'Rofi MuhammadAinda não há avaliações

- Equation H-1 Calculation SpreadsheetDocumento2 páginasEquation H-1 Calculation Spreadsheetram_90000Ainda não há avaliações

- GH G ConversionDocumento146 páginasGH G ConversionjorgeAinda não há avaliações

- Piping Class ExampleDocumento302 páginasPiping Class Examplejowar75% (4)

- B31.3 Process Piping Code PD643 Updated October 2012Documento3 páginasB31.3 Process Piping Code PD643 Updated October 2012jowarAinda não há avaliações

- Princess Noura Bint Abdulrahman University For Women Project Joint Venture El Seif/CCCDocumento3 páginasPrincess Noura Bint Abdulrahman University For Women Project Joint Venture El Seif/CCCjowarAinda não há avaliações

- Pipeline Tie-In Spoolpiece MeasurementsDocumento4 páginasPipeline Tie-In Spoolpiece MeasurementsjowarAinda não há avaliações

- Cálculo Flange ASME VIII 1 Apendice 2Documento10 páginasCálculo Flange ASME VIII 1 Apendice 2jowarAinda não há avaliações

- AA-SM-219 Tools - Various Mass Balances - Linear and RotationalDocumento22 páginasAA-SM-219 Tools - Various Mass Balances - Linear and RotationaljowarAinda não há avaliações

- AA-SM-004-003 Bolt Group - 3 - 3D Bolt Group Short VersionDocumento4 páginasAA-SM-004-003 Bolt Group - 3 - 3D Bolt Group Short VersionjowarAinda não há avaliações

- AA SM 001 002 Section Properties GeneralDocumento4 páginasAA SM 001 002 Section Properties GeneraljowarAinda não há avaliações

- AA-SM-004-004 Bolt Group - 1 - 2D Bolt Group - 2 Bolts - Multiple CasesDocumento3 páginasAA-SM-004-004 Bolt Group - 1 - 2D Bolt Group - 2 Bolts - Multiple CasesjowarAinda não há avaliações

- AA-SM-001-003 Section Properties - Node BasedDocumento2 páginasAA-SM-001-003 Section Properties - Node BasedjowarAinda não há avaliações

- AA-SM-001-001 Section Properties - Seat TracksDocumento2 páginasAA-SM-001-001 Section Properties - Seat TracksjowarAinda não há avaliações

- AA-SM-224 Tools - Intersection of Line and A CircleDocumento18 páginasAA-SM-224 Tools - Intersection of Line and A CirclejowarAinda não há avaliações

- AA SM 008ContactStressesDocumento3 páginasAA SM 008ContactStressesjowarAinda não há avaliações

- AA SM 031RambergOsgoodappliedtoCozzoneDocumento1 páginaAA SM 031RambergOsgoodappliedtoCozzonejowarAinda não há avaliações

- AA-SM-025-002 Shape Factors of Complex ShapesDocumento12 páginasAA-SM-025-002 Shape Factors of Complex ShapesjowarAinda não há avaliações

- AA SM 024ShearinMulti CelledsectionsduetoshearandtorsionDocumento8 páginasAA SM 024ShearinMulti CelledsectionsduetoshearandtorsionjowarAinda não há avaliações

- AA SM 019 BendingDocumento18 páginasAA SM 019 BendingjowarAinda não há avaliações

- A Comparison of Physical Solvents For Acid Gas Removal PDFDocumento10 páginasA Comparison of Physical Solvents For Acid Gas Removal PDFVirnia PatziAinda não há avaliações

- Classification of MatterDocumento23 páginasClassification of MatterJhaymie Marbi MallariAinda não há avaliações

- Advanced Materials For Ultrahigh Temperature StrucDocumento23 páginasAdvanced Materials For Ultrahigh Temperature StrucMüslüm KOÇAinda não há avaliações

- Apparatus, Reagents, and Safety Precautions For Chemical Analysis of MetalsDocumento28 páginasApparatus, Reagents, and Safety Precautions For Chemical Analysis of Metalsvuqar0979Ainda não há avaliações

- Factors Affecting Vibrational Frequenciesand IR Spectroscopy of HydrocarbonsDocumento17 páginasFactors Affecting Vibrational Frequenciesand IR Spectroscopy of HydrocarbonsMuhammad HussnainAinda não há avaliações

- Carbon Residue TestDocumento5 páginasCarbon Residue TestJerico Llovido100% (1)

- The World of Chemistry Video Guide SetDocumento10 páginasThe World of Chemistry Video Guide SetrkvAinda não há avaliações

- Revision Notes On P-Block Elements:: BoronDocumento15 páginasRevision Notes On P-Block Elements:: BoronKarthikayan BalajiAinda não há avaliações

- Microfine Carbon BlackDocumento4 páginasMicrofine Carbon BlackongkewAinda não há avaliações

- Qatar Gas Painting Procedure PDFDocumento99 páginasQatar Gas Painting Procedure PDFBalaji Guru67% (3)

- Rev HANI SKENARIO KETERAMPILAN DASAR MENGAJARDocumento2 páginasRev HANI SKENARIO KETERAMPILAN DASAR MENGAJARHanifatin AzizahAinda não há avaliações

- Chemetall - (Data Sheet) Oakite 33Documento3 páginasChemetall - (Data Sheet) Oakite 33Pubcrawl100% (1)

- Second GradingDocumento4 páginasSecond GradingBillones Rebalde MarnelleAinda não há avaliações

- Akışı Bozan Cümle 150 SoruDocumento26 páginasAkışı Bozan Cümle 150 SoruMurat SakaAinda não há avaliações

- NASA RP1113 - LOX CompatibilityDocumento83 páginasNASA RP1113 - LOX CompatibilityclevercogAinda não há avaliações

- Ramcharan Plastic News Letter Issue 6 - September 2012Documento4 páginasRamcharan Plastic News Letter Issue 6 - September 2012Madan SainiAinda não há avaliações

- Astm B488 PDFDocumento8 páginasAstm B488 PDFmunnizza64100% (1)

- Chemistry 2Documento16 páginasChemistry 2Ronnith NandyAinda não há avaliações

- Which Instrument Is Used To Tell DirectionDocumento12 páginasWhich Instrument Is Used To Tell DirectionLousy MoAinda não há avaliações

- AISI1040Documento2 páginasAISI1040Anonymous qRbPsLpuNAinda não há avaliações

- Common Metallurgical Defects in Grey Cast IronDocumento9 páginasCommon Metallurgical Defects in Grey Cast IronRolando Nuñez Monrroy100% (1)

- AluminiumDocumento12 páginasAluminiumalbidaiaAinda não há avaliações

- Aniline Point Lab ReportDocumento2 páginasAniline Point Lab ReportJoos Monkeyfied89% (9)

- KKXXDocumento4 páginasKKXXThilagaAinda não há avaliações

- A Critical Review of Carbon Fiber and Related Products From An Industrial PerspectiveDocumento17 páginasA Critical Review of Carbon Fiber and Related Products From An Industrial Perspectivechatgpt51023Ainda não há avaliações

- Engineering Chemistry by P. N. Dave and S. G. PillaiDocumento29 páginasEngineering Chemistry by P. N. Dave and S. G. PillaiKrishna92Ainda não há avaliações

- Hyvolt IIIDocumento1 páginaHyvolt IIIfaisiiAinda não há avaliações

- Influence of Process Gases in Laser Cladding ITSC 2018Documento7 páginasInfluence of Process Gases in Laser Cladding ITSC 2018lazaroccsAinda não há avaliações

- Mark Schemes: Quick Quiz 1 Matching End of Unit Test Marks To NC LevelsDocumento3 páginasMark Schemes: Quick Quiz 1 Matching End of Unit Test Marks To NC LevelsVictor Barber Sanchis60% (10)

- Corrosive Sulfur Effects in Transformer Oils and Remedial ProceduresDocumento9 páginasCorrosive Sulfur Effects in Transformer Oils and Remedial Proceduresandres100% (1)