Escolar Documentos

Profissional Documentos

Cultura Documentos

(Luthier) Making A Ukulele, Plans 1915

Enviado por

Esteban HDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

(Luthier) Making A Ukulele, Plans 1915

Enviado por

Esteban HDireitos autorais:

Formatos disponíveis

Comments on Making a

Ukulele.

W

hile the Panama-Pacific Inter-

national Exposition is almost

always touted as the event which popular-

ized the ukulele on the Mainland, the

instrument had already enjoyed several

years of notoriety on the West Coast, par-

ticularly in California. Bird of Paradise,

which featured a quintette of native

Hawaiians with guitars and ukuleles,

opened in Los Angeles in 1911, and

debuted on Broadway the following year,

Sears, Roebuck & Co. began selling

ukuleles in 1914 and at least a half-dozen

ukulele method books had been published

by the time Jonah Kumalae was awarded

the Gold Medal for his exhibit at the

P.P.I.E. in 1915. So it isnt surprising that

John Bangerter, a Los Angeles manual

arts teacher, would be among the first on

the Mainland to publish plans for making

an ukulele.

Written for the secondary, or high

school, shop teacher, the plans are of the

most rudimentary kind and are more

remarkable for their early appearance than

accurate directions. For instance, the

placement of the frets are poorly measured,

and while the resulting instrument may

resemble an ukulele, its intonation would

surely be faulty.

The plans were originally pub-

lished in The Industrial-Arts Magazine, a

Milwaukee, Wisconsin based publication,

in December, 1915. The copy that this

electronic file was made from survived

precisely because its previous owner was

interested in making an ukulele: Making

a Ukulele is boldy inscribed and under-

lined on the cover. In the same large

manilla envelope with the magazine were a

1917 catalog from C. F. Martin and sever-

al ukulele templates and unused

mahogany ukulele sets.

-John King

2003 NALU Music

MAKING A UKULELE.

By J. E. Bangerter, Los Angeles, Cal.

D

URING the past two years the

musical world has received a new

instrument. The bringing of the Ukulele

to the Pacific Coast States has created

much interest. It is used in accompanying

the voice in the native Hawaiian melodies

or in other Popular Airs. It is an instru-

ment that can be played with only a little

instruction. The construction is so simple

that many students in Manual Training

Shops of Southern California have made

their own instruments.

Being a teacher of Manual Arts I

became interested in the making of the

Ukulele and found that the instrument

would be a good project for advance grade

or highschool students to make, provided

careful instructions were given. The fol-

lowing is the method that I used in the

Carroll Park School of Long Beach,

California, and found it to be both satis-

factory and practical.

Materi al s Requi red for the

Ukul el e.

1 Pc. Tobasco Mahogany 1 3/4 x 2 1/4 x

12 (Neck)

1 Pc. Tobasco Mahogany Veneer 1/16 full

x 6 1/2 x 20 (Top and Bottom)

1 Pc. Tobasco Mahogany Veneer 1/16 x 1

1/2 x 27 (Sides)

1 Pc. White Pine 1/4 x 6 20 (Support,

Braces, etc.)

1 Pc. White Pine 1/2 x 2 x 2 1/2

(Sounding Post)

1 Pc. White Pine 5/8 x 10 x 14

(Clamping Board)

1 Pc. White Pine 2 1/4 x 10 x 14 (Form)

1 Dozen Frets

1 Violin A String

1 Violin E String

Di recti ons.

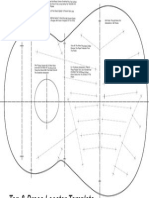

The first part to make is the form

for the bending of the sides of the Ukulele.

The form will require a piece of wood 2

1/4 by 10 by 14 inches in size as stated in

lumber bill. Lay out the outline of the

Ukulele body as shown on drawing. Make

the slant required before the form is sawed

out. In sawing, be sure to use a saw that

has enough kurf that will be equal to the

thickness of the veneer. After this form is

made we are ready for the bending of the

sides. Take a piece of string or paper and

measure the distance around the outside of

the inside of the form, to find out the exact

length of the strips of veneer that are

required for the sides. Cut them to the

dimensions found and boil in water or

steam for one hour, when they will be

ready to put in the form. Be careful not to

let any blisters form when clamping. Use

two bar clamps to hold form together and

do not remove clamps for 24 hours. The

surplus wood may then be removed and

the clamps taken off being careful to mark

the edge that is to join the top of the

Ukulele, so there will be no mistake when

the neck and the sides are glued together.

While the sides are drying, the

neck, sounding post, supports, braces,

keys and bridge may be made according to

the drawing.

The sides are fastened to the neck

by making a saw cut just large enough to

let the veneer slip into and then glued.

Also glue in the sounding post and leave

the glue set over night. In order to get the

sounding post in the center, measure half

the distance around the side by the use of a

string or a strip of paper. The supports

which are made out of the 1/4" piece of

white pine may now be glued in around the

sides; their shape being traced from the

inside of the form used in forming the

sides. After the glue that holds the sup-

ports to the sides has set, the braces may be

mortised in to the supports by making a

half lap joint and gluing.

To make the top: Trace from the

form the shape of the top and back on the

piece of mahogany 6 by 20 inches and

allow about 3/8 inches all around the out-

line drawn, as it will be easier to make the

exact size after it has been glued on.

Cutout the hole and then glue to sides.

When gluing on the top, be sure to keep

the center of the neck and the body of the

Ukulele in a straight line and lying in the

same plane. To do this clamp the instru-

ment to a long, flat board. Leave the

instrument set over night and then remove

clamps.

We may now proceed with gluing

on the back. In order to get the desired

curve in the back a device for clamping

will have to be made which is as follows:

Take the 5/8 inch board and trace the out-

line of the body of the Ukulele as shown in

drawing. Make another line 1/4 inch

inside of this outline which will be the

required line to saw on. This leaves the

outside piece whole. This follow board will

allow the back to rise and help to make a

good joint at the same time. Before gluing

on back, moisten it with hot water to make

it bend easier, and then clamp on tight.

Dry out back by holding over a fire and

then remove clamps. It may now be glued

and clamped again and allowed to dry for

48 hours. Wedges may be driven between

follow board and back to help make a bet-

ter joint.

The frets and bridge may then be

glued on after the top and back have been

trimmed even with the sides, and the

Ukulele sandpapered all over until all the

mill and tool marks have been removed.

Fi ni shi ng the Ukul el e.

After it has been sandpapered give

the instrument a heavy coat of boiled lin-

seed oil, and then put on a coat of paste

wood filler. Rub this filler in good with the

hands; and then remove the surplus with a

rag and allow to dry over night. Several

coats of shellac or varnish may then be put

on, rubbing down between coats with

pumice stone and finishing with rotten

stone. If a flat finish is desired use water

with pumice stone, or oil, if a polish is

cared for.

NoteThe word ukulele is pro-

nounced u-ku-lay-lee.

Você também pode gostar

- The Uke Book Illustrated: Design and Build the World's Coolest UkuleleNo EverandThe Uke Book Illustrated: Design and Build the World's Coolest UkuleleNota: 5 de 5 estrelas5/5 (1)

- Introduction to Kit Acoustic Guitars (or) Life is Short...Build a GuitarNo EverandIntroduction to Kit Acoustic Guitars (or) Life is Short...Build a GuitarNota: 1 de 5 estrelas1/5 (1)

- Acoustic Travel Ukulele Plans PDFDocumento17 páginasAcoustic Travel Ukulele Plans PDFblancofrank545Ainda não há avaliações

- How To Make A Cigar Box UkuleleDocumento8 páginasHow To Make A Cigar Box UkuleleDmitry Kolotov100% (1)

- Acoustic Guitar PlansDocumento7 páginasAcoustic Guitar PlansFrançesko Astroza80% (5)

- Ukulele ConcertDocumento1 páginaUkulele Concertakomac100% (3)

- Ukelele Tenor PlanosDocumento1 páginaUkelele Tenor PlanosBROSHER100% (2)

- Construcción Paso A Paso UkeleleDocumento20 páginasConstrucción Paso A Paso UkeleleNosoytansolo Unabarbabonita100% (1)

- Rosettes PDFDocumento7 páginasRosettes PDFjuvemoraisAinda não há avaliações

- Guitar Guru: What'S The Difference Between Handmade and Handcrafted?Documento2 páginasGuitar Guru: What'S The Difference Between Handmade and Handcrafted?Jared WilliamsAinda não há avaliações

- April 2015 Professional Guitar Price ListDocumento1 páginaApril 2015 Professional Guitar Price ListAndrey BalalinAinda não há avaliações

- Instructions Neck AngleDocumento21 páginasInstructions Neck Angleandua40100% (2)

- The History and Manufacture of the GuitarDocumento9 páginasThe History and Manufacture of the GuitarMeiliana NaAinda não há avaliações

- (Luthieria) Acoustic Guitar MakingDocumento63 páginas(Luthieria) Acoustic Guitar MakingKa LuthieriaAinda não há avaliações

- Kasha Guitar PlanDocumento1 páginaKasha Guitar PlanAndrey BalalinAinda não há avaliações

- Stewart Mcdonald Plans GuitarsDocumento40 páginasStewart Mcdonald Plans GuitarsHide Pandini100% (1)

- Heating Cartridge Installation GuideDocumento1 páginaHeating Cartridge Installation Guidepeter100% (1)

- Crack alignment jig dimensions and instructionsDocumento1 páginaCrack alignment jig dimensions and instructionsGiorgio Napoleone100% (2)

- Acoustic Travel Ukulele PlansDocumento17 páginasAcoustic Travel Ukulele PlansEmii SalvaAinda não há avaliações

- 11 Free Guitar Plans, 20 Guitar Building Jigs and 35 More Resources For Newbie Luthiers - PDFDocumento22 páginas11 Free Guitar Plans, 20 Guitar Building Jigs and 35 More Resources For Newbie Luthiers - PDFBatik Kambangsri100% (4)

- Top Plate Brace Layouts: Classical Guitar Plan #3Documento1 páginaTop Plate Brace Layouts: Classical Guitar Plan #3Michele PacilliAinda não há avaliações

- A Luthiers LegacyDocumento17 páginasA Luthiers LegacyUill Cana Brava100% (1)

- Bolt On Acoustic Guitar NeckDocumento1 páginaBolt On Acoustic Guitar NeckJayMorgan50% (2)

- Hollows and rounds molding planes guideDocumento3 páginasHollows and rounds molding planes guideKaren RathbunAinda não há avaliações

- United States Patent: (12) (10) Patent N0.: US 6,894,209 B2Documento14 páginasUnited States Patent: (12) (10) Patent N0.: US 6,894,209 B2Arnab BhattacharyaAinda não há avaliações

- The Kasha GuitarDocumento15 páginasThe Kasha GuitarhaziboAinda não há avaliações

- Make A Steel GuitarDocumento6 páginasMake A Steel GuitarPimpinela GrooveAinda não há avaliações

- Acoustic Guitars: Woods and ShapesDocumento11 páginasAcoustic Guitars: Woods and ShapesLucas Man80% (5)

- Classic3plan 2Documento1 páginaClassic3plan 2Michele Pacilli100% (1)

- Construction Notes For A Steel String Guitar - SampleDocumento32 páginasConstruction Notes For A Steel String Guitar - SampleDennistoun75% (4)

- Classic 3 PlanDocumento1 páginaClassic 3 PlanMichele PacilliAinda não há avaliações

- Classic 2 TemplatesDocumento1 páginaClassic 2 TemplatesDaniel Garfo100% (3)

- HHHDocumento3 páginasHHHAsemAinda não há avaliações

- Acoustic Guitar Building InstructionsDocumento40 páginasAcoustic Guitar Building InstructionsLeeUnder100% (2)

- Electric Guitar Order Form: Custom Fitted Instrument CasesDocumento1 páginaElectric Guitar Order Form: Custom Fitted Instrument CasesArnab BhattacharyaAinda não há avaliações

- Prs NeckDocumento3 páginasPrs NeckAnonymous DNSgTc8pkRAinda não há avaliações

- Acoustic Guitar InnovationsDocumento27 páginasAcoustic Guitar InnovationsAugusto Espejo100% (1)

- LuthieryDocumento29 páginasLuthieryapi-249392674100% (2)

- Building An Acoustic GuitarDocumento24 páginasBuilding An Acoustic GuitarPedro RodriguezAinda não há avaliações

- Electric Ukulele Plan NotesDocumento9 páginasElectric Ukulele Plan Notesmking_6100% (1)

- The Acoustics of The Steel String GuitarDocumento418 páginasThe Acoustics of The Steel String Guitaraboutsoundcraft100% (3)

- Classic3plan 2 PDFDocumento1 páginaClassic3plan 2 PDFarantxa16Ainda não há avaliações

- Acoustic Guitar MakingDocumento1.000 páginasAcoustic Guitar MakingRicardo Luis Martin Sant'Anna100% (9)

- Guitar Sound StudyDocumento21 páginasGuitar Sound StudyJim SaligAinda não há avaliações

- Build Your Own Router Plane for Less Than $5Documento4 páginasBuild Your Own Router Plane for Less Than $5jucassabao75% (4)

- Bridge TemplatesDocumento5 páginasBridge TemplatesnhandutiAinda não há avaliações

- Guitar Making Guide - Jon SevyDocumento170 páginasGuitar Making Guide - Jon Sevyaboutsoundcraft100% (5)

- Classic3plan 3Documento1 páginaClassic3plan 3Michele PacilliAinda não há avaliações

- GuitarBuildingJigsTools v1.1Documento16 páginasGuitarBuildingJigsTools v1.1Mochamad Rizal Jauhari86% (7)

- Guitar Assembly Work Board - Top View 1937 Hauser Classical Guitar ShapeDocumento1 páginaGuitar Assembly Work Board - Top View 1937 Hauser Classical Guitar ShapeDaniel Garfo100% (1)

- Building A Guitar: Preparing Thin StockDocumento40 páginasBuilding A Guitar: Preparing Thin StockJosué S. De Jesus - JorgeAinda não há avaliações

- Voicing The GuitarDocumento24 páginasVoicing The GuitarHoàng Ngọc-TuấnAinda não há avaliações

- Ukulele PlanDocumento3 páginasUkulele Planapi-300791497Ainda não há avaliações

- Double Top BuildingDocumento18 páginasDouble Top BuildingaboutsoundcraftAinda não há avaliações

- Guitar DimensionsDocumento4 páginasGuitar DimensionsWalied SamiAinda não há avaliações

- La Guitare Friederich Et Leipp Bulletin Gam 92 - EnglishDocumento18 páginasLa Guitare Friederich Et Leipp Bulletin Gam 92 - EnglishVlad100% (1)

- Voicing Steel String Guitar TopsDocumento12 páginasVoicing Steel String Guitar Topsandrea_albrile100% (1)

- 16 Archtop Guitar BuildDocumento123 páginas16 Archtop Guitar Buildluis7oliveira_2100% (4)

- Ervin Somogyi ShowcaseDocumento46 páginasErvin Somogyi Showcaseaxemanarnab100% (3)

- Guitar Inside Mold - Side View 1937 Hauser Classical Guitar ShapeDocumento1 páginaGuitar Inside Mold - Side View 1937 Hauser Classical Guitar ShapeDaniel GarfoAinda não há avaliações

- AkzoNobel-Trigonox 239Documento6 páginasAkzoNobel-Trigonox 239Wafa AjiliAinda não há avaliações

- Guía Fallas para Ricoh Aficio 220Documento31 páginasGuía Fallas para Ricoh Aficio 220desechableAinda não há avaliações

- Energy Analysis of Closed Systems BreakdownDocumento31 páginasEnergy Analysis of Closed Systems Breakdownايات امجد امجدAinda não há avaliações

- How To Use Dr. Foster's Essentials: Essential Oils and BlendsDocumento5 páginasHow To Use Dr. Foster's Essentials: Essential Oils and BlendsemanvitoriaAinda não há avaliações

- Ross 308 AP Broiler PO2019-EN PDFDocumento16 páginasRoss 308 AP Broiler PO2019-EN PDFJORGE GALVISAinda não há avaliações

- Analytical Chemistry Lecture Exercise 2 Mole-Mole Mass-Mass: Sorsogon State CollegeDocumento2 páginasAnalytical Chemistry Lecture Exercise 2 Mole-Mole Mass-Mass: Sorsogon State CollegeJhon dave SurbanoAinda não há avaliações

- Project Information for 2x660 MW Lube Oil PumpsDocumento93 páginasProject Information for 2x660 MW Lube Oil PumpsghostamirAinda não há avaliações

- Malaria Epidemiology & PreventionDocumento92 páginasMalaria Epidemiology & PreventionritikaritikaAinda não há avaliações

- RLCraft v2.9 ChangelogDocumento28 páginasRLCraft v2.9 ChangelogSơn TrươngAinda não há avaliações

- Operational Transconductance Amplifier ThesisDocumento6 páginasOperational Transconductance Amplifier ThesislaurahallportlandAinda não há avaliações

- CV of Shaila (Me)Documento4 páginasCV of Shaila (Me)Masud RanaAinda não há avaliações

- Minicargador Cat 246Documento22 páginasMinicargador Cat 246Juanca FerroAinda não há avaliações

- Discrete Variable Probability Distribution FunctionsDocumento47 páginasDiscrete Variable Probability Distribution FunctionsJanine CayabyabAinda não há avaliações

- WIP CaseStudyDocumento3 páginasWIP CaseStudypaul porrasAinda não há avaliações

- Traffic Sign Detection and Recognition Using Image ProcessingDocumento7 páginasTraffic Sign Detection and Recognition Using Image ProcessingIJRASETPublicationsAinda não há avaliações

- SIC CodeDocumento424 páginasSIC CodeZohra MerchantAinda não há avaliações

- Operating Systems: Chapter 3: DeadlocksDocumento46 páginasOperating Systems: Chapter 3: DeadlocksManoel Katlib100% (1)

- Dr. Ghusoon Mohsin Ali: Al-Mustansiriya University College of Engineering Electrical Engineering DepartmentDocumento89 páginasDr. Ghusoon Mohsin Ali: Al-Mustansiriya University College of Engineering Electrical Engineering Departmentهمام الركابي100% (1)

- Painting, DrawingDocumento22 páginasPainting, DrawingMithilesh_Kuma_7083Ainda não há avaliações

- Pharmaceutics | Water Solubility and Dissolution RateDocumento11 páginasPharmaceutics | Water Solubility and Dissolution RateAnnisa AgustinaAinda não há avaliações

- Solving Rational Equations and InequalitiesDocumento5 páginasSolving Rational Equations and InequalitiesJaycint - Rud PontingAinda não há avaliações

- General Science EnvironmentDocumento28 páginasGeneral Science EnvironmentHamza MujahidAinda não há avaliações

- Sepuran® N Module 4": in NM /H at 7 Barg 25°CDocumento2 páginasSepuran® N Module 4": in NM /H at 7 Barg 25°CsanjaigAinda não há avaliações

- Name: Amir Bin Rossaifuddin Id: 2016307153 Group: Emd2M2ADocumento2 páginasName: Amir Bin Rossaifuddin Id: 2016307153 Group: Emd2M2AamirossaifuddinAinda não há avaliações

- Divide and Conquer (Closest Pair, Convex Hull, Strassen Matrix Multiply) DemoDocumento27 páginasDivide and Conquer (Closest Pair, Convex Hull, Strassen Matrix Multiply) DemoAnand KumarAinda não há avaliações

- Briefing Paper No 4 CV Electrification 30 11 17 PDFDocumento5 páginasBriefing Paper No 4 CV Electrification 30 11 17 PDFAlex WoodrowAinda não há avaliações

- Xoro Hrs 8540 HD Sat ReceiverDocumento33 páginasXoro Hrs 8540 HD Sat ReceiverPinoAinda não há avaliações

- Indian War of Independence 1857 - Part 2Documento150 páginasIndian War of Independence 1857 - Part 2BISWAJIT MOHANTYAinda não há avaliações

- Iot Finals Clap Switch Group 5Documento15 páginasIot Finals Clap Switch Group 5RICHYBOY SALACAinda não há avaliações

- Nutrition and Athletic PerformanceDocumento16 páginasNutrition and Athletic PerformancemarisolAinda não há avaliações