Escolar Documentos

Profissional Documentos

Cultura Documentos

Mechanical Properties of Rocks,,....

Enviado por

Ali WassanDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Mechanical Properties of Rocks,,....

Enviado por

Ali WassanDireitos autorais:

Formatos disponíveis

10-04-2014

Abdul Jabbar 12 MN 40

Group # 03

Mechanical Properties of Rocks

Group members

Abdul Jabbar 12 MN 40

Saqib Ali 12 MN 36

Abdullah 12-11 MN 88

Fahad Akash 12 MN 38

Teacher Name

Sir Agha Shafi Jawaid Pathan

MECHANICAL PROPERTIES OF ROCKS

1. Engineering design properties .

Uni-axial compressive strength ( E and ).

Tensile strength of rocks.

Shear strength of rocks. Shear strength of rocks.

Tri-axial- Cohesion and internal angle of friction.

2. Index properties.

3. Intrinsic properties.

Uni-axial compressive strength

A compressive strength is the stress required to rupture a

specimen in compression.

The compressive strength is the capacity of a material or

structure to withstand (resist) the compressive forces.

The rock sample is unconfined at its side while the load is

applied vertically until failure occurs. In this case, the applied vertically until failure occurs. In this case, the

compressive strength is called unconfined compressive

strength (uni-axial compressive strength).

In a uni-axial strain test, a cylindrical specimen is loaded

axially.

As the axial load is applied, the material (typically rock or

concrete) tries to expand.

Uni-axial compressive strength

It is one of the most important mechanical properties of rock

material, used in design, analysis and modelling.

In this test, a standard specimen is gripped between the jaws

movable and fixed jaw, and load is applied.

The compression in the specimen The compression in the specimen

is measured by extensometer.

Standard conditions for Ucs

P = Load at failure

D = core diameter of specimen

= Uni-axial compressive strength

c

= P / ( /4 X D

2

)

c

= Uni-axial compressive strength

Axial load on cylindrical specimen

Core diameter of 32-75mm

H/d ratio is 2.5 -3.0

Minimum number of tests 10 -20.

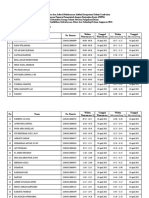

Uni-axial Compressive Strength: ISRM Standard Terminology

Ucs < 5 MPa Very Low

Ucs_ 5 25 MPa Low

Ucs_ 25 50 MPa Moderate

Ucs_ 50 100 MPa Medium

Ucs_100 250 MPa High

Ucs > 250 MPa Very High Ucs > 250 MPa Very High

Uni-axial compressive test

Modes of failure of rocks in Ucs

CRUMBLING SHEAR SLABING STRESS PATTERN CONICAL FAILURE

Factor affecting the ucs of rock

Ucs decreases with increasing H/d ratio of specimen.

Ucs decreases with increasing moisture % of specimen.

Ucs decreases with increasing relative humidity of specimen.

Ucs increases with increasing density of specimen.

Low strain rate shows lower Ucs of the specimen.

Low porosity rock has high strength.

Strength decreases with increases in slenderness.

Strength decreases with increase in size of specimen.

Types of Curves

Stress Stress

Linear (Igneous) Convex (sandstone)

Strain Strain

Stress stress

Concave (Shale , limestone ) S shaped (Coal, Rock salt)

Strain Strain

Brazilian Test

It is an indirect tensile test, that consists of applying diametric

Compressive stress to the sample.

Tensile stress will be induced in the lateral direction or

perpendicular of the applied load.

F

P = Load at failure (MN)

D = Diameter of the disc (m)

t = Thickness of the disc (m)

t

= Tensile strength of rock

t

= 2P/D t

F

F

Brazilian test

Minimum diameter NX core (54 mm)

H/d ratio of 0.5:1

The specimen loaded through a

curved jig with spherical seating.

A rate of deformation of 64 mm/ minute A rate of deformation of 64 mm/ minute

is recommended.

Shear strength of rock specimen

The stress or load at which a material fails in shear.

The internal resistance of a body to shear stress, typically

including a frictional part (called Angle of internal friction )

and the part independent of friction (called cohesion C).

The most important parameter for planning and designing of

underground and surface mines. underground and surface mines.

There are two (02) methods of shear strength determination:

Direct Shear testing.

Tri-axial compression test.

Direct shear test

A specimen is placed in a shear box.

A confining stress is applied vertically to the specimen, and the

upper ring is pulled laterally until the sample fails.

After applying the normal force, the shear force is applied

horizontally.

After rupture, the shear force can continue to be applied to

obtain the residual strength values.

normal stress

Rock specimen fracture plane

Shear Rrr

stress

Direct shear test

This force causes a shear failure (fracture) along the juncture

between the box sections.

Direct Shear Box assembly for 60mm x 60mm x 25mm thick

specimen

Several specimens are tested at various confining stresses to

determine the shear strength parameters, the rock cohesion (c) determine the shear strength parameters, the rock cohesion (c)

and the angle of internal friction, commonly known as friction

angle (). Normal stress

Rock specimen

fracture plane

Shear Shear

stress

Direct shear test

Core diameter of 25-50mm.

H/d ratio 2.0-3.0.

Minimum no of tests 5-10.

Direct shear test

For a single shear test

A = Area of cross section

=Shear force

1

= Shear strength

1

= /A

1

= Shear strength

For a double shear test

A = Area of cross section

=Shear force

1

= Shear strength

1

= /2A

Punch test

A cylindrical specimen of 150mm diameter and 150mm height.

The test specimen is placed in a clamp such that its upper and

lower surfaces are supported.

A punch type shear tool with a 25.4 mm (1 in) diameter is bolted

to the specimen and a load is applied to the punch

1

= Shear strength

= Shear force at failure along

the shear plane

t= Thickness of disc specimen

D= Diameter of the punch

1

= /D t

Punch test

For a double punch

A cylindrical rock is placed vertically between the loading

platens of the machine and is compressed by two steel

punches placed parallel to the top and bottom of end surfaces.

Tri-axial test

A cylindrical rock core is placed in a cell, subjected to all around

(confining) pressure by hydraulic oil acting through a thin

impermeable membrane, and loaded axially to failure.

The specimen is enclosed in an impregnable, airtight flexible

membrane is placed between two hardened spherical seated

platens. platens.

Confining pressure

3

is applied and held constant during the

test by means of a cell hydraulic fluid.

Axial stress

1

is then applied and continuously increased until

failure occurs.

Tri-axial test Parameters

Testing machine capacity 150- 250 MN.

Hoek and Franklin type tri-axial cell.

The cell pressure range is equal to

1700 - 3800 kPa).

Flexible membrane : Flexible membrane :

Rubber tubing 1.6 mm thick wall

and 40-60 Duro hardness.

Cohesive strength and internal

Angle of friction ()

THANK YOU THANK YOU

Você também pode gostar

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Jurisprudence NotesDocumento76 páginasJurisprudence NotesAli Wassan100% (1)

- Amer Jassim Al-Khafaji IRAQI Oil and GAS PDFDocumento1 páginaAmer Jassim Al-Khafaji IRAQI Oil and GAS PDFQ12w3e4r5tAinda não há avaliações

- The Lives of Man-Imam Abdallah Al - HaddadDocumento50 páginasThe Lives of Man-Imam Abdallah Al - Haddadfirasmax80% (10)

- Ihya Ulum Al-Din - Al Ghazali's Purification of The SoulDocumento7 páginasIhya Ulum Al-Din - Al Ghazali's Purification of The SoulSopheaAinda não há avaliações

- Fashion As Cultural TranslationDocumento14 páginasFashion As Cultural TranslationMinette ShuenAinda não há avaliações

- Cracking CSS English EssayDocumento3 páginasCracking CSS English EssayAli WassanAinda não há avaliações

- Overview of Pak's Foreign PolicyDocumento24 páginasOverview of Pak's Foreign PolicyAli WassanAinda não há avaliações

- Media Ethics in Professional JournalismDocumento4 páginasMedia Ethics in Professional JournalismAli WassanAinda não há avaliações

- Countering Radicalisation Through MediaDocumento3 páginasCountering Radicalisation Through MediaAli WassanAinda não há avaliações

- Women in The TTP: Recruiting Across The Gender Divide: Meera NadeemDocumento2 páginasWomen in The TTP: Recruiting Across The Gender Divide: Meera NadeemAli WassanAinda não há avaliações

- A New U.S. Defense Strategy For The FutureDocumento4 páginasA New U.S. Defense Strategy For The FutureAli WassanAinda não há avaliações

- The Out-Of-school Children ChallengeDocumento2 páginasThe Out-Of-school Children ChallengeAli WassanAinda não há avaliações

- Landmarks in The Global Movement For WomenDocumento3 páginasLandmarks in The Global Movement For WomenAli WassanAinda não há avaliações

- Russia and The West in A New StandoffDocumento9 páginasRussia and The West in A New StandoffAli WassanAinda não há avaliações

- Donald Trump and The Return of ClassDocumento1 páginaDonald Trump and The Return of ClassAli WassanAinda não há avaliações

- How America Lost AfghanistanDocumento5 páginasHow America Lost AfghanistanAli WassanAinda não há avaliações

- Descent Into Chaos: All Rationality Is Lost in The Haze of The Politics of RevengeDocumento3 páginasDescent Into Chaos: All Rationality Is Lost in The Haze of The Politics of RevengeAli WassanAinda não há avaliações

- Water Wars: "The Supreme Art of War Is To Subdue The Enemy Without Fighting". - Sun TzuDocumento3 páginasWater Wars: "The Supreme Art of War Is To Subdue The Enemy Without Fighting". - Sun TzuAli WassanAinda não há avaliações

- The New World DisorderDocumento3 páginasThe New World DisorderAli WassanAinda não há avaliações

- Brexit-Britain's Big MistakeDocumento3 páginasBrexit-Britain's Big MistakeAli WassanAinda não há avaliações

- The New Great GameDocumento3 páginasThe New Great GameAli WassanAinda não há avaliações

- Ethnicity in PakistanDocumento2 páginasEthnicity in PakistanAli Wassan100% (1)

- Intro Scope Nature and Evolution of International LawDocumento2 páginasIntro Scope Nature and Evolution of International LawAli WassanAinda não há avaliações

- The Morality ProblemDocumento2 páginasThe Morality ProblemAli WassanAinda não há avaliações

- This Is The List of Festivals in PakistanDocumento3 páginasThis Is The List of Festivals in PakistanAli Nawaz AyubiAinda não há avaliações

- XXXXXXXXXXXXXXXXXXXXXXXXXXDocumento43 páginasXXXXXXXXXXXXXXXXXXXXXXXXXXMohd touseefAinda não há avaliações

- 167 ##Default - Genres.article## 466 1 10 20200918Documento13 páginas167 ##Default - Genres.article## 466 1 10 20200918vanesanindylovita88Ainda não há avaliações

- Non Muslim FestivalDocumento89 páginasNon Muslim FestivalScoot QahAinda não há avaliações

- AIS-R Yearbook 1991-1992Documento108 páginasAIS-R Yearbook 1991-1992American International School Riyadh100% (1)

- My Research About The Marudhu Servai BrothersDocumento27 páginasMy Research About The Marudhu Servai BrothersSharmalan Thevar100% (2)

- Summer Break Homework Advance Montessori 2022 23Documento6 páginasSummer Break Homework Advance Montessori 2022 23Umar HarrisAinda não há avaliações

- Zindagi Ye Nahin Hay Kisi Ke Liye (Kalaam Taaj-As-Shariah)Documento2 páginasZindagi Ye Nahin Hay Kisi Ke Liye (Kalaam Taaj-As-Shariah)Sheraz Ibrahim100% (1)

- Names of AllahDocumento8 páginasNames of AllahAfshaan BanuAinda não há avaliações

- From NilaiDocumento28 páginasFrom Nilairisky zulkarnainAinda não há avaliações

- COMSATS University Islamabad, Lahore Campus: Department: Computer ScienceDocumento8 páginasCOMSATS University Islamabad, Lahore Campus: Department: Computer ScienceMuhammad Abubakar SiddiqueAinda não há avaliações

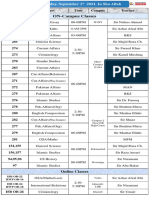

- ON-Campus Classes: Batch # Subject Time Campus TeacherDocumento2 páginasON-Campus Classes: Batch # Subject Time Campus TeacherhamzaAinda não há avaliações

- Application FormDocumento2 páginasApplication FormAbdul GhaffarAinda não há avaliações

- Mazaar BazaarDocumento4 páginasMazaar Bazaarahmed shumailAinda não há avaliações

- Rahmi Junianti Lestari J-JlecDocumento23 páginasRahmi Junianti Lestari J-Jlecrahmi junianti lestariAinda não há avaliações

- Diminishing Musharakah: Meezan Bank's Guide To Islamic BankingDocumento6 páginasDiminishing Musharakah: Meezan Bank's Guide To Islamic BankingSayed Sharif HashimiAinda não há avaliações

- BSMMU Otolaryngology March 2020Documento1 páginaBSMMU Otolaryngology March 2020Nurul AminAinda não há avaliações

- Lecture 14. Dilemma of Constituation Makink in PakistanDocumento4 páginasLecture 14. Dilemma of Constituation Makink in PakistanMalikAinda não há avaliações

- Highlights in Philippine HistoryDocumento27 páginasHighlights in Philippine HistoryJayson LeybaAinda não há avaliações

- Fariba Faizi Final Research Paper.Documento12 páginasFariba Faizi Final Research Paper.Fariba FaiziAinda não há avaliações

- Ushul Fikih X KeagamaanDocumento1 páginaUshul Fikih X KeagamaanMuhammad Dandy MuslimAinda não há avaliações

- Business Law Case Study On EthicsDocumento9 páginasBusiness Law Case Study On EthicsTip TaptwoAinda não há avaliações

- Haqeeqat o MarfatDocumento10 páginasHaqeeqat o Marfatحسیب احمد محبوبی100% (1)

- Universitas Lambung Mangkurat (New)Documento7 páginasUniversitas Lambung Mangkurat (New)Mastur GuruAinda não há avaliações

- Ancient Activity of Gold Mining in The Eastern DesertDocumento52 páginasAncient Activity of Gold Mining in The Eastern DesertShady Shokri50% (2)

- Public Statement On Miyah PoetryDocumento8 páginasPublic Statement On Miyah PoetryThe Wire100% (1)