Escolar Documentos

Profissional Documentos

Cultura Documentos

2 - Cause Way Design

Enviado por

Sandeep VaishnavTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

2 - Cause Way Design

Enviado por

Sandeep VaishnavDireitos autorais:

Formatos disponíveis

Learning Element: LE-4 Causeways

CAUSEWAYS

Remember that:

- the culverts should be distributed evenly throughout the length of the structure;

- an apron of reinforced concrete or hand-packed stones is essential to break the energy of the over-flowing water;

- causeways should have a one-way camber of 3 per cent towards the down-stream edge and their up-stream edge should be rounded;

- road-side markers should be streamlined to limit their resistance to the over-flowing water;

- drifts and causeways should not be located near or in a river bend but in a stable portion of the river bed so that a good foundation can be constructed;

- the culvert bed should be a 15 cm gravel layer, preferably topped by a 7.5 cm concrete floor;

- the minimum width of the apron should be two times the height of the causeway from the river bed. This width should never be less than two metres;

- the depth of the foundation trench at the down-stream side of the causeway should be at least the height of the expected overflow of water over the structure.

Construction

- See FIELD INSTRUCTIONS - DRIFTS.

- Place reference pegs, survey pegs and multi-purpose pegs. Excavate the foundation trenches.

- Prepare the bed for the culverts. A layer of gravel (minimum 15 cm) preferably topped with a layer of 7.5 cm of concrete.

- Lay the culverts on the correct positions and at the correct gradient (3.5 per cent).

- Construct the headwalls up to road level.

- Backfill the area between the head walls with a suitable material and compact this material thoroughly.

- Pour a layer of concrete (10 cm) to provide a smooth surface for the traffic. The transitions between the horizontal stretch and the approaches should be gentle.

- Excavate the trench for the apron and place the stones (the largest at river bed level near the down-stream edge of the causeway).

After you have learned this element you should be able to:

- explain what a causeway is;

- describe which specific design points are particular to a causeway;

- comment on how to locate a causeway;

- describe how a typical small causeway is constructed.

In engineering textbooks a water crossing having a number of culverts to receive regular waterflows and which is submersed during floods is described with a great number

of names; culverts drift, causeway, submersible bridge or vented drift. In this learning element the structure is described as a causeway.

A causeway can be defined as a structure which has a double function:

(a) it allows the normal dry weather flow of a river/stream to pass through the culverts below the roadway; and

(b) the occasional floods pass both through the culverts and over the roadway.

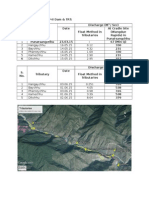

Fig 13A

Fig 13B

Because they have this dual function causeways present hydraulic problems which are peculiar to this type of structure and great care should be taken with their

construction. Many causeways have failed because of a wrong location or a wrong design.

Design

If the culverts are concentrated in the centre of the causeway, the high speed water jets coming out of these culverts will cause heavy scour at the sides of the culverts

(figure 13A).

This implies that in designing causeways the culverts should be distributed evenly throughout the length of the structure (figure 13B).

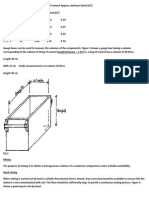

When the water flows over the causeway it moves as shown in figure 14. The forward roller shown on the right moves the sand forward. The back roller makes the sand

surface on the left side steeper and steeper until it collapses. This effect causes the foundation to be exposed very quickly unless effective protective measures are taken.

Fig 14

A suitable apron of concrete or well-graded stones is therefore absolutely necessary to break the energy of the falling water.

Fig 15

To improve the hydraulic properties of the causeway it is recommended to have a one-way camber towards the downstream end of the causeway. The rounding of the

upstream edge further contributes to a smooth discharge of the overflowing water.

Fig 16

As regards the culvert capacity, when suitable divergences (flared end sections) are provided at the end of the pipes this can be increased by as much as 50 per cent. Such

sections are manufactured in steel or concrete and should be considered when more major causeways are constructed.

Fig 17

Plan

Elevation

When roadside markers are provided to show the edges of the causeway and to indicate the stream level, care should be taken that these offer as little resistance as

possible to the flow. This means that such markers should be streamlined to the greatest possible extent.

Location

The location of a causeway is - as with all structures - extremely important. Efforts should be made to locate the most stable portion of the river bed, so that a better

foundation can be provided to the structure.

Also, avoid locating a drift, bridge or causeway near or in a river/stream bend. During floods the water will tend to cling to the concave bend of the river and cause

continuous erosion at that side. At the convex bank silting will take place.

When a lot of debris (tree trunks or branches, etc.) floats in the river there will be a danger that the culverts get blocked. If this happens, usually a transverse flow will occur

along the upstream side of the culverts creating a deep trench which can undermine the structure. To avoid this, debris diverting or collecting structures, such as debris

deflectors or racks, may be necessary.

Construction

Two trenches are dug at the up and downstream edges of the causeway. The trench at the downstream side should be at least 1.50 metres deep if an overflow of 50 cm

over the roadway is expected (see figure 16).

Between these trenches a suitable bed for the culverts is prepared of a well-graded gravel material. The provision of a 7.5 cm concrete floor is recommended. This floor

should be indented to accommodate the shape of the culvert, so that the culvert is evenly supported. After the culverts are laid the head walls are constructed up to the

road level and the area between the head walls is backfilled with a well-graded stony/gravelly material. Lean concrete may be used also as a backfilling material, although

the costs of the structure will be considerably higher in this case.

Fig 18

A 1:3:6 concrete surface layer of 10 cm thickness is laid at a 3 per cent cross-fall, the highest point being at the upstream side. If possible, the upstream side edge is

rounded. The connections between the approaches and the horizontal stretch are rounded to provide a smooth riding surface. Finally, the aprons are constructed, as

shown in figure 18. For this type of small causeway the minimum width of the apron at the downstream side should be two times the height of the causeway from the river

bed.

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Manning Equation For Discharge & Rating Puna-1Documento30 páginasManning Equation For Discharge & Rating Puna-1Sandeep VaishnavAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Height of Colimation MethodDocumento4 páginasHeight of Colimation MethodSandeep VaishnavAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- WTP Design 3.12 MLDDocumento21 páginasWTP Design 3.12 MLDSandeep VaishnavAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Discharge KamechhuDocumento1 páginaDischarge KamechhuSandeep VaishnavAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Discharges of Punatsangchhu River Near Taksha Parameters Computed DischargesDocumento2 páginasDischarges of Punatsangchhu River Near Taksha Parameters Computed DischargesSandeep VaishnavAinda não há avaliações

- Final EmoDocumento21 páginasFinal EmoSandeep VaishnavAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Routine Maintenance Activities For RoadDocumento1 páginaRoutine Maintenance Activities For RoadSandeep VaishnavAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Function and Composition of A Surface LayerDocumento2 páginasFunction and Composition of A Surface LayerSandeep VaishnavAinda não há avaliações

- Nature, Definition and of Soil Mechanics PDFDocumento1 páginaNature, Definition and of Soil Mechanics PDFSandeep VaishnavAinda não há avaliações

- LE-5 Placing, Compacting and Curing of Concrete - 2Documento1 páginaLE-5 Placing, Compacting and Curing of Concrete - 2Sandeep VaishnavAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- LE-4 The Manufacture of Concrete (Part1)Documento2 páginasLE-4 The Manufacture of Concrete (Part1)Sandeep VaishnavAinda não há avaliações

- AggregateDocumento1 páginaAggregateSandeep VaishnavAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- LE-4 The Manufacture of Concrete (Part2)Documento4 páginasLE-4 The Manufacture of Concrete (Part2)Sandeep VaishnavAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- LE-5 Placing, Compacting and Curing of Concrete - 1Documento1 páginaLE-5 Placing, Compacting and Curing of Concrete - 1Sandeep VaishnavAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Improvement of Soils by Mechanical MeansDocumento3 páginasImprovement of Soils by Mechanical MeansSandeep VaishnavAinda não há avaliações

- Gravel, Sand and Fine Particles in A Soil SampleDocumento3 páginasGravel, Sand and Fine Particles in A Soil SampleSandeep VaishnavAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Simple Field Tests To Determine Soil PropertiesDocumento2 páginasSimple Field Tests To Determine Soil PropertiesSandeep VaishnavAinda não há avaliações

- Catchwater Drains and Scour ChecksDocumento3 páginasCatchwater Drains and Scour ChecksSandeep Vaishnav50% (2)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Types of DrainageDocumento2 páginasTypes of DrainageSandeep VaishnavAinda não há avaliações

- Types of DrainageDocumento2 páginasTypes of DrainageSandeep VaishnavAinda não há avaliações

- Catchwater Drains and Scour ChecksDocumento3 páginasCatchwater Drains and Scour ChecksSandeep Vaishnav50% (2)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Catchwater Drains and Scour ChecksDocumento3 páginasCatchwater Drains and Scour ChecksSandeep Vaishnav50% (2)

- Side Drains and Mitre DrainsDocumento3 páginasSide Drains and Mitre DrainsSandeep VaishnavAinda não há avaliações

- Catchwater Drains and Scour ChecksDocumento3 páginasCatchwater Drains and Scour ChecksSandeep Vaishnav50% (2)

- 3 Culvert DesignDocumento5 páginas3 Culvert DesignSandeep VaishnavAinda não há avaliações

- Field Instruction For DrainageDocumento4 páginasField Instruction For DrainageSandeep VaishnavAinda não há avaliações

- Water Table DrainageDocumento2 páginasWater Table DrainageSandeep VaishnavAinda não há avaliações

- LE 5 CulvertsDocumento3 páginasLE 5 CulvertsSandeep VaishnavAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- 4 Bridge DesignDocumento7 páginas4 Bridge DesignSandeep VaishnavAinda não há avaliações

- Transient Stability of A Multi Machine Power System: Devender Kumar, Balwinder Singh SurjanDocumento4 páginasTransient Stability of A Multi Machine Power System: Devender Kumar, Balwinder Singh SurjanVerruumm AmineAinda não há avaliações

- Buk Uuuuuu UuuuuuuDocumento92 páginasBuk Uuuuuu UuuuuuuJanaliyaAinda não há avaliações

- Gas Permeability, Diffusivity and Solubility of Nitrogen, Helium, Methane, CO2, CH2O in Dense Polymeric Membranes Using A New On-Line Permeation ApparatusDocumento12 páginasGas Permeability, Diffusivity and Solubility of Nitrogen, Helium, Methane, CO2, CH2O in Dense Polymeric Membranes Using A New On-Line Permeation ApparatusCinthiaCevallosAinda não há avaliações

- Catalog Prince Hydraulic Cylinders Valves Pump Motors Accessories PDFDocumento123 páginasCatalog Prince Hydraulic Cylinders Valves Pump Motors Accessories PDFBruno CecattoAinda não há avaliações

- Full Site PDFDocumento23 páginasFull Site PDFpursuwAinda não há avaliações

- A Study On Risk Assessment in The Construction of High-Rise BuildingsDocumento5 páginasA Study On Risk Assessment in The Construction of High-Rise BuildingsMohamedSaidAinda não há avaliações

- MHFU Hunter RankDocumento5 páginasMHFU Hunter RankGustin PrayogoAinda não há avaliações

- Manuel Alava 01-12-10 PLDocumento3 páginasManuel Alava 01-12-10 PLAshley RodriguezAinda não há avaliações

- Parasites in Reptile PDFDocumento21 páginasParasites in Reptile PDFRamadhani SyafitriAinda não há avaliações

- Easy Guide For Fujitsu T901 LaptopDocumento141 páginasEasy Guide For Fujitsu T901 LaptopElaineAinda não há avaliações

- Art Lab For Little Kids - Susan Schwake PDFDocumento146 páginasArt Lab For Little Kids - Susan Schwake PDFEmma Alfonzo67% (3)

- Ags 30Documento1 páginaAgs 30Anonymous jIzz7woS60% (1)

- TMJDocumento38 páginasTMJAnonymous 6kAmeZzIAinda não há avaliações

- HLN Applications enDocumento27 páginasHLN Applications enClint TcAinda não há avaliações

- Adsorption Processes For Water Treatment and Purification PDFDocumento266 páginasAdsorption Processes For Water Treatment and Purification PDFVictor Rezende Moreira100% (1)

- Barge 180Ft Deck Load Capacity & Strength-Rev1Documento52 páginasBarge 180Ft Deck Load Capacity & Strength-Rev1Wahyu Codyr86% (7)

- Yu-Gi-Oh GX Duel Academy - Written ExamDocumento26 páginasYu-Gi-Oh GX Duel Academy - Written ExamisishamalielAinda não há avaliações

- Super GisDocumento535 páginasSuper GisNegrescu MariusAinda não há avaliações

- Optimizing With eGaN FETsDocumento6 páginasOptimizing With eGaN FETskhsniperAinda não há avaliações

- Factory Program Library List v1.0Documento9 páginasFactory Program Library List v1.0Ronaldo DamattaAinda não há avaliações

- IJHIM 6 - Nur Husnina (36 SD 42)Documento7 páginasIJHIM 6 - Nur Husnina (36 SD 42)RSU Sayang BundaAinda não há avaliações

- Better Place - Heaven or HellDocumento3 páginasBetter Place - Heaven or HellToto SammyAinda não há avaliações

- Higher Unit 11 Topic Test: NameDocumento17 páginasHigher Unit 11 Topic Test: NamesadiyaAinda não há avaliações

- Journal of Environmental Management: Ajay Singh TDocumento7 páginasJournal of Environmental Management: Ajay Singh TNestor Garay CahuanaAinda não há avaliações

- CHEM333 Syllabus 2020 2021Documento4 páginasCHEM333 Syllabus 2020 2021lina kwikAinda não há avaliações

- Manual CaladoraDocumento32 páginasManual CaladoraMiguel Angel Vega TrejoAinda não há avaliações

- The Past Is A Foreign Country-1.2Documento25 páginasThe Past Is A Foreign Country-1.2Xinyu DongAinda não há avaliações

- Acute and Chronic Gastrointestinal BleedingDocumento7 páginasAcute and Chronic Gastrointestinal BleedingMarwan M.100% (1)

- Brochure Smart Grid Foundation CourseDocumento6 páginasBrochure Smart Grid Foundation CourseKULDEEP MEENAAinda não há avaliações

- Measuring Salinity in Crude Oils Evaluation of MetDocumento9 páginasMeasuring Salinity in Crude Oils Evaluation of Metarmando fuentesAinda não há avaliações

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincNo EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincNota: 3.5 de 5 estrelas3.5/5 (137)

- Water to the Angels: William Mulholland, His Monumental Aqueduct, and the Rise of Los AngelesNo EverandWater to the Angels: William Mulholland, His Monumental Aqueduct, and the Rise of Los AngelesNota: 4 de 5 estrelas4/5 (21)

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseNo EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseNota: 3.5 de 5 estrelas3.5/5 (69)