Escolar Documentos

Profissional Documentos

Cultura Documentos

Modification Thickness of A Flange

Enviado por

Peter PerezTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Modification Thickness of A Flange

Enviado por

Peter PerezDireitos autorais:

Formatos disponíveis

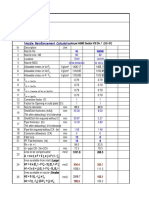

Flange Calculation sheet

Doc No Sheet

1/3

Bolted flange connections to ASME VIII, div. 2 Appendix 2

Design Basis

Design Code:

ASME Boiler & Pressure Vessel Code - section VIII, Division 1, Appendix 2

Units of calculation

Input Data

Variable Notes

Flange and Flange facing

Pipe Data Nominal Pipe Size

Pipe Schedule

Flange Pressure Rating

Pipe OD (actual)

Pipe wall thickness (Uncorroded)

Length Through Hub

Flange thickness

Bolt circle diameter

Hub Diameter (Largest)

Flange outside diameter

Bolts Bolt Standard

Bolt Size (Specify M-Type , ISO)=

Number of Bolts=

Bolt stress area (per bolt)

Gasket Gasket Type

Gasket diameter , MEAN(RTJ)/OD(RF):

Gasket contact width w(RTJ) or N(RF)

Min. design seating stress

Gasket factor

Design Design Pressure

Conditions Design Temperature

Corrosion Allowance

External Axial Force (strain)

Loads Moment

Moment

Moment

Orientation of flange

Stresses Material

At design temperature

At ambient

Material

At design temperature

At ambient

E Modulus

Conclusion

Flange design is acceptable for listed design pressure 52.6

Bolting design is acceptable for design pressure

Max. operating pressure before failure of flange or bolting is 477.4 psi

Bolting design is acceptable for gasket seating condition

% close of Max.

Oper. Pressure

36" Flange

Max. value

could be

modified

(-15.9 mm

from original

88.9mm )

0.0 N/mm

ASME B31.3

ASME B31.3

Sa

Sb

Flange

Flange

Sf_oper

Sf_atm

P

ca

Faxial

w or N

y

m

Bolting

M

x

M

y

M

z

x,y,z

d

bolt

n

bolt

A

bolt

t

max

PCD

X

A

OD

pipe

tn

h

t

NPD

Source of data Input

ASME B31.3

ASME VIII, table 2-4- Pag 380

ASME VIII, table 2-5.1-Pag 381

ASME VIII, table 2-5.1-Pag 381

ASME B16.5

ASME B31.3

ASME B1.1

ASME B36.10 (Table 1)

ASME B36.10 (Table 1)

ASME B16.5 Modified

ASME B16.5

ASME B16.5

ASME B16.5

137.9 N/mm

y

485.0 N/mm

485.0 N/mm

137.9 N/mm

A320 L7 d-<2.5"

ASME B16.5

ASME B16.5

ASME B16.5

1,083.9 mm

977.9 mm

32.0 mm

69.0 N/mm

2.5

ASME 16.20 Table 10

Bolt Data

73.0 mm

RF ASME B16.5

ASME B36.10

ASME B36.10

A350 LF2 Cl.1

STD

150 #

0.0 Nmm

0.0 Nmm

65.6 C

1.5 mm

1.72 N/mm

0.0 Nmm

1,085.8 mm

Metric

SPWnd - 304 FG

914.0 mm

9.5 mm

156.0 mm

Flange design is OK

0.0 N

36.0 ''

3.3 N/mm

914.4 mm

1,170.0 mm

Imperial

1 5/8 in

32

FLANGE THICKNESS 36' MODIFICATION

Page 1 of 3

Flange Calculation sheet

Doc No Sheet

2/3

Bolted flange connections to ASME VIII, div. 2 Appendix 2

Calculations

Gasket key dimensions

Gasket outside diameter 977.9 mm

Basic gasket seating width b

0

= N/2 or w / 8 (RF or RTJ) Table 2-5-2 16.0 mm

Effective gasket seating width b=b

0

for b

0

< 1/4"

or b = 0.5(or 2.52 for metric) * (b

0

)

0.5

for b

0

> 1/4" Table 2-5-2 10.1 mm

Gasket load reaction diameter G = mean gasket diameter for b

0

< 1/4"

or G = Gasket OD - 2*b for b

0

> 1/4" 957.7 mm

Flange values

Thickness of hub at small end g

0

= t

n

- ca = 8.0 mm

Thickness of hub at back of flange g

1

= (X-B)/2 = 8.2 mm

Radial dist. from PCD to large hub diam. R = (PCD-X)/2 = 85.7 mm

Inside diameter of flange B (Corroded ID) = OD

pipe

- 2 * g

0

= 898.0 mm

Equivalent Working Pressure using Kellogs Method

Resulting Bending Moment Mres = SQRT(Mx^2+Mz^2) 0 Nmm

Equivalent Pressure Peq = 16 * M

res

/ ( * G

3

) + 4 * Faxial / ( * G

2

) 0.00 N/mm

Calculation Design Pressure P

d

= P + P

eq

1.72 N/mm

Load and Bolt Calculations

Total joint-contact surface compression load Hp = 2 * b * * G * m * P

d

= 261,436 N

Total hydrostatic end force H = / 4 * G

2

* P

d

= 1,242,002 N

Min. required bolting load for operating conditions Wm1 = Hp+H = 1,503,438 N

Min. required bolting load for gasket seating Wm2 = * b * G * y = 2,091,184 N

Total required cross-sectional area of bolts Am = greater of Wm1/Sb or Wm2/Sa = 15,164 mm

Total available cross-sectional area of bolts A

bolts

= 34,684 mm

Flange design bolt load W = 0.5 * ( Am+ A

bolts

) * Sa = 3,437,040 N

Required bolt rootdiameter= = ( 4 * A

m

/ ( n

bolt

* ) )

0.5

24.6 mm

Flange Moment Calculations

Flange Loads Lever arm Flange Moments

Operating Conditions

H

D

= / 4 * B

2

* P

d

= 1,091,844 N hD = R + 0.5 * g1 = 89.8 mm M

D

= H

D

* hD = 98,053,023 Nmm

H

G

= H

p

= 261,436 N hG = 0.5 * ( PCD - G) = 64.0 mm M

G

= H

G

* hG = 16,739,743 Nmm

H

T

= H - H

D

= 150,159 N hT = 0.5 * ( R+g1+h

G

) = 79.0 mm M

T

= H

T

* hT = 11,858,024 Nmm

M

0 oper

= M

D

+ M

G

+ M

T

= 126,650,790 Nmm

Seating Conditions

H

G

= W = 3,437,040 N h

G

= 64.0 mm M

0 atm

= 220,073,687 Nmm

Bolt Spacing= = PCD * SIN( / n

bolt

) 106.4 mm

Bolt pitch correction factor CF = [bolt_spacing / (2 * d

bolt

+ 6 * t / ( m + 0.5))]

0.5

(or minimum 1.0) 1.00

Flange Factors from fig. 2-7.1 Flange factors involving H/H_0 or g1/g0 Stress formula factors

K =A / B 1.303 h

0

= (B * go)

0,5

84.8 mm = t * e +1 1.774

T 1.796 h / h

0

1.839 =

4

/

3

* e * t+1 2.032

U 8.225 g

1

/ g

0

1.025 = / T 0.988

Y 7.484 F 0.899 = t

3

/ d 4.497

Z 3.867 V 0.517 = + 5.480

f 1.000 m0 =CF * M

0 oper

/ B 141,040 N

e = F / ho 0.0106 mm- mG =CF*M

0 atm

/ B 245,076 N

Poisson's Ratio Assumed = 0.3 d = U / V * h

0

* g

0

2

86,511 mm

36" Flange

Page 2 of 3

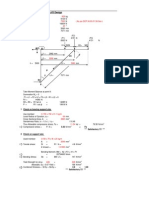

Flange Calculation sheet

Doc No

36" Flange

Sheet

3/3

Bolted flange connections to ASME VIII, div. 2 Appendix 2

Calculations

SUMMARY OF STRESSES:

Calculated Allowable Accept

Operating

Longitudinal Hub Stress: S

H

=f * m

0

/ ( * g

1

2

) = 382 N/mm 1.5 * S

f oper

= 728 N/mm OK

Radial Flange Stress: S

R

= * m

0

/ ( * t

2

) = 10 N/mm S

f oper

= 485 N/mm OK

Tangential Flange Stress: S

T

= m

0

* Y / ( t

2

) - Z * S

R

= 160 N/mm S

f oper

= 485 N/mm OK

Combined Stress: greater of (S

H

+S

R

) / 2 or (S

H

+S

T

) / 2 = 271 N/mm S

f oper

= 485 N/mm OK

Bolt Stress W

m1

/ A

bolts

43 N/mm S

b

138 N/mm OK

Seating

Longitudinal Hub Stress: S

H

= f * m

G

/ ( *g

1

2

) = 663 N/mm 1.5 * S

f atm

= 728 N/mm OK

Radial Flange Stress: S

R

= * m

G

/ ( * t

2

) = 17 N/mm S

f atm

= 485 N/mm OK

Tangential Flange Stress: S

T

= m

G

* Y / ( t

2

) - Z * S

R

= 278 N/mm S

f atm

= 485 N/mm OK

Combined Stress: greater of (S

H

+S

R

) / 2 or (S

H

+S

T

) / 2 = 471 N/mm S

f atm

= 485 N/mm OK

Bolt Stress W

m2

/ A

bolts

60 N/mm S

a

138 N/mm OK

REVERSE CALCULATION - max operating pressure

m

0

values due to allowable stresses:

Longitudinal Hub Stress: m

01

= * g

1

2

* 1.5 * S

f oper

/ f = 268,720 N

Radial Flange Stress: m

02

= * t

2

* S

f oper

/ = 6,971,100 N

Tangential Flange Stress: m

03

= * t

2

* S

f oper

/ ( * Y- * Z ) = 427,154 N

Combined Stress: largest of m

04

= 2 * S

f oper

/ ( f / ( * g

1

2

) + Y / t

2

+ / ( * t

2

) ) = 231,985 N

m

04

= 2 * S

f oper

/ ( f / ( * g

1

2

) + / ( * t

2

) ) = 349,316 N

Select min. m

01

to m

04

m

0

= 268,720 N

Max flange moment M

0

= = m

0

* B / C

F

= 241,305,119 Nmm

Max operating pressure P=

= 8 * M0 / [ * (B

2

* ( PCD - (X + B) / 2) + 8 * b * G * m * (PCD - G) + (G

2

- B2) * (PCD - (G + B)/ 2))] = 3.3 N/mm

Bolting P= = A

bolts

* S

b

/ ( * ( 2 * b * m * G + 0.25 * G

2

) ) = 5.5 N/mm

BLIND FLANGE THICKNESS CALCULATION: (3.5.5)

Minimum thickness of flange

(Operating - W=Wm1) e

oper

= ( 0.3 * G

2

* P / ( S

f oper

) + 1.909 * W

m1

* h

G

/ ( S

f oper

* G ) )

0.5

+ ca 38.6 mm

Minimum thickness of flange

(Seating - P=0) e

oper

= ( 0.3 * G

2

* P / ( S

f oper

) + 1.909 * W * h

G

/ ( S

f oper

* G ) )

0.5

+ ca 31.6 mm

Max pressure for actual thickness

Operating p

max

= (e - ca )

2

* S

f oper

/ ( 0.3 * G

2

+ 1.909 * * h

G

* (2 * b * m + 0.25 * G )) 6.4 N/mm

Flange Rigidity Check (According to Appendix S)

Rigidity index J = 52.14 * M

0 oper

* V / ( * Emod * G

0

2

* h

0

* 0.3) = #DIV/0! #DIV/0!

{

Page 3 of 3

Você também pode gostar

- U-V-673 - Manual Flange and GussetDocumento8 páginasU-V-673 - Manual Flange and GussetDarshan PanchalAinda não há avaliações

- Base Ring Fillet Size CalculationDocumento4 páginasBase Ring Fillet Size Calculationmiteshpatel191Ainda não há avaliações

- Analysis of Pipe NetworksDocumento14 páginasAnalysis of Pipe NetworksAhmad Sana100% (2)

- Nozzle Reinforcement Calculation Excel SheetDocumento3 páginasNozzle Reinforcement Calculation Excel Sheetramesh punjabiAinda não há avaliações

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocumento14 páginasStorage Tank Design Calculation - Api 650: Close Floating Roofhgagselim2012Ainda não há avaliações

- Design of Flanges - Weld Neck Type 2010Documento58 páginasDesign of Flanges - Weld Neck Type 2010bakellyAinda não há avaliações

- The Interaction of Mercury and Aluminium in Heat Exchangers in A Natural Gas PDFDocumento7 páginasThe Interaction of Mercury and Aluminium in Heat Exchangers in A Natural Gas PDFToth IstvanAinda não há avaliações

- Mig Guide From Zero PDFDocumento10 páginasMig Guide From Zero PDFHugo SalazarAinda não há avaliações

- Blind Flange (10 Bar)Documento7 páginasBlind Flange (10 Bar)SyedZainAliAinda não há avaliações

- 1) Design Data: Ref: Procedure No. 3-4 Pg. No. 169, Pressure Vessel Design Manual by Dennis Moss, 4rd EditionDocumento6 páginas1) Design Data: Ref: Procedure No. 3-4 Pg. No. 169, Pressure Vessel Design Manual by Dennis Moss, 4rd Editionsouren1975Ainda não há avaliações

- Compress EvaluateDocumento23 páginasCompress EvaluateVishalDhiman100% (1)

- Stress Sample Calculation On Base EllDocumento1 páginaStress Sample Calculation On Base EllLionel TorradoAinda não há avaliações

- Flange Asme ViiiDocumento21 páginasFlange Asme Viiizahidwahla1Ainda não há avaliações

- New - Reinforcement of NozzleDocumento31 páginasNew - Reinforcement of NozzleNithin ZsAinda não há avaliações

- New - Reinforcement of NozzleDocumento24 páginasNew - Reinforcement of NozzleVaniya GoelAinda não há avaliações

- Tema ChecklistDocumento2 páginasTema ChecklistAdrian Stoicescu100% (1)

- Bolt Torque Calculation For Girth Flange (Ref.: Dennis Moss Procedure 2-10)Documento2 páginasBolt Torque Calculation For Girth Flange (Ref.: Dennis Moss Procedure 2-10)Manoj MulikAinda não há avaliações

- Nozzle and Flange Check Calculation at OWT For CN-3-02 (Heavy Duty Pump)Documento17 páginasNozzle and Flange Check Calculation at OWT For CN-3-02 (Heavy Duty Pump)SingoAinda não há avaliações

- Saddle v1-5: Fixed Saddle Sliding SaddleDocumento9 páginasSaddle v1-5: Fixed Saddle Sliding Saddleduf fuAinda não há avaliações

- Body Flange .PVDB FlangeDocumento1 páginaBody Flange .PVDB FlangeAnonymous aBg51lbe18Ainda não há avaliações

- Dennis R Moss 4th EditionDocumento5 páginasDennis R Moss 4th Editionsenthil kumarAinda não há avaliações

- Manual de Generadores de Gas SolarDocumento49 páginasManual de Generadores de Gas SolarJuvenal Segundo Chavez Acosta100% (7)

- Design of Flanges - Loose Hub Type 2010Documento58 páginasDesign of Flanges - Loose Hub Type 2010bakellyAinda não há avaliações

- Ref: Procedure No. 2-10 Pg. No. 59, Pressure Vessel Design Manual by Dennis Moss, 3rd EditionDocumento4 páginasRef: Procedure No. 2-10 Pg. No. 59, Pressure Vessel Design Manual by Dennis Moss, 3rd Editionsouren1975Ainda não há avaliações

- Variable Speed Pumping A Guide To Successful Applications PDFDocumento22 páginasVariable Speed Pumping A Guide To Successful Applications PDFGilberto Sanchez100% (1)

- Blind Flange DesignDocumento1 páginaBlind Flange DesignSachin5586Ainda não há avaliações

- Nozzle Reinforcement Calculations: HH1&HH2 (Hand Hole) : Description Regulation Formula Symbol Value UnitDocumento1 páginaNozzle Reinforcement Calculations: HH1&HH2 (Hand Hole) : Description Regulation Formula Symbol Value Unitmiteshpatel191Ainda não há avaliações

- Pipe Is Under Clamping ForceDocumento7 páginasPipe Is Under Clamping Forcejosediaz141Ainda não há avaliações

- Pipes. Maximum Span Between Pipe Supports For A Given Maximum Bending StressDocumento75 páginasPipes. Maximum Span Between Pipe Supports For A Given Maximum Bending StressMarius GhitaAinda não há avaliações

- 5 Asme Viii A-24 Clamp ConnectionDocumento6 páginas5 Asme Viii A-24 Clamp ConnectionpastylAinda não há avaliações

- Check 18Documento6 páginasCheck 18Anonymous qBwHKusAinda não há avaliações

- Cálculo Flange ASME VIII 1 Apendice 2Documento5 páginasCálculo Flange ASME VIII 1 Apendice 2Anonymous gfR3btyUAinda não há avaliações

- Saddle Calc PD5500Documento6 páginasSaddle Calc PD5500Vamsi SAinda não há avaliações

- Weld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersDocumento25 páginasWeld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersLipika GayenAinda não há avaliações

- Standard Shoe Verification Rev - ADocumento19 páginasStandard Shoe Verification Rev - AballisnothingAinda não há avaliações

- Flange Calculation As Per JIS B 8243 Appendix 2: Internal Pressure, Integral Flange R (C-B) /2-gDocumento10 páginasFlange Calculation As Per JIS B 8243 Appendix 2: Internal Pressure, Integral Flange R (C-B) /2-gAsep MulyadiAinda não há avaliações

- Pressure Design Straight Pipe (Run Pipe)Documento6 páginasPressure Design Straight Pipe (Run Pipe)gembirasekaliAinda não há avaliações

- ASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelDocumento16 páginasASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelPanya Purahong100% (1)

- 5.7 Asmeviii A-2 & Tema Split Backing RingDocumento1 página5.7 Asmeviii A-2 & Tema Split Backing RingpastylAinda não há avaliações

- Sample FLG CalcDocumento6 páginasSample FLG CalcameyyammaiAinda não há avaliações

- Saddle SupportDocumento12 páginasSaddle SupportrustamriyadiAinda não há avaliações

- Aspen HX Design ReportDocumento78 páginasAspen HX Design ReportberylqzAinda não há avaliações

- Centrifugal Pump DesignDocumento11 páginasCentrifugal Pump DesignPeter PerezAinda não há avaliações

- Centrifugal Pumps Training CourseDocumento125 páginasCentrifugal Pumps Training CourseHECTOR IBARRA100% (3)

- Design of Flanges - Optional Type 2010Documento59 páginasDesign of Flanges - Optional Type 2010bakellyAinda não há avaliações

- Technical DataDocumento48 páginasTechnical Datashekhar2681Ainda não há avaliações

- Reinf S1Documento2 páginasReinf S1tasingenieriaAinda não há avaliações

- FlangeCalculationASMEVIII Version5Documento3 páginasFlangeCalculationASMEVIII Version5alvinchuan100% (1)

- Piping Engineering - Tank Nozzle Loads 1Documento1 páginaPiping Engineering - Tank Nozzle Loads 1Nasrul AdliAinda não há avaliações

- Calculo de Brida Segun ASMEDocumento29 páginasCalculo de Brida Segun ASMEakarcz6731Ainda não há avaliações

- Platform - Bracing SupportDocumento12 páginasPlatform - Bracing Supportpandiangv100% (1)

- C17058 XXXXXXXX FPSO Carioca MV30: Lthe Offshore Engineering Nozzle Evaluation SheetDocumento3 páginasC17058 XXXXXXXX FPSO Carioca MV30: Lthe Offshore Engineering Nozzle Evaluation SheetJ A S JASAinda não há avaliações

- Trunnion Calculation SheetDocumento3 páginasTrunnion Calculation Sheetsudhisnair67% (3)

- ThickAndThin JointsDocumento31 páginasThickAndThin JointsHùng Mạnh NguyễnAinda não há avaliações

- Agitator Nozzle Load Data SheetDocumento1 páginaAgitator Nozzle Load Data SheetAnonymous MB5YbaLrBEAinda não há avaliações

- Checking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumberDocumento1 páginaChecking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumbershazanAinda não há avaliações

- Wind Calculation SheetDocumento32 páginasWind Calculation SheetaauppalAinda não há avaliações

- Muk 61 2 PLL 0007 9H8Documento34 páginasMuk 61 2 PLL 0007 9H8Suresh MahalingamAinda não há avaliações

- FEMA 451B Topic15-5a - Advanced Analysis Part1 Notes PDFDocumento85 páginasFEMA 451B Topic15-5a - Advanced Analysis Part1 Notes PDFNivan RollsAinda não há avaliações

- Structural TrunnionDocumento4 páginasStructural TrunnionecsalomAinda não há avaliações

- BlindDocumento3 páginasBlindSajal KulshresthaAinda não há avaliações

- Flange KOD Vessel Calculation - Actual ConditionDocumento21 páginasFlange KOD Vessel Calculation - Actual ConditionPeter PerezAinda não há avaliações

- Flange KOD Vessel Calculation - Actual ConditionDocumento21 páginasFlange KOD Vessel Calculation - Actual ConditionPeter PerezAinda não há avaliações

- Aspen HYSYS Simulation of CO2 Removal by Amine Absorption From A Gas Based Power PlantDocumento9 páginasAspen HYSYS Simulation of CO2 Removal by Amine Absorption From A Gas Based Power PlantLina1929Ainda não há avaliações

- Fine Tune Relief Calculations For Supercritical FluidsDocumento10 páginasFine Tune Relief Calculations For Supercritical FluidsPeter PerezAinda não há avaliações

- Tailing LugDocumento2 páginasTailing Lugjagannadha varmaAinda não há avaliações

- N-318-5 Lug Local StressDocumento3 páginasN-318-5 Lug Local StresscohenfuAinda não há avaliações

- Max Allowable Nozzle LoadDocumento1 páginaMax Allowable Nozzle Loaddskr fkshAinda não há avaliações

- PSV Reaction Force CalculationDocumento2 páginasPSV Reaction Force CalculationSuthanAinda não há avaliações

- PSV Reaction Force - Closed SystemDocumento5 páginasPSV Reaction Force - Closed SystemWayne MonneryAinda não há avaliações

- Nozzle TempDocumento2 páginasNozzle TempRakeshAinda não há avaliações

- 5 Asmeviii A-24 Clamp ConnectionDocumento6 páginas5 Asmeviii A-24 Clamp ConnectionpastylAinda não há avaliações

- Glacier and Periglacial LandformsDocumento4 páginasGlacier and Periglacial LandformsPeter PerezAinda não há avaliações

- Sivalls Crude Oil Treating Systems Design ManualDocumento51 páginasSivalls Crude Oil Treating Systems Design ManualElias Torca100% (1)

- Liquid Expanders PhillipsDocumento7 páginasLiquid Expanders PhillipsPeter PerezAinda não há avaliações

- General Purpose Gear DrivesDocumento11 páginasGeneral Purpose Gear DrivesPeter PerezAinda não há avaliações

- Flashing Liquid Expanders For Crygenic IndustriesDocumento18 páginasFlashing Liquid Expanders For Crygenic IndustriesPeter PerezAinda não há avaliações

- Minimum Practical Wall Thickness of VesselsDocumento2 páginasMinimum Practical Wall Thickness of VesselsPeter PerezAinda não há avaliações

- Thermal ExpansionDocumento8 páginasThermal ExpansionPeter PerezAinda não há avaliações

- Compressor ProgrammeDocumento52 páginasCompressor ProgrammePeter PerezAinda não há avaliações

- مضخة الطرد المركزى- كتيب للتحميلDocumento128 páginasمضخة الطرد المركزى- كتيب للتحميلGrundfosEgypt100% (4)

- Water Hammer AnalysisDocumento85 páginasWater Hammer AnalysisPeter PerezAinda não há avaliações

- Is 456 2000 Most Expected Questions (Avnish Sir) 30-03-22Documento35 páginasIs 456 2000 Most Expected Questions (Avnish Sir) 30-03-22Satypal NishadAinda não há avaliações

- PH6151 QuestionsDocumento2 páginasPH6151 Questionsvenkateswaran k.sAinda não há avaliações

- Study of Steel Hardness Effect On The Abrasive Wear ResistanceDocumento7 páginasStudy of Steel Hardness Effect On The Abrasive Wear ResistanceArslan Zulfiqar AhmedAinda não há avaliações

- Main Thesis Report1613025 PDFDocumento102 páginasMain Thesis Report1613025 PDF17-004 ASHISH SARKERAinda não há avaliações

- Head Loss Calculator by Fadi YasinDocumento8 páginasHead Loss Calculator by Fadi YasinYasser ShehataAinda não há avaliações

- Heat ExchangerDocumento11 páginasHeat ExchangerLouise DimaunahanAinda não há avaliações

- DNA Origami Presentation 52215Documento22 páginasDNA Origami Presentation 52215jabalrhmhAinda não há avaliações

- Chapter 3 - Global Analysis EquationsDocumento54 páginasChapter 3 - Global Analysis EquationsCarl Chester RagudoAinda não há avaliações

- Chem Lec. Module 5Documento8 páginasChem Lec. Module 5Aivan NovillaAinda não há avaliações

- Cond. Multiposicion Runway ROV-72HR1 (OnOff)Documento2 páginasCond. Multiposicion Runway ROV-72HR1 (OnOff)ctaarielAinda não há avaliações

- The Importance of Furniture Testing: (Mandy)Documento2 páginasThe Importance of Furniture Testing: (Mandy)Summer GanAinda não há avaliações

- III SEM Question BankDocumento110 páginasIII SEM Question BankGowtham SAinda não há avaliações

- M1Documento29 páginasM1MJ SabioAinda não há avaliações

- Williams Landel Ferry - JACS55 PDFDocumento7 páginasWilliams Landel Ferry - JACS55 PDFrishikeshmandawadAinda não há avaliações

- Lesson in ScienceDocumento27 páginasLesson in SciencereymartAinda não há avaliações

- Sec-Butyl Alcohol Sec-Butyl Acetate N, N-Dimethyl FormamideDocumento22 páginasSec-Butyl Alcohol Sec-Butyl Acetate N, N-Dimethyl FormamideCorona MarcUsAinda não há avaliações

- Low Pressure Drop HVAC Design For LaboratoriesDocumento9 páginasLow Pressure Drop HVAC Design For LaboratoriesankAinda não há avaliações

- 4.convection Heat TransferDocumento26 páginas4.convection Heat TransferMohammed Zahran Mohammed Hashil Al HinaiAinda não há avaliações

- TPFT IG1 Jan 2020 PDFDocumento6 páginasTPFT IG1 Jan 2020 PDFrehanAinda não há avaliações

- MAhoney TableDocumento7 páginasMAhoney TableSanty SanAinda não há avaliações

- CLS Aipmt 16 17 XII Che Study Package 5 SET 1 Chapter 2Documento8 páginasCLS Aipmt 16 17 XII Che Study Package 5 SET 1 Chapter 2Kareena Gupta100% (3)

- Moving Charge in A Magnetic FieldDocumento3 páginasMoving Charge in A Magnetic FieldEntertainmentAinda não há avaliações

- Emm Question Bank Unit3Documento3 páginasEmm Question Bank Unit3MANOJ MAinda não há avaliações

- Determination of Angle of Divergence of Laser Beam: Physics Open Ended Experiment ReportDocumento10 páginasDetermination of Angle of Divergence of Laser Beam: Physics Open Ended Experiment ReportDeepak ZillaAinda não há avaliações

- Electric Charge, Coulomb'S Law, Electric Fields, and Electric FluxDocumento7 páginasElectric Charge, Coulomb'S Law, Electric Fields, and Electric FluxCAROLAinda não há avaliações