Escolar Documentos

Profissional Documentos

Cultura Documentos

GSD-SM Instruction Book

Enviado por

Ken LeeDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

GSD-SM Instruction Book

Enviado por

Ken LeeDireitos autorais:

Formatos disponíveis

Operation and Maintenance Manual Of Gearless PM Elevator Traction Machine

GSD-SM

SHANGHAI YUNGTAY GIE EM CO., LTD

SHANGHAI YUNGTAY GIE EM CO., LTD

Preface

Thank you for using Mini-Machine room GSD-SM Series Compact PM gearless motors for

elevators, which is manufactured by SHANGHAI YUNGTAY GIE EM Co., Ltd. GSD-SM

Series Compact PM gearless motors for elevators is R & D and manufactured by SHANGHAI

YUNGTAY GIE EM Co., Ltd., with high efficiency, energy saving, stable and low noise

characteristics of the elevator traction machine.

The traction machine is mainly used in Mini-engine room elevator. Before each traction

machine leave factory ,the torque, braking force, vibration, noise and voltage insulation and

other performance indicators were carried out strict quality inspection, its performance indicators

are comply with the EN 81-1:1998 ,GB7588-2003 ,SHANGHAI YUNGTAY GIE EM

CO., LTDrelevant provisions.

When you receive this product, please make sure:

Whether the products accord with your order requirements;

Whether the product is damaged or fasteners are loose.

When you found the above-mentioned adverse or other abnormal situation, please contact

our Company's agents or sales department.

Manual attached icons is the schematic (such as plan or exploded view.) in order to explain

the characteristics and structure of the Product, but it does not mean the actual using state, the

specific color, appearance and construction confirm with real products.

When the product improvements and specification changes, this manual will has a

correspond change. When you use the manual is not agree with the actual product, damaged or

missing, please ask the company's agents or sales department to order.

Traction engine installation, maintenance work is carried out by professionals. Professionals

are specialized training, has extensive knowledge and familiarity with the Elevator Products

installation, commissioning and operation personnel.

Installation and operation personnel should strictly comply with theelevator manufacturing

and installation of the safety norms(GB7588-2003) concerning the escalator is in operation,

maintenance and inspection of safety rules and other related industry standards.

Any personal injury or product quality question caused by staff incorrect operation, our

company will not bear any responsibility

Before using this Traction machine, please be sure to read the manual carefully.

SHANGHAI YUNGTAY GIE EM CO., LTD

Address: Building 3,No.180 Yanghebang Road,High Tech Garden Area.

Jiuting Songjiang,Shanghai 201615

1

SHANGHAI YUNGTAY GIE EM CO., LTD

Product conform standards

elevator manufacturing and installation of the safety norms(EN 81-1:1998)

elevator manufacturing and installation of the safety norms(GB7588-2003)

SHANGHAI YUNGTAY GIE EM Co., Ltd Enterprise Standard

Working conditions and environment

The room environment temperature should be maintained at (5 ~40) .

Relative humidity of the environment on the average of the maximum not more than 90

percent, while the monthly mean minimum temperature is not higher than 25

Supply voltage fluctuations and rating deviation does not exceed 7%

Environment air does not contain corrosive and flammable gases

Matching tractor wire surface shall not besmear lubricant and other sundry.

Tractor performance should be consistent with the GB7588-2003 relevant provisions.

Transport and storage environment temperature should be between (-20 ~50)

Handling and storage

Please use clean, dry, with means of transport to transport Products. Products in transit shall

not be exposed to moisture; handling should prevent human and mechanical damage. Product

stacking, it must have the appropriate protective measures. Do not allow a long time on the

open-air exposure and rain. Unless there is reliable device to prevent falling or damaged

packaging, product does not allow the high-stacked pile.

Products (including packaging and annex) of the single goods weight about 400kg, loading

and unloading with forklift or crane transportation equipment for handling.

2

SHANGHAI YUNGTAY GIE EM CO., LTD

Notes

The products have assembled, adjusted and tested qualified before leave factory, user can

not disassembly and adjustment arbitrarily, if users find products are abnormal, please contact

with the product professional or contact with our company.

Product specifications show on nameplate.

Can't live operation

When connect the power cable, please accordance with the leaflet "seven, electrical

connection" requirements.

Power cables and wires cannot be too much bended, stretched and embedded.

Grounding terminal must be grounded.

When traction machine running, it must not be near and contacts the rotating components

(including the sheav, axes, etc.)

If appear power outage situation when running, please cut off power first then do other

operations.

After installation, maintenance and inspection, it needs to recover the correspond

components then running.

Handling, installation, running, operation, maintenance and inspection, must be carried by

professional staff.

Before release, maintenance and inspection the brake, we must first confirm elevator "car"

and "counterweight" does not exit the fall or upgrade hidden dangers.

When there is water, oil and other debris (such as bolts, gaskets, scrap iron, etc.) fall into

the main frame, do not install and run, it should be contact with the professionals to resolve.

Please do not use non-this product brake specification for replacement, otherwise there

may be exit an ineffective brake and release risk.

Put one part of the body (such as finger) or items in traction machine open position are

extremely dangerous behavior.

When this product is installed on other products, please try to avoid using the product rings

lift it overall, unless the customers can ensure reliability.

The machine room installed traction machine should be ventilated, and do not place

flammable objects or obstacles around.

The line connecting with traction machine should have effective insulation measures

Before cut off the traction machine power, it cant be carried out conventional traction

machine maintenance work, such as additional lubricants conventional operating.

Protective equipment is not this product accessory.

Please use dedicated power supply to the products wiring.

Please use the dedicated control cabinet to the products control and wiring.

Please according to electrical equipment technical specifications and industry standards for

construction, electrical equipment construction should be carried by professionals.

The traction machine running and after running surface temperature is very high, it should

be avoid contacting with body parts

When products need scrapped, please make sure it will be treated environmentally

according to industry waste disposal norms.

There has permanent magnets installed in the Product stator, it should be heated to above

500 demagnetizing before scrapped treatment.

3

SHANGHAI YUNGTAY GIE EM CO., LTD

From the date tractions machine leave factory, the length of warranty is 12 months, beyond

the length of warranty, our company will charge appropriately. If there have another warranty

agreement user sign with our company, warranty accordance with the warranty agreement term.

All components and accessories of the product are specially designed by our Company,

before our company approved, if customer use specifications parts replacement or transformation

the product, there no longer in the scope of our company's warranty, our company will not bear

any responsibility.

Product structure

Product schematic

3D schematic front schematic behind schematic

Product structure dimension schematic

4

SHANGHAI YUNGTAY GIE EM CO., LTD

Traction machine installation.

Traction machine is adjusted and tested before leaving factory, the parts shouldt be moved

when installed..

For some reasons (transport, handling, etc.), there may cause abnormal conditions such as

traction machine damaged or components loose. Traction machine should be inspected

comprehensibly before install, when found abnormal situation shall notify the professional to

solve.

Traction machine should be installed in ventilated, dry, dust less, no liquid leakage, easy to

check environment.

Traction machine should be installed in certain height location so that it will not be

flooded.

Traction machine installation and construction should be based on the drawing which

provided by elevator manufacturer.

Traction machine installed, its traction conditions should be consistent with national

standards.

When foreign matter falling into the traction machine, it should be cleared immediately

then install, if it cant be removed, please contact with the professionals to solve.

Traction machine should be installed levelly, tilt, vertical or invert installation is wrong.

After installation, the traction machines rotating parts (such as traction sheave) should

install protective shield that accordance with industry-standard to prevent the harm cause by

people unconscious near.

When the elevator has guide pulley, should check the guide pulley slot distance and

traction sheave slot distance is the same, and if not, it may increase rope and traction sheave

wear and tear.

When guide pulley with the traction sheave have large center distance deviation, it may be

one of the vibration reasons.

Traction machine base is not level or base of the anti-vibration device (such as shockproof

rubber pads) install or choose unreasonable, it may be one of the vibration reasons.

Placed traction machine steel beam strength should be consistent with industry standards,

the installation level is 1 / 1000.

After traction rope installation, check the anti-jump device settings whether is correct.

5

SHANGHAI YUNGTAY GIE EM CO., LTD

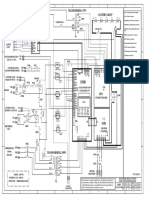

Electrical connections

Protective equipment (such as leakage protector) is not the product accessories but the

protective equipment which provided by elevator machine manufacturer.

Traction machine protection rating is IP 42.

Wiring accordance with industry standard of electrical equipment technology, constructed

by professional.

Please use dedicated power supply to the products wiring.

Please use the dedicated control cabinet to control and wiring of the products.

In the power on situation, touching the bare terminal is extremely dangerous behavior.

Please note: Wiring distance too long may cause the voltage or signal line drop.

Traction machine should have a good grounding, there is grounding device (grounding

terminal) on lower right of the base, use the M6 spanner operate.

Control cabinet supply the traction machine power, junction box has power lines terminal

blocks, Brake terminal blocks. From the power lines Terminal Blocks leads U, V, W three-phase

line, from the brake terminal blocks leads two-phase line. Terminal Blocks used M6, M3.5 Cross

Screwdriver operation.

Please keep junction box dry, cant have foreign matter.

After wiring, wiring shall lid tightly and locks before other operations.

Encoder wiring and power line (or brake line) should be separated to avoid signal

interference. If the encoder line and power line (or brake lines) through the same tube, there may

occurred vibration accident.

Use shielded cable, ensure that the cable shield metal large area contact rack, it also can

use specialize shield contacts casing.

6

SHANGHAI YUNGTAY GIE EM CO., LTD

Pulse sensor using Caution

This product use pulse sensors for rotary encoder. Our company also can according to

customer requirements configure other pulse sensors.

The encoder used in Traction machine is square-wave encoder manufactured by J apan

TAMAGAWA, power supply is DC +5 V (5%), 200mA (MAX.) pulses 6000, 15 lines.

Specific connection as the following table:

ITEM COLOR FUNCTION ITEM COLOR FUNCTION ITEM COLOR FUNCTION

CYAN Ach Output TAWNY Uch Output RED DC+5V

CYAN/BLACK Ach Output TAWNY/BLACK Uch Output BLACK GND

GREEN/BLACK Bch Output GRAY Vch Output NC

GREEN/BLACK Bch Output GRAY/BLACK Vch Output

YELLOW Zch Output Wch Output

YELLOW/BLACK Zch Output WHITE/BLACK Wch Output

7

SHIELD

ENCODER WTRING ILLUSTRATE

3

2

1 4

5

6

Encoder has installed on the product before product leave factory. Encoder use shaft hole

connect, first use a M5 hexagon socket head screw to lock it in the taper hole of the shaft end,

and then use two M3 pan head screws through the encoder bracket lock the encoder on the back

cover of shaft..

When replace the encoder, please refer to technical documentation GMP-0005

"TAMAGAWA Taper Shaft OIH48 encoder dismounting operation order", using special fixtures

and related tools operations.

Wrong wiring will damage the internal circuitry, sure to confirm wiring carefully.

Cant connect the (or disassembly) signal line charged under, so as to avoid short circuit

and damaging encoder.

Cant use megohmmeter test the encoder, so as to avoid damage.

7

SHANGHAI YUNGTAY GIE EM CO., LTD

Traction machine maintenance

Ensure that tractions wouldt restart accidentally before carry out maintenance.

If need to inspect brake should note: When there is load torque applied on the sheav or

traction machine. Release or dismantle the brake is extremely dangerous. Brake is safe

components should be adjusted by the staff with expertise.

Check the bolts and screws whether are loosen. If loosen, should tighten all the bolts and

screws.

The outer surface of the traction machine should be cleaned regularly. The oil or other

impurities between brake drum and brake shoe will lead abnormal brake force. If such situation

happens, ask maintenance personnel notify the owners of elevators stop running immediately,

then contact with the professionals to solve.

Checking regularly: Include check the traction sheave wear and tear situation, brake

flexibility, brake shoe wear and tear situation, and bearing situation.

Traction machine Bearing Life expectancy is 10 years generally. If the bearing have

abnormal noise, it may be bearing damage, abrasive situation, and so on, should replace the

bearings immediately, the replacement of bearings and oil seals should be carried by the

professionals, please contact with me on this situation.

Traction machine bearing has injected grease when leave factory, but in order to ensure the

traction machine normal use, need to add grease regularly (every 1 year). Bearings use DAPHNE

BEARING GREASE EP NO.2 (light 2) grease. If mixed-use different specification (or brand)

grease, may shorten the life span of grease.

Bearing grease supply: Grease inlet and Grease outlet is on the back of products, using

joint and rubber gasket seal to airproof it.Make the tip of the grease gun towards the grease inlet,

and press grease gun pressure lever continually, pressed into grease, about100 cm

3

everytime,

and then use joints to lock the grease inlet and gease outlet

Please do not arbitrarily discard waste grease; It should be deal with environmentally

according to industry standard.

Grease Inlet

Grease Outlet

Brake shoe wear and tear inspection: Middle of the brake shoe thickness is 10mm, when it

reaches 2mm, it need replacement. Brake shoe replacement should be carried by professionals, in

order to ensure the safety of elevators running, please use the brake shoe that our company

certified.

Inspect the traction sheave wear and tear situation regularly. When the traction sheave each

slot wear uneven, resulting that the wire rope in different level, the wire rope tension different,

8

SHANGHAI YUNGTAY GIE EM CO., LTD

should consider replace the traction sheave.

Traction sheave slot cant have oil or other debris.

Please do not transform the traction machine; Traction machine dismounting work should

be carried by our company professionals.

After inspection and maintenance, it should be confirmed the elevator and traction machine

can run normally.

Recommended maintenance cycle

MAINTENANCE ITEM MAINTENANCE CYCLE

traction machine cleaning every month or accord need

bearing lubrication every two years

brake shoe thickness inspection every six months

brake interstice inspection first run; every two months

brake force inspection every six months

bearing abnormal noise inspection every six months

fastener inspection every six months

traction sheave wear inspection every six months

traction force inspection every six months

anti-jump device inspection every six months

Wires &Cables inspection every six months

Maintenance tools

T OOL NUM BER I T EM

M 16 spanner 2 traction machine installation

M 10 spanner 1 brake adjustment

M 12 spanner 1 brake adjustment

filler gauge 1 brake adjustment

1 grounding

anti-jump wire device

termianlwire

junction box open

brake cover

encoder installation

M 5 M 8 socket head spanner 1 encoder installation

oil gun A 200 GB1164 -89 1 add lubrication

M 8 socket spanner Straight Screwdriver 1 add lubrication

1

Cross Screwdriver for M 4,M 6 bolt

9

SHANGHAI YUNGTAY GIE EM CO., LTD

Accessory OneAdjustingMaintenance and Use of Brake

A traction machine is equipped with two brakes.When one of the brakes doesnt

work,another brake still can slow down the car,travelling downwards at rated speed and with

rated load,plays a role in protection.

The type of the brake is DRUM-50R. Its both a safety component of traction machine and a

major component of ascending elevator overspeed protection means.As the major component of

ascending elevator overspeed protection means,its speed monitoring device is overspeed

governor(at least electric two-way)

The lining of the brake is non-asbestos, semi-rigid.

The connection of the two brakes is parallel.

As safety component, only familiar with the brake and qualified personnel are

allowed to perform any adjusting and maintenance work.

The two brakes must be adjusted and maintained one by one,they cant be adjusted at the

same time.

Make sure nobody in the car before adjusting and maintenance.

Make sure the car and counterweight dont have any accidental travelling downwards or

upwards incipient fault exsits,before adjusting and maintenance.

When passengers are stranded in the car because of the elevator faults or power cut, if the

rescue needs to use the release handle and handwheel,then it must be actualized by two qualified

personnel who are familiar with the brake(at least two).

Work principle of brake:When the coil in the core isnt excitated,the brake lining is pressed

against the surface of the drum by the force of the brake spring,and then it produces braking

force to prevent the machine from turning;when the coil in the core is excitated, armature is

attracted to the core(overcome the force of the brake spring),makes a clearance appears between

the brake lining and drum,and then release the braking force ,the braking force is 0 now.

Structure of the brake

The brake can be released by the release handle.It can also be released by connect to the electric

release device which is according with the standard.

1 Guide Bolt 1

2 Core

3 Lining Shoe

4 Lining

5 Guide Bolt 2

6 Armature

7 Release Handle

8 Release Device

The brake torque of two brakes is 490Nm.

The oil or other impurity between the lining and drum can make the braking force

abnormal,when this status occurs,the maintenance personnel must inform the owner to stop the

elevator immediately,and then contact the qualified personnel to solve the problem.

10

SHANGHAI YUNGTAY GIE EM CO., LTD

The measureadjusting of the air gap and clearance

The measureadjusting of the air gap and clearance should be cooperated by two qualified

personnel who are familiar with the brake.

Standard data of the air gap and clearance

Position

Occasion

Clearance Air gap

Factory Assembly 0.10~0.11mm

0.20~0.35mm

The difference among 4 poins

doesnt exceed 0.1mm

Locale QC

(1)

0.07~0.08mm

0.20~0.35mm

The difference among 4 poins

doesnt exceed 0.1mm

Maintenance

(2)

0.07mm OK

0.10mm NG

0.20~040mm

The difference among 4 poins

doesnt exceed 0.1mm

(1) When locale QC,please check the air gap and clearance is according with the (Locale

QC)standard,if not,please adjust to the standard data of factory assembly.All the red marks

should be marked again.

(2) When maintenance, please check the air gap and clearance is according with the

(Maintenance)standard,if not,please adjust the the air gap and clearance by qualified

personnel.When adjusting,please adjust to the standard data of factory assembly in a cold

state. All the red marks should be marked again.

Measureadjust the air gap and clearance as follows:

First,make sure the car is no load and located in the middle of the well,cut the power of

control cabinet, install the two release handles, loosen the bolt and remove the cover .loosen the

bolt and remove the cover.

COVER

1 Guide Bolt1

2 Guide Bolt2

11

SHANGHAI YUNGTAY GIE EM CO., LTD

Clockwise

4 poins of air gap measure (red marks on the edge of the core)

Measure the air gap:In the state of the brake works,measure the air gap between the core

and armature of the 4 poins by means of the thickness gauge.

Measure the clearance: Tighten the middle bolt using a spanner,make the armature is

attracted to the core, measure the clearance between the lining and drum of the poins by means

of the thickness gauge.

Adjust the air gap: Tighten the middle bolt using a spanner,make the armature is attracted to

the core,,adjust the corresponding guide bolt.If the air gap is too large,turn the guide bolt2

anticlockwise using a 19mm open spanner,and then tighten the guide bolt1 clockwise using a

16mm open spanner,so the air gap will diminish. If the air gap is too small,turn the guide bolt1

anticlockwise using a 16mm open spanner,and then turn the guide bolt2 clockwise using a 19mm

open spanner,at last tighten the guide bolt1,so the air gap will largen.

In the course of adjusting,need to measure the air gapclearance and adjust bolts many

times,in order to ensure the air gap and clearance of 4 poins is according with the standard data.

When adjusting,the bolts should be turned slightly.If not,the adjusting distance will be too

large,and the guide bolt or brake will be uninstalled.

After adjusting,please ensure the guide bolt1 and guide bolt2 are tight,and then make sure to

loosen the middle bolt and put it in a loose state,to ensure the brake is braking,at last install the

cover.

AttentionThe two brakes cant be adjusted at the same time,after the

adjusting of one brake, make sure to loosen the middle bolt and put it in a loose

state,to ensure the brake is braking

Accessory Two:Rescue when passengers are stranded in the car because of the elevator

faults or power cut

When the elevator occurs faults or power cut,if passengers are stranded in the car,the rescue

must be performed by qualified personnel.

Before rescue,the main power must be cut off,avoid any accidental act of the elevator.

If the distance between the elevator location and one leveling location is 500mm,the

qualified personnel can open the landing door using the special key,and assist the passengers to

leave the car safety.

12

SHANGHAI YUNGTAY GIE EM CO., LTD

If the elevator isnt in the foregoing position the rescue needs to use handwheel to move

the car,and it needs more than 2 qualified personnels, steps are as follows:

1. Inform the passengers that rescue will be performed at once using call device, let the

passengers keep calm and tell them rescue related matters;

2. Screw the release handle to the release device as the Fig.;Insert the handwheel to the

middle hole on the basemake the small gear of the handwheel mesh with the big gear

on the sheave.

3. One personnel press the release handlesanother personnel turn the handwheel at the

same time,then the car will travel downwards or upwards slowly,when the distance

between the elevator location and leveling location is 150mm,loosen the release

handles;

4. The qualified personnel open the landing door using the special key,and assist the

passengers to leave the car safety;

5. After the passengers leave the car safety,remove the release handleand handwheel,and

lay them to the special place,and manual reset the switch on the base.

If any accidental status occurs during the rescue,stop the rescue immediately,tell the

passengers to keep calm,and contact the company of the elevator.

Fig.Handwheel

Fig.Release Handlle

Base

Fig.Traction without handwheel

release handele

Fig.Install the handwheel release

handel

13

SHANGHAI YUNGTAY GIE EM CO., LTD

Accessory Three:Trouble shooting

Fault Possible cause Inspection Method Remedy

Power cut

Measure the input voltage of

converter

Contact the owner

Coil of stator is

interrupted

Check the three-phase voltage of

traction

Contact the qualified

personnel

Safety chain is open

circuit

Check the safety chain Reset the safety chain

Fault of converter Check the converter

Treat according to the

manual of converter

Traction doesnt

work

Input parameter of

control system doesnt

matching

Check the input parameter

Input the right

parameter

Elevator surfing

or reverse

Connection of encoder

is wrong

Check the connection

Connect according to

the right connection

method

Voltage is abnormal Check the input voltage of brake

Contact the qualified

personnel

Friction remains

after releasing the

brake

Clearance is

unsuitable

Check the clearance Adjust the clearance

Traction reverse

Connection of phase is

wrong

Check the connection of control

cabinet and junction box

Exchange the two

phases

Traction base is not

horizontal or rigidity is

low

Check it with gradienter Adjust and equalize

Traction shake

Rubber is unsuitable Check the rubber Change the rubber

14

Você também pode gostar

- Caterpillar c4 4 Engine ManualDocumento3 páginasCaterpillar c4 4 Engine ManualAndré58% (31)

- Elevator Troubleshooting & Repair: A Technician's Certification Study GuideNo EverandElevator Troubleshooting & Repair: A Technician's Certification Study GuideNota: 4 de 5 estrelas4/5 (9)

- Elevator Mechanic: Passbooks Study GuideNo EverandElevator Mechanic: Passbooks Study GuideAinda não há avaliações

- Sigma Elevator Manual PDFDocumento3 páginasSigma Elevator Manual PDFNadeem KhanAinda não há avaliações

- Iris NVDocumento28 páginasIris NVAnonymous npV5h90% (1)

- SXD-12PC2 MaintenancesManualsDocumento488 páginasSXD-12PC2 MaintenancesManualssilviaAinda não há avaliações

- ME-LIFT-P Microprocessor Control User Manual 20071226 PDFDocumento38 páginasME-LIFT-P Microprocessor Control User Manual 20071226 PDFKen LeeAinda não há avaliações

- SigmaDocumento5 páginasSigmaFERNSAinda não há avaliações

- Toshiba Spacel IIIDocumento11 páginasToshiba Spacel IIITran Huy50% (2)

- Afpelevator Doorcontroller Ec10 DDocumento40 páginasAfpelevator Doorcontroller Ec10 DTroubleshootingAinda não há avaliações

- SHG Mitsubishi - lehy-II C-1 - enDocumento24 páginasSHG Mitsubishi - lehy-II C-1 - enEri Wanto SihombingAinda não há avaliações

- Aljotronic Control 2 PDFDocumento30 páginasAljotronic Control 2 PDFjhfbtyAinda não há avaliações

- Orona LiftDocumento4 páginasOrona LiftMarius Ionita100% (1)

- Group Control System Troubleshooting Manual - Ring-Type - ENGDocumento25 páginasGroup Control System Troubleshooting Manual - Ring-Type - ENGReynold Suarez100% (1)

- Mashiba Catalogue - Elevator (2019)Documento20 páginasMashiba Catalogue - Elevator (2019)Wassim BaccariAinda não há avaliações

- Elevator Inspector: Passbooks Study GuideNo EverandElevator Inspector: Passbooks Study GuideAinda não há avaliações

- New KingKan&M100 Use and Maintenance ManualDocumento180 páginasNew KingKan&M100 Use and Maintenance Manualmanuelvalencia1100% (3)

- MV600J Servo Drive Special For Injection Molding Machine User Manual V1.0Documento101 páginasMV600J Servo Drive Special For Injection Molding Machine User Manual V1.0Trần Đình100% (1)

- Reciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)Documento17 páginasReciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)tutuionutAinda não há avaliações

- CLG766A 777A (Perkins) OM 201811004-ENDocumento172 páginasCLG766A 777A (Perkins) OM 201811004-ENTalita Yasmin Talita100% (1)

- ZFPumpen E 08Documento22 páginasZFPumpen E 08help3rAinda não há avaliações

- Diesel Fuel Metering Device, Component DescriptionDocumento1 páginaDiesel Fuel Metering Device, Component DescriptionTamer Moustafa100% (2)

- 1200A and 1200D Electric Power Supplement TPD2144 Production Release V6 0Documento91 páginas1200A and 1200D Electric Power Supplement TPD2144 Production Release V6 0Mostafa Shanna83% (6)

- GSD SM Instruction Book PDFDocumento15 páginasGSD SM Instruction Book PDFMitro100% (1)

- MMR Elevator - SI: FOD Test & Commissioning For SI210 ControllerDocumento20 páginasMMR Elevator - SI: FOD Test & Commissioning For SI210 ControllerBrahim Chergui100% (1)

- 25 TM Installation ManualDocumento18 páginas25 TM Installation ManualReynold Suarez83% (6)

- NexwayDocumento5 páginasNexwayLuisa BlancoAinda não há avaliações

- IC Card Instruction Manual A00Documento1 páginaIC Card Instruction Manual A00Mahmoud Omar Rob50% (2)

- Elevador SWORD HAMCB Tipo OtisDocumento41 páginasElevador SWORD HAMCB Tipo OtisRaul GutierrezAinda não há avaliações

- Hyundai Elevator Preventive Maintenance ProcedureDocumento19 páginasHyundai Elevator Preventive Maintenance ProcedureTrebor Santos100% (2)

- AscensoresDocumento12 páginasAscensoresOvidio ReyesAinda não há avaliações

- Dell Sigma-Error PDFDocumento6 páginasDell Sigma-Error PDFkabalAinda não há avaliações

- NICE3000 User Manual. PrefaceDocumento184 páginasNICE3000 User Manual. PrefaceОщттнAinda não há avaliações

- Parameter TableDocumento16 páginasParameter TableBahodur ToshevAinda não há avaliações

- Mitsubishi Manuals 1422Documento33 páginasMitsubishi Manuals 1422ronesromualdoAinda não há avaliações

- PDFDocumento239 páginasPDFSodov Odbaatar80% (5)

- 02 IRIS2 - NV - Controller-ENDocumento36 páginas02 IRIS2 - NV - Controller-ENAhmedAinda não há avaliações

- LiftUnit7 DocumentationDocumento44 páginasLiftUnit7 Documentationangela1590Ainda não há avaliações

- Mitsubishi Elevator GPS-III Fault Code - A Water Logging - Netease BlogDocumento7 páginasMitsubishi Elevator GPS-III Fault Code - A Water Logging - Netease BlogTroubleshootingAinda não há avaliações

- ACRA SigmaDocumento32 páginasACRA SigmaSyed iliyasAinda não há avaliações

- Solucion de Problemas Sigma Solon LD 2Documento4 páginasSolucion de Problemas Sigma Solon LD 2Jesus ChecaAinda não há avaliações

- 211Documento14 páginas211AdjieAinda não há avaliações

- Mitsubishi GPSDocumento3 páginasMitsubishi GPSaliakhterattariAinda não há avaliações

- VVVF Control (Variable Voltage and Variable Feriquency) : 1-LX Operator PanelDocumento13 páginasVVVF Control (Variable Voltage and Variable Feriquency) : 1-LX Operator PanelKen LeeAinda não há avaliações

- Slow Down Switch AND ROPINGDocumento30 páginasSlow Down Switch AND ROPINGEtienneAinda não há avaliações

- Hamcb SwordDocumento101 páginasHamcb SwordNaseh Ya NasehAinda não há avaliações

- Powernet Elevators BroucherDocumento16 páginasPowernet Elevators BroucherDEEPU KRISHNAN0% (1)

- Nice1000+ Quick Start Up Guide v1.0 PDFDocumento81 páginasNice1000+ Quick Start Up Guide v1.0 PDFali100% (1)

- DiSi Flash MemoryDocumento8 páginasDiSi Flash MemoryFERNSAinda não há avaliações

- Hitachi Lift UAG SN1Documento20 páginasHitachi Lift UAG SN1Taimoor Ahmed100% (1)

- 11 - Solon TCD171-188Documento8 páginas11 - Solon TCD171-188Fabian VirgiliAinda não há avaliações

- BMK PDFDocumento8 páginasBMK PDFHuỳnh Minh SángAinda não há avaliações

- ElenessaDocumento7 páginasElenessaLuisa BlancoAinda não há avaliações

- NICE3000 电梯一体化控制器用户手册 (英文详版) - V1.0 PDFDocumento232 páginasNICE3000 电梯一体化控制器用户手册 (英文详版) - V1.0 PDFAsdrubal Fredy GutierrezAinda não há avaliações

- Nice 1000Documento204 páginasNice 1000Elius AhmedAinda não há avaliações

- Project Managers Program: Technical NoteDocumento20 páginasProject Managers Program: Technical NotealfreliaAinda não há avaliações

- 7502.9042 MANUAL KONE MAC DOB Rev 2 0 PDFDocumento51 páginas7502.9042 MANUAL KONE MAC DOB Rev 2 0 PDFwalidAinda não há avaliações

- Asanoor Compact IranDocumento51 páginasAsanoor Compact IranSatheesh RamaAinda não há avaliações

- EC100 Operation ManualDocumento252 páginasEC100 Operation ManualRamananda Muhammad FirmansyahAinda não há avaliações

- Diag1FarbeEnglisch PDFDocumento119 páginasDiag1FarbeEnglisch PDFDikaAinda não há avaliações

- Gearless Machines March 2018 2 PDFDocumento39 páginasGearless Machines March 2018 2 PDFMauro Enrique Ortiz Castelán100% (1)

- CMCO Catalog - Cosmo Petra - Safe Lifting Solutions - Hoisting Equipment - Ratchet Lever Hoists - Hand Chain Hoists - Winches - Trolleys - Crane SystemsDocumento132 páginasCMCO Catalog - Cosmo Petra - Safe Lifting Solutions - Hoisting Equipment - Ratchet Lever Hoists - Hand Chain Hoists - Winches - Trolleys - Crane SystemsSafe Lifting SolutionsAinda não há avaliações

- XGC55操作手册(英文) 0 封面、前言、目录、封底Documento11 páginasXGC55操作手册(英文) 0 封面、前言、目录、封底Rony Yang BudimanAinda não há avaliações

- Manual Xj350 PeruDocumento115 páginasManual Xj350 PeruVctorEritkPMAinda não há avaliações

- WZ30 25使用说明书(英文)Documento58 páginasWZ30 25使用说明书(英文)Jorge MirandaAinda não há avaliações

- 01 - SKGD2400 - 001 - 200808 (En) PDFDocumento75 páginas01 - SKGD2400 - 001 - 200808 (En) PDFTrengginas Bima0% (1)

- SCM Go Flex: Product Technical SheetDocumento8 páginasSCM Go Flex: Product Technical SheetKen LeeAinda não há avaliações

- Transformer-1 /75W Battery Group: Drw. Apprv. M. Aybey Date Series Proj. Rev. LRS LRS02 M. AkkuşDocumento1 páginaTransformer-1 /75W Battery Group: Drw. Apprv. M. Aybey Date Series Proj. Rev. LRS LRS02 M. AkkuşKen LeeAinda não há avaliações

- 9.15 Opposite Door Control SchemeDocumento4 páginas9.15 Opposite Door Control SchemeKen LeeAinda não há avaliações

- Planning GuideDocumento11 páginasPlanning GuideKen LeeAinda não há avaliações

- Car Door M-TypeDocumento1 páginaCar Door M-TypeKen LeeAinda não há avaliações

- Gate Controller Manual: AAD03010 Frequency Control SystemDocumento17 páginasGate Controller Manual: AAD03010 Frequency Control SystemKen LeeAinda não há avaliações

- Transformer-1 /75W Battery Group: 12V 12V 12V 12V 12VDocumento1 páginaTransformer-1 /75W Battery Group: 12V 12V 12V 12V 12VKen LeeAinda não há avaliações

- Lrs 3Documento1 páginaLrs 3Ken Lee100% (1)

- Emesa CAR FRAMES 1Documento2 páginasEmesa CAR FRAMES 1Ken LeeAinda não há avaliações

- Emesa Tech SheetDocumento3 páginasEmesa Tech SheetKen LeeAinda não há avaliações

- Planning Guide: For Residential Elevator With Hydraulic Drive or Winding Drum Drive ASME A17.1-2000 Part 5.3Documento8 páginasPlanning Guide: For Residential Elevator With Hydraulic Drive or Winding Drum Drive ASME A17.1-2000 Part 5.3Ken LeeAinda não há avaliações

- Galaxy Traction Elevator ControllerDocumento327 páginasGalaxy Traction Elevator ControllerKen LeeAinda não há avaliações

- Windsor: Self-Contained Drive System! Optional Recessed Telephone Box Operating Controls No Pit!Documento2 páginasWindsor: Self-Contained Drive System! Optional Recessed Telephone Box Operating Controls No Pit!Ken LeeAinda não há avaliações

- Bl3-U AsyncDocumento23 páginasBl3-U AsyncKen Lee100% (1)

- Safety For Technicians: 2 EN 81-20 & EN 81-50Documento2 páginasSafety For Technicians: 2 EN 81-20 & EN 81-50Ken LeeAinda não há avaliações

- Service Manual: SchematicsDocumento42 páginasService Manual: SchematicsKen LeeAinda não há avaliações

- Series Incremental Encoders: Environmental SpecificationsDocumento2 páginasSeries Incremental Encoders: Environmental SpecificationsKen LeeAinda não há avaliações

- MicroZed v33Documento18 páginasMicroZed v33Ken LeeAinda não há avaliações

- NICE3000 - Technical Manual-060710Documento109 páginasNICE3000 - Technical Manual-060710Ken Lee100% (8)

- Omega LiftDocumento2 páginasOmega LiftKen LeeAinda não há avaliações

- Operation Manual: Rcf-1 Door Operator ControllerDocumento31 páginasOperation Manual: Rcf-1 Door Operator ControllerKen LeeAinda não há avaliações

- VVVF Control (Variable Voltage and Variable Feriquency) : 1-LX Operator PanelDocumento13 páginasVVVF Control (Variable Voltage and Variable Feriquency) : 1-LX Operator PanelKen LeeAinda não há avaliações

- A30t U Type C Type Photoemission Switch For Lift and Elevator User Manual 2009Documento3 páginasA30t U Type C Type Photoemission Switch For Lift and Elevator User Manual 2009Ken LeeAinda não há avaliações

- Kasvar: User ManualDocumento31 páginasKasvar: User ManualKen LeeAinda não há avaliações

- Explosion-Proof DrivesDocumento48 páginasExplosion-Proof DrivesArtifoxAinda não há avaliações

- Toyota Camry Gracia Scepter Vienta Vista Windom Holden Apollo Lexus Es 300 1991-97Documento12 páginasToyota Camry Gracia Scepter Vienta Vista Windom Holden Apollo Lexus Es 300 1991-97Shaun HarlandAinda não há avaliações

- Final Project Report SalesDocumento48 páginasFinal Project Report Salessaid mohamudAinda não há avaliações

- 10 - Beaver600c Dredger Technical DataDocumento2 páginas10 - Beaver600c Dredger Technical Datahanisry baseriAinda não há avaliações

- Reverse Power TroubleshootDocumento2 páginasReverse Power TroubleshootMegat Rambai Sr100% (4)

- A CinspectionandHumanfactorDocumento26 páginasA CinspectionandHumanfactorLiam SkrooAinda não há avaliações

- What Makes The Motor of Tesla Cars So Special - QuoraDocumento2 páginasWhat Makes The Motor of Tesla Cars So Special - QuoraAnimeshAinda não há avaliações

- Shipping Container PreservationDocumento16 páginasShipping Container PreservationMohamed Sahnoun100% (1)

- COmpanies Above 20 CR 20130927Documento36 páginasCOmpanies Above 20 CR 20130927venkatesh_1829Ainda não há avaliações

- Profile ADocumento36 páginasProfile AAsad AliAinda não há avaliações

- Who CDS Whopes GCDPP 2003.5 PDFDocumento45 páginasWho CDS Whopes GCDPP 2003.5 PDFRockersmalaya889464Ainda não há avaliações

- 600@1800 Kta19 M3 Tontek PowerDocumento3 páginas600@1800 Kta19 M3 Tontek PowerStenny LumiAinda não há avaliações

- RTX100 Spec Sheet1Documento2 páginasRTX100 Spec Sheet1RojasAinda não há avaliações

- Manipulador Telescopico Skytrak 10042Documento2 páginasManipulador Telescopico Skytrak 10042osky1954trigoAinda não há avaliações

- Vibrovaljak Dynapac (Jež) CA 182 DDocumento1 páginaVibrovaljak Dynapac (Jež) CA 182 DIgnjatov MilutinAinda não há avaliações

- Generator Diesel Chicago Pneumatic CPSG 750Documento2 páginasGenerator Diesel Chicago Pneumatic CPSG 750dicon100% (1)

- Emmission and Peformance Analysis of The Ternary DDocumento21 páginasEmmission and Peformance Analysis of The Ternary DSHYAM SUNDARAinda não há avaliações

- KW (Stage Iiia) KW (Stage V) KW (Electo) : Material Handling Crawler MachineDocumento20 páginasKW (Stage Iiia) KW (Stage V) KW (Electo) : Material Handling Crawler MachinevitaliyAinda não há avaliações

- PC210 PC210LC: Hydraulic ExcavatorDocumento13 páginasPC210 PC210LC: Hydraulic ExcavatorNay Min KhaAinda não há avaliações

- Komatsu 6d125 Engine Short ReviewsDocumento1 páginaKomatsu 6d125 Engine Short Reviewsmilad rahimiAinda não há avaliações

- Flygt 3057, 50Hz: Technical SpecificationDocumento18 páginasFlygt 3057, 50Hz: Technical SpecificationMartinDiazAinda não há avaliações

- GENERAL SCIENCE 50 MCQsDocumento8 páginasGENERAL SCIENCE 50 MCQsKhabir IslamAinda não há avaliações

- Firman GenDocumento18 páginasFirman GenAnonymous xifNvNAinda não há avaliações

- Tractor MechanicsDocumento165 páginasTractor Mechanicsprem100% (7)