Escolar Documentos

Profissional Documentos

Cultura Documentos

Cassava Starch Granule Structure-Function Properties - Influence of Time and Conditions at Harvest On Four Cultivars of Cassava Starch

Enviado por

wahyuthp430 notas0% acharam este documento útil (0 voto)

94 visualizações10 páginasjournal

Título original

Cassava Starch Granule Structure–Function Properties- Influence of Time and Conditions at Harvest on Four Cultivars of Cassava Starch

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentojournal

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

94 visualizações10 páginasCassava Starch Granule Structure-Function Properties - Influence of Time and Conditions at Harvest On Four Cultivars of Cassava Starch

Enviado por

wahyuthp43journal

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 10

Cassava starch granule structurefunction properties: inuence of time

and conditions at harvest on four cultivars of cassava starch

K. Sriroth

a,

*

, V. Santisopasri

b

, C. Petchalanuwat

c

, K. Kurotjanawong

a

, K. Piyachomkwan

d

,

C.G. Oates

e

a

Department of Biotechnology, Kasetsart University, Bangkok, Thailand.

b

Department of Biochemistry, Kasetsart University, Bangkok, Thailand.

c

Department of Agriculture, Ministry of Agriculture, Thailand.

d

Cassava Starch Technology Research Unit/National Center for Genetic Engineering and Biotechnology, Thailand.

e

Department of Biochemistry, National University of Singapore, Singapore.

Received 12 January 1998; received in revised form 11 May 1998; accepted 18 June 1998

Abstract

Impact of environmental conditions on cassava starch variability was examined by studying four commercially important cultivars,

Rayong 1, Rayong 60, Rayong 90, and Kasetsart 50 (KU 50). Age of the root and environmental conditions at harvest inuenced granule

structure and hydration properties. All cultivars were grown under identical eld conditions, and harvested at different times. Starches

extracted from cassava roots harvested at different times were characterised by unique starch granule structure and function. Apparent

amylose size of starches from all cultivars did not change signicantly during the trial period. However, apparent amylose content of starches

changed, decreasing in the older roots. Granule size distribution was affected by age of the root, gradually changing from normal to bimodal

distribution when harvested very late during the trial. The integrity and crystalline structure of starch granules also depended on the

environmental conditions, evidenced as a change in peak prole obtained by thermal analysis. This can result in the difference in water

uptake of starches, and their consequent swelling power and gelatinization. Pasting temperature of all starches increased during the dry

period, and was lowered during the wet period. Peak and nal viscosity of starch decreased from early to mid-harvest time when environ-

mental conditions became drier, and increased close to or greater than the original value when conditions became wet again. Breakdown and

setback also followed a similar trend to viscosity. This study suggests an impact of time and conditions of harvest on the structural and

functional properties of all cassava cultivars, and based on this study, it is recommended that starch should be extracted from either early or

very late harvested roots. q1999 Elsevier Science Ltd. All rights reserved.

Keywords: Cassava starch; Rayong 1; New cassava cultivars

1. Introduction

Ensuring consistent quality of cassava starch remains a

problem despite advances and upgrading of technology used

for the extraction of this material. Variation derived from

different cultivars accounts for some of the deviation

between processing operations in Thailand. However,

within a geographic area single cultivars tend to dominate

and therefore it is unlikely that this is a source of variation

for starch produced in the same factory at different times of

the year. Variation reportedly can signicantly alter the

functional properties of the starch making application of

the native material difcult in some circumstances.

In Thailand a number of cultivars of cassava are grown

for commercial purposes. One of the rst cultivars to be

developed for improved economic return was Rayong 1,

which is a selection from a local land race. Due, in part,

to its excellent agronomic traits (Rodjanaridpiched et al.,

1993) more than 1 million hectares are planted annually to

this cultivar. Since 1984, and in parallel with the growth of

the cassava industry, several new cultivars suitable for

industrial purposes have been developed, including Rayong

3, Rayong 60, Rayong 90 and Kasetsart 50 (Table 1).

Agronomic characteristics of the four cultivars summar-

ized in Table 1 have been examined in extensive trials,

designed to determine the most suitable time for harvest,

either early (9 months) or late (12 months). The largest trial,

Carbohydrate Polymers 38 (1999) 161170

0144-8617/99/$ - see front matter q 1999 Elsevier Science Ltd. All rights reserved.

PII: S0144-8617(98)00117-9

* Corresponding author. Klanarong Sriroth,Cassava and Starch Technol-

ogy Research Unit, Kasetsart Agricultural and Agro-Industrial Product

Improvement Institute (KAPI), Kasetsart University, Bangkok 10900,

Thailand. Tel.: 662 9405634; Fax: 662 9405634; e-mail: aapkrs@ku.ac.th

conducted at 9 locations in 1994, evaluated the inuence of

time of harvest on fresh root yield, dry root yield and root

dry matter (Rodjanaridpiched et al., 1993). For all cultivars

wet root yield was higher at 12 months but dry root yield

and root dry material was lower at this time. However, these

studies did not evaluate quality of starch produced at the

different harvest times, or consider the intervening months.

The rate of decrease of dry root yield was greatest for

Rayong 60 and Rayong 1.

Plants harvested at 12 months were found to be respond-

ing to climatic change, associated with transition from dry

to wet season. The authors concluded that post dry season

the plants renew their top growth at the expense of root

growth, resulting in a reduction of root dry matter content.

This response to re-growth was variable between the

cultivars.

Cassava roots are harvested manually with a little help

from small tools. The harvest can be through the year except

in the rainy season (June/July/August). From age of

12 months, the roots are considered as ripe and are often

left in the ground until 1416 months, depending on the

economic situation. The young roots contain more water

and less starch ( , 20%) as compared with older roots

(more than 12 months), but extractability of starch from

the older roots is more difcult due to a higher ber content.

In general, starch structure-function properties alter

according to the stage of development of the plant and the

botanical source. Demonstrated by most cereals, amylose

content is lower at early stages of grain development (Inou-

chi et al., 1984; Asaoka et al., 1985). A similar trend

between amylose content ad developmental age is also

seen in potato, where increasing root size is associated

with a greater amylose content (Geddes et al., 1965). This

is, however, not the case during development of tuberous

roots such as cassava (Asaoka et al., 1992) or sweet potato

(Noda et al., 1992).

Previous work has demonstrated that both genetic consti-

tution and environmental conditions inuence functional

properties of the starch, including gelatinization properties

(Asaoka et al., 1992). However, this work did not fully

describe the inuence of rainfall, which will promote

canopy growth, on starch functional properties. These

factors will be investigated in this article which forms part

of a larger study mapping the inuence of environmental

conditions on starch structure-function properties.

The present study attempts to provide a more detailed

understanding of environmental inuences and age of the

root on quality and functional properties of the extracted

starch. This information is important for a number of

reasons, primarily it could form the basis of a model to

probe structure-function relationships of cassava starch.

Understanding the reasons responsible for variability of

this starch is required both by the processor and user, hope-

fully a better appreciation of the mechanisms responsible for

variation will lead to the production of higher quality starch.

2. Materials and methods

2.1. Materials

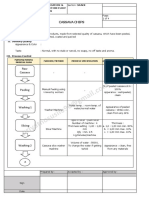

Cassava plants were planted in May 1995 at Rayong Field

Crops Research center, Department of Agriculture, Thai-

land using Split-plot in Randomized Complete Block

(RCB) design. During growth, fertilizer (15-15-15) was

applied at the rate of 312.5 kg/ha. No extra irrigation was

applied. Precipitation was as indicated in Fig. 1.

Soil conditions for the experiment area were; pH 5.4,

organic matter content 0.5%, phosphorus and potassium

content 24 and 20 ppm, respectively.

Roots were manually harvested each month and samples

representing all experimental cultivars collected and

analyzed for starch content by a specic gravity method

as described by Brautlecht (1953). Starch extraction was

conducted within 12 h of harvesting using water as extrac-

tion solvent and a laboratory blender for breaking the plant

K. Sriroth et al. / Carbohydrate Polymers 38 (1999) 161170 162

Table 1

Recommended cassava cultivars in Thailand

Cultivar Year released Parents Main features

Rayong 1 1957 From local cultivars High yield, good adaptability

Rayong 60 1987 Mcol 1684 * Rayong 1 Early harvest, high yield

Rayong 90 1991 CMC 76 * V43 High root DM, high yield

Kasetsart 50 1992 Rayong 1 * Rayong 90 High root Dm, high yield,

good adaptability

Figure 1. Rainfall during the growing period. Monthly values represent the

accumulative rainfall in the previous four weeks.

K. Sriroth et al. / Carbohydrate Polymers 38 (1999) 161170 163

T

a

b

l

e

2

E

f

f

e

c

t

o

f

c

u

l

t

i

v

a

r

s

a

n

d

h

a

r

v

e

s

t

i

n

g

d

a

t

e

o

n

a

v

e

r

a

g

e

s

t

a

r

c

h

c

o

n

t

e

n

t

(

%

)

a

n

d

y

i

e

l

d

(

t

o

n

/

h

a

)

o

f

c

a

s

s

a

v

a

r

o

o

t

s

.

C

u

l

t

i

v

a

r

s

A

g

e

(

m

o

n

t

h

)

6

1

0

1

2

1

4

1

6

S

t

a

r

c

h

c

o

n

t

e

n

t

(

%

)

Y

i

e

l

d

(

t

o

n

/

h

a

)

S

t

a

r

c

h

c

o

n

t

e

n

t

(

%

)

Y

i

e

l

d

(

t

o

n

/

h

a

)

S

t

a

r

c

h

c

o

n

t

e

n

t

(

%

)

Y

i

e

l

d

(

t

o

n

/

h

a

)

S

t

a

r

c

h

c

o

n

t

e

n

t

(

%

)

Y

i

e

l

d

(

t

o

n

/

h

a

)

S

t

a

r

c

h

c

o

n

t

e

n

t

(

%

)

Y

i

e

l

d

(

t

o

n

/

h

a

)

R

a

y

o

n

g

1

1

8

.

1

1

1

.

3

1

3

.

8

1

7

.

1

1

8

.

6

2

5

.

8

2

3

.

0

2

7

.

7

2

1

.

9

2

2

.

2

R

a

y

o

n

g

6

0

1

7

.

2

7

.

5

1

5

.

4

1

3

.

6

1

9

.

0

2

1

.

8

2

2

.

6

2

8

.

3

1

9

.

7

3

0

.

4

R

a

y

o

n

g

9

0

2

3

.

3

1

0

.

9

2

0

.

8

2

3

.

1

2

7

.

1

3

4

.

0

2

9

.

1

4

3

.

7

2

6

.

1

4

4

.

5

K

a

s

e

r

s

a

r

t

5

0

2

3

.

4

8

.

0

1

9

.

3

1

6

.

8

2

4

.

7

2

1

.

8

2

7

.

4

2

8

.

5

2

4

.

4

3

1

.

9

tissue to liberate the starch granules. Fiber was separated by

sieving through a 170-mesh screen (90 mm). After washing

several times, starch was oven dried at 50558C. Starch

properties were analyzed immediately on production with

suitable controls to ensure reproducibility of the methods

between analysis periods.

2.2. Proximate analysis

The content of protein, fat and ash were determined

according to AOAC methods (AOAC, 1990). The amount

of phosphorous was quantied by the method described by

FAO (Food and Agricultural Organization of the United

Nations, 1988).

2.3. Scanning electron microscopy

Dried starch samples were prepared for observation by

scanning electron microscopy by sprinkling the starch on

double-sided adhesive tape attached to a circular specimen

stub and coating with gold using a Baltzers SCD 004 sputter

coater. The samples were viewed and photographed using a

JEOL JSM-5300LV scanning electron microscope on

AGAFAPAN-APX 100 lm.

2.4. Sonication for HPSEC

An aqueous starch slurry (20 mg in 15 ml) was gelati-

nized at 1008C for 10 min, cooled to 508C and sonicated.

Samples, 15 ml, were sonicated in tubes (internal diameter,

20 mm) using a Sonicator

TM

Cell Disrupter, model XL-2020

(Heat systems Ultrasonic, Inc.) and Misonix probe (exter-

nal diameter, 4 mm) (Model 419A). Power was set at 45%

of the maximum 550 W (output frequency 20 kHz).

2.5. Amylose Size

The proportion of the major starch fractions and apparent

molecular size of amylose after sonication were determined

by high performance size exclusion chromatography

(HPSEC) according to the method of Govindasamy et al.

(1992).

2.6. Swelling and Solubility

Swelling and solubility determinations were carried out at

958C by the procedure of Schoch (1964).

2.7. Differential scanning calorimetry

Gelatinization properties of the starches were analyzed

using a Perkin Elmer Differential Scanning Calorimeter

(DSC7; Norwalk, CT) equipped with an intercooler. Alumi-

num pans (Perkin Elmer) were used for the analysis. Starch

samples were slurried with water to give a volume fraction

between 0.680.69. The starch slurry was dispensed, after

mixing, into empty aluminum pans and hermetically sealed.

Following equilibration at room temperature for 1 h the

samples were heated from 20 to 1108C at a heating rate of

108C/min. An empty pan was used as reference. Enthalpy

changes, integrated using DSC software, were calibrated on

the basis of the melting of indium metal. All pans were

reweighed after cooling. To calculate enthalpy values accu-

rately on a dry basis, each pan was carefully punctured,

dried at 1108C for 2 h and reweighed to determine moisture

content of the scanned and rescanned samples.

2.8. Granule size distribution

Granule size distribution was determined by image analy-

sis (Carl Zeiss, KS400 v2) recorded directly from a Carl

Zeiss Axiophol 2 microscope. Starch samples were

suspended in 80% sucrose solution to minimize the effects

of refractive index and provide a sharper image of the gran-

ules (Baldwin, 1994).

2.9. Pasting proles

Pasting proles were recorded on a RVA 4 (Newport

Scientic, Australia) using standard program Number 1.

The starch sample was 3.00 g (on 14% moisture basis).

The starch suspension was held at 508C for 1 min and subse-

quently heated to 958C at 12.28C/min. Holding time at 958C

was 2.5 min. Subsequently, the sample was cooled to 508C

at 12.28C/min, where it was kept for 2.1 min. A rotation

speed of the paddle of 160 rpm was used and cooling was

performed with water circulated through cooler.

3. Results and discussion

During the study two rainy seasons were recorded, the

rst coinciding with planting and the second in the later

months of the trial. Months 7, 8, 9 and 11 were compara-

tively dry months interspersed with one wet month (month

K. Sriroth et al. / Carbohydrate Polymers 38 (1999) 161170 164

Table 3

Proximate analysis of cassava starches.

Cultivars Protein (% w/w) Lipid (% w/w) Ash (% w/w) Phosphorus (mg/kg)

Rayong 1 0.17 ^ 0.04 nil 0.10 ^ 0.02 2.45 ^ 0.08

Rayong 60 0.15 ^ 0.02 0.01 0.15 ^ 0.04 2.20 ^ 0.14

Rayong 90 0.28 ^ 0.06 nil 0.08 ^ 0.01 2.04 ^ 0.05

KU 50 0.30 ^ 0.04 0.01 0.15 ^ 0.02 2.04 ^ 0.05

10). The roots were harvested at 6, 10, 12, 14 and

16 months.

Previous work (unreported) suggested that rainfall had a

strong inuence if high in the month immediately prior to

harvest. However, time of harvest was not a major determi-

nant during the growing period up to 16 months. For this

reason and in order to investigate the inuence of cumula-

tive conditions, samples were harvested during only ``wet''

months, and harvesting pre and post dry period was during

months that had experienced a similar level of rainfall.

For all cultivars, starch content was lowest at 10th month

(Table 2). Plants harvested in the 10th month were subjected

to heavy rainfall in the previous four weeks. Prior to which,

drought conditions had prevailed for about 2 months. Starch

content increased again and reached the maximum at 14th

month. In general, root yield increased with a greater age of

the cassava plant.

The proximate composition of the starches is presented in

Table 3. Starches from different cultivars were low in lipid

(,0.01%), protein (0.15%0.30%), ash (0.08%0.15%)

and phosphorous (2.042.45 mg/kg). Values were in the

range expected for cassava starches (Rickard et al., 1991).

3.1. Starch structure

3.1.1. Macromolecule components

Starch structure was different if extracted from cassava

harvested prior to the onset of the rainy season. Apparent

amylose size did not appear to be inuenced by either age of

the root or growing conditions immediately prior to harvest

(Table 4).

The proportion of amylose changed within a narrow band

during the period of the trial. Starch extracted from roots

harvested late in the trial, (14th and 16th month), was gener-

ally lower in amylose content (Table 4). Previous studies

(Inouchi et al., 1984; Asaoka et al., 1985) have reported a

variability of amylose content as inuenced by time of

harvest. In cereals and potato amylose increases in later

K. Sriroth et al. / Carbohydrate Polymers 38 (1999) 161170 165

Table 4

Apparent size and content of amylose in cassava starch at different harvest time

a

.

Time of harvest / months

6 10 14 16

Dp Content

b

(%) DP Content

b

(%) DP Content

b

(%) DP Content

b

(%)

Rayong 1 1175 24.1 1188 23.5 1148 20.6 1161 20.6

Rayong 60 1122 22.5 1096 20.5 1035 20.7 1148 20.8

Rayong 90 1202 23.1 1216 21.3 1122 22.3 1135 22.5

KU 50 1175 21.4 1161 21.5 1135 19.5 1121 19.6

a

Values are the mean of ve determinations, the range of each values was , ^ 0.2%

b

Amylose content, expressed as a percentage of the total granule carbohydrate

Figure 2. Rayong 1 size distribution prole. A representative example for cassava starch granules obtained from Rayong cultivars as inuenced by time of

harvest. X axis represents the size of starch granule in micron whereas Y axis represents the percentage of distribution.

stages of development (Inouchi et al., 1984; Asaoka et al.,

1985; Gedds et al., 1965). In comparison for cassava and

sweet potato there was little difference in amylose content

(Asaoka et al., 1992; Noda et al., 1992). Results of the

present study are not in agreement with those of Asaoka

et al. (1992), amylose content was highest (for all cultivars)

at the early harvest time, but dropped to a constant level

during the dry period. In two samples, Rayong 60 & 90,

amylose content decreased during the extended dry period.

For the other two samples amylose decreased during the dry

period and continued the trend into the wet period. This

suggests that inuences on amylose content are more

complicated than length of time in the ground.

3.2. Starch granule

The size and morphological appearance of the starch was

as expected for cassava starch (Rickard et al., 1991).

Size distribution of the granules followed a trend similar

to swelling with respect to harvest time. Slight differences

are evident between cultivars (Fig. 2), though with the

exception of KU 50, all were similarly effected by condition

at harvest.

The range of granule sizes approached a normal distribu-

tion in samples harvested up to 14th month. For all cultivars

the mean size was centered at about 15 mm and the distribu-

tion was from about 822 mm. There was no signicant

shift in the mean granule size with harvest time, but for

all Rayong cultivars there was a slight shoulder at about

12 mm, which developed to such an extent that by the

16th month granule size was bimodally distributed. The

two distinct populations of granule were centered at about

15 and 12 mm. In contrast, size distribution for granules of

Ku 50 appeared to be similar for all times of harvest and

normally distributed.

Electron micrographs suggest that granules are consider-

ably irregular in shape with oval, round and truncated gran-

ules present within the same sample. There were no

apparent differences, between species with respect to gran-

ule morphology (Fig. 3 and data not shown).

K. Sriroth et al. / Carbohydrate Polymers 38 (1999) 161170 166

Figure 3. Scanning electron photomicrographs of cassava starch from Rayong 60 at different harvest times (a) 6th, (b) 10th, (c) 14th and (d) 16th month.

Comparative information on the integrity and crystal

structure of starches can be obtained by thermal analysis.

For starches in this study, intercultivar comparisons are only

possible for starches collected in the early months. There

were only slight difference between the cultivars in respect

to gelatinization temperature and enthalpy. Peak tempera-

tures (T

p

) were similar for all cultivars and in the range 69

718C (Kasetsart 50 and Rayong 90/Rayong 1 respectively)

(Fig. 4). Starches extracted from roots harvested in later

months of the trial exhibited unusual thermal properties

K. Sriroth et al. / Carbohydrate Polymers 38 (1999) 161170 167

Figure 4. Representative thermoanalysis proles for cassava starch harvested at different times. (a) Rayong 90; (b) KU 50. Dry sample weight: (a) Rayong 90

(1) 4.54, (2) 4.22, (3) 4.34 and (4) 4.50 mg for 6, 10, 14 and 16 months respectively; (b) KU 50 (1) 4.56, (2) 4.48, (3) 4.45 and (4) 4.51 mg for 6, 10, 14 and

16 months respectively. The bar corresponds to 1 mW.

that made comparison between the starches difcult. The

single endothermic peak evident in samples harvested

early in the study developed into a biphasic peak with

concomitant increase in temperature of the original peak

(Fig. 4). In this study starch samples were hydrated to a

point close to that known to inuence the gelatinization

mechanism. For starch water mixtures containing more

than 60% water (WSB) a single symmetrical endothermic

peak is usually observed. At moisture contents lower than

the critical point, size of the transition progressively

decreases with concomitant development of a second transi-

tion. The later peak moves to higher temperature as the

amount of water is further reduced.

Differences in thermal behavior as inuenced by moisture

content are assumed indicative of non-equilibrium melting

and support the notion that structure reorganization during

heating is water dependent. At lower moisture, melting

temperature and transition can not be accurately determined

because of the resulting broad fusion range.

Temperature of gelatinization (T

P

, T

o

, T

f

) for cassava

starch is variably reported in the literature, values (T

p

)

range from as low as 588C (Asaoka et al., 1992) to as

high as 658C (Yamada et al., 1987) for cassava starch

from Thailand. Such differences suggest that genetic varia-

tion and environmental conditions impact on structure-func-

tion of the starch. Comparisons with the current study would

be difcult, as the moisture content is lower than that custo-

marily used for starch thermoanalysis. Though the range

recorded in this study for T

P

(69718C) is comparable,

considering the lower moisture content. Studies at high

moisture conrm that the gelatinization temperature (T

P

)

is as expected at 668C (data not presented).

Root and cereal starches are assumed to have similar

melting mechanisms. The melting of starch granules is

governed by the speed in which water can enter the starch

granule. The event is thought to comprise of two stages,

involving plasticizing of the amorphous amylose followed

by hydration and melting of the crystallites. In excess water

rapid plasticizing can occur and the two endotherms merge

as one, in the range of the single endotherm, as the rate of

water penetration will be the same as the rate of crystallite

disruption. At intermediate water conditions the endother-

mic peak splits forming a biphasic endotherm, as the amor-

phous regions are slowly plasticized causing a delay in

hydration which forces gelatinization temperatures towards

higher regions.

This study suggests that starch granules may differ in

their response to water uptake and consequent gelatiniza-

tion, depending on environmental conditions. This phenom-

enon is not apparent when samples are examined at higher

K. Sriroth et al. / Carbohydrate Polymers 38 (1999) 161170 168

Table 5

Swelling power of cassava starch at 958C as inuenced by time of harvest.

Time of harvest (months)

6 10 12 14 16

Rayong 1 55 ^ 1 58 ^ 7 59 ^ 7 53 ^ 1 51 ^ 2

Rayong 60 58 ^ 7 61 ^ 4 54 ^ 7 48 ^ 1 45 ^ 6

Rayong 90 60 ^ 6 59 ^ 2 55 ^ 2 59 ^ 7 66 ^ 1

KU 50 54 ^ 4 77 ^ 12 64 ^ 3 51 ^ 1 51 ^ 2

Table 6

Pasting properties of cassava starch as inuenced by time of harvest.

Pasting temperature (8C) Peak viscosity (RVU) Trough (RVU) Final viscosity (RVU) Breakdown* Setback*

Rayong 1

6 71.35 ^ 0.35 419 ^ 21

b

169 ^ 17 284 ^ 10

a

250 ^ 6

b

115 ^ 12

a

10 71.38 ^ 0.04 363 ^ 10

c

154 ^ 17 221 ^ 10

c

209 ^ 7

c

67 ^ 8

c

12 72.60 ^ 0.76 357 ^ 2

c

158 ^ 8 205 ^ 10

c

200 ^ 10

c

47 ^ 4

d

14 72.00 ^ 0.64 436 ^ 33

b

160 ^ 20 245 ^ 16

b

265 ^ 29

b

74 ^ 12

bc

16 71.08 ^ 0.35 502 ^ 4

a

182 ^ 15 268 ^ 10

ab

324 ^ 14

a

85 ^ 5

b

Rayong 60

6 70.98 ^ 0.16 402 ^ 12

ab

156 ^ 3

ab

266 ^ 10

a

246 ^ 15

ab

111 ^ 11

a

10 71.30 ^ 0.99 382 ^ 25

bc

156 ^ 18

ab

238 ^ 13

b

226 ^ 24

b

82 ^ 6

b

12 70.80 ^ 0.57 336 ^ 11

c

133 ^ 8

c

183 ^ 8

c

203 ^ 12

b

50 ^ 4

c

14 70.30 ^ 0.64 351 ^ 37

c

147 ^ 7

bc

196 ^ 3

c

205 ^ 47

b

50 ^ 7

c

16 69.50 ^ 0.78 459 ^ 45

a

169 ^ 4

a

265 ^ 14

a

288 ^ 41

a

96 ^ 13

ab

Rayong 90

6 71.10 ^ 0.82 396 ^ 3

b

145 ^ 21 271 ^ 10

a

251 ^ 20

b

125 ^ 13

a

10 72.90 ^ 0.79 395 ^ 27

b

157 ^ 31 243 ^ 19

a

239 ^ 15

b

71 ^ 4

b

12 72.10 ^ 0.49 304 ^ 2

c

158 ^ 14 177 ^ 4

b

150 ^ 18

d

23 ^ 20

c

14 72.07 ^ 0.40 351 ^ 53

bc

163 ^ 23 244 ^ 31

a

198 ^ 30

c

69 ^ 22

b

16 70.68 ^ 0.66 480 ^ 12

a

177 ^ 6 262 ^ 6

a

302 ^ 15

a

84 ^ 8

b

KU 50

6 72.57 ^ 0.70

bc

439 ^ 4

b

174 ^ 13 278 ^ 17 265 ^ 9

b

98 ^ 6

a

10 74.32 ^ 0.60

a

369 ^ 4

c

145 ^ 19 213 ^ 23 214 ^ 7

c

69 ^ 4

ab

12 73.22 ^ 0. 435 ^ 1

b

170 ^ 27 224 ^ 26 254 ^ 27

ab

54 ^ 8

b

14 71.25 ^ 0.42

cd

404 ^ 26

c

160 ^ 4 253 ^ 29 243 ^ 28

ab

92 ^ 31

a

16 70.38 ^ 0.53

d

531 ^ 8

a

164 ^ 4 261 ^ 13 369 ^ 6

a

92 ^ 17

a

or lower moisture contents. The precise mechanism is not

known, but would appear to be subtle and assumed to repre-

sent structural differences that cause an apparent variation in

the rate of hydration for late harvested samples. For starches

extracted from other botanical sources physical properties

of starch granules, such as gelatinization temperature, are

affected by environmental temperature during growth. This

is probably not a key issue in tropical crops where tempera-

ture varies very little during the year. However, variation in

rainfall could lead to differences in soil temperature in the

immediate environment of the growing roots. Tempering,

mechanical damage and thermal history of the starch during

extraction and drying may also inuence thermal properties.

This is unlikely to be the case in this study, granules look to

be morphologically similar and care was exercised during

the extraction, ensuring experimental uniformity through-

out.

3.3. Hydration properties

Swelling power of starches followed less of a general

trend in some samples, for example Rayong 60 and KU

50 (Table 5). For Rayong 60 starch, swelling power was

higher when extracted from root harvested at 6, 10 and

12 months. Swelling power of KU 50 peaked in the 10th

month, and then decreased through the extended growing

period. For Rayong 1 and Rayong 90, swelling power did

not decrease with a similar trend, suggesting that their swel-

ling power might be affected by other factors such as gran-

ule size, structure and composition.

3.4. Pasting properties

To detect pasting differences, Rapid Visco Analyser

(RVA) was used (Table 6). Pasting temperatures were little

effected by harvest time irrespective of the cassava cultivar.

Viscosity was high in samples harvested at 6th month,

however at the 10th month peak viscosity dropped, reaching

a low value by the 12th month for all Rayong cultivars and

the 10th month for KU 50. The level of decrease ranged

from 15%23% for Rayong cultivars and 16% for KU 50.

With further growing time in the wet season, roots produced

starch with a peak viscosity higher than that of the 6th

month harvested sample; the percentage increased ranged

from 14%21%, when comparing the increase in peak visc-

osity between 6th and 16th month samples. Final viscosity

followed a similar trend to that of peak viscosity; being low

at 10th12th month, and becoming high again in the wet

season at 14th16th month. At age of 6th month, all culti-

vars showed the most susceptibility to breakdown and

setback, then the viscosity became more stable until the

age of 14th16thmonth. The change in breakdown and

setback was compatible with the change in peak and nal

viscosity of starch solutions, and also the amylose content,

implying a relation between pasting properties and amylose

content. The root at 6th month contained high amylose

content (21%24%), and produced starch with high nal

viscosity and setback. Amylose content of starch decreased

later during the dry period, and was also lower in nal

viscosity and setback. Starch content of the roots was also

lowest at 10 months, suggesting utilization of starch by the

plant with the onset of rain, immediately post dry period

(Table 2). It is reasonable to assume that the internal archi-

tecture of the granules will be different, as they will contain

a lower proportion of amorphous material. These structural

changes are assumed to impact on the functional properties

of the starch and are presently being studied.

4. Conclusions

Previous work has shown differences between starch

harvested at two extreme times, but the current work

suggests that starch properties can change in mid-cycle.

Results of this study also show that starch granules differ

in their response to water uptake and consequent gelatiniza-

tion depending on the environmental conditions at the time

of harvest, expressed as a change in peak prole obtained by

thermal analysis for samples harvested at 14th and 16th

month. This change is similar to that seen when moisture

content is reduced. The precise mechanism is not known,

and is not evident at higher or lower moisture content. This

effect is therefore subtle, but real, and can be assumed to

arise from structural differences, which give rise to apparent

variation in the rate of hydration for late harvest samples.

All the cultivars examined show this phenomenon. In a

similar manner the size distribution prole of the granules

changed from a normal distribution, gradually developing

into a bimodal distribution. Again the mechanism is not

known, and we are unable to speculate whether the two

phenomena are related.

This study also suggests that starch extracted from roots

harvested late will have good pasting and swelling proper-

ties. This may be related to the large amylose size in these

starches or greater proportion of amylopectin. The dry

season has an impact on starch properties, as does the

immediate onset of the rainy season. We would therefore

recommend based on these ndings that starch be extracted

from either early or very late harvested roots.

The work reported in this article forms part of a more

detailed project to probe the structure-function relationships

of cassava starch, future efforts will involve the production

of cassava under controlled environmental conditions with

subsequent isolation and characterization of structural or

functional features of the starch unique to a particular set

of environmental conditions.

Acknowledgements

This work was kindly supported by Thai Tapioca Devel-

opment Institute (TTDI) and National Center for Genetic

Engineering and Biotechnology (BIOTEC), Ministry of

Science, Technology and Environment, Thailand. Technical

K. Sriroth et al. / Carbohydrate Polymers 38 (1999) 161170 169

assistance of Miss Lee Woan Ping, National University of

Singapore is gratefully acknowledged.

References

Asaoka, M., Blanshard, J. M. V., & Rickard, J. E. (1992). Effects of cultivar

and growth season on the gelatinization properties of casava starch.

Journal Science Food & Agriculture, 59, 5358.

Asaoka, M., Okumo, K., Sugimoto, Y., & Fuwa, H. (1985). Developmental

changes in the structure of endosperm starch of rice (Oryza sativa L.).

Agric. Biol. Chem., 49, 19731978.

Association of Ofcial Analytical Chemists (AOAC) (1990). Ofcial

method of analysis (15th ed.). Virginia: The Association of Ofcial

Agricultural Chemists.

Baldwin, P. M. (1994). Holes in starch granules: confocal. SEM and light

microscopy studies of starch granule structure. Starch/Starke, 46, 341

346.

Brautlecht, C.A. (1953). Starch: its sources, production and uses. New

York: Reinhold.

Food and Agricultural Organization of the United Nations. 1988 Specica-

tions for Identity and Purity. FAO Food and Nutrition Paper.

Geddes, R., Greenwood, C. T., & Mackenzie, S. (1965). Studies on the

biosynthesis of starch granules. Carbohydrate Research, 1, 7182.

Govindasamy, S., Oates, C. G., & Wong, H. W. (1992). Characterisation of

changes of sago starch components during hydrolysis by thermostable

alpha-amylase. Carbohydrate Polymers, 18, 89100.

Inouchi, N., Glover, D. V., Sugimoto, Y., & Fuwa, H. (1984). Develop-

mental changes in starch properties of several endosperm mutants of

maize. Starch/Starke, 36, 812.

Noda, T., Takahatana, Y., & Nagata, T. (1992). Developmental changes in

properties of sweet potato starches. Starch/Starke, 44, 405409.

Rickard, J. R., Asoaka, M. A., & Blanashard, J. M. V. (1991). The physi-

cochemical properties of cassava starch. Tropical Science, 31, 189

207.

Rodjanaridpiched, C., Limsila, A., Suprahan, D., Boonsenf, O., Poolsan-

guan, P., Tiraporn, C., & Kawano, K. (1993). Recent progress in

cassava varietal improvement in Thailand. In R.H. Howelr (Ed.),

Cassava breeding, agronomy research and technology transfer in

Asia, Proc. 4th Regional workshop held in Trivandrum, India (pp.

125134).

Schoch, T.J. (1964) Swelling power and solubility of granular starches. In

R.L. Whistler, R.J. Smith, & J.N. Be Miller (Eds.) Methods in

Carbohydrate Chemistry, Vol. 4. (pp. 106108). New York: Academic

Press.

Yamada, S., Nagashima, N., & Kawabata, A. (1987). Thermal properties of

some tropical starches by differential scanning calorimetry. Journal

Home Econ. Japan., 38, 647.

K. Sriroth et al. / Carbohydrate Polymers 38 (1999) 161170 170

Você também pode gostar

- 20 Paleo AIP Sweet Things by Sophie Van TiggelenDocumento28 páginas20 Paleo AIP Sweet Things by Sophie Van TiggelenMihaela Lucia Baragan100% (1)

- VCA of Banana Cardava (Mindanao)Documento88 páginasVCA of Banana Cardava (Mindanao)lani_concepcion100% (1)

- Fermented Cassava NewDocumento2 páginasFermented Cassava NewYanisNuranaAinda não há avaliações

- Lightning Protection Systems - Advantages and Disadvantages PDFDocumento11 páginasLightning Protection Systems - Advantages and Disadvantages PDFwahyuthp43Ainda não há avaliações

- AFA With AnswersDocumento17 páginasAFA With AnswersLovely day ybanezAinda não há avaliações

- Work ImmersionDocumento90 páginasWork ImmersionJen Amor Revaula100% (1)

- Malokun Festival and Practices Among The Mahin OnDocumento12 páginasMalokun Festival and Practices Among The Mahin OnS.A. KaluAinda não há avaliações

- National Cassava Policy 2020-2025: Royal Government of CambodiaDocumento52 páginasNational Cassava Policy 2020-2025: Royal Government of CambodiaBORINHYAinda não há avaliações

- Biomass Business Opportunities in Vietnam eDocumento85 páginasBiomass Business Opportunities in Vietnam eTuấn Thế Nguyễn100% (1)

- In AustraliaDocumento5 páginasIn AustraliaMannekkeAinda não há avaliações

- 7Documento13 páginas7thechezzmazterAinda não há avaliações

- Effect of Harvesting Time On Yield, Composition and Forage Quality of Some Forage Sorghum CultivarsDocumento8 páginasEffect of Harvesting Time On Yield, Composition and Forage Quality of Some Forage Sorghum Cultivarsarid132Ainda não há avaliações

- Kidney BeanDocumento18 páginasKidney BeanLuis10301Ainda não há avaliações

- Physiological Alterations in Wheat DuringDocumento9 páginasPhysiological Alterations in Wheat DuringWaqas AhmadAinda não há avaliações

- Sanjivani C. Karne, Et AlDocumento10 páginasSanjivani C. Karne, Et AlGaurav RajputAinda não há avaliações

- An Evaluation of The Yield of Corn (Zea Mays L.) and Bean (Phaseolus Vulgaris) IntercropDocumento5 páginasAn Evaluation of The Yield of Corn (Zea Mays L.) and Bean (Phaseolus Vulgaris) Intercrophaidhar grandeAinda não há avaliações

- NK Pareek JSWCDocumento5 páginasNK Pareek JSWCKushika AroraAinda não há avaliações

- 10 NK PareekDocumento5 páginas10 NK PareekKushika AroraAinda não há avaliações

- Studies On Seed Priming With Hydrogen Peroxide For Mitigating Salt Stress in RiceDocumento6 páginasStudies On Seed Priming With Hydrogen Peroxide For Mitigating Salt Stress in Riceshiksha torooAinda não há avaliações

- 10 JTAS Vol.18 (2) 1995 (PG 141-147)Documento7 páginas10 JTAS Vol.18 (2) 1995 (PG 141-147)SF MasturahAinda não há avaliações

- Effect of Soil Salinity On The Yield and Yield ComDocumento7 páginasEffect of Soil Salinity On The Yield and Yield ComAdrian BrownAinda não há avaliações

- MSRC Proposal StrawberryDocumento13 páginasMSRC Proposal StrawberryEdgel O. EscomenAinda não há avaliações

- Comparative Study On Growth and Yield PerformanceDocumento9 páginasComparative Study On Growth and Yield PerformancekingwinyashAinda não há avaliações

- Effect of Different Levels of NPK Fertilizers On The Growth and Yield of Greenhouse Cucumber (Cucumis) by Using Drip Irrigation TechnologyDocumento11 páginasEffect of Different Levels of NPK Fertilizers On The Growth and Yield of Greenhouse Cucumber (Cucumis) by Using Drip Irrigation Technologyjeymararizalapayumo.bascAinda não há avaliações

- SoyabeanRama 2021Documento10 páginasSoyabeanRama 2021marielmaigue02Ainda não há avaliações

- Germination Behavior of Jatropha Curcas L. After Different Imbibition TimesDocumento7 páginasGermination Behavior of Jatropha Curcas L. After Different Imbibition Timesrocio quispe cruzAinda não há avaliações

- Ecobios Paper ......... PDFDocumento10 páginasEcobios Paper ......... PDFhrishikesh08Ainda não há avaliações

- Effect of Temperature, Relative Humidity and Moisture Content On Germination Percentage of Wheat Stored in Different Storage StructuresDocumento9 páginasEffect of Temperature, Relative Humidity and Moisture Content On Germination Percentage of Wheat Stored in Different Storage StructuresRevathi SoundiranAinda não há avaliações

- The Sprout Production and Water Use Efficiency of Some Barley Cultivars Under Intensive Hydroponic SystemDocumento10 páginasThe Sprout Production and Water Use Efficiency of Some Barley Cultivars Under Intensive Hydroponic SystemKasaye AssefaAinda não há avaliações

- Chemical and Physical Characteristics of Cocopeat-Based Media Mixtures and Their Effects On The Growth and Development of Celosia CristataDocumento10 páginasChemical and Physical Characteristics of Cocopeat-Based Media Mixtures and Their Effects On The Growth and Development of Celosia CristataGeofrey GodfreyAinda não há avaliações

- 124220120406Documento13 páginas124220120406Siska B SiregarAinda não há avaliações

- Moskito Thesis 2Documento29 páginasMoskito Thesis 2Andrei Vista BatallaAinda não há avaliações

- 1 s2.0 S2666154323003794 MainDocumento9 páginas1 s2.0 S2666154323003794 Mainbse.imane8Ainda não há avaliações

- Germination Behavior of Jatropha Curcas L. After Different Imbibition TimesDocumento7 páginasGermination Behavior of Jatropha Curcas L. After Different Imbibition Timesp3dr0javaAinda não há avaliações

- Quality Traits of SoybeanDocumento9 páginasQuality Traits of SoybeanWaqas AhmadAinda não há avaliações

- Biofertilzer Application)Documento10 páginasBiofertilzer Application)ahmad baqir taqiyAinda não há avaliações

- 10Documento4 páginas10HadjerAinda não há avaliações

- Boussakouran2019 Article MorphologicalTraitsAssociatedWDocumento9 páginasBoussakouran2019 Article MorphologicalTraitsAssociatedWAizaz AliAinda não há avaliações

- ICMV 221 Drought TolerantDocumento10 páginasICMV 221 Drought Tolerant10sgAinda não há avaliações

- Agri Sci - IJASR - Effect of Salt Stress On Physiological - Ferdaous ManiDocumento14 páginasAgri Sci - IJASR - Effect of Salt Stress On Physiological - Ferdaous ManiTJPRC PublicationsAinda não há avaliações

- Effect of Variety and Seed Rate On Hydroponic Maize Fodder Biomass Yield, Chemical Composition, and Water Use EfficiencyDocumento14 páginasEffect of Variety and Seed Rate On Hydroponic Maize Fodder Biomass Yield, Chemical Composition, and Water Use EfficiencyPonechor HomeAinda não há avaliações

- Yield and Fruit Quality in Processing Tomato UnderDocumento8 páginasYield and Fruit Quality in Processing Tomato UnderTuấnAnhTrầnAinda não há avaliações

- Pakistan-Evaluation of Soybean Genotypes For Yield and Other Economically Important Traits Under Rainfed ConditionDocumento8 páginasPakistan-Evaluation of Soybean Genotypes For Yield and Other Economically Important Traits Under Rainfed ConditionWaqas AhmadAinda não há avaliações

- Mohan KumarDocumento8 páginasMohan KumarMuthu KumarAinda não há avaliações

- Influence-Of-Organic-Manures-On-Carrot-Daucus-Carota-L-Crops-Grown-In-A-Long-Term-Field-Experiment-In-Sweden 1Documento11 páginasInfluence-Of-Organic-Manures-On-Carrot-Daucus-Carota-L-Crops-Grown-In-A-Long-Term-Field-Experiment-In-Sweden 1NDANYUZWE HeritierAinda não há avaliações

- 10379-Article Text-9966-1-10-20170703Documento8 páginas10379-Article Text-9966-1-10-20170703Olatunde PedroAinda não há avaliações

- Morphological and Biochemical Responses of Sorghum Bicolor (L.) Moench Under Drought StressDocumento12 páginasMorphological and Biochemical Responses of Sorghum Bicolor (L.) Moench Under Drought StressKhadijaAinda não há avaliações

- WheatDocumento5 páginasWheatLokesh ChaudharyAinda não há avaliações

- Al-Maskri Et Al 2010Documento5 páginasAl-Maskri Et Al 2010Gabriela Arrieta VelaAinda não há avaliações

- 6 Naeem Et Al 2018 (Drip Fertigation Technology For Enhancing Date Pal... )Documento9 páginas6 Naeem Et Al 2018 (Drip Fertigation Technology For Enhancing Date Pal... )suggyAinda não há avaliações

- Growth Response of Pre-Sprouted Seedlings of Sugarcane in The Presence of The Bacterium Herbarspirillum FrisingenseDocumento5 páginasGrowth Response of Pre-Sprouted Seedlings of Sugarcane in The Presence of The Bacterium Herbarspirillum FrisingenseIJEAB JournalAinda não há avaliações

- To PrintDocumento5 páginasTo PrintGebrelle CastilloAinda não há avaliações

- 1 s2.0 S2095311916614417 MainDocumento9 páginas1 s2.0 S2095311916614417 MainJhivanAinda não há avaliações

- Cultivation of Calocybe Indica (P & C) in Konkan Region of Maharashtra, IndiaDocumento6 páginasCultivation of Calocybe Indica (P & C) in Konkan Region of Maharashtra, IndiaAbhijit JadhavAinda não há avaliações

- The Growth and Yield of Sweet Corn As Affected by Palm-Oil Sludge and Liquid Organic FertilizerDocumento6 páginasThe Growth and Yield of Sweet Corn As Affected by Palm-Oil Sludge and Liquid Organic FertilizerajmrdAinda não há avaliações

- Acta Phyisology Planturam Chickpea GA3Documento10 páginasActa Phyisology Planturam Chickpea GA3Tariq AzizAinda não há avaliações

- 08Documento6 páginas08Muhammad SarwarAinda não há avaliações

- Squash (Cucurbita Pepo L.) Growth and Yield in Response To Different Types of Fertilizers (Farmyard, Chicken Manures, Urea and NPK Granules)Documento126 páginasSquash (Cucurbita Pepo L.) Growth and Yield in Response To Different Types of Fertilizers (Farmyard, Chicken Manures, Urea and NPK Granules)Anonymous V53hX2nrTAinda não há avaliações

- Usha Et Al 2024 - IJECCDocumento9 páginasUsha Et Al 2024 - IJECCsbpatil84_885356542Ainda não há avaliações

- Entin Zubaedah (14320055)Documento4 páginasEntin Zubaedah (14320055)Entin ZAinda não há avaliações

- Investigation of Seed Priming On Some Germination Aspects of Different Canola CultivarsDocumento5 páginasInvestigation of Seed Priming On Some Germination Aspects of Different Canola CultivarsHamza bukhariAinda não há avaliações

- Fagodiya Et Al., 2017 (IJCMAS) Impacts of Short-Term Sequential Stresses On Maize (Zea Mays L.) and Its Simulation Using Info Crop-Maize ModelDocumento11 páginasFagodiya Et Al., 2017 (IJCMAS) Impacts of Short-Term Sequential Stresses On Maize (Zea Mays L.) and Its Simulation Using Info Crop-Maize ModelgorditoAinda não há avaliações

- 140 MichaelDocumento8 páginas140 MichaelfatmawatiAinda não há avaliações

- Agronomic and Phytochemical Characterization of CaiguaDocumento6 páginasAgronomic and Phytochemical Characterization of Caiguaquiron333Ainda não há avaliações

- E1f5 PDFDocumento10 páginasE1f5 PDFimellia deviAinda não há avaliações

- Effect of Different Transplanting Depth On The GrowthDocumento12 páginasEffect of Different Transplanting Depth On The GrowthPORTERA, JOHN CARLO PASION.Ainda não há avaliações

- Green Manure in CoconutDocumento4 páginasGreen Manure in CoconutNandakumar PalaparambilAinda não há avaliações

- From Seed to Harvest : Expert Insights into Gardening TechniquesNo EverandFrom Seed to Harvest : Expert Insights into Gardening TechniquesAinda não há avaliações

- Plants From Pitlakes: An inventory of plants from the pitlakes of Eastern Coalfields, IndiaNo EverandPlants From Pitlakes: An inventory of plants from the pitlakes of Eastern Coalfields, IndiaAinda não há avaliações

- Measurement of The Starch Content of Commercial Starches PDFDocumento3 páginasMeasurement of The Starch Content of Commercial Starches PDFwahyuthp43Ainda não há avaliações

- Impact of The Political Context On Foreign Policy Decision-Making PDFDocumento24 páginasImpact of The Political Context On Foreign Policy Decision-Making PDFwahyuthp43Ainda não há avaliações

- International Decision Making - Leadership Matters PDFDocumento15 páginasInternational Decision Making - Leadership Matters PDFwahyuthp43100% (1)

- Size and Foreign Policy Behavior - A Test of Two Models PDFDocumento22 páginasSize and Foreign Policy Behavior - A Test of Two Models PDFwahyuthp43Ainda não há avaliações

- BM Iii (Tpa)Documento29 páginasBM Iii (Tpa)wahyuthp43Ainda não há avaliações

- Mainstreaming - A Study of The Variables Affecting Teacher Attitude PDFDocumento11 páginasMainstreaming - A Study of The Variables Affecting Teacher Attitude PDFwahyuthp43Ainda não há avaliações

- Management Strategy in A Large Accounting Firm PDFDocumento12 páginasManagement Strategy in A Large Accounting Firm PDFwahyuthp43Ainda não há avaliações

- Lean Software Development - A Tutorial PDFDocumento7 páginasLean Software Development - A Tutorial PDFwahyuthp43100% (1)

- Liquid Membranes For Gas Vapor Separations PDFDocumento11 páginasLiquid Membranes For Gas Vapor Separations PDFwahyuthp43Ainda não há avaliações

- Learning Strategies in Instrumental Music PDFDocumento17 páginasLearning Strategies in Instrumental Music PDFwahyuthp43Ainda não há avaliações

- Pengaruh Defatting, Frekuensi Pencucian Dan Jenis Dryoprotectant Terhadap Mutu Tepung Surimi Ikan Lele Kering BekuDocumento10 páginasPengaruh Defatting, Frekuensi Pencucian Dan Jenis Dryoprotectant Terhadap Mutu Tepung Surimi Ikan Lele Kering Bekuwahyuthp43Ainda não há avaliações

- Performance Evaluation of Root Crop HarvestersDocumento15 páginasPerformance Evaluation of Root Crop HarvestersIJERDAinda não há avaliações

- Group 9 LAS 1Documento20 páginasGroup 9 LAS 1Sharyn BarinoAinda não há avaliações

- Extraction and Scanning Electron Microscopic Studies Of: Curcuma Angustifolia Roxb. StarchDocumento4 páginasExtraction and Scanning Electron Microscopic Studies Of: Curcuma Angustifolia Roxb. StarchsandhyAinda não há avaliações

- Game Changer Cassava VarietyDocumento15 páginasGame Changer Cassava VarietyWillis LavisAinda não há avaliações

- Sopa de MondongoDocumento4 páginasSopa de MondongoK-rina G-lezAinda não há avaliações

- Bahasa Inggris: Text 1Documento8 páginasBahasa Inggris: Text 1suhardiAinda não há avaliações

- PB Heavy Metal Pollution in Plants in Ex-Coal Mining AreasKutai Kertanegara East Kalimantan IndonesiaDocumento2 páginasPB Heavy Metal Pollution in Plants in Ex-Coal Mining AreasKutai Kertanegara East Kalimantan IndonesiaInternational Journal of Innovative Science and Research TechnologyAinda não há avaliações

- F201contaminants and Natural ToxicantsDocumento8 páginasF201contaminants and Natural Toxicantsbelas728Ainda não há avaliações

- HRM 482 - Ass, Data Collection & AnalysisDocumento6 páginasHRM 482 - Ass, Data Collection & Analysismartin sirifaveAinda não há avaliações

- Nutritional and Anti-Nutritional Evaluation of Garri Processed by Traditional and Instant Mechanical MethodsDocumento14 páginasNutritional and Anti-Nutritional Evaluation of Garri Processed by Traditional and Instant Mechanical MethodsBienvenu KakpoAinda não há avaliações

- A Study On Moringa Oleifera Leaves As A Supplement To West African Weaning Foods BA - Kayi - Kristina - KoueviDocumento72 páginasA Study On Moringa Oleifera Leaves As A Supplement To West African Weaning Foods BA - Kayi - Kristina - KoueviNutri MoringaAinda não há avaliações

- CassavaDocumento18 páginasCassavabocAinda não há avaliações

- Morphological and Physiological Characters of Cassava (Manihot Esculenta Crantz) Which Wet TolerantDocumento4 páginasMorphological and Physiological Characters of Cassava (Manihot Esculenta Crantz) Which Wet TolerantShelina ObnimagaAinda não há avaliações

- Effect of Biodegradation by Lactic Acid Bacteria On Physical Properties of Cassava StarchDocumento6 páginasEffect of Biodegradation by Lactic Acid Bacteria On Physical Properties of Cassava Starchrizki30kiAinda não há avaliações

- Major Process in Making Cassava 1. Bioplastic PreparationDocumento4 páginasMajor Process in Making Cassava 1. Bioplastic PreparationjjAinda não há avaliações

- Making Sweet Potato Chips and FlourDocumento8 páginasMaking Sweet Potato Chips and FlourErick Villacorta100% (1)

- Flow Process - Cassava Chips General - XXXXDocumento1 páginaFlow Process - Cassava Chips General - XXXXPriyatno SusiloAinda não há avaliações

- Amazon: The Rainforest RiverDocumento12 páginasAmazon: The Rainforest RiverSudarshan S KAinda não há avaliações

- PearsallDocumento46 páginasPearsallManuel AndradeAinda não há avaliações

- Microbial Biotechnology and Industrial ApplicationDocumento13 páginasMicrobial Biotechnology and Industrial ApplicationinnocentAinda não há avaliações

- Report47 WaterFootprintCrops Vol1Documento42 páginasReport47 WaterFootprintCrops Vol1Veer BharatAinda não há avaliações

- Women-Farmers Productivity in Sub Saharan AfricaDocumento9 páginasWomen-Farmers Productivity in Sub Saharan Africaapi-240305975Ainda não há avaliações