Escolar Documentos

Profissional Documentos

Cultura Documentos

Cooling Tower TNC

Enviado por

Aarol Hatta100%(1)100% acharam este documento útil (1 voto)

106 visualizações6 páginasThe document discusses testing and commissioning procedures for cooling tower systems. It states that testing and commissioning must be witnessed by a registered professional engineer and recommends personal protective equipment for safety. Guidelines are provided for maintaining design and commissioning records, as well as operation and maintenance manuals, and qualified engineers must design the systems. Sample checklists are included to test physical components, thermal performance, fans, electricity, and safety equipment.

Descrição original:

Part 1: Design, Installation and Commissioning of Cooling Towers

Título original

Cooling Tower TnC

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoThe document discusses testing and commissioning procedures for cooling tower systems. It states that testing and commissioning must be witnessed by a registered professional engineer and recommends personal protective equipment for safety. Guidelines are provided for maintaining design and commissioning records, as well as operation and maintenance manuals, and qualified engineers must design the systems. Sample checklists are included to test physical components, thermal performance, fans, electricity, and safety equipment.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

100%(1)100% acharam este documento útil (1 voto)

106 visualizações6 páginasCooling Tower TNC

Enviado por

Aarol HattaThe document discusses testing and commissioning procedures for cooling tower systems. It states that testing and commissioning must be witnessed by a registered professional engineer and recommends personal protective equipment for safety. Guidelines are provided for maintaining design and commissioning records, as well as operation and maintenance manuals, and qualified engineers must design the systems. Sample checklists are included to test physical components, thermal performance, fans, electricity, and safety equipment.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 6

Code of Practice for Water-cooled Air Conditioning Systems

Part 1: Design, Installation and Commissioning of Cooling Towers

2006 Edition (Jan.2007) 27

8. Testing and Commissioning of Cooling Tower Systems

8.1 Testing and Commissioning

Testing and commissioning of cooling tower shall be witnessed by a registered

professional engineer (RPE) in building services engineering or mechanical

engineering discipline. A sample checklist for testing and commissioning of cooling

tower system can be referred to Appendix 1C.

8.2 Occupational Safety and Health

8.2.1 Sufficient personal protective equipment shall be provided to the personnel

responsible to carry out testing and commissioning work of a cooling tower system.

Recommended list of personal protective equipment required related to different

job nature is shown in Appendix 1D.

8.2.2 Eye wash bottles or washing basin with fresh water tap shall be provided adjacent

to water treatment chemicals tanks or any appropriate location for emergency use.

However, the water contained in the eye wash bottle shall be replaced periodically.

8.2.3 Water treatment chemical shall be stored at an appropriate location to facilitate

chemical handling.

8.2.4 Mechanical / natural ventilation shall be provided to the room entirely / partially

used for water treatment chemical storage.

8.2.5 Electrical fittings and luminaries serving water treatment chemical storage area shall

be weather-proof and corrosion resistant type.

Code of Practice for Water-cooled Air Conditioning Systems

Part 1: Design, Installation and Commissioning of Cooling Towers

2006 Edition (Jan.2007) 28

9 Design and Commissioning Records

9.1 Formal design and commissioning records of a cooling tower system shall be kept

by the cooling tower owner for the whole life of the system. The records shall be

made available for inspections upon request by Government appointed officials.

The record shall include, but not limited to the following:

a) The name, contact phone and address of the owner of the cooling tower

system;

b) The name, contact phone and address of the cooling tower specialist

contractor(s) (CTSC), who is responsible for the design, installation, testing

and commissioning of the cooling tower system;

c) Design details of the cooling tower system;

d) Descriptions of the cooling towers and water treatment equipment, including

their locations, technical specifications, models, capacities and year of

manufacture / installation as well as correct operation procedure;

e) Testing results of all equipment in the cooling tower system; and

f) Water sampling results.

9.2 The operation and maintenance (O&M) manual of the cooling tower system shall

be prepared by the cooling tower specialist contractor and kept by the cooling

tower system owner. The O&M manual shall at least consist of the followings:

a) Technical details of all equipment in a cooling tower system, including

drawings of the plant, equipment and systems;

b) System schematic and layout plan showing the locations of cooling towers

and the nearby openings in the building and the adjacent buildings;

c) Manufacturers recommendations on operation and maintenance of all

equipment in the cooling tower system;

d) A programme for routine chemical treatment, cleaning, desludging and

disinfection of the cooling tower;

e) Details of water chemicals used for water treatment;

f) Recommended cleaning methods and dismantling instructions; and

g) Start-up, operating and shut-down procedures.

Code of Practice for Water-cooled Air Conditioning Systems

Part 1: Design, Installation and Commissioning of Cooling Towers

2006 Edition (Jan.2007) 29

10 Qualification of System Designer

Water-cooled air conditioning system shall be designed by a registered professional

engineer (RPE) in building services engineering or mechanical engineering discipline.

Code of Practice for Water-cooled Air Conditioning Systems

Part 1: Design, Installation and Commissioning of Cooling Towers

2006 Edition (Jan.2007) 36

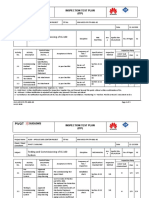

Appendix 1C

Sample Checklist for Minimum Testing and Commissioning Procedures of Water-

cooled Air Conditioning Systems

Building Name :

Cooling Tower Designation :

Cooling Tower Type :

Manufacturer / Model No. :

Location :

A. Physical Check

Items Accepted Not Accepted

1. General Condition of Unit

2. Cleanliness of basin

3. Fixing of Drift Eliminator

4. Fixing of Fill

5. Fans Rotation without Obstruction

6. Fan & Pump Motor for Proper Rotation

7. Noise / Vibration

8. Drive Alignment / Belt Tension

9. Other Components, Bolts, Fixing, etc.

10. Bearings Lubrication

11. Drainage & Fall

12. Strainer Cleanliness

13. Ball Valve Function

14. Tower Water Level

15. Water Distribution

16. Water Treatment Equipment

17. Electrical Supply Connection

18. Earth Bonding

B. Cooling Tower Thermal Performance Check

Parameters Unit Design Data Test Results

1. Heat Rejection Capacity kW

2. Air Flowrate m

3

/s

3. Entering Air Dry Bulb Temperature

C

4. Entering Air Wet Bulb Temperature

C

5. Leaving Air Dry Bulb Temperature

C

6. Leaving Air Wet Bulb Temperature

C

7. Cooling Water Flow Rate L/s

8. Cooling Water Entering Temperature

C

9. Cooling Water Leaving Temperature

C

10. Make-up Water Quantity L/s

11. Constant Bleed Water Quantity L/s

Code of Practice for Water-cooled Air Conditioning Systems

Part 1: Design, Installation and Commissioning of Cooling Towers

2006 Edition (Jan.2007) 37

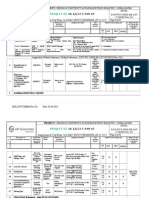

C. Cooling Tower Fan Check

Parameters Unit Design Data Test Results

1. Fan Type -

2. Fan Diameter m

3. Fan Volume m

3

/s

4. Fan Power kW

5. Fan Pressure Pa

D. Cooling Tower Electrical Test

Parameters Unit Design Data Test Results

1. Supply Voltage V

2. Motor Starting Current A

3. Motor Running Current A

4. Motor / Fan Speed rpm

5. Phase Phase Motor Insulation

(RY/YB/BR)

M

6. Phase Earth Motor Insulation

(RY/YB/BR)

M

7. Motor Starter Type -

Code of Practice for Water-cooled Air Conditioning Systems

Part 1: Design, Installation and Commissioning of Cooling Towers

2006 Edition (Jan.2007) 38

Appendix 1D

Recommended List of Personal Protective Equipment

Job Potential Hazard Respirator and Clothing

Testing and commissioning Aerosol Half face piece, capable of filtering

smaller than 5m particulates, ordinary

work clothing

Inspection Aerosol Half face piece, capable of filtering

smaller than 5m particulates, ordinary

work clothing

Water Sampling Aerosol Half face piece, capable of filtering

smaller than 5m particulates, ordinary

work clothing

High pressure spraying Aerosol Respirator as above, waterproof overalls,

gloves, boots, goggles or face shield

Chemical treatment with sodium

hypo-chlorite solution in

ventilated space

Spray mist and very low

concentration chlorine

Half face piece, acid gas and particulate

respirator, goggles or face shield,

overalls, gloves, and boots

As above, confined space Unknown chlorine

concentration, high mist,

possible lack of oxygen

To comply with the requirement under

The Factories and Industrial

Undertakings (Confined Spaces)

Regulation

Você também pode gostar

- Fan Coil Unit Installation Check ListDocumento5 páginasFan Coil Unit Installation Check ListAkshay GarudAinda não há avaliações

- Fcu Method StatementDocumento3 páginasFcu Method StatementBalajiAinda não há avaliações

- Mels Constuction Limitada: Commercial Management Mechanical Completion CertificateDocumento1 páginaMels Constuction Limitada: Commercial Management Mechanical Completion CertificateDeonAinda não há avaliações

- Method Statement For HoistingDocumento5 páginasMethod Statement For HoistingKAY UNAAinda não há avaliações

- PC - EXHAUST FANS ID #'SDocumento3 páginasPC - EXHAUST FANS ID #'SAbdul Mohid SheikhAinda não há avaliações

- 7104 - PW - TRC001-D Inspection & Test PlanDocumento6 páginas7104 - PW - TRC001-D Inspection & Test PlanPaul KwongAinda não há avaliações

- HVAC System: Exhaust FanDocumento4 páginasHVAC System: Exhaust FanAnsari1918Ainda não há avaliações

- Technical Compliance Sheet Butterfly ValveDocumento5 páginasTechnical Compliance Sheet Butterfly Valvebiswasdipankar05Ainda não há avaliações

- Evaluations of VendorsDocumento4 páginasEvaluations of VendorsWael_Barakat_3179Ainda não há avaliações

- Testing and Commissioning of IG 100 System: Inspection Test Plan (ITP)Documento3 páginasTesting and Commissioning of IG 100 System: Inspection Test Plan (ITP)Samboy DionisioAinda não há avaliações

- Commissioning Plan: File Reference: Xxxx/Yyyy/ZzDocumento6 páginasCommissioning Plan: File Reference: Xxxx/Yyyy/ZzRaghavendraAinda não há avaliações

- Installation of Underground Drainage Piping: ChecklistDocumento1 páginaInstallation of Underground Drainage Piping: Checklistakash nairAinda não há avaliações

- Water Flushing Witnessing and TestDocumento3 páginasWater Flushing Witnessing and TestNeguib FarahAinda não há avaliações

- Installation Manual OXYFLEX® MF1100 October 2014 PDFDocumento8 páginasInstallation Manual OXYFLEX® MF1100 October 2014 PDFRomuel PioquintoAinda não há avaliações

- QIPDocumento9 páginasQIPzahid_497Ainda não há avaliações

- Msra T&C FM 200 SystemDocumento10 páginasMsra T&C FM 200 SystemSharvin NageebAinda não há avaliações

- Ahu ItpDocumento3 páginasAhu ItpMEELMAHDYAinda não há avaliações

- ITP For Cleaning Flushing & Chemical Dosing SystemDocumento1 páginaITP For Cleaning Flushing & Chemical Dosing SystemDong Vanra100% (1)

- 800D SeriesDocumento3 páginas800D Seriesvkeie0206Ainda não há avaliações

- F 04 SitehandoverDocumento2 páginasF 04 SitehandoverSpyros BibirisAinda não há avaliações

- Testing and Commissioning Check ListDocumento1 páginaTesting and Commissioning Check ListarifzakirAinda não há avaliações

- Check List For Sub Main Distribution Board InstallationDocumento2 páginasCheck List For Sub Main Distribution Board InstallationNaing Win TunAinda não há avaliações

- Tie in MosDocumento2 páginasTie in MosAAISATAinda não há avaliações

- Lockstop SDS GreenstreakDocumento8 páginasLockstop SDS Greenstreakrobox514Ainda não há avaliações

- Certificate Aboveground PipingDocumento5 páginasCertificate Aboveground Pipingsajeed76740Ainda não há avaliações

- MOS - Air Duct Cleaning & DisnfectionDocumento4 páginasMOS - Air Duct Cleaning & DisnfectionAmal SaAinda não há avaliações

- Project Schedule Unit 1Documento6 páginasProject Schedule Unit 1Keev LisAinda não há avaliações

- R07-HC3C05-FET-MTS-ME-0012 - C1 Method Statement For Installation of DX UnitsDocumento46 páginasR07-HC3C05-FET-MTS-ME-0012 - C1 Method Statement For Installation of DX Unitslike saddamAinda não há avaliações

- Method Statement For Ultrasonic Testing: DCSM Project 2019Documento5 páginasMethod Statement For Ultrasonic Testing: DCSM Project 2019Thinh NguyenAinda não há avaliações

- GREASE, SAND + OIL INTERCEPTORS Inspection Checklist V 1.0 - 201511041303368641Documento4 páginasGREASE, SAND + OIL INTERCEPTORS Inspection Checklist V 1.0 - 201511041303368641bradalbiAinda não há avaliações

- Final Report Fire Fighting EquipmentDocumento12 páginasFinal Report Fire Fighting Equipmentsharjeel39Ainda não há avaliações

- Precommision Cleaning of Piping SystemsDocumento10 páginasPrecommision Cleaning of Piping SystemsElias EliasAinda não há avaliações

- Weld Cleaning MethodsDocumento7 páginasWeld Cleaning MethodsTrần Thùy LinhAinda não há avaliações

- MSN 057 Solas II 2 Maintenance and Inspection of Fire Protection Systems and AppliancesDocumento14 páginasMSN 057 Solas II 2 Maintenance and Inspection of Fire Protection Systems and AppliancesJothimanikkam SomasundaramAinda não há avaliações

- EXW-P015-0000-QM-LNT-IT-00066 Rev CADocumento4 páginasEXW-P015-0000-QM-LNT-IT-00066 Rev CAbinunalukandamAinda não há avaliações

- MTS Check ListDocumento1 páginaMTS Check Listabdlelah.zreikAinda não há avaliações

- Handover To QAQC-Anand KumarDocumento6 páginasHandover To QAQC-Anand KumarAnonymous fBkcEze1Ainda não há avaliações

- Sprinkler and SystmesDocumento4 páginasSprinkler and SystmesridwanAinda não há avaliações

- Air Cooled Chiller ChecklistDocumento3 páginasAir Cooled Chiller ChecklistDevendra DhumalAinda não há avaliações

- Methodology For Installation of Fire Pro PDFDocumento4 páginasMethodology For Installation of Fire Pro PDFswamyAinda não há avaliações

- WPS Sa 517Documento2 páginasWPS Sa 517DHANANNJAI SINGH -Ainda não há avaliações

- Division 15 Mechanical IBS HVACDocumento164 páginasDivision 15 Mechanical IBS HVACmasahinAinda não há avaliações

- Project Name: Al Ruwais Housing Complex 663 Villas: ElectricalDocumento3 páginasProject Name: Al Ruwais Housing Complex 663 Villas: Electricalabdallah salama100% (1)

- Structural Inspection Checklist For FactoryDocumento1 páginaStructural Inspection Checklist For FactoryAnonymous FD64zqL6S100% (1)

- Samsung VRF Installation Trend For BuildingDocumento55 páginasSamsung VRF Installation Trend For BuildingNaseemAinda não há avaliações

- PC - Packaged DX Air Conditioning or Heat Pump, IdDocumento7 páginasPC - Packaged DX Air Conditioning or Heat Pump, Idsushilalway4uAinda não há avaliações

- ITR-B (Piping) Witness Joint1Documento1 páginaITR-B (Piping) Witness Joint1Momo ItachiAinda não há avaliações

- Aerosol System Functional Test QCDD FormDocumento3 páginasAerosol System Functional Test QCDD FormMahmoud HassanAinda não há avaliações

- SOP16 Testing of Fire Alarm SystemDocumento1 páginaSOP16 Testing of Fire Alarm Systemanil kumarAinda não há avaliações

- SKM Chiller Pre-Commissioning Check List Rev 20.06.2022Documento2 páginasSKM Chiller Pre-Commissioning Check List Rev 20.06.2022Riju Scaria/EMD/QTRAinda não há avaliações

- Disinfection Procedure For Water Distribution LinesDocumento3 páginasDisinfection Procedure For Water Distribution Linesfa forb100% (1)

- Standard Technical Requirements For Sub-Metering System: T D H B I A FDocumento25 páginasStandard Technical Requirements For Sub-Metering System: T D H B I A Fshadi sabikAinda não há avaliações

- Project: Project Name Site No.:: Commissioning Check Sheet For Chilled Water Pump Sheet NoDocumento24 páginasProject: Project Name Site No.:: Commissioning Check Sheet For Chilled Water Pump Sheet NoNay Win MaungAinda não há avaliações

- Subcontractor: Equipment / Ref.: Manufacturer: Model: Serial NoDocumento1 páginaSubcontractor: Equipment / Ref.: Manufacturer: Model: Serial NoAzwan SunlineAinda não há avaliações

- EEHA Inspection Sheet TemplateDocumento3 páginasEEHA Inspection Sheet Templatedavid.bradley83Ainda não há avaliações

- PHE Method StatementDocumento3 páginasPHE Method Statementzampacaanas0% (1)

- Air Conditioning System: Section 15 / 1Documento12 páginasAir Conditioning System: Section 15 / 1Ahmed Yousri AhmedAinda não há avaliações

- Method Statement For The Testing - Commissioning of FM 200 SystemDocumento6 páginasMethod Statement For The Testing - Commissioning of FM 200 SystemkiranramAinda não há avaliações

- CoP-Water Cool ACDocumento51 páginasCoP-Water Cool ACkevinbovoAinda não há avaliações

- Grasa LO 915Documento2 páginasGrasa LO 915Angelo Carrillo VelozoAinda não há avaliações

- Four Hour Body Experiment Tracker TemplateDocumento4 páginasFour Hour Body Experiment Tracker Templatechanellekristyweaver100% (1)

- Process Industry Practices Insulation: PIP INEG2000 Guidelines For Use of Insulation PracticesDocumento15 páginasProcess Industry Practices Insulation: PIP INEG2000 Guidelines For Use of Insulation PracticesZubair RaoofAinda não há avaliações

- EDB Postgres Failover Manager Guide v2.1Documento86 páginasEDB Postgres Failover Manager Guide v2.1Anggia MauritianaAinda não há avaliações

- Tourbier Renewal NoticeDocumento5 páginasTourbier Renewal NoticeCristina Marie DongalloAinda não há avaliações

- Jones Et - Al.1994Documento6 páginasJones Et - Al.1994Sukanya MajumderAinda não há avaliações

- Shift in Business Strategy of 10 Minute School - B2B To B2CDocumento40 páginasShift in Business Strategy of 10 Minute School - B2B To B2CSadiaAinda não há avaliações

- USDA List of Active Licensees and RegistrantsDocumento972 páginasUSDA List of Active Licensees and Registrantswamu885Ainda não há avaliações

- Biscotti: Notes: The Sugar I Use in France, Is CalledDocumento2 páginasBiscotti: Notes: The Sugar I Use in France, Is CalledMonica CreangaAinda não há avaliações

- Corporate Restructuring Short NotesDocumento31 páginasCorporate Restructuring Short NotesSatwik Jain57% (7)

- Friday 25 Mar 12:15 AM Friday 25 Mar 5:30 AM: Emirates CGK DXBDocumento3 páginasFriday 25 Mar 12:15 AM Friday 25 Mar 5:30 AM: Emirates CGK DXBDONI ARTAAinda não há avaliações

- Plant Report Template Class 81Documento2 páginasPlant Report Template Class 81Kamran KhanAinda não há avaliações

- Parker HPD Product Bulletin (HY28-2673-01)Documento162 páginasParker HPD Product Bulletin (HY28-2673-01)helden50229881Ainda não há avaliações

- The History of Music in Portugal - Owen ReesDocumento4 páginasThe History of Music in Portugal - Owen ReeseugenioamorimAinda não há avaliações

- 02 Chapter 2 - Corporate Governance MechanismDocumento19 páginas02 Chapter 2 - Corporate Governance MechanismHanis ZahiraAinda não há avaliações

- Em FlexicokingDocumento8 páginasEm FlexicokingHenry Saenz0% (1)

- CL200 PLCDocumento158 páginasCL200 PLCJavierRuizThorrensAinda não há avaliações

- Pautas Anatómicas para La Inserción de Minitornillos: Sitios PalatinosDocumento11 páginasPautas Anatómicas para La Inserción de Minitornillos: Sitios PalatinosValery V JaureguiAinda não há avaliações

- 7 ElevenDocumento80 páginas7 ElevenakashAinda não há avaliações

- Brochure GM Oat Technology 2017 enDocumento8 páginasBrochure GM Oat Technology 2017 enArlette ReyesAinda não há avaliações

- University Fees Structure (Himalayan Garhwal University) - UttarakhandDocumento1 páginaUniversity Fees Structure (Himalayan Garhwal University) - UttarakhandabhaybaranwalAinda não há avaliações

- Introduction To FluidizationDocumento9 páginasIntroduction To FluidizationEriCisacAinda não há avaliações

- Ariba Collaborative Sourcing ProfessionalDocumento2 páginasAriba Collaborative Sourcing Professionalericofx530Ainda não há avaliações

- Flip The Coin - EbookDocumento306 páginasFlip The Coin - EbookAjesh Shah100% (1)

- Forces L2 Measuring Forces WSDocumento4 páginasForces L2 Measuring Forces WSAarav KapoorAinda não há avaliações

- 03-F10 Planned Job ObservationDocumento1 página03-F10 Planned Job ObservationSn Ahsan100% (1)

- India Biotech Handbook 2023Documento52 páginasIndia Biotech Handbook 2023yaduraj TambeAinda não há avaliações

- Beamng DxdiagDocumento22 páginasBeamng Dxdiagsilvioluismoraes1Ainda não há avaliações

- Reproduction in PlantsDocumento12 páginasReproduction in PlantsAnand Philip PrasadAinda não há avaliações

- Lotus Exige Technical InformationDocumento2 páginasLotus Exige Technical InformationDave LeyAinda não há avaliações

- Arizona, Utah & New Mexico: A Guide to the State & National ParksNo EverandArizona, Utah & New Mexico: A Guide to the State & National ParksNota: 4 de 5 estrelas4/5 (1)

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoNo EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoNota: 5 de 5 estrelas5/5 (1)

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptNo EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptNota: 5 de 5 estrelas5/5 (1)

- New York & New Jersey: A Guide to the State & National ParksNo EverandNew York & New Jersey: A Guide to the State & National ParksAinda não há avaliações

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensNo EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensAinda não há avaliações