Escolar Documentos

Profissional Documentos

Cultura Documentos

Bahmanyar Et Al. - 2011 - The Influence of Nanoparticles On Hydrodynamic Characteristics and Mass Transfer Performance in A Pulsed Liquid-Liquid Extraction Column

Enviado por

Kita de AzevedoDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Bahmanyar Et Al. - 2011 - The Influence of Nanoparticles On Hydrodynamic Characteristics and Mass Transfer Performance in A Pulsed Liquid-Liquid Extraction Column

Enviado por

Kita de AzevedoDireitos autorais:

Formatos disponíveis

Please cite this article in press as: A. Bahmanyar, et al.

, The inuence of nanoparticles on hydrodynamic characteristics and mass transfer

performance in a pulsed liquidliquid extraction column. Chem. Eng. Process. (2011), doi:10.1016/j.cep.2011.08.008

ARTICLE IN PRESS

GModel

CEP-6047; No. of Pages 9

Chemical Engineering and Processing xxx (2011) xxxxxx

Contents lists available at SciVerse ScienceDirect

Chemical Engineering and Processing:

Process Intensication

j our nal homepage: www. el sevi er . com/ l ocat e/ cep

The inuence of nanoparticles on hydrodynamic characteristics and mass

transfer performance in a pulsed liquidliquid extraction column

Amir Bahmanyar

a

, Naseh Khoobi

b

, Mohammad Reza Mozdianfard

a

, Hossein Bahmanyar

c,

a

Separation Processes Research Group (SPRG), Department of Engineering, University of Kashan, Iran

b

Department of Chemical Engineering, Sharif University of Technology, Tehran, Iran

c

Surface Phenomena and Liquid-Liquid Extraction Research Laboratory, University of Tehran, Tehran, Iran

a r t i c l e i n f o

Article history:

Received 28 April 2011

Received in revised form4 August 2011

Accepted 16 August 2011

Available online xxx

Keywords:

Pulsed column

Dynamic hold-up

Static hold-up

Enhancement factor

Nanouids

a b s t r a c t

With respect to the inuence of nanoparticles on mass transfer characteristics, limited number of studies

available in the literature, deal primarily with gasliquid systems. In this work, mass transfer perfor-

mance and hydrodynamic characteristics including static and dynamic dispersed phase hold-ups of

nanouids have been investigated for pulsed liquidliquid extraction column (PLLEC). The nanouids

used were prepared by dispersing SiO

2

nanoparticles of 0.01, 0.05 and 0.1 volume percent with two

different hydrophobicities in kerosene as base uid using ultrasonication. UVvis spectrophotometer

was also used for evaluation of the nanouids stability. The results were compared with conditions of

no-nanoparticles in the dispersed phase and in the absence of mass transfer effect (no acetic acid as

solute). Different pulsation intensities were maintained for the xed mass ow rates of dispersed (Q

d

)

and continuous (Q

c

) phases (with ratio Q

c

/Q

d

= 1.2) with mass transfer direction being made from the

dispersed phase to the continuous one. The results indicate that in the presence of the nanouids, static

and dynamic dispersed phase hold-ups increased by 23398%, and 23257%, respectively, while mass

transfer performance was enhanced by 460%.

2011 Elsevier B.V. All rights reserved.

1. Introduction

Nanouids have been extensively studied within the last two

decades, primarily in association with their heat transfer enhance-

ment characteristics. Hence, classic metal conductive nanoparticles

such as Al and Cu [1] and their oxides [2] have been used with base

uids including water and ethylene glycol which have increased

thermal conductivity by 1540%. Some studies [3] have attempted

measurement of convective heat transfer coefcient, claimed to be

far moredifcult thanconductiveone[4] andreported60%increase

in the heat transfer coefcient [5]. These studies which are mostly

conducted in the laboratory scale have employed nanoparticles of

less than 100nm, 0.54 volume percent (vol%) and temperature

range of 2050

C.

The inuences of nanoparticles on heat transfer are reviewed

adequately in the literature [4,6]. However, by comparison, the

inuence of nanoparticles onmass transfer operations has received

much less attention. This approach has been initiated by con-

sideration of Brownian movement of the nanoparticles by some

researchers to be responsible as the primary factor in the enhance-

Corresponding author. Tel.: +98 21 61112213.

E-mail address: hbahmany@ut.ac.ir (H. Bahmanyar).

ment characteristics of nanouids in both convective [7] and

conductive [8] heat transfer.

Assuming convection and mass transfer to be similar in nature,

Krishnamurthy et al. [9] studied mass diffusion of uoresein dye in

nanouids by taking time-dependent images. Their images, illus-

trated much faster dye diffusion in nanouids than in pure water

and their calculations of mean displacement equation suggested

that the Brownian motion of the nanoparticles did not contribute

directly tothe mass transport enhancement; rather it is the velocity

disturbance eld in the uid, created by the motion of the nanopar-

ticles which is most likely responsible for such enhancement. In

other words, the enhancement in diffusivity is likely due to the

increased nanoscale stirring of the liquid, caused by the nanopar-

ticles Brownian motion. They also observed an unexpected clear

peak in the enhanced diffusivity of the dye in nanouid which they

could not justify.

In several previous studies [10,11], the effect of particles in

micron size have been investigated on bubble columns and adsorp-

tionoperations. Signicant enhancement of gas adsorption(usually

CO

2

) in various liquids has been attributed to grazing or shut-

tle mechanism [12] believed to be the transfer phenomenon

mechanism responsible for a gas from the gasliquid interface to

the bulk of the liquid [13]. With recent advancement in nano-

technology, previous micro-sized applications are being extended

to nanoparticles, and following meeting challenges such as

0255-2701/$ see front matter 2011 Elsevier B.V. All rights reserved.

doi:10.1016/j.cep.2011.08.008

Please cite this article in press as: A. Bahmanyar, et al., The inuence of nanoparticles on hydrodynamic characteristics and mass transfer

performance in a pulsed liquidliquid extraction column. Chem. Eng. Process. (2011), doi:10.1016/j.cep.2011.08.008

ARTICLE IN PRESS

GModel

CEP-6047; No. of Pages 9

2 A. Bahmanyar et al. / Chemical Engineering and Processing xxx (2011) xxxxxx

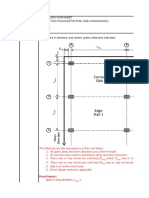

Fig. 1. Schematic of the pulsed liquidliquid extraction column used in this study.

stability of phase containing nanoparticles and agglomeration

diverse possible applications of nanoparticles in mass transfer

operations are being opened up. Falling lmowof binary nanou-

ids were studied by Kang et al. [13] who measured the vapor

absorption rate as well as heat transfer rate for falling lmow of

binary nanouids. They used H

2

O/LiBr solution with nanoparticles

of FeandCarbonnanotubes (CNT) withvarious concentrations of up

to 0.1wt% as their binary nanouids and found that vapor absorp-

tion rate increased with increasing the solution mass owrate and

the concentration of Fe and CNT nanoparticles. More importantly,

they illustrated that mass transfer enhancement due to nanoparti-

cles presence was much more signicant than that of heat transfer.

Oxygen-transfer enhancement in the presence of colloidal disper-

sions of magnetite (Fe

3

O

4

) nanoparticles coated with oleic acid is

also observed by Olle et al. [14] who claimed gasliquid oxygen

mass transfer improvement of up to 6-fold (600%) at nanoparti-

cle volume fractions below 1% in an agitated, sparged reactor and

reported enhancement of both mass transfer coefcient (K

d

) and

the gasliquid interfacial area (a) in the presence of nanoparticles.

Interestingly, the enhancement in K

d

leveled off at a nanoparticle

volume fraction of about 1% (v/v). In another study [15], however,

contrary to the above, gasliquid mass transfer coefcient in a

three-phase internal loop airlift reactor was reduced in the pres-

ence of TiO

2

nanoparticles. They blamed increased aggregation of

nanoparticles due to increased particle holdup, to be responsible

for adverse mass transport.

As far as hydrodynamic characteristics are concerned, Kimet al.

[16] examined the bubble behaviors during the bubble absorp-

tion process for 8.0% ammonia solution. They reported spherical

but smaller bubble sizes, increased residence time and 22% lower

speed of bubble rise in the presence of Cu nanoparticles of 0.1wt%,

while the bubble shape was hemi-spherical in the absence of

nanoparticles. Fan et al. [17] studied the anomalous gas holdup

and bubble behavior in a bubble column or a micro-channel with

the presence of silicon dioxide (SiO

2

) nanoparticles in water. They

observed reduction in bubble sizes and increase in the gas holdup

in the bubble column in the presence of nanoparticles at super-

cial gas velocities above 710cm/s. In another study, Feng et al.

[18] investigated volume fraction of 1.13.3% hydrophobic TiO

2

nanoparticles inwater andcontrary to the above reporteda general

trend of decreased gas holdup with increasing volume fraction of

the nanoparticles.

As can be seen the above work on the application of nanouids

onmass transfer has dealt withgasliquidsystems, wherenanopar-

ticles are added to the liquid phase. Since hydrodynamics play an

important role on mass transfer operations, and considering the

mainadvantages of pulsed liquidliquid extractioncolumn(PLLEC)

[19,20] it was decidedtousethis columninthis studywhichis capa-

ble of offering a more roust mediumof investigations for studying

the inuence of nanoparticles on mass transfer and hydrodynamic

characteristics.

Three forms of holdup have been discussed in the literature:

static, dynamic, and total holdup [21]. static holdup refers to that

portion of the dispersed phase which is being trapped under the

discs [22] while dynamic holdup refers to the moving fraction of

the dispersed phase; these are being obtained by shut-down pro-

cedure; total holdup on the other hand, equals the sumof both.

2. Experimental

2.1. Experimental setup

Schematic diagramof the PLLEC used in this study is presented

in Fig. 1. The specication of PLLEC and range of operating variables

Please cite this article in press as: A. Bahmanyar, et al., The inuence of nanoparticles on hydrodynamic characteristics and mass transfer

performance in a pulsed liquidliquid extraction column. Chem. Eng. Process. (2011), doi:10.1016/j.cep.2011.08.008

ARTICLE IN PRESS

GModel

CEP-6047; No. of Pages 9

A. Bahmanyar et al. / Chemical Engineering and Processing xxx (2011) xxxxxx 3

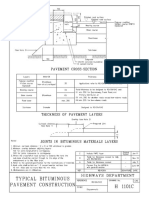

Table 1

The specication of PLLEC and range of operating variables.

Column material Pyrex

Column height (cm) 70

Internal diameter of the column (mm) 90

Plate material Stainless steel 316

Plate diameter (mm) 88

Plate thickness (mm) 1

Number of sieve plates 10

Number of holes in plate 170

Plate hole diameter (mm) 3

Distance between hole pate (mm) 6

Hole pitch (mm) 6

Average free area of the plates (%) 20

Compartment height (cm) 5

Mass ux ratio (Qc/Q

d

) 1.2

Compressed air pressure (KPa) 60300

Range of pulsation intensity (cm/s) 0.32.3

are listed in Table 1. The column consists of a 70cm long vertical

Pyrex tube, i.d. =90mm, 10 perforated stainless steel plates reg-

ularly spaced by 5cm apart and supported on a 8mm diameter

central rod, as well as two separating chambers at either sides of

the column. Holes of 3mmdiameter were arranged in a 6mmtri-

angular pitch at each plate, providing a nominal free fraction area

of 0.20. Pulsation was obtained via a newly designed pulsator, con-

sisting an air compressor, a 3way-2 position-direct acting solenoid

valve and a micro controller (AVR-8051) as a programmable con-

troller unit (PCU) capable of energizing periodically the solenoid

valve to allow ow of the compressed air for an adjustable period

of time, thus pulsating the owalong the column with an intensity

of 0.32.3cm/s. The PCU provided adjustable time-off in the range

of 0.02065.535s. This pulsator which was specically designed

and built for this type of research works offers the advantages of

1ms accuracy in pulsation time, and does not require maintenance

of mechanical pump pulsators, nor suffers from the limitations of

airlift pulsators. Two ow meters were employed to supply and

monitor the xed ow rates of continuous and dispersed phases.

Photographs were taken using a Canon G9 digital camera (12.1

Mpix, ZoomLens 6 IS, 7.444.4mm, 1:2.84.8).

2.2. Experiments procedure

Both continuous and dispersed phases were mutually saturated

before being used in the experiments. At the beginning of each test

run, the continuous phase was initially allowed into the column

from the top which was lled up to the specied height (valve 4,

H=44.5cm). Dispersed phase was then fed into the column via a

glassy nozzle (inside diameter 2mm) from the bottom. The ow

Fig. 2. UVvis spectrumof SiO

2

nanoparticles in kerosene suspension.

Table 2

Description of chemical systems used.

Systems name Continuous phase Dispersed phase

WK SW

a

SK

WAAK SW SK+AA

WNF

1

SW SK+AA+0.01vol% HDK H18

WNF

2

SW SK+AA+0.05vol% HDK H18

WNF

3

SW SK+AA+0.1vol% HDK H18

WNF

4

SW SK+AA+0.01vol% HDK H20

WNF5 SW SK+AA+0.05vol% HDK H20

WNF

6

SW SK+AA+0.1vol% HDK H20

a

SW: saturated water; SK: saturated kerosene; AA: 0.05vol% acetic acid; NF:

nanouid.

meters are then xed to the specied amounts (Q

c

/Q

d

=1.2). Pulsa-

tion amplitude and frequency were then adjusted to desired values

by setting the time-on and time-off periods in PCU.

To investigate droplets behavior, the column was divided into

four different sections of 14 starting fromspaces betweenthe bot-

tom of the column and 1st valve, 1st and 2nd valves, 2nd and 3rd

valves, and 3rd and 4th valves, respectively. Apart from section 1

which had only one stage, each section consisted of three stages.

Once achieving steady state, photographs were taken of the

droplets using continuous shooting method at different sections

along the column, using the digital camera. At the end of a run,

the pulsation was turned off and the dynamic holdup was deter-

mined by the shut down method. In this method, after the system

was stabilized to allow steady state to be reached. Then, the inlet

and outlet valves were shut simultaneously and the moving frac-

tion of dispersed phase was allowed to coalesce at the interface.

The dynamic holdup was then measured either by determining

the change of interface height or displacing the solvent layer into

graduated cylinder. Finally, strong pulsation (2.3cm/s) was used to

move that portion of the dispersed phase which was being trapped

under the discs, and the static holdup was then measured.

2.3. Chemical systems

Acetic acid in the order of 5vol% was added to the saturated

kerosenetoprovidethebaseuidinall systems under investigation

listed in Table 2, except for the WK system. The nanouid was

prepared by dispersing two kinds of SiO

2

nanoparticles supplied by

WackerChemie Company (HDK H20 and HDK H18 with different

hydrophobicities of 20 and 18, respectively.) into the base uid.

To ensure efcient stability of nanoparticles, Hielscher ultrasound

generator (24kHz, 400W) was used for 1h duration (using H14

sonotrode with125m, 105W/cm

2

and 0.7s pulse duration).

Fig. 3. Linear relationship between light absorption and concentration of H18

nanoparticles in kerosene suspension at wavelength of 356.8nm.

Please cite this article in press as: A. Bahmanyar, et al., The inuence of nanoparticles on hydrodynamic characteristics and mass transfer

performance in a pulsed liquidliquid extraction column. Chem. Eng. Process. (2011), doi:10.1016/j.cep.2011.08.008

ARTICLE IN PRESS

GModel

CEP-6047; No. of Pages 9

4 A. Bahmanyar et al. / Chemical Engineering and Processing xxx (2011) xxxxxx

Fig. 4. Relative supernatant particle concentration of nanouids with respect to the

sediment time.

The amorphous fumed hydrophobic and highly hydrophobic

silica powders (HDK H18 and HDK H20, respectively) are highly

pure with nanoparticles in the range of 530nm and density of

2200kg/m

3

. Their surfaces have been modied by OSi(CH

3

)

2

groups. Densities of water and kerosene are 996 and 800kg/m

3

,

respectively. In addition, viscosities of the mentioned liquids are

1.0 and 1.67mPa s, respectively.

3. Results and discussion

3.1. Nanouids stability

The stability of nanouid was investigated with respect to

the sediment time using a UVvis spectrophotometer (UVICAM

8700 Series). The peak absorbance of both nanouids for WNF

3

and WNF

2

systems in saturated kerosene-based suspensions

presented in Fig. 2 appeared at 356.8nm. The absorbance of

nanoparticles decreased with increasing sediment time. A linear

relation as illustrated in Fig. 3 was obtained between the super-

Fig. 6. Sphericity of droplets versus volume fraction of nanoparticles at the 3rd

stage; PI =1.3cm/s, mass ux ratio=1.2.

natant concentration and the absorbance of suspended particles

fromwhich, the relative stability of nanouids was estimated with

respect to the sediment time.

Fig. 4 depicts the colloidal stability of the nanouids where after

8h, relative concentrations were maintained over 96% compared

with the initial concentrations, indicating acceptable stability of

the nanouids used in this work.

3.2. Inuence of nanoparticles on the droplet geometry

Experimental observations indicated that addition of various

contents of nanoparticles had a marked inuence on the geometri-

cal shapes of the droplets. To illustrate this, Fig. 5 demonstrates the

droplets formed at the 3rd stage, in similar operating conditions

of PI =1.3cm/s, mass ow ratio 1.2, with different nanoparticles

contents of 0.0, 0.01, 0.05 and 0.1vol% corresponding to WAAK,

WNF

1

, WNF

2

and WNF

3

, respectively.

As can be seen, droplets formed at zero or low nanoparti-

cles content (WAAK or WNF

1

) are ellipsoidal and those at

Fig. 5. Illustration of the inuence of SiO

2

nanoparticles content on the geometrical shape of droplets in the PLLEC (WAAK: 0.0vol%, WNF

1

: 0.01vol%, WNF

2

: 0.05vol%,

WNF

3

: 0.1vol%).

Please cite this article in press as: A. Bahmanyar, et al., The inuence of nanoparticles on hydrodynamic characteristics and mass transfer

performance in a pulsed liquidliquid extraction column. Chem. Eng. Process. (2011), doi:10.1016/j.cep.2011.08.008

ARTICLE IN PRESS

GModel

CEP-6047; No. of Pages 9

A. Bahmanyar et al. / Chemical Engineering and Processing xxx (2011) xxxxxx 5

Fig. 7. Dispersed phase static hold-up versus the pulsation intensity for different

chemical systems; mass ux ratio=1.2.

WNF

3

with 0.1vol% nanoparticles is almost spherical in shape,

indicating a trend in changing shape from ellipsoidal to spherical

droplets as nanoparticles content increased. Similar behavior has

been reported [16] for bubble columns in the presence of nanopar-

ticles. On the other hand, droplet sphericity (dened as the ratio of

the length of minor axis over the major axis), corresponds to higher

interfacial tension. This indicates that addition of nanoparticles

may havecontributedtothechangingshapetrendexplainedabove.

Very good explanation can be found for increasing the sphericity of

a droplet with interfacial tension [23].

Sphericity was measured for some 200 droplets at each

nanoparticles vol% (from0.00 to 0.1) and an average was taken as

demonstrated in Fig. 6, where almost complete spherical droplets

was observed at 0.1vol%.

3.3. Dispersed phase static hold-up

The experiments were designed for the PLLEC to operate at

no ooding conditions and in accordance to prescribed operating

condition recommended in the literature [24]. In the analysis of

data obtained froma PLLEC, conventionally pulsation intensity (PI),

dened as product of pulsation frequency, f, and stroke length or

pulsation amplitude, A, with the unit of (cm/s) is used.

PI = A f (1)

Fig. 7 shows the static hold-up versus the pulsation intensity

for different chemical systems used in this study for the given

mass owratio of 1.2. As expected, for all chemical systems under

investigation, maximum static hold-up was observed at the low-

est PI (namely 0.3cm/s). Maximum hold-up (7.08% at PI =0.3)

and minimumhold-up (0.22% at PI =2.3) observed throughout the

experiments, occurred for WNF

3

and WAAK systems, respec-

tively (see Fig. 8).

It should be noted that apart from the WK system, the static

hold-upreductiontookplacemorerapidlybyincreasingthePI upto

1.3. As canbe seenfromFig. 7, generally, static hold-updecreasedto

an asymptotic minimumwith increasing PI. This could well be due

to breakage of dispersed phase trapped droplets passing through

plate holes, and also conrms that the experimental set-up has

operated correctly. Different behavior of the WK system is most

likely due to lack of interactive inuence of both nanoparticles and

acetic acid in this system.

As far as the inuence of the nanoparticles presence in the sys-

tems studied is concerned, it can be seen that there is a marked

difference in the static hold-up of studied systems with different

nanoparticles contents subjected to various PIs. This difference in

static hold-up is more apparent for lower PIs, indicating more sig-

Fig. 8. Maximumand minimumhold-ups observed throughout the experiments for (a) WAAK and (b) WNF

3

.

Please cite this article in press as: A. Bahmanyar, et al., The inuence of nanoparticles on hydrodynamic characteristics and mass transfer

performance in a pulsed liquidliquid extraction column. Chem. Eng. Process. (2011), doi:10.1016/j.cep.2011.08.008

ARTICLE IN PRESS

GModel

CEP-6047; No. of Pages 9

6 A. Bahmanyar et al. / Chemical Engineering and Processing xxx (2011) xxxxxx

Fig. 9. Dispersedphasestatic hold-upfor all systems at PIs of (a) 1.3and(b) 1.8cm/s;

mass ux ratio=1.2.

nicant effect inthis pulsationrange due tonanoparticles presence.

In order to compare more clearly the impact of nanoparticles vol-

ume fraction and investigate the effect of hydrophobicity, the plot

of static hold-ups for all systems at PIs of 1.3 and 1.8cm/s were

prepared as presented in Fig. 9.

As for hydrophobicity, increase in it caused static hold-up to

increase for both PIs. Also considering Figs. 7 and 9 it may be

claimed that, higher volume fraction of nanoparticles led to an

increase in static hold-up for PI =1.3 or less, while it made little

difference when PI =1.8 or higher.

Increase in static hold-up caused by higher nanoparticles con-

tent, could be attributed to increased coalescence of droplets under

the plates. The coalescence of drops was observed under the plates

Fig. 11. Dispersed phase dynamic hold-up versus the pulsation intensity for differ-

ent chemical systems; mass ux ratio=1.2 (d

32

is expressed for WNF

3

).

in this experiment. It is mentioned by previous researchers that

the larger the interfacial tension, the more easily coalescence of

drops will occur [25]. So, Improved interfacial tension (as discussed

in Section 3.2) might be responsible for coalescence tendency of

droplets under the plates.

Fig. 10 illustrates the extent of this coalescence taken place

at Plate 3 in the presence of nanoparticles and compares it with

WAAK where no nanoparticles existed in the system.

As mentioned before, the increase in static hold-up with

nanoparticles content was more apparent for lower PIs (as con-

rmed by Fig. 7). This might be explained by the fact that high

PI provides such intensive turbulence and consequently more

droplets breakage that it supersedes the impact of coalescence

caused by the presence of nanoparticles.

3.4. Dispersed phase dynamic hold-up

Fig. 11 illustrates the dynamic hold-up versus PI for different

chemical systems at the mass owratio of 1.2. As shown, dynamic

hold-up generally increased with increased PI. Based on experi-

mental observation (not explained here for the sake of brevity)

obtainedfromthe photographic technique, the meandroplet diam-

eter decreased with higher PI leading to longer droplets resident

time. In other words, enhanced dispersed phase dynamic hold-up

was caused by higher population density of droplets inside the

column imposed by increased PI. This phenomenon continued up

to the highest hold-up attempted in the experiment and corre-

sponded to the minimumdrop size (see for example d

32

for WNF

3

expressedinFig. 11) obtainedunder available operatingconditions.

Fig. 10. Extent of coalescence taken place at Plate 3 for (a) WAAK (0.0vol%) and (b) WNF

3

(0.1vol%) systems.

Please cite this article in press as: A. Bahmanyar, et al., The inuence of nanoparticles on hydrodynamic characteristics and mass transfer

performance in a pulsed liquidliquid extraction column. Chem. Eng. Process. (2011), doi:10.1016/j.cep.2011.08.008

ARTICLE IN PRESS

GModel

CEP-6047; No. of Pages 9

A. Bahmanyar et al. / Chemical Engineering and Processing xxx (2011) xxxxxx 7

Fig. 12. Dispersed phase static hold-up for all systems at PI =1.3; mass ux

ratio=1.2.

As can be seen from Fig. 11, dynamic hold-up increased for

higher nanoparticles content. There are two possible explanations

for this which are associated with the increased density of the dis-

persedphase andenhancedopportunity for droplet breakage. With

regards to the former, increase in nanoparticles content, causes

higher density of the dispersed phase, which leads to increased

residence time and consequently increased dynamic hold-up. To

interpret the latter, as previously expressed, nanoparticles content

increased static hold-up as very large droplets coalesced in their

presence, thereby covering almost the entire plate surface in a sin-

gle layer (see Fig. 10). Subsequent pulsations therefore, have more

opportunity to break up these droplets into smaller ones leading

to increased dynamic hold-up. On the other hand, in the absence

of nanoparticles, (or lowquantity say 0.01vol%), the droplets were

mostly in the formof small scattered ones attached under the plate

with much less coverage of the plate holes, consequently, giving

less opportunity for droplet breakage in the following pulsations.

To compare more clearly the impact of nanoparticles volume

fraction, and investigate the effect of hydrophobicity, the plot of

dynamic hold-up for all systems at PI of 1.3 was prepared as

presented in Fig. 12. As for hydrophobicity, increase in it made

little increase in the dynamic hold-up while similar trend to H18

was observed for H20 nanoparticles, too. Similar results were also

obtained when PI changed from1.3 to 1.8.

3.5. Mass transfer performance

3.5.1. Theoretical background in calculation of experimental

dispersed phase mass transfer coefcients

Theoverall mass transfer of dispersedor continuous phaseis one

of the fundamental parameters in liquidliquid extractor design. In

this study, mass transfer coefcients were calculated using a semi-

empirical method described below. The mass balance for droplet

may be written as:

K

d

(C C

) 4r

2

=

4

3

r

3

dc

dt

(2)

Rearranging and integrating gives:

K

d

=

d

6t

ln(1 E) (3)

where

E =

C

0

C

C

0

C

(4)

C

0

, C, and C* are the solute concentration in the primary droplet

(before contact), at a specied height from the bottom of the col-

umn (44.5cm for the set-up in this work taken from valve 4), and

Fig. 13. Effect of PI onenhancement factor for different chemical systems; mass ux

ratio =1.2.

in equilibriumwith the continuous phase, respectively. The solute

concentrations of collected droplets were determined by titration

with 0.1N NaOH solution.

The relationbetweencontact time (t), dispersedphase volumet-

ric owrate (Q

d

), and hold-up () is as follows [25]:

L =

Q

d

t

S

(5)

When the experimental data (, d

32

, and Q

d

) throughout the

height of columnareavailable, as is thecaseinthis work, thecontact

timebetweentwo phases wereobtainedusingEq. (5). Mass transfer

coefcient (K

d

) along the column height could then be obtained

using Eqs. (3) and (4).

3.5.2. Determination of mass transfer enhancement and

interfacial area

Fig. 13 shows the effect of PI on the enhancement factor (E).

As demonstrated, mass transfer in the presence of the nanouids

has been improved by 421%, 547% and 560% for 0.01, 0.05 and

0.1vol%, respectively. This enhancement could be attributed to the

Brownian motion of nanoparticles. The gure also shows that for

WAAKsystem, Esignicantlyimproves whenPI is increasedfrom

1.3 to 1.8cm/s. The same trend is observed for WNF

1

systemhow-

ever, enhancement in E levels off at the latter PI. This leveling off

could be contributed to the substantial decrease of mass transfer

rates due to small droplets, behaving as rigid spheres, in which

case molecular diffusion would be governing mass transfer in the

system.

Moreover, a clear peak for both WNF

2

and WNF

3

systems are

observed at 1.8 and 1.3cm/s, respectively, suggesting that in the

presence of nanouids, mass transfer rate may not improve above

a certain PI (1.8cm/s in the present experiment). Nanoparticles,

on the other hand may have facilitated increasing the regidica-

tion of small drops which may have caused the peak for WNF

3

(0.1vol%) to occur at lower pulsation intensity compared to WNF

2

(0.05vol%).

Theinterfacial areaavailableinacounter-current extractioncol-

umn depends upon the volume fraction or dynamic holdup, of the

dispersed phase, as well as on the mean droplet size and can be

evaluated by [24]:

a =

6

d

d

32

(6)

As it is explained in Section 2.2 in each experiment, the sauter

mean diameter. d

32

, was obtained by photographic technique at a

Please cite this article in press as: A. Bahmanyar, et al., The inuence of nanoparticles on hydrodynamic characteristics and mass transfer

performance in a pulsed liquidliquid extraction column. Chem. Eng. Process. (2011), doi:10.1016/j.cep.2011.08.008

ARTICLE IN PRESS

GModel

CEP-6047; No. of Pages 9

8 A. Bahmanyar et al. / Chemical Engineering and Processing xxx (2011) xxxxxx

Fig. 14. Effect of PI on interfacial area for different chemical systems; mass ux

ratio=1.2.

few stages of column height and then calculated by following Eq.

(7):

d

32

=

n

i

d

3

i

n

i

d

2

i

(7)

When the experimental data (, d

32

) are available, as is the

case in this work, the interfacial was obtained using Eq. (6). The

effect of PI on the interfacial area is illustrated in Fig. 14, where

interfacial area increased with an increase in PI. Dynamic holdup

and Sauter mean diameter are function of physical properties and

operating conditions. So, due to above mentioned equations dif-

ferent variation trends could be expected for different systems in

Fig. 14. As mentioned previously, at higher PI, sauter mean diam-

eter decreased and consequently dynamic hold-up increased (see

Fig. 11), both of which may have contributed to the increased inter-

facial area observed.

Table 3 shows the mass transfer coefcient (K

d

) for vari-

ous systems tested, where evidently K

d

generally decreased with

increasing PI. Experimental observations, indicated that increas-

ing PI, decreased d

32

and consequently increased resident time (t).

However, as expressed by Eq. (2), K

d

decreases with both effects.

Having established experimentally that nanoparticles presence

do affect parameters such as enhancement factors, static and

dynamic hold-ups, it was expected to observe more clearly their

inuence on K

d

, which was not the case here. Considering con-

icting reports from the available literature on the inuence of

nanoparticles on K

d

[9,14,15], and mass transfer performance, it

could only be said that the inuence is less clear on K

d

as compared

to the mass transfer performance. This suggest the need for further

research to be carried out into modeling exercise of mass trans-

fer coefcient in the presence of nanoparticles, for liquidliquid

systems, similar to those carried out by Nagy et al. [26] on the

gasliquid systems.

Table 3

Experimental value of mass transfer coefcient at different PI.

Pulse intensity

PI (cm/s)

Mass transfer coefcient for different systems,

k

d

10

5

(m/s)

WAAK

a

WNF

1

a

WNF

2

a

WNF

3

a

0.3 7.10 3.11 4.21 4.44

0.7 3.15 2.56 2.72 2.55

1.3 2.71 1.94 2.01 1.87

1.8 1.48 1.26 1.28 0.90

2.3 1.06 0.69 0.81 0.62

a

Systems name, WAAK, WNF

1

, WNF

2

, WNF

3

, are dened in Table 2.

4. Conclusion

To investigate the inuence of nanoparticles on the hydrody-

namic characteristics and mass transfer performance of pulsed

liquidliquid extraction column different nanouids have been

applied as dispersed phase. From the experimental results, it can

be seen that there is a marked difference in the static and dynamic

hold-ups as well as enhancement factor of studiedsystems withdif-

ferent nanoparticles contents subjected to various PIs. It is found

that static and dynamic dispersed phase hold-ups for the nanou-

ids increased 23398%, and 23257%, respectively while the mass

transfer for the nanouids enhances 460%. The increase in static

hold-up and enhancement factor with nanoparticles content was

more apparent for lower PIs indicating more signicant effect

in this pulsation range due to nanoparticles presence. As far as

hydrophobicity is concerned, little increases in both static and

dynamic holdups were observed as hydrophobicity increased and

interestingly, similar trend was observed for both H18 and H20

nanoparticles.

Appendix A. Nomenclature

a interfacial area (m

2

/m

3

)

A pulsation amplitude (cm)

C solute concentration in dispersed phase (kg/m

3

)

C

0

initial concentration of solute in dispersed phase (kg/m

3

)

C* equilibrium concentration of solute in dispersed phase

(kg/m

3

)

d droplet diameter (m)

d

32

sauter mean diameter of droplets (mm)

E enhancement factor

f pulsation frequency (s

1

)

H effective height of column (cm)

K

d

dispersed phase mass transfer coefcient (m/s)

L column height (m)

PI pulsation intensity (cm/s)

Q

c

continuous phase owrate (m

3

/s)

Q

d

dispersed phase owrate (m

3

/s)

R

1

length of major axis (mm)

R

2

length of minor axis (mm)

S column cross-sectional area (m

2

)

t resident time of dispersed phase in column, contact time

(s)

Greek symbols

dispersed phase hold-up

Subscripts

c continuous phase

d dispersed phase

References

[1] J.A. Eastman, S.U.S. Choi, S. Li, W. Yu, L.J. Thompson, Anomalously increased

effective thermal conductivities of ethylene glycol based nanouids containing

copper nanoparticles, Appl. Phys. Lett. 78 (2001) 718720.

[2] S.K. Das, N. Putra, P. Thiesen, W. Roetzel, Temperature dependence of thermal

conductivity enhancement for nanouids, Trans. ASME, J. Heat Transfer 125

(2003) 567574.

[3] S.Z. Heris, S.G. Etemad, M.N. Esfahany, Experimental investigation of oxide

nanouids laminar ow convective heat transfer, Int. Commun. Heat Mass

Transfer 33 (2006) 529535.

[4] W. Yu, D.M. France, J.L. Routbort, S.U.S. Choi, Review and comparison of

nanouid thermal conductivity and heat transfer enhancements, Heat Trans.

Eng. 29 (2008) 432460.

[5] Y.M. Xuan, Q. Li, Investigation on convective heat transfer and owfeatures of

nanouids, Trans. ASME, J. Heat Transfer 125 (2003) 151155.

Please cite this article in press as: A. Bahmanyar, et al., The inuence of nanoparticles on hydrodynamic characteristics and mass transfer

performance in a pulsed liquidliquid extraction column. Chem. Eng. Process. (2011), doi:10.1016/j.cep.2011.08.008

ARTICLE IN PRESS

GModel

CEP-6047; No. of Pages 9

A. Bahmanyar et al. / Chemical Engineering and Processing xxx (2011) xxxxxx 9

[6] S.K. Das, S.U.S. Choi, H.E. Patel, Heat transfer innanouids a review, Heat Trans.

Eng. 27 (2006) 319.

[7] R. Prasher, P. Bhattacharya, P.E. Phelan, Brownianmotion-based convective-

conductive model for the effective thermal conductivity of nanouids, Trans.

ASME, J. Heat Transfer 128 (2006) 588595.

[8] S.P. Jang, S.U.S. Choi, Role of Brownian motion in the enhanced thermal con-

ductivity of nanouids, Appl. Phys. Lett. 84 (2004) 43164318.

[9] S. Krishnamurthy, P. Bhattacharya, P.E. Phelan, R.S. Prasher, Enhanced mass

transport in nanouids, Nano Lett. 6 (2006) 419423.

[10] H. Li, A. Prakash, A. Margaritis, M.A. Bergougnou, Effects of micron-sized par-

ticles on hydrodynamics and local heat transfer in a slurry bubble column,

Powder Technol. 133 (2003) 171184.

[11] G. Quicker, A. Schumpe, W.D. Dechwer, Gasliquid interfacial-areas in a bubble

column with suspended-solids, Chem. Eng. Sci. 39 (1984) 179183.

[12] M.V. Dagaonkar, H.J. Heeres, A.A.C.M. Beenackers, V.G. Pangarkar, The applica-

tion of ne TiO

2

particles for enhanced gas absorption, Chem. Eng. J. 92 (2003)

151159.

[13] Y.T. Kang, H.J. Kim, K.I. Lee, Heat and mass transfer enhancement of binary

nanouids for H

2

O/LiBr falling lmabsorption process, Int. J. Refriger. 3 (2008)

850856.

[14] B. Olle, S. Bucak, T.C. Holmes, L. Bromberg, A. Hatton, D.I.C. Wang, Enhancement

of oxygen mass transfer using functionalized magnetic nanoparticles, Ind. Eng.

Chem. Res. 45 (2006) 43554363.

[15] J. Wen, X. Jia, W. Feng, Hydrodynamic and mass transfer of gasliquidsolid

three-phase internal loop airlift reactors with nanometer solid particles, Chem.

Eng. Technol. 28 (2005) 5360.

[16] J.K. Kim, J.Y. Jung, Y.T. Kang, The effect of nano-particles on the bubble absorp-

tion performance in a binary nanouid, Int. J. Refriger. 29 (2006) 2229.

[17] L.S. Fan, O. Hemminger, Z. Yu, F. Wang, Bubbles in nanouids, Ind. Eng. Chem.

Res. 46 (2007) 43414346.

[18] W. Feng, J. Wen, J. Fan, Q. Yuan, X. Jia, Y. Sun, Local hydrodynamics of gasliquid-

nanoparticles three-phase uidization, Chem. Eng. Sci. 60 (2005) 68876898.

[19] K. Gottliebsen, B. Grinbaum, D. Chen, G.W. Stevens, The use of pulsedperforated

plate extraction column for recovery of sulphuric acid fromcopper tank house

electrolyte bleeds, Hydrometallurgy 58 (2000) 203213.

[20] Y. Wang, S. Jing, G. Wu, W. Wu, Axial mixing and mass transfer characteristics

of pulsed extraction Column with discs and doughnuts, Trans. Nonferrous Met.

Soc. Chin. 16 (2006) 178184.

[21] S.S. Puranik, A. Vogelpohl, Effective interfacial area inirrigatedpackedcolumns,

Chem. Eng. Sci. 29 (1974) 501507.

[22] M.J. Brodkorb, M.J. Slater, Multicomponent and contamination effects on mass

transfer in a liquidliquid extraction rotating disc contactor, Trans. IChemE 79

(2001) 335345.

[23] D. Mobius, R. Miller, Drops andBubbles inInterfacial Research, Elsevier Science,

NewYork, 1998, pp. 189197.

[24] J.C. Godfrey, M.J. Slater, LiquidLiquid Extraction Equipment, 2nd ed., John

Wiley and Sons, NewYork, 1994, pp. 227305.

[25] R.E. Treybal, Mass Transfer Operations, 3rd ed., McGraw Hill, Japan, 1990, pp.

488490.

[26] E. Nagy, T. Feczk, B. Koroknai, Enhancement of oxygen mass transfer

rate in the presence of nanosized particles, Chem. Eng. Sci. 62 (2007)

73917398.

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Co ., LT D.: ASME A-106/A-106M - 2019 EDITION Material Verification The Original Markings On ProductionDocumento2 páginasCo ., LT D.: ASME A-106/A-106M - 2019 EDITION Material Verification The Original Markings On ProductionBalaji SelvarajAinda não há avaliações

- Quiz 1-2-3Documento3 páginasQuiz 1-2-3Hassan AhmedAinda não há avaliações

- Micro-Concrete Roofing Tile Production: Quality ControlDocumento1 páginaMicro-Concrete Roofing Tile Production: Quality ControlPietrus NimbusAinda não há avaliações

- Welding: Krishnanand Prasad 0501213359 (04) Mechanical Engg 8 SemesterDocumento21 páginasWelding: Krishnanand Prasad 0501213359 (04) Mechanical Engg 8 SemesterSuphi YükselAinda não há avaliações

- Flow SwitchDocumento16 páginasFlow Switchsales1068100% (1)

- Atterberg LimitsDocumento6 páginasAtterberg LimitsShakil HossainAinda não há avaliações

- Sawdust Brick A Quantitative Study On Sawdust Substitute For Concrete Brick ProductionDocumento21 páginasSawdust Brick A Quantitative Study On Sawdust Substitute For Concrete Brick ProductionChristian Andre FloresAinda não há avaliações

- Non-Metallic Expansion Joints: Industries, IncDocumento26 páginasNon-Metallic Expansion Joints: Industries, IncMauricio ChucuyaAinda não há avaliações

- Cement Hydration Inhibition With SucroseDocumento8 páginasCement Hydration Inhibition With SucroseJaq Plin PlinAinda não há avaliações

- InDocumento135 páginasInNAVNEET BAGGAAinda não há avaliações

- Handbook of Building Materials For Fire Protection - Engineering ReferenceDocumento5 páginasHandbook of Building Materials For Fire Protection - Engineering ReferenceDorinAinda não há avaliações

- Flat SlabDocumento69 páginasFlat Slabmukhlesh100% (1)

- Lecture LinimentsDocumento22 páginasLecture LinimentsAlena Golod33% (3)

- Wearing Coat ThicknessDocumento1 páginaWearing Coat ThicknessanjanaAinda não há avaliações

- GSE StudLiner - 09.12.2011 - Youngblood - New DesignDocumento60 páginasGSE StudLiner - 09.12.2011 - Youngblood - New Designhassen gannouniAinda não há avaliações

- Two Bedroom Apartment 2Documento1 páginaTwo Bedroom Apartment 2RUTH ELIZABETH NAMUTEBIAinda não há avaliações

- CH 4 PE PipeDocumento22 páginasCH 4 PE Pipeanon_104613317Ainda não há avaliações

- Concrete Beam DesignDocumento3 páginasConcrete Beam Designheherson juanAinda não há avaliações

- MSDS - GBH7107Documento2 páginasMSDS - GBH7107pankaj111Ainda não há avaliações

- Steel Wire, Oil-Tempered For Mechanical SpringsDocumento1 páginaSteel Wire, Oil-Tempered For Mechanical SpringsJunAinda não há avaliações

- Glass Powder and Flyash Replacing CementDocumento3 páginasGlass Powder and Flyash Replacing CementaryanAinda não há avaliações

- Material Take-Off List: Rev. CodeDocumento6 páginasMaterial Take-Off List: Rev. CodeSIVAAinda não há avaliações

- Metamorphic Rocks PracticalDocumento27 páginasMetamorphic Rocks PracticalMr Gk meenaAinda não há avaliações

- Separation of Ions by Fractional PrecipitationDocumento45 páginasSeparation of Ions by Fractional PrecipitationPrincess NavarroAinda não há avaliações

- 2 Open ChannelDocumento1 página2 Open ChannelAhmed NabilAinda não há avaliações

- Group 1 (Alkali Metals) - Lithium, Sodium, Potassium QPDocumento8 páginasGroup 1 (Alkali Metals) - Lithium, Sodium, Potassium QPRODGERS BANDAAinda não há avaliações

- Compressive Strength Modelling of Concrete Mixed With Fly Ash and Waste Ceramics Using K-Nearest Neighbor AlgorithmDocumento6 páginasCompressive Strength Modelling of Concrete Mixed With Fly Ash and Waste Ceramics Using K-Nearest Neighbor AlgorithmNewton GalileoAinda não há avaliações

- Deflection in BimetalDocumento4 páginasDeflection in BimetalRoisin ClearAinda não há avaliações

- 1.TDS MIXO Plast D100Documento2 páginas1.TDS MIXO Plast D100mohamed ragabAinda não há avaliações

- Salient Features of LHB CoachesDocumento3 páginasSalient Features of LHB CoachesVijay AnandAinda não há avaliações