Escolar Documentos

Profissional Documentos

Cultura Documentos

Effect of Environmental Temperature and PH Water On Compressive Strength of Clay Brick Mixed Wood Chips Mahogany Based Building Materials

Enviado por

thesijTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Effect of Environmental Temperature and PH Water On Compressive Strength of Clay Brick Mixed Wood Chips Mahogany Based Building Materials

Enviado por

thesijDireitos autorais:

Formatos disponíveis

The SIJ Transactions on Industrial, Financial & Business Management (IFBM), Vol. 2, No.

6, August 2014

ISSN: 2321-242X 2014 | Published by The Standard International Journals (The SIJ) 296

AbstractBricks using local materials were manufactured in order to reduce the cost of the housing and take

into account the waste wood management to protect the environment. Wood Chips were built-in clay bricks

building materials in order to study the effect of environmental temperature on compressive strength. The

resistance tests in simple compression were made on the parallel epipedic test-tubes out of ground, stabilized

with different percentage of cement with incorporation to various percentages of wood chips (mahogany),

using a universal press. The obtained results were presented and discussing. These results shows that the

incorporation of mahogany wood chips in the clay brick decrease the compressive strength at air atmosphere

temperature. It was found that the compressive strength can be increase when the environment temperature was

increase below 25

0

C. The decrease of compressive strength was attributed to the content acidity in the wood

chips.

KeywordsBrick Clay; Building Materials; Cement; Compressive Strength; Environment; Mahogany; Wood;

Wood Chips.

I. INTRODUCTION

ENTRAL Africa is a timber-producing sub-region.

Wood industries generate a great quantity of wood

waste which management has serious pollution

problems. The use of waste wood in construction can be an

alternative for the protection of the environment. The

incorporation of wood waste in building materials has been

the subject of diverse studies [Ngoma & Poungui, 2011; Ganga,

2013], most of them were focused on the influence on the

mechanical properties [Meukam, 2004; Taoukil et al., 2011;

Ganga, 2013; Nzabana, 2013]. The purpose of this work is to

minimize the cement content in brick clay in order to study

the effect of environment temperature on compression

strength. The choice of mahogany is justified by its extensive

use in the wood industry which release huge waste [Gaye,

2001; Goteicha et al., 2007; Batkidila, 2009; Mambouana,

2010]. The motivation for this study is based on the fact that

we found no reference to previous work on the recycling of

waste mahogany in Central Africa. The objectives of this

work are: at environmental, geotechnical and economical

level: to Manage wood chips as an alternative to protect

environment; to incorporate the wood chips in the building

construction industry in order to use brick based clay

materials as acoustic barriers to protect against noise

pollution and to reduce the cost of building construction by

using local brick materials. The contribution of this

manuscript is to find a experimental conditions for improving

compressive strength of brick clay materials mixed to wood

chips in building construction.

II. MATERIALS AND METHODS

The experimental device manufacturing test is made up of the

following components: a tank, a brick mold, a wooden

device, a screed, a precision scale and a graduated cylinder

and water from the BCBTP drilling, an electronic KERN KB

scale type of the (10100g,d = 0.1 g) range, a trowel. The earth

material used for the manufacture of bricks was made at air

atmosphere and various environment temperature. A mass of

6 kg of land was used; this mass corresponds to 12 small

bricks at 3 samples per test and drying time. The water

content is determined by the Proctor: 22%.The test for

determining the compressive strength machine is a universal

C

*University Marien NGOUABI / National High School of Polytechnic, Brazzaville, CONGO. E-Mail: ganga.gilbert{at}yahoo{dot}fr

**University Marien NGOUABI / Center of Geological and Mining Research, Brazzaville, CONGO. E-Mail: hilaire_elenga{at}yahoo{dot}fr

***University Marien NGOUABI / Center of Geological and Mining Research, Brazzaville, CONGO. E-Mail: nsongo{at}yahoo{dot}com

****University of Yaound1 / National High School of Polytechnic, Yaound, CAMEROUN. E-Mail: thom2t{at}yahoo{dot}fr

Gilbert Ganga*, Hilaire Elenga**, Timothe Nsongo*** & Thomas Tamo Tatsiete****

Effect of Environmental Temperature

and pH Water on Compressive Strength

of Clay Brick Mixed Wood Chips

Mahogany based Building Materials

The SIJ Transactions on Industrial, Financial & Business Management (IFBM), Vol. 2, No. 6, August 2014

ISSN: 2321-242X 2014 | Published by The Standard International Journals (The SIJ) 297

G.I.M. press brand (General Engineering Measurement), used

according to the NF EN 196-1, the compressive force of

250kN (Figure 3). It is equipped with an indicator device

which is constructed so that the previous value of the failure

of the specimen is shown on the screen after returning to zero

load. This may be achieved by using an indicator of a

maximum pressure monitor or on a digital memory device

(computer). The test machine, the charging is controlled

manually, is provided with a measuring device controlling the

loading speed.16 cm x 4cm x4cm parallelepiped small bricks

are centered between the plates of the press and loaded

continuously at an average speed of 0.20 MPa / s by a

compressive force to crush. Calculating thereafter the

compressive strength, which is the ratio between the

compressive stress and the maximum section and the cross

section of the crushed test device?

III. OPERATING PROCEDURE OF

COMPRESSION TEST

After measuring the size of the brick clay sample, weighed,

and then placed on the plate of the press. Then start the test

compression control computer is controlled. A compression

test is carried out in two different phases: the first phase,

which depends on the operator, allows to bring the piston in

integral contact to compress the sample, placed on the plate

of the press until the timber is well stuck. During this phase,

the counter of the applied load is set to zero. The second

phase is also initiated by the operator. This is the phase of the

course of the compression; the piston instantly compresses

the sample to overcome the maximum resistance, the

resulting rupture is automatically stopped. The computer after

data processing using software, displays the load -

deformation curve, the values of the module of the resistance

of charge (RC) in N/mm

2

and the breaking load in kN.

IV. RESULTS AND DISCUSSION

4.1. I nfluence the Content of Wood Chips on the

Compressive Strength at Air Atmosphere

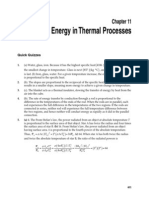

Figure 1 shows the evolution of compressive strength as a

function of the content of chips in air atmosphere when the

cement content is varied.

Figure 1: Variations in Compressive Strength as a Function of

Content Chips

The compressive strength decreases with increasing

content of chips to 4 % cement, it passes through a minimum

of 6% of cement and up to 8 %.

This result is consistent with that reported in the

literature [Tamba et al., 2007; Ngoma & Poungui, 2011;

Khelifi Belouettar, 2012].

4.2. I nfluence the Environment Temperature on the

Compressive Strength of Brick Clay

We have varied the environment temperature of the clay

brick mixed with chips. We then conducted compression tests

on samples for every temperature. Figure 2 shows the

obtained results. These results show that it is possible to

increase the compressive strength when the environment

temperature increase, whatever the nature of the waste (wood

chips).

Figure 2: Variations of Compressive Strength as Function of

Temperature at Various Wood Chips Content

4.3. Effect of Use Water pH for made Brick

We analyzed water from sample water drilling and the one

which was immersed samples of mahogany chips. We then

measured the chemical parameters of the water. The results

obtained are given in Table 1. These results show that the

chemical components in water drilling is low compared to the

water containing wood chips mahogany; and show that the

water becomes highly acidic after immersion of mahogany

wood.

Table 1: Measured o Chemical Parameters for the Water which is using to make Brick Clay

pH t Ca

2+

K

+

Mg

2+

Mn

2+

PO

4

3-

Al

3+

Water drilling with emersing wood mahogany

chips

3,67 26,2 13mg/L 5,7mg/L 21mg/L 0,05mg/L 1,05mg/L 0,8mg/L

Water drilling 7,08 26,8 6mg/L 0,123mg/L 3,66mg/L 0,02mg/L 0,008mg/L 0,043mg/L

0

5

10

15

0% 2% 4% 6% 8% 10%

C

o

m

p

r

e

s

s

i

v

e

s

t

r

e

n

g

t

h

[

M

p

a

]

Content in mahogany wood chips [%]

4% of cement 6% of cement 8% of cement

3

5

7

9

11

13

15

0 1 2 3 4

c

o

m

p

r

e

s

s

i

v

e

s

t

r

e

n

g

t

h

(

M

P

a

)

Temperature (C)

wood chips

S 0%

S 2%

S 4%

S 6%

S 8%

25C 75C 105C 150C

The SIJ Transactions on Industrial, Financial & Business Management (IFBM), Vol. 2, No. 6, August 2014

ISSN: 2321-242X 2014 | Published by The Standard International Journals (The SIJ) 298

The compressive strength of brick made with water of

drilling and water of the slightly acid (pH= 3.67) where

measured. The obtained results are presented on figure 3.

This results show that using the acid water increase the

compressive strength.

Figure 3: Variation of Compressive Strength as Function of Wood

Chips Content and Water Nature

The compressive strength has been measured as a

function of the content of chips mahogany at different

temperature. The results in figures 5, 6, 7 and 8 show that the

compressive strength decreased with increasing the content of

waste wood. The compressive strength as a function of the

chip content seems to stabilize at 75C.

The compressive strengths increase with temperature that

is explained by the fact that the clay particles when heating

molten punctually touch and consolidated thereby conferring

a significant resistant bricks for the compressive strength of a

Brick cooked can go generally from 10 to 20 MPa [Pehanich

et al., 2004; Mambouana, 2010; Mabiala Bototo, 2012]. The

resistance of bricks in the open air were obtained after 28

days. The results of the decrease in the compressive strength

of the bricks are in agreement with the work of KHELEFI

BELOUATTAR [Khelifi Belouettar, 2012]. This can be

explained by the fact that the amount of wood waste

contained in the brick created voids or pores thereby reducing

the resistance to compression. The low resistance in wood

chips is due to the fact that in the clay matrix cement, the

chips have a very fibrous appearance as marked channels

leading sap confer to these materials in a high porosity and a

high rate of dragging voids in the brick which are responsible

for the resistance. These values of compressive strengths are

well suited to the Australian standard which recognizes that

the compressive strength of 2 MPa and the British Standard

BS 59211985 which secures a minimum of 5 MPa. Compared

to our results we note cement bricks conferred resistance in

the incorporation of the mahogany tree waste on the clay

brick.

V. CONCLUSION AND FUTURE WORK

In this work, wood Chips were built in clay bricks building

materials in order to study the effect of environmental

temperature on compressive strength. The obtained results

shows that the incorporation of mahogany wood chips in the

clay brick decrease the compressive strength at air

atmosphere temperature. It was found that the compressive

strength can be improved with the environment temperature.

The advantage using the wood chips is the facilities to collect

them easily and can be move easily, the clay materials can be

product also locally. The importance of this conclusion is to

extend these results to industries applications in order to

product local brick mixed to wood chips using clay materials.

The following step of this work will study the

relationship between noise pollution as function of wood

chips content in order to made brick clay as noise barrier.

REFERENCES

[1] S. Gaye (2001), Characterization of Mechanical, Acoustic and

Thermal Properties of Local Building Materials in Senegal,

Thesis Status of Science, University Cheikh Anta Diop, Senegal

Doctorate.

[2] L.J. Pehanich, P.R. Blankenhom & M.R. Silsbee (2004),

Wood Fiber Surface Treatment Level Effects on Selected

Mechanical Properties of Wood Fiber Cement Composite,

Cement and Concrete Research, Vol. 34, Pp. 5965.

[3] P. Meukam (2004), Characterization of Local Materials for

the Thermal Insulation of Buildings, PhD Thesis, University of

Yaound 1,Cameroun.

[4] S. Tamba, M.L. Voumbo, et al., (2007), Durability of

Lightweight Concrete made of Wood Chips, Journal of

Sciences, Vol. 7, No. 4, Pp. 6772.

[5] M. Goteicha, N. Khenfer & M. Bederine (2007),

Characterization of Sand Concrete made up of Treated Wood

Chips, National Seminar of Civil Engineering, Annaba from

20 to 21 November, 2007.

[6] J.V.S. Batkidila (2009), Mineralogical, Physical and

Chemical Study of some Clay Soils Congo: The Case of

Mouyondzi, Impfondo and Cuvetteclays, Master Thesis, Ecole

Normale Suprieure / Marien Ngouabi University, Brazzaville.

[7] J.P. Mambouana (2010), Study of Flexural and Compressive

Strength of Mud Bricks of Talanngaand Yengola, Stabilized

with Cassava Flour and Plastic Waste, Engineer Dissertation,

National Polytechnic College / Marien NGOUABI University,

Brazzaville.

[8] K. Ngoma & B. Poungui (2011), Effect of Temperature on the

Drying Kinetics of Mud Bricks Stabilized with Cassava Flour,

Engineer Dissertation, National Engineering College, Marien

NGOUABI University, Brazzaville.

[9] D. Taoukil et al., (2011), Mechanical and Water

Characterization of a Lighter Concrete with Wood Waste,

International Journal of Solar Technology, Vol. 43.

[10] G.R. Mabiala Bototo (2012), Effect of Water Environment on

the Change of Mechanical Proprieties of Wood during Drying

Process, Master Thesis, University Marien NGOUABI,

Brazzaville (Congo).

[11] W.R. Khelifi Belouettar (2012), Influence of the Nature of the

Wood Chips on the Physical and Mechanical Properties of

Concrete Made from Wood Chips, Twentieth Meeting of Civil

Engineering University.

[12] G. Ganga (2013), Impact of Wood Waste on the Mechanical

and Acoustic Properties of Stabilized Mud Bricks, Master

Thesis, University of Yaound1, Cameroun.

[13] A. Nzabana (2013), Study of the Influence of the Content of

the Shavings and Sawdust Mahogany Stresses and Strains on

the Clay Brick during Drying in the Open Air and in the Oven,

Master Thesis, Marien Ngouabi University, Faculty of Sciences

and Technology, Brazzaville (Congo).

0

1

2

3

4

5

6

7

0% 5% 10%

C

o

m

p

r

e

s

s

i

v

e

s

t

r

e

n

g

t

h

(

M

P

a

)

Content of chips (%)

Compressive

strength of

water of drilling

Compressive

strength of the

slightly acid

water

The SIJ Transactions on Industrial, Financial & Business Management (IFBM), Vol. 2, No. 6, August 2014

ISSN: 2321-242X 2014 | Published by The Standard International Journals (The SIJ) 299

Prof. Timothe Nsongo is currently Scientist

at Physics Department (Faculty of Science

University Marien NGOUABI CONGO

Brazzaville) who he is conducted a research

program in the research group of physics and

mechanical properties of materials and also

he is a Director of scientific and information

of technology Department at the research

center of mining and geology. His current

research involves the clay based materials characterization and

industrial applications, the nano particles growth, the structure and

mechanical properties of alloys for Biomaterials applications.

Gilbert Ganga. He is working as a Lecturer

at the University of Marien NGOUABI. He is

preparing under the joint direction of

Professor Timothe NSONGO and Thomas

Tamo TATSIETE a ph.D thesis. Gilbert

GANGA has already published one paper and

make two oral scientific presentations at the

international conference. He is an Engineer of

mechanical Engineering graduated. He is

working as a Lecturer at the University of Marien NGOUABI. He is

preparing under the joint direction of Professor Timothe NSONGO

and Thomas Tamo TATSIETE a ph.D thesis. Gilbert GANGA has

already published one paper and make two oral scientific

presentations at the international conference. He is an Engineer of

mechanical Engineering graduated.

Prof. Thomas Tamo Tatsiete is a professor at

the University of Yaound1.He is a Manager

Director at the Department of development

research for industry at University of Yaound.

He has directed more of 10 Ph.D and published

more of 20 papers. He has a Ph.D in Civil

engineering.

Dr. Hilaire Elenga is a lecturer Assistant at

department of Geology of University Marien

NGOUABi. He also is a Manager Director of

the Research center of Mining and Geology.

Dr Hilaire Elenga is the head of the project on

clay materials in CONGO. He has published

more of 10 papers. He is a Ph.D graduate of

university of Marseille.

Você também pode gostar

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsNo EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsAinda não há avaliações

- 09 Safe Handling of ChemicalsDocumento23 páginas09 Safe Handling of ChemicalsOladimeji Taiwo100% (1)

- Sibco CatalogueDocumento112 páginasSibco CatalogueMonika SenAinda não há avaliações

- Influence of Cement ContentDocumento9 páginasInfluence of Cement ContentAthanas KoninAinda não há avaliações

- Ijciet: International Journal of Civil Engineering and Technology (Ijciet)Documento5 páginasIjciet: International Journal of Civil Engineering and Technology (Ijciet)IAEME PublicationAinda não há avaliações

- Ijaret: ©iaemeDocumento5 páginasIjaret: ©iaemeIAEME PublicationAinda não há avaliações

- Research Paper Studies On Strength of Concrete by Partial Replacement of Sand With SawdustDocumento3 páginasResearch Paper Studies On Strength of Concrete by Partial Replacement of Sand With SawdustjasimabdAinda não há avaliações

- Producing Lightweight Foam Concrete Building Units Using Local ResourcesDocumento10 páginasProducing Lightweight Foam Concrete Building Units Using Local Resourcesrahmadi syahrezaAinda não há avaliações

- Batch-7 Phase - LI FinalDocumento45 páginasBatch-7 Phase - LI Final19TUCV038 SHUHAIL AKTHAR.AAinda não há avaliações

- Comparative Study On The Strength of Lightweight Foamed Concrete Prepared Using Different ReagentsDocumento3 páginasComparative Study On The Strength of Lightweight Foamed Concrete Prepared Using Different ReagentsIJARP PublicationsAinda não há avaliações

- Recycled Plastic Aggregates in Manufacturing of Insulating MortarsDocumento7 páginasRecycled Plastic Aggregates in Manufacturing of Insulating MortarsBasil Baby-PisharathuAinda não há avaliações

- Study On Breathe Bricks: International Research Journal of Engineering and Technology (IRJET)Documento4 páginasStudy On Breathe Bricks: International Research Journal of Engineering and Technology (IRJET)Frida Faye LacsamanaAinda não há avaliações

- Utilizing Eucalyptus Waste Cement BoardDocumento10 páginasUtilizing Eucalyptus Waste Cement Boardneed to knowAinda não há avaliações

- Pridiction of Compressive Strength of Cement by Using Regression Technique With Partial Replacement of Hylam Powder in Cement MortarDocumento8 páginasPridiction of Compressive Strength of Cement by Using Regression Technique With Partial Replacement of Hylam Powder in Cement MortarMatthew JohnsonAinda não há avaliações

- Mechanical Behavior of Mortar Reinforced With Sawdust WasteDocumento8 páginasMechanical Behavior of Mortar Reinforced With Sawdust WasteJhon PerezAinda não há avaliações

- Experimental Investigation of Papercrete BrickDocumento17 páginasExperimental Investigation of Papercrete Brickxl LolpAinda não há avaliações

- Guntekin and SahinDocumento9 páginasGuntekin and SahinYuri KomissarovAinda não há avaliações

- Green High Performance Concrete Using Eco Sand and Industrial WastesDocumento11 páginasGreen High Performance Concrete Using Eco Sand and Industrial WastesSOMAinda não há avaliações

- Comparative Study On The Strength of Lightweight Foamed Concrete Prepared Using Different ReagentsDocumento3 páginasComparative Study On The Strength of Lightweight Foamed Concrete Prepared Using Different ReagentsReethika SAinda não há avaliações

- GGBS Concrete Strength AnalysisDocumento3 páginasGGBS Concrete Strength AnalysisSoundar PachiappanAinda não há avaliações

- An Engineering Approach To Predict The Proportion of Fines (Documento18 páginasAn Engineering Approach To Predict The Proportion of Fines (Thomas LawsonAinda não há avaliações

- Use of Aluminium Powder in The Production of Lightweight ConcreteDocumento12 páginasUse of Aluminium Powder in The Production of Lightweight ConcreteTan Khern Wee17% (6)

- Experimental investigation on concrete paver block using PVC plastic (38Documento6 páginasExperimental investigation on concrete paver block using PVC plastic (38GUGANATHAN AAinda não há avaliações

- A Study On The Properties of Air-Entrained Concrete For Masonary BlocksDocumento4 páginasA Study On The Properties of Air-Entrained Concrete For Masonary BlocksInnovative Research PublicationsAinda não há avaliações

- Predicting The Compressive Strength of Ground Granulated Blast Furnace Slag Concrete Using Artificial Neural NetworkDocumento7 páginasPredicting The Compressive Strength of Ground Granulated Blast Furnace Slag Concrete Using Artificial Neural NetworkomarbossAinda não há avaliações

- Cement effects on physical properties of expansive clay soil and compressive strength of blocksDocumento9 páginasCement effects on physical properties of expansive clay soil and compressive strength of blocksSam ChongAinda não há avaliações

- 1 PB PDFDocumento6 páginas1 PB PDFRIZALAinda não há avaliações

- Comparative Study of Cement Concrete and Geopolymer Masonry BlocksDocumento5 páginasComparative Study of Cement Concrete and Geopolymer Masonry BlocksManishDasAinda não há avaliações

- Recycled Plastic Used in Concrete Paver BlockDocumento3 páginasRecycled Plastic Used in Concrete Paver BlockInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- NSPDF PDFDocumento13 páginasNSPDF PDFmrcopy xeroxAinda não há avaliações

- 4N5 Ijeset0202520 PDFDocumento8 páginas4N5 Ijeset0202520 PDFBia MughalAinda não há avaliações

- Acoustic Properties of Sound Absorbing, Poly-Mer-Modified Porous Cement MortarsDocumento12 páginasAcoustic Properties of Sound Absorbing, Poly-Mer-Modified Porous Cement MortarsDomenico VizzariAinda não há avaliações

- Experimental Studies On Concrete Replacing Fine Aggregate With Blast Furnace SlagsDocumento3 páginasExperimental Studies On Concrete Replacing Fine Aggregate With Blast Furnace Slagsபுருஷோத்தமன் சரவணன்Ainda não há avaliações

- Experimental Study On Self Curing Concrete Using Sodium LignosulphonateDocumento5 páginasExperimental Study On Self Curing Concrete Using Sodium LignosulphonateijeteeditorAinda não há avaliações

- Experimental Study On Paver Blocks Utilize in Pet FibresDocumento7 páginasExperimental Study On Paver Blocks Utilize in Pet FibresijaertAinda não há avaliações

- Materials: Waste Utilization: Insulation Panel From Recycled Polyurethane Particles and Wheat HusksDocumento12 páginasMaterials: Waste Utilization: Insulation Panel From Recycled Polyurethane Particles and Wheat HusksANGELIQUE -Ainda não há avaliações

- Effect of Polypropylene Fibres On Fresh and Hardened Properties of Self-CompactingDocumento7 páginasEffect of Polypropylene Fibres On Fresh and Hardened Properties of Self-Compactingmudasar205Ainda não há avaliações

- Investigation of The Effect of Water-Cement Ratio On The Modulus of Rupture of ConcreteDocumento8 páginasInvestigation of The Effect of Water-Cement Ratio On The Modulus of Rupture of ConcreteRevati PatilAinda não há avaliações

- The Role of Soil Cement Blocks in Housing: Seminar ReportDocumento29 páginasThe Role of Soil Cement Blocks in Housing: Seminar ReportJayan VijayanAinda não há avaliações

- Effects of Partial Replacement of Cement With Marble Dust Powder On Properties of ConcreteDocumento5 páginasEffects of Partial Replacement of Cement With Marble Dust Powder On Properties of ConcreteIJIRSTAinda não há avaliações

- Ejemplo 1Documento11 páginasEjemplo 1Carlos AlmanzaAinda não há avaliações

- Compressive Strength of Concrete by Using Coconut Shell: Parag S. Kambli, Sandhya R. MathapatiDocumento7 páginasCompressive Strength of Concrete by Using Coconut Shell: Parag S. Kambli, Sandhya R. MathapatiIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalAinda não há avaliações

- Effects of Aggregate Gradation On The Properties of Concrete Made From Granite ChippingsDocumento5 páginasEffects of Aggregate Gradation On The Properties of Concrete Made From Granite ChippingsArham Sheikh100% (1)

- Concept of Green Concrete Using Construction Demolished Waste As Recycled Coarse AggregateDocumento6 páginasConcept of Green Concrete Using Construction Demolished Waste As Recycled Coarse AggregateseventhsensegroupAinda não há avaliações

- Partial Replacement of Fine Aggregate Using Sludge in ConcreteDocumento16 páginasPartial Replacement of Fine Aggregate Using Sludge in ConcreteBala GaneshAinda não há avaliações

- Fly Ash-Cement Based Structural Materials: B. "BaradanDocumento4 páginasFly Ash-Cement Based Structural Materials: B. "BaradanChin KamRongAinda não há avaliações

- Properties of Palm Ash Concrete: P.Premalatha, K.R.Vinodh, L.Chris Anto, R.NithiyaDocumento4 páginasProperties of Palm Ash Concrete: P.Premalatha, K.R.Vinodh, L.Chris Anto, R.NithiyainventionjournalsAinda não há avaliações

- Wood AshDocumento11 páginasWood Ashr;rAinda não há avaliações

- Compressed Earth Blocks PDFDocumento15 páginasCompressed Earth Blocks PDFPrashanth Penta ReddyAinda não há avaliações

- Article Text 463742 1 10 20190116 2Documento7 páginasArticle Text 463742 1 10 20190116 2Jiu ShitzukiAinda não há avaliações

- Mechanical Properties of High Volume Fly Ash Concrete: F.N.Okoye, N.B.SinghDocumento8 páginasMechanical Properties of High Volume Fly Ash Concrete: F.N.Okoye, N.B.SinghIOSRjournalAinda não há avaliações

- 181945-Article Text-463772-1-10-20190116Documento12 páginas181945-Article Text-463772-1-10-20190116IyaadanAinda não há avaliações

- Effective Thermal Conductivity of Foamcrete of Different DensitiesDocumento9 páginasEffective Thermal Conductivity of Foamcrete of Different DensitiesAmbeelAinda não há avaliações

- Producing Lightweight Foam Concrete Building Units Using Local ResourcesDocumento11 páginasProducing Lightweight Foam Concrete Building Units Using Local ResourcesPrakash Kumar PandeyAinda não há avaliações

- Effect of Sawdust As Fine Aggregate in Concrete Mixture: AbstractDocumento12 páginasEffect of Sawdust As Fine Aggregate in Concrete Mixture: AbstractOudhai VONGKEOAinda não há avaliações

- Ijet V4i3p47 PDFDocumento12 páginasIjet V4i3p47 PDFInternational Journal of Engineering and TechniquesAinda não há avaliações

- Abrasion ResistanceDocumento5 páginasAbrasion ResistanceHafiz Zain AkramAinda não há avaliações

- Me136p Exp7 Design of Concrete MixDocumento14 páginasMe136p Exp7 Design of Concrete MixJohn Henry SalvadoAinda não há avaliações

- A Study On The Compressive and Tensile Strength of Foamed Concrete PDFDocumento12 páginasA Study On The Compressive and Tensile Strength of Foamed Concrete PDFJohnAinda não há avaliações

- Experimental Study On Partial Replacement of Fine Aggregate With Quarry Dust and Saw DustDocumento13 páginasExperimental Study On Partial Replacement of Fine Aggregate With Quarry Dust and Saw DustPerarasan MAinda não há avaliações

- Daniel Limantara 2020 IOP Conf. Ser. Earth Environ. Sci. 498 012033Documento9 páginasDaniel Limantara 2020 IOP Conf. Ser. Earth Environ. Sci. 498 012033Tiara MonicaAinda não há avaliações

- Parallel Computing Zernike Moments Via Combined AlgorithmsDocumento9 páginasParallel Computing Zernike Moments Via Combined AlgorithmsthesijAinda não há avaliações

- A Model of Consumer Perception and Behavioral Intention For E-ReadingDocumento6 páginasA Model of Consumer Perception and Behavioral Intention For E-Readingthesij100% (1)

- Edge Ratio of Nifty For Last 15 Years On Donchian ChannelDocumento8 páginasEdge Ratio of Nifty For Last 15 Years On Donchian ChannelthesijAinda não há avaliações

- An Entrepreneurial Mindset and Factors' Effect On Entrepreneur's Spirit in IndonesianDocumento6 páginasAn Entrepreneurial Mindset and Factors' Effect On Entrepreneur's Spirit in IndonesianthesijAinda não há avaliações

- The Role of Total Productive Maintenance (TPM) in Safety Improvement and Decreasing Incidents in Steel IndustryDocumento6 páginasThe Role of Total Productive Maintenance (TPM) in Safety Improvement and Decreasing Incidents in Steel IndustrythesijAinda não há avaliações

- Effectiveness Evaluation of Behavioural Training and Development ProgrammesDocumento9 páginasEffectiveness Evaluation of Behavioural Training and Development ProgrammesthesijAinda não há avaliações

- Using PECVD Technology To Manufacture Environmental Products To Meet Consumer Demand and Improve ProductivityDocumento12 páginasUsing PECVD Technology To Manufacture Environmental Products To Meet Consumer Demand and Improve ProductivitythesijAinda não há avaliações

- ROI of Training and Development Programmes: Challenges and DevelopmentsDocumento6 páginasROI of Training and Development Programmes: Challenges and DevelopmentsthesijAinda não há avaliações

- The Behavioural Finance: A Challenge or Replacement To Efficient Market ConceptDocumento5 páginasThe Behavioural Finance: A Challenge or Replacement To Efficient Market ConceptthesijAinda não há avaliações

- Module Information Booklet (MIB) As A Sagacious Learning EffectivenessDocumento6 páginasModule Information Booklet (MIB) As A Sagacious Learning EffectivenessthesijAinda não há avaliações

- A Critical Review of The Advanced Research On Emotional Intelligence in Management - Based On Relationship With OCBDocumento7 páginasA Critical Review of The Advanced Research On Emotional Intelligence in Management - Based On Relationship With OCBthesijAinda não há avaliações

- Principals' Instructional Leadership: Fostering Teacher Professional DevelopmentDocumento7 páginasPrincipals' Instructional Leadership: Fostering Teacher Professional DevelopmentthesijAinda não há avaliações

- A Comparative Study of Customer Satisfaction of Islamic Banks and Conventional Banks in OmanDocumento5 páginasA Comparative Study of Customer Satisfaction of Islamic Banks and Conventional Banks in OmanthesijAinda não há avaliações

- Modeling Inland Intermodal Container Transport Systems in TaiwanDocumento6 páginasModeling Inland Intermodal Container Transport Systems in TaiwanthesijAinda não há avaliações

- Vaclav Havel: The Politician Practicizing CriticismDocumento9 páginasVaclav Havel: The Politician Practicizing CriticismthesijAinda não há avaliações

- The Tourism Activities and The Impact of Public PoliciesDocumento4 páginasThe Tourism Activities and The Impact of Public PoliciesthesijAinda não há avaliações

- Contributions On The Economic Assessment Methodology of Industrial Projects (E.A.M.I.P)Documento9 páginasContributions On The Economic Assessment Methodology of Industrial Projects (E.A.M.I.P)thesijAinda não há avaliações

- Significant Economic Applications of Long Term Financial Theories and PracticesDocumento4 páginasSignificant Economic Applications of Long Term Financial Theories and PracticesthesijAinda não há avaliações

- The Sustainable Logistics Strategies For Intermodal Transport Systems of Container Ports in TaiwanDocumento7 páginasThe Sustainable Logistics Strategies For Intermodal Transport Systems of Container Ports in TaiwanthesijAinda não há avaliações

- Gender and Violence in School: Current Phenomena and Copping StrategiesDocumento8 páginasGender and Violence in School: Current Phenomena and Copping StrategiesthesijAinda não há avaliações

- Enhancing Professional Learning and Development in The Teaching of Early Childhood Mathematics Through Action ResearchDocumento5 páginasEnhancing Professional Learning and Development in The Teaching of Early Childhood Mathematics Through Action ResearchthesijAinda não há avaliações

- Spending & Saving Habits of Youth in The City of AurangabadDocumento8 páginasSpending & Saving Habits of Youth in The City of Aurangabadthesij100% (2)

- Attributable E-Commerce Toward Purchase Intention: Online Search of Food ProductDocumento7 páginasAttributable E-Commerce Toward Purchase Intention: Online Search of Food ProductthesijAinda não há avaliações

- Student Engagement: A Strategic Tool To Reform The Quality of Management EducationDocumento5 páginasStudent Engagement: A Strategic Tool To Reform The Quality of Management EducationthesijAinda não há avaliações

- Robust Algorithm For Multiclass Weighted Support Vector MachineDocumento5 páginasRobust Algorithm For Multiclass Weighted Support Vector MachinethesijAinda não há avaliações

- Research On Hyper-Connectivity Element and Its Utilization On Consumer Performance Expectancy: A Literature AnalysisDocumento9 páginasResearch On Hyper-Connectivity Element and Its Utilization On Consumer Performance Expectancy: A Literature AnalysisthesijAinda não há avaliações

- The Effects of Earnings Management On Dividend Policy in Nigeria: An Empirical NoteDocumento8 páginasThe Effects of Earnings Management On Dividend Policy in Nigeria: An Empirical NotethesijAinda não há avaliações

- Transformation and Consolidation of Bodo Identity: An Enquiry Into The Role of The Middle ClassDocumento5 páginasTransformation and Consolidation of Bodo Identity: An Enquiry Into The Role of The Middle ClassthesijAinda não há avaliações

- An Impact of Self-Leadership On Innovative Behaviour in Sports Educators and Understanding of Advanced ResearchDocumento6 páginasAn Impact of Self-Leadership On Innovative Behaviour in Sports Educators and Understanding of Advanced Researchthesij100% (1)

- Iron Sulfides - Effect On Amine PlantsDocumento6 páginasIron Sulfides - Effect On Amine PlantsHsien Yu100% (1)

- Measuring errors and their classificationDocumento6 páginasMeasuring errors and their classificationNarendra Reddy0% (1)

- XH3-HE User'S Manual: Self-Contained, Single Pump Wellhead Control Panel For Harsh EnvironmentsDocumento9 páginasXH3-HE User'S Manual: Self-Contained, Single Pump Wellhead Control Panel For Harsh EnvironmentsprabuAinda não há avaliações

- Bio Molecules 9Documento3 páginasBio Molecules 9SilVI MARDELAinda não há avaliações

- Carbon Steel Flanges - Pressure and Temperature Ratings - Group 1.1 - Carbon SteelDocumento7 páginasCarbon Steel Flanges - Pressure and Temperature Ratings - Group 1.1 - Carbon Steelnoha azamaliAinda não há avaliações

- Device Fabrication Technology: Modern Semiconductor Devices For Integrated Circuits (C. Hu) Slide 3-1Documento40 páginasDevice Fabrication Technology: Modern Semiconductor Devices For Integrated Circuits (C. Hu) Slide 3-1EASACOLLEGEAinda não há avaliações

- Fluid Mechanics Basics for ECW 211Documento53 páginasFluid Mechanics Basics for ECW 211dixn__Ainda não há avaliações

- Establishing Scientifically Justified Acceptance Criteria For The Cleaning Validation of Apis (Active Pharmaceutical Ingredients) (Le Blanc)Documento6 páginasEstablishing Scientifically Justified Acceptance Criteria For The Cleaning Validation of Apis (Active Pharmaceutical Ingredients) (Le Blanc)jorgeAinda não há avaliações

- Chemistry 9 Chap 1 Long QADocumento17 páginasChemistry 9 Chap 1 Long QAAkbar Ali AhmedAinda não há avaliações

- Processing and Fish PreservationDocumento13 páginasProcessing and Fish PreservationAbdiqadir JibrilAinda não há avaliações

- Prehensive Viva Test (Responses)Documento80 páginasPrehensive Viva Test (Responses)Srikanth TanguduAinda não há avaliações

- Ats 2 (Csir Net) PDFDocumento17 páginasAts 2 (Csir Net) PDFAayushi VermaAinda não há avaliações

- EOR Screening-TaberDocumento14 páginasEOR Screening-TaberAjeng AyuAinda não há avaliações

- Acoustical Ceiling Tile SpecificationDocumento5 páginasAcoustical Ceiling Tile SpecificationuddinnadeemAinda não há avaliações

- CHEM 1015 Lab 2 - ExtractionDocumento17 páginasCHEM 1015 Lab 2 - ExtractionKnzy ElmasryAinda não há avaliações

- Analisis Karbohidrat MetodeDocumento28 páginasAnalisis Karbohidrat MetodearikuraAinda não há avaliações

- 1 s2.0 S1876610211005960 MainDocumento8 páginas1 s2.0 S1876610211005960 MainRenalyn TorioAinda não há avaliações

- College Physics 7th Ed Serway Chapter 11Documento30 páginasCollege Physics 7th Ed Serway Chapter 11Jorge GomezAinda não há avaliações

- Patrick Biller, Brajendra K. Sharma, Bidhya Kunwar, Andrew B. RossDocumento9 páginasPatrick Biller, Brajendra K. Sharma, Bidhya Kunwar, Andrew B. RossBrahian Alexander RinconAinda não há avaliações

- 442-032 PDF PDFDocumento12 páginas442-032 PDF PDFCalAinda não há avaliações

- Mnemonics ExampleDocumento10 páginasMnemonics ExampleArchana PattnaikAinda não há avaliações

- Notice: Applications, Hearings, Determinations, Etc.: Lin Zhi International Inc.Documento1 páginaNotice: Applications, Hearings, Determinations, Etc.: Lin Zhi International Inc.Justia.comAinda não há avaliações

- Global Warming TextsDocumento3 páginasGlobal Warming TextsAnonymous NbKeZIGDVMAinda não há avaliações

- FTJ Series Product Guide PDFDocumento12 páginasFTJ Series Product Guide PDFJhon SendokAinda não há avaliações

- Cold Formed Steel Design.Documento8 páginasCold Formed Steel Design.Shivaji SarvadeAinda não há avaliações

- HVAC Validation TestsDocumento4 páginasHVAC Validation TestsemonwreAinda não há avaliações

- TemperatureDocumento51 páginasTemperaturekartheek viswanathAinda não há avaliações

- MNL 67-2009 PDFDocumento128 páginasMNL 67-2009 PDFlolo100% (2)