Escolar Documentos

Profissional Documentos

Cultura Documentos

Sap MM Business Blue Print - Sample

Enviado por

Suvendu BishoyiTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Sap MM Business Blue Print - Sample

Enviado por

Suvendu BishoyiDireitos autorais:

Formatos disponíveis

SAP MM BLUE PRINT_SAMPLE G.V.

SHIVAKKUMAR

ZZZ MODEL GROUP

Version 1.0

MM MODULE G.V.SHIVAKKUMAR

VENKATESANSIVAKUMAR@YAHOO.CO.IN

Project: ZZZ Model Company

Business Blueprint

Materials Management

Version 1.0

Please use my link to download the SAP articles:-

http://gvshivakkumar.blogspot.in/?view=flipcard

http://www.sapfunctional.com/WM/Configuration/Index.htm

http://www.sapfunctional.com/WM/WMQ1.htm

http://www.sapfunctional.com/MM/MMQ1.htm

http://www.mediafire.com/view/hdfm84rmkq7h495/SAP_INTEGRATION_BETWEEN_MM+SD+PP.docx

http://www.mediafire.com/view/29trlg8qtn8z0nj/SAP_FI-MM_and_FI-SD_Integration.docx

http://www.mediafire.com/view/cxajoijh3j5s6es/Materials_Management_Step_by_Step_Configuration.docx

http://www.mediafire.com/view/svz777fpr8w0o2e/Systematic_Approach_to_Run_SAP_Implementation-Support-

Maintenance_Project.docx

http://www.mediafire.com/view/3cq2e2etbq0uty5/SD_Blue_Print_Document_Sample.docx

http://www.mediafire.com/view/lcf45t12n4899nx/SAP_Workflow_for_MM_Purchase_order.docx

G.V.SHIVAKKUMAR

Venkatesansivakumar@yahoo.co.in

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ MODEL GROUP

Version 1.0

MM MODULE G.V.SHIVAKKUMAR

VENKATESANSIVAKUMAR@YAHOO.CO.IN

Document Information

Document Owner: G.V.Shivakkumar

Document Distribution

Name Organization Distribution Date

Document History

All revisions made to this document are listed here in chronological order.

Version

No.

Brief

Description

Page

No

Author Reviewed by Approved

by

Released

by

Release

date

1.0

Initial Version

G.V.Shivakkumar

25.06.2014

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ MODEL GROUP

Version 1.0

MM MODULE G.V.SHIVAKKUMAR

VENKATESANSIVAKUMAR@YAHOO.CO.IN

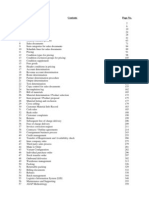

Contents

1. INTRODUCTION .............................................................................................................. 1

1.1 OBJECTIVE OF THIS REPORT ............................................................................................... 1

1.2 ORGANIZATION OVERVIEW ............................................................................................... 1

1.2.1 ABOUT ZZZ CHEMICALS ................................................................................................. 1

1.2.2 ABOUT ZZZ POLYMERS .................................................................................................. 2

1.3 MATERIALS MANAGEMENT AT ZZZ .................................................................................... 3

2. ORGANIZATIONAL ELEMENTS IN MM ........................................................................... 6

2.1.1 PLANTS ....................................................................................................................... 6

2.1.2 PURCHASE ORGANIZATIONS............................................................................................ 7

2.1.3 PURCHASING GROUPS ................................................................................................... 8

2.1.4 STORAGE LOCATIONS .................................................................................................... 9

2.1.5 WAREHOUSE ............................................................................................................. 11

3. PROCESS ARCHITECTURE ............................................................................................. 19

3.1 MATERIAL MASTER ....................................................................................................... 19

3.1.1 THE MATERIAL TYPES IDENTIFIED FOR ZZZ ....................................................................... 19

3.1.2 ASSUMPTIONS ........................................................................................................... 20

3.1.3 UNIT OF MEASUREMENT.............................................................................................. 20

3.2 VENDOR MASTER ......................................................................................................... 21

3.2.1 ASSUMPTIONS ........................................................................................................... 21

3.3 BATCH MANAGEMENT ................................................................................................... 21

3.4 EXCISE MASTERS ........................................................................................................... 22

4. PROCUREMENT............................................................................................................. 23

4.1 PURCHASE REQUISITION ................................................................................................. 24

4.1.1 PROCESS FLOW .......................................................................................................... 24

4.2 REQUEST FOR QUOTATION (RFQ) ................................................................................... 25

4.2.1 PROCESS FLOW .......................................................................................................... 25

4.3 VENDOR QUOTATION AND BID EVALUATION ...................................................................... 26

4.3.1 PROCESS FLOW .......................................................................................................... 26

4.3.2 GAPS / ISSUES IDENTIFIED AND SOLUTIONS ...................................................................... 28

4.3.3 FORMS AND REPORTS REQUIRED .................................................................................... 28

4.4 PURCHASE ORDER STOCK ITEMS ....................................................................................... 28

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ MODEL GROUP

Version 1.0

MM MODULE G.V.SHIVAKKUMAR

VENKATESANSIVAKUMAR@YAHOO.CO.IN

4.4.1 PROCESS FLOW .......................................................................................................... 28

4.4.2 EXCEPTIONS AND VARIATIONS ....................................................................................... 31

4.4.3 FORMS AND REPORTS REQUIRED .................................................................................... 31

4.4.4 CONDITIONS IN PURCHASE ORDER ................................................................................. 31

4.4.5 DELIVERY COSTS IN PURCHASE ORDERS .......................................................................... 32

4.4.6 EXCISE AND SALES TAX RELATED DETAILS ......................................................................... 32

4.4.7 ACCOUNT ASSIGNED PO (CONSUMPTION ORDERS) .......................................................... 33

4.4.8 ASSET PURCHASE ....................................................................................................... 33

4.4.9 RELEASE PROCEDURE FOR PURCHASE ORDER ................................................................... 33

4.4.10 FORMS AND REPORTS REQUIRED .................................................................................. 34

4.5 HIGH SEA SALES ........................................................................................................... 34

4.5.1 EXCEPTIONS AND VARIATIONS ....................................................................................... 35

5. INVENTORY MANAGEMENT ........................................................................................ 36

5.1 MATERIAL RECEIPT ........................................................................................................ 36

5.1.1 GOODS RECEIPT PROCEDURE ........................................................................................ 37

5.1.2 EXCISE DETAILS TO BE CAPTURED AT GOODS RECEIPT FROM VENDOR ..................................... 47

5.1.3 GAPS / ISSUES IDENTIFIED AND SOLUTIONS ...................................................................... 48

5.1.4 FORMS AND REPORTS REQUIRED .................................................................................... 48

5.1.5 INTERFACES ............................................................................................................... 48

5.2 MATERIAL ISSUES (CONSUMPTION) ................................................................................. 48

5.2.1 TRANSFER POSTINGS ................................................................................................... 49

5.2.2 PLANT TO PLANT TRANSFERS ......................................................................................... 50

5.2.3 TRANSFER OF MATERIAL FROM MANUFACTURING PLANT TO STOCKING PLANT OR C&F (WITH

EXCISE INVOICE) ..................................................................................................................... 50

5.2.4 MATERIAL TRANSFER FROM STORAGE LOCATION TO STORAGE LOCATION .............................. 51

5.2.5 MATERIAL TO MATERIAL TRANSFER ............................................................................... 51

5.2.6 STOCK TO STOCK......................................................................................................... 51

5.2.7 BIN TO BIN TRANSFER .................................................................................................. 52

5.3 MATERIAL RETURNS ...................................................................................................... 52

5.3.1 MATERIAL RETURN TO VENDOR .................................................................................... 52

5.3.2 MATERIAL RETURN TO STORES ...................................................................................... 53

5.3.3 FORMS AND REPORTS REQUIRED .................................................................................... 53

5.4 MATERIAL RESERVATION ................................................................................................ 53

5.5 STOCK TRANSFER ORDER ................................................................................................ 55

5.5.1 CHARACTERISTICS OF A STOCK TRANSFER ORDER .............................................................. 55

5.5.2 PROCESSING OF STOCK TRANSFERS BETWEEN THE TWO PLANTS .......................................... 56

5.6 VENDOR EVALUATION ................................................................................................... 57

5.6.1 ASSUMPTION ............................................................................................................. 62

5.6.2 EXCEPTIONS AND VARIATIONS ....................................................................................... 62

5.7 PHYSICAL INVENTORY .................................................................................................... 62

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ MODEL GROUP

Version 1.0

MM MODULE G.V.SHIVAKKUMAR

VENKATESANSIVAKUMAR@YAHOO.CO.IN

5.7.1 PHYSICAL INVENTORY IN WAREHOUSE MANAGEMENT ....................................................... 63

5.7.2 EXCEPTIONS AND VARIATIONS ....................................................................................... 65

5.7.3 AUTHORISATION REQUIREMENTS ................................................................................... 65

5.8 LOGISTICS INVOICE VERIFICATION / BILL PASSING ............................................................... 65

5.8.1 PROCESS FLOW .......................................................................................................... 66

6. EXCISE JVS .................................................................................................................... 68

7. SCRAP IDENTIFICATION ................................................................................................ 70

7.1.1 PROCESS FLOW .......................................................................................................... 70

8. INFORMATION SYSTEM IN MM ................................................................................... 71

9. LIST OF ABAP DEVELOPMENTS .................................................................................... 72

9.1 FORMS & REPORTS ....................................................................................................... 72

9.2 DATA MIGRATION STRATEGY .......................................................................................... 72

9.2.1 MASTER DATA ........................................................................................................... 72

9.2.2 BALANCES ................................................................................................................. 72

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 1 -PAGE 1 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 1

- 1 -OF 78

1.Introduction

1.1 Objective of this report

The report initially gives an overview of the Materials management Module purview along with

CIN and Warehouse Management. This would essentially help in defining the boundaries of the

module and also in identifying the activities to be performed within Materials management

Module in SAP. Subsequently, the report discusses in detail, the proposed coverage of SAP at

ZZZ, in terms of organisational entities and business processes. Each business process has been

described with all the variations. The authorisation requirements would be identified and

configured during the configuration phase

1.2 Organization Overview

ZZZ Group SAP implementation spans the following two group companies:

ZZZ Chemicals Limited

ZZZ Polymers Limited

1.2.1 About ZZZ Chemicals

ZZZ Chemicals Ltd. is in the business of manufacturing and marketing of petroleum products

It serves the following market segments:

The industrial market consisting of industrial users of oils who buy the products in bulk

on regular basis. These include private sector as well as public sector companies.

The retail market consisting of small users of oils to whom products are sold through

multiple levels of demand chain (C&F Agents, Dealers and Retailers).

Export market

The product categories of ZZZ are:

Specialty oils, with a focus on Industrial customers, consisting of:

Transformer oils

Light Liquid Paraffin

Heavy Liquid Paraffin

White Oils

Speciality Oils

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 2 -PAGE 2 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 2

- 2 -OF 78

Lube Oils with a focus on retail users

ZZZ has about 350 stock keeping units, consisting of Product, Grade, Brand and Pack size.

ZZZs business units are:

Head office in Mumbai

Two factories Thane and Silvassa

One packing unit at Mahape

Five branch offices

About 40 C&F Agents spread all over India

1.2.2 About ZZZ Polymers

ZZZ Polymers Ltd. is situated in Coimbatore and in engaged in the business of manufacturing and

selling petroleum products and polymers catering to the requirement of telecom industry,

pharmaceutical & cosmetic industry as well as manufacturing emulsifiable waxes & emulsions

for textile industry. Presently about 80% of the turnover is for Export products viz.: CFC,

Transformer Oils, White Oil and Petroleum Jelly. The domestic market demand involves

emulsifiable wax BW 300 and small quantities of CFC, Petroleum Jelly and Optical Fibre Jelly. SPL

employs about 75 people.

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 3 -PAGE 3 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 3

- 3 -OF 78

1.3 Materials Management at Savita

The Material Management Module has multiple processes broadly divided into Procurement,

Good Receipt and Inventory Management across businesses in ZZZ Group.

Purchasing is a component of Materials Management (MM). The Materials Management (MM)

module is fully integrated with the other modules of the SAP System. It supports all the phases

of materials management: materials planning and control, purchasing, goods receiving,

inventory management, and invoice verification

The purchasing module deals with the:

External procurement of materials and services

Determination of possible sources of supply for a requirement identified by the

materials planning and control system or arising directly within a user department

Purchasing communicates with other modules in the SAP System to ensure a constant

flow of information. For example, it works side by side with the following modules like

Controlling (CO), Financial Accounting (FI), Sales and Distribution (SD), Quality Control

(QM).

Inventory Management component of Material management deals with the following tasks:

Management of material stocks on a quantity and value basis

Planning, Entry, and Documentation of all Goods Movements

Carrying out the Physical Inventory.

Logistics Invoice Verification is a part of Materials Management (MM). It is situated at the end of

the logistics supply chain that includes Purchasing, Inventory Management, and Invoice

Verification. It is in Logistics Invoice Verification that incoming invoices are verified in terms of

their content, prices, and arithmetic. When the invoice is posted, the invoice data is saved in the

system. The system updates the data saved in the invoice documents in Materials Management

and Financial Accounting.

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 4 -PAGE 4 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 4

- 4 -OF 78

SAP R/3 Materials Management

Material

Special stock

Batch

Vendor/one-time

customer

Purchasing

info record

Service

specifications

Texts

Mail

Communication

Classification

Conditions

BASIC DATA BASIC DATA

P

u

r

c

h

a

s

i

n

g

i

n

f

o

r

m

a

t

i

o

n

s

y

s

t

e

m

V

e

n

d

o

r

e

v

a

l

u

a

t

i

o

n

Purchase requisition

PURCHASING PURCHASING

MRP

Direct requisition

Release procedures

RFQ/Quotation

Material/service

Price comparisons

Price comparison list

Purchasing

Purchase orders

Outline agreements

Scheduling agreements

Goods receipt/issue

Transfer posting

Quantities and values

Physical inventory

Storage bins

Check and post

Price update

INVENTORY MANAGEMENT INVENTORY MANAGEMENT

INVOICE VERIFICATION INVOICE VERIFICATION

SD SD

PP PP

PM PM

QM QM

FI FI

AM AM

CO CO

WM WM

Third-party

order

Requirements

Service /

spare parts

Inspection lot

G/L accounts

Cash management

and forecast

Fixed assets

Cost center /

Budget

Ware house

management

SAP R/3 Materials

Management

Mater ials

Planning

Inv oic e Ver ifi ca tion

Financial a nd C os t

Accounti ng

Sales and

Distr ibut ion

Mas ter Da ta

Material

Batches

Vendors

G/L accounts

Storage bins

Goods Receipt Tr ansfer

Posting

Goods

Issue

Invoice

Receipt

Inve ntor y Ma na geme nt

Impor ts PO

Pur chasing

Pur chase

Or der

Materials Manage ment

Business Process Scope:

The Materials Management (MM) module will cover the following business processes:

Organization Structure (Related to Materials)

Consumption Based MRP Planning of material either based on Reorder Point or Forecast

based.

Purchase Requisition Processing Generation of Requisitions for materials and services based

on MRP, Real time (manual), sales order and projects.

RFQ/Quotation Processing Generation of Request for Quotation (RFQ), Quotation processing

and comparison.

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 5 -PAGE 5 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 5

- 5 -OF 78

Purchase Order Processing Creating Purchase Orders (PO) for materials and services with

respect to PR, Quotation, Contracts, direct PO, Stock Transfer Order, Sub-Contracting, Releasing

the PO to vendors.

Vendor Evaluation Vendor Evaluation based on Quality and reliability parameters.

Inventory Management Managing material receipt, Issues and transfers in the plants, and

Physical Inventory.

Inventory Valuation Material Valuation based on moving average price and standard price

based on inventory transactions.

Invoice Verification Bill passing for the vendors for materials and services, Credit Note

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 6 -PAGE 6 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 6

- 6 -OF 78

2.Organizational elements in MM

2.1.1 Plants

The Plant is an operating area within a company where there is stock movement. Each of the

manufacturing locations and C & F locations shall be identified as a Plant in SAP. For the

purposes of valuation of inventory at ZZZ Group, the Plant is defined as the Valuation Level

within SAP where materials will be valued.

The plant is embedded in the organizational structure as follows:

The Plant is assigned to a single Company code. A Company code can have several plants. As ZZZ

has two companies i.e. ZZZ Chemical and ZZZ Polymer each companies will have their own set of

Plants.

Several Storage Locations in which material stocks are managed can belong to a plant. A plant

can have one or more storage locations.

A Plant can be assigned to several combinations of Sales Organisation and Distribution Channel.

(will be mentioned normally-Details in the SD blue print)

A Plant can have several Shipping Points. A Shipping Point can be assigned to several Plants (will

be mentioned normally-Details in the SD blue print).

A plant has an Address, Language, and Country.

A plant has its own material master data. You can maintain data at plant level for the following

views on a material master record in particular: MRP, Purchasing, Storage, Work scheduling,

Production resources/tools, Forecasting, Quality management, Sales, Accounting and Costing.

The plant plays an important role in Material Valuation, Inventory Management, MRP,

Production, and Costing & Plant Maintenance.

The list of plants attached to ZZZ Chemicals Limited as under:

ZZZ Chemicals

Trichy Plant - 1100

Madras Plant - 1200

Salem Plant - 1300

Outside Storage - 1400

Delhi Branch - 1500

8 Windmills - 1701 1708

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 7 -PAGE 7 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 7

- 7 -OF 78

43 C & F Locations - 1601 1643

Head Office - 1800

The list of plants attached to Savita Polymers Company is as under:

ZZZ

mohali Plant - 2100

SSSS Plant - 2200

Head Office - 2300

Outside Location - 2400

Dependencies

One additional logical plant of Head office has to be created as the procurement activities for

ZZZ chemical and ZZZ polymer is handled centrally from head office.

SSSS Plant 2200 attached to company ZZZ will be used only for managing initial assets and

inventory. Transactions for this plant will not be mapped.

The procurement of administrative and Service items at head office will have to be identified as

per the companies.

All the material stored in the outside locations will have to be identified as per the company

code and will be accounted in one Plant for each company code i.e. Outside Locations

For identification of stock at various Storage Locations and tanks within the storage locations

will done through ware house management.

As materials are stored at C&F and each C&F has its own valuation, the same will be created as

Plants.

2.1.2 Purchase Organizations

A Purchase Organization is an organizational unit within logistics in SAP R/3, which subdivides an

enterprise to facilitate efficient and effective Purchasing. A Purchase Organization procures

materials and services, negotiates conditions of purchase with vendors, and bears responsibility

for such transactions.

A Purchasing Organization can be divided into several purchasing groups that are responsible for

different operational areas. Each purchasing organization has its own

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 8 -PAGE 8 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 8

- 8 -OF 78

Vendor Master Data

Purchase Info Records

Conditions for Pricing

Purchasing Organisation for ZZZ Group: ZZZ group will have one Central Purchase Organisation

which will be responsible for procurement for ZZZ Chemical and ZZZ Polymers.

ZZZ Group will also have plant wise Decentralised Purchase Organisation to cater miscellaneous

procurement handled independently by each plant.

T001 - Central Purchase Org (handled by Head office)

C001 - Decentralised P org for Trichy

C002 - Decentralised P org for Mohali

C003 - Decentralised P org for Salem

C003 - Central P org for ZZZ

P001 - Decentralised P org for Mangalore

These purchasing organisations will cater to all the procurement activities required for the

plants.

For example all the plant specific raw materials/spares/tools etc. will be bought by the plant

procurement department using the respective purchasing organisation.

2.1.3 Purchasing Groups

The purchasing organisation is further subdivided into purchasing groups (buyer groups), which

are responsible for day-to-day buying activities. A purchasing group is an entity, which

communicates with the vendor.

The purchasing group is internally responsible for the procurement of a material or an external

service and as a rule the principal channel for a company's dealings with its vendors.

Purchasing groups for Savita Group

H01 - Imports Presently the person Responsible are Mr xxxxl and yyyyy

H02 - RM Domestic, Packing and Transport Presently the person responsible Mr cccc

H03 - Engineering & capital & consumables purchase Presently the person responsible Mr

ffffff

H04 For administrative purchases

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 9 -PAGE 9 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 9

- 9 -OF 78

P01 Trichy Plant Presently the person responsible is Plant Head Trichy

P02 Salem Plant Presently the person responsible is Plant Head Salem

P03 Mangalore Plant Presently the person responsible is Plant Head Mangalore

P03 Madras Plant Presently the person responsible is Plant Head Madras

2.1.4 Storage Locations

A storage location is the place where stock is physically kept within a plant.

A storage location has the following attributes:

There shall one or more storage locations within a plant.

A storage location has its code and description.

It is possible to store material data specific to a storage location.

Stocks are managed only on a quantity basis and not on a value basis at storage location

level.

Physical inventories are carried out at storage location level.

Storage location are always created for a plant

Storage Locations for Savita Group are

Plant: Trichy 1100

CODE Description

1100 Tank Farm

L001 TG-3

L002 Hydrocarbon

L003 M TOP Plant.

L004 Behind New Godown

L005 New Tank Farm

L006 LLP Godown

L007 OIL-1 Tank Area

L008 Near Weigh BRIDGE.

L009 PM Speciality Open

L010 Scrap

L011 Rejected Speciality

L012 Rejected Lubes.

L013 Engineering Stores

L014 R & D

L015 TO Godown.

L016 Lube Plant

L017 Lube open

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 10 -PAGE 10 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 10

- 10 -OF 78

CODE Description

L018 New warehouse I

L019 New warehouse 2

Plant: Mohali 1200

CODE Description

1200 Tank Farm

L101 Scrap

L102 Rejected

L103 Engineering Stores

L104 Trading Stores

L105 FG/PM Stores

L106 Returnable Stores.

Plant: Salem 1300

CODE Description

1300 Tank Farm

L201 Shed adjoining to unit II

L202 Area behind Unit I / II

L203 FG Drums storage BSR

L204 Unit No. 1

L205 Unit No. 2

L206 Rear end road

L207 New BSR -Road

L208 Area OPP .to Unit I & II

L209 Unit NO.2

L210 Unit NO. 1

L211 Engg. Stores

L212 Utility Block

L213 Scrap

Plant: Outside location 1400

CODE Description

1400 Tank Farm

Plant: Madras 2100

CODE Description

2100 Tank Farm

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 11 -PAGE 11 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 11

- 11 -OF 78

L301 CFC PLANT

L302 CFC PLANT OPEN YARD

L303 CFC SHED NO.1

L304 CFC SHED NO.2

L305 MCW PLANT

L306 MCW PLANT OPEN YARD

L307 TBS SHED

L308 RAW MATERIAL WAREHOUSE

L309 RAW MATERIAL WAREHOUSE OPEN YARD

L310 PPD WAREHOUSE

L311 E.WAX PLANT

L312 OFC PLANT & POWDER ROOM

L313 PETRO.JELLY PLANT OPEN YARD

L314 PETRO.JELLY PLANT

L315 BFP

L316 BFP OPEN YARD

L317 D.G.ROOM

L318 ENGG.STORES

L319 ENGG.STORES OPEN YARD

Plant: Outside location 2400 (SPL)

CODE Description

2400 Tank Farm

Dependencies

Each plant will have minimum one storage location to monitor inventory related transaction

For ZZZ company

Delhi Plant, C & F Plants, Wind Mill Plants and HO will have one Storage location each

For ZZZ company

Salem Plant and HO will have one storage location

2.1.5 Warehouse

The Warehouse Management (WM) application provides flexible, automated support to assist

you in processing all goods movements and in maintaining current stock inventories in your

warehousing complex.

WM supports warehousing processes by making it possible for you to

Define and manage complex warehousing structures

Optimize material flow using advanced put away and picking techniques

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 12 -PAGE 12 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 12

- 12 -OF 78

Process goods receipts, goods issues and stock transfers quickly and easily

For ZZZ Group Ware house structure is as follows

For Trichy Plant Storage Location Tanks

TRICHY

1100

TANK FARM

1100

TANK

110

Ex-Bonded

E01

Bonded

B01

Tank

B001 B067

Tanks

E001 E067

Plant Code

Storage

Location

Section

Bins

Storage Type

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 13 -PAGE 13 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 13

- 13 -OF 78

For Mohali Plant Storage Location Tanks

Mohali

1200

Tank Farm

1200

Tank

120

Receiving

R01

Tanks

R101 R126

Plant Code

Storage

Location

Section

Bins

Storage Type

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 14 -PAGE 14 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 14

- 14 -OF 78

For Salem Plant Storage Location Tanks

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 15 -PAGE 15 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 15

- 15 -OF 78

Salem

1300

Tank Farm

1300

Tank

130

Ex-Bonded

E01

Bonded

B01

Tank

B201 B229

Tanks

E201 E229

Plant Code

Storage

Location

Section

Bins

Storage Type

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 16 -PAGE 16 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 16

- 16 -OF 78

For Outside Plant Storage Location Tanks

Outside

1400

Tank Farm

1400

Andheri

141

Tank

B900 B999

Tanks

E900 E999

Plant Code

Storage

Location

Section

Bins

Storage Type

New

Mum

144

BPT

143

Out

Tank

145

Out

Tank

146

JNPT

142

Ex Bonded

E01

Bonded

B01

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 17 -PAGE 17 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 17

- 17 -OF 78

For Madras Plant Storage Location Tanks

Assumptions

Madras

2100

Tank Farm

2100

Tank

210

Ex-Bonded

E01

Bonded

B01

Tank

B301 B350

Tanks

E301 E350

Plant Code

Storage

Location

Section

Bins

Storage Type

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 18 -PAGE 18 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 18

- 18 -OF 78

1. In ZZZ Group Ware House Management will activated only for Tanks in the respective

plants.

2. All the tanks will be created as BIN.

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 19 -PAGE 19 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 19

- 19 -OF 78

3.Process Architecture

3.1 Material Master

The material master contains information on all the materials that a company procures or

produces, stores, and sells. It is the company's central source for retrieving material-specific

data. This information is stored in individual material master records.

Material master is integrated with

Material Management

Production Planning

Sales and Distribution

Accounting and Controlling

Creation of material code is always with reference to the material type for which it is created

Material number generation is at the Level of Material Type.

Each material type will be identified with a different number range series.

Uniform material codification has to be maintained across all the plants of ZZZ

Material code has to be maintained on which CENVAT is allowed as per CIN

requirement.

3.1.1 The material types identified for ZZZ

Raw Materials

Stores and Spares

Packing Material

Semi-Finished goods (Intermediate Goods)

Finished goods

Scrap

Trading goods

Engineering for capital goods

Administration

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 20 -PAGE 20 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 20

- 20 -OF 78

3.1.2 Assumptions

1. ZZZ will follow the external numbering for material codification system.

2. The numbering will be restricted to maximum 6 characters

3. Material Code will unique across all plants

4. Raw material e.g. Base oil will be batch managed

5. Raw Material, Stores and Spares, Packing Material and Trading Goods will have Moving

Average Price (MAP)

6. Semi Finished, Finished and Scraps goods will have Standard Price (SP)

7. If the same material is sourced from local and foreign vendors, it will have a separate

code and valuations

8. Bonded and Ex-bonded material will have a unique code and hence one valuation

9. Each material type will have a valuation class and a G/L A/c linked to it for inventory

postings

3.1.3 Unit of Measurement

Following Units of measurement can be maintained in material master.

Base Unit of Measurement

Sales Unit of measurement

Ordering Unit of measurement

Issue Unit of measurement

For any entry of UOM other than base unit of measurement, a conversion factor with respect to

the base UOM will have to be maintained. At The material transactions the appropriate

conversion will be carried out. For e.g. base UOM is KG however Issue UOM is L & the

Conversion rate is 1kg=2L then if 100kg of material is issued the stock will be reduced by

200L.The stock overview report can be seen in both UOMs.

SAP standard reports provide the information in the Base Unit of Measurement.

The relation between base unit of measure and alternative unit of measure has to be identified

properly and relationship will be unique for the material. The material cannot have multiple

values for an alternative unit of measure with respect to the base unit of measure.

For ZZZ

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 21 -PAGE 21 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 21

- 21 -OF 78

Base oils the base unit of measurement will be Litres.

The base UOM will be unique for a material for all the plants.

3.2 Vendor Master

Vendor shall be created for the Purchasing Organisation and company code wherein its going to

be used. The various Account groups, which shall be used to create a vendor, are:

Domestic Vendors

Import Vendors

Service Vendors

Employees

FI vendors

For advanced licence tracking

3.2.1 Assumptions

1. Vendor numbering will be alpha-numeric linked to Account Groups and the number ranges

will be externally generated with separate no. range assigned to various account groups

2. If a vendor is supplying from multiple location, separate vendor codes shall be created for

each of the vendor location.

3. Dummy Vendors will be created for each of the Advance License. A separate reconciliation

account will be identified for these type of vendors created per advance license

4. The vendors are maintained at company code and purchasing organisation level and cannot

be identified by plant level.

3.3 Batch Management

Certain raw materials in stores be batch managed. For these materials, batch numbering shall be

externally assigned. Material having similar characteristics but slight difference in specifications

shall be managed with activation of batch management.

Batch will be at plant level, while transferring the material from one plant to another; same

batch number shall be identified at the receiving plant.

Batches will be identified manually during issue. There will be no batch for SFG. All FGs except

lubes will be batch managed.

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 22 -PAGE 22 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 22

- 22 -OF 78

The batches Number will be captured at the time of GRN preparation which will be entered

manually. Batch number can be maintained as vendor wise, make wise, date wise etc. as per

requirement.

Savita will use vessel wise batch numbers for imports raw material

3.4 Excise Masters

Following India-specific (from statutory standpoint) masters need to be created in SAP

Chapter ID Descriptions

Material Chapter ID combination

Material Assessable values

Modvat determination

Vendor Excise details

Customer Excise details

Excise rates

Exceptional Excise rates

Additional Excise rates

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 23 -PAGE 23 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 23

- 23 -OF 78

4.Procurement

In SAP the procurement process can be broadly defined as per the eight steps defined below. In

ZZZ the Material requirement planning (MRP) of raw material will be derived based on Bill of

Material of finished goods. The forecast for the finished goods will be indicated in the Sales and

operation planning (SOP). The requirement of the raw material will be net of the available stock,

open purchase order and open purchase requisition. The details of processes of MRP and SOP

will be covered in PP and SD blueprint

Purch. req.

Procurement Procurement

Determination of Req.

Payment processing

1 1

8 8

Vendor selection 3 3

Source determination

2 2

PO processing 4 4

Purch. ord.

10

20

30

Goods receipt 6 6

Invoice verification 7 7

Invoice

? ?

PO monitoring 5 5

Purchase

Order

10

20

30

Procurement Cycle Summary

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 24 -PAGE 24 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 24

- 24 -OF 78

4.1 Purchase Requisition

A Purchase Requisition is an internal document, which is a request or instruction to Purchasing

Department to procure a certain quantity of a material or services so that it is available at a

certain point in time.

The following shall be the source of Purchase Requisition (PR):

MRP (Materials requirement planning including reorder /forecast)

Manual

Maintenance Order

4.1.1 Process Flow

From MRP:

For Raw materials, Packing materials and Stores and Spares the Purchase Requisition will be

automatically created through MRP run. Raw material and Packing material requirement will be

based on the BOM of FG and SFG. In case of Stores and Spares the material requirement will be

based on reorder point, which will be defined in the Material Masters.

Manual:

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 25 -PAGE 25 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 25

- 25 -OF 78

The user can also create a Manual Requisition for specific requirement and will be created by

authorised personnel.

From Maintenance Order:

System will automatically generate the PR for the non stock able items in the order.

Document types for Purchase Requisitions NB- Purchase requisitions

4.2 Request for Quotation (RFQ)

4.2.1 Process Flow

Request for Quotations are the enquiries issued to the identified vendors for receiving the Price

quote of required materials.

RFQs will be issued to each of the approved vendors for a particular material. Based on the

numbers of vendors the same number of RFQs will be issued i.e. A unique RFQ will be issued to

each of the approved vendors for a particular material.

RFQ will be created with reference to the Purchase requisition if it exists as per the PR

procedure earlier defined e.g. PR created manually or through MRP. RFQs also will be created

without any reference if no PR exists.

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 26 -PAGE 26 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 26

- 26 -OF 78

Each individual RFQ created will have Header and Item Information.

Header Information will capture vendor details based on the Vendor Master and

General Information in the form Text.

Item Information will capture the details of the material, the quantity required and

delivery dates.

In the RFQ the user will identify the following details

Purchasing Organisation

Purchase Group

Deadline for Submission of quotation

Material and Quantity

Plant for which the material is required

All the RFQ issued to different vendors for the procurement of the same material will be

identified with a same and unique collective number. The collective number will be identified by

the user as it will form a base for comparison of quotation from different vendors for the same

material

A tracking number also can be identified by the user for each of the RFQs for the his operating

convenience

There shall be RFQ document type: AN

4.3 Vendor Quotation and Bid evaluation

4.3.1 Process Flow

Quotations will be received from the vendors based on the RFQ sent to them. The Quotations

will have the various pricing conditions quoted by the vendor for the material specified in RFQ.

The quotation received will be entered in the system with reference to RFQ issued. The RFQ and

quotation will be identified with the same number.

The detail price break up will be identified in the quotation. For e.g. some of the details are

stated below.

Basic Rate

Discount

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 27 -PAGE 27 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 27

- 27 -OF 78

Packing and Forwarding

Excise Duty

VAT

Freight (Inward and Outward)

Assumptions

The above price break-up will be the form pricing condition in the Price Schema which will be

attached in the Vendor master.

Quotation compare

The quotation compare will be based on the collective number identified in the RFQ. All the RFQ

identified with a unique collective number will be compared. The system will calculate the net

effective price after taking into consideration the secondary elements in the price i.e. Discount,

Freight, packing etc.

The system will consider the taxation during calculate the effective / net price. I.e. The net price

will be net of excise, but the sales tax will not be taken into account.

All quotation comparisons will be on the net landed price. If the user wants to refer the detail

pricing of each quotation, then on the same screen the user will have to click on the quotation

and the data will be furnished.

All the quotations also can be compared with reference to ideal quotation which will have a best

price.

The system will rank the compared quotation based on the landed price.

Based on the RFQ generated in the SAP, the vendor sends his quotation this is captured in the

RFQ made for the vendor in the SAP.

The details of the quote, i.e. the conditions (like Basic price, freight, discounts etc) are keyed

into the system. Quotations received from the various suppliers shall be entered into the system

with reference to RFQ generated in the system. Quotation comparison can be carried out using

various Quotation numbers or using the Collective number.

In SAP the RFQ & Quotations shall have the same number.

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 28 -PAGE 28 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 28

- 28 -OF 78

The quotation shall be compared based on the pricing conditions entered in the system.

4.3.2 Gaps / Issues Identified and Solutions

The system does not compare the quotations based on payment terms, Inco terms and technical

aspects of the material.

4.3.3 Forms and reports required

Report on Quotation Compare will have to be developed.

4.4 Purchase order Stock items

A purchase order is a formal request to a vendor to supply certain goods or services under

certain conditions.

4.4.1 Process Flow

A purchase order is a formal request to a vendor to supply certain goods or services under

certain conditions.

The user will create Purchase Order can be created with reference to the RFQ or Last Purchase

Order, this will help the system to copy all the details in the RFQ on to the purchase order and

the relation of the RFQ and the purchase order is set in the system

If purchase order is created with reference the vendor details e.g. Vendor Address, Payment

Terms, Inco terms will be copied from the vendor master.

Purchase Order can also be created with out any reference, in this case the user will have to

enter all the details e.g. Vendor, material, pricing condition etc

Purchase Order will be made by ZZZ Group for those material for which the price is negotiated

for each transaction are subject to change for ever new transaction e.g. Base Oils , Additives etc.

For a particular transaction if the Payment Terms and Inco term are different from the vendor

master, the same can be changed in the Purchase order.

The pricing related conditions will be copied from the RFQ and also can be independently

maintained in the Purchase Orders. The pricing conditions shall be assigned a value either in

percentage terms, value terms or per quantity basis.

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 29 -PAGE 29 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 29

- 29 -OF 78

The different conditions (primary and secondary price elements) get defaulted in the Quotations

or purchase order based on the pricing schema attached to the schema group field of vendor

master. New pricing conditions can also be added and existing condition shall be changed only

before first goods receipt entry posted against PO.

Material and Vendor related Excise and Sales tax details shall be identified using the Tax Code at

the Item level in PO. The tax codes will have to be entered in the PO at the item level and

contain the following information:

Excise Duty

Additional Excise duty

Special Excise duty

Sales Tax applicable / VAT related condition

Surcharges over tax as applicable for a specific region

Turnover tax

The excise duty shall be populated in the PO based on the Excise masters maintained for the

material code in the CIN version of SAP to be entered in the PO at an item level. Excise rate

master and material excise detail has to be maintained for proper excise duty calculation and

CENVAT claim.

The user shall specify the Plant, Purchasing organisation, Purchasing group, Material code,

quantity of the material in the purchase order.

Over delivery tolerances will be maintained in the purchase order as per the requirements for

e.g. imported material where excess receipts are expected to certain extent. In case if there is

an excess stock receipt beyond the over delivery tolerance identified in PO, receipts can be

made only after changing the quantities in PO.

Header text and Item text shall be maintained to communicate the vendor regarding specific

terms and conditions which are specific to the purchase

Savita will have the following document types for a purchase order.

Import Purchase Order

Domestic Purchase Order this will cover Subcontracting also

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 30 -PAGE 30 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 30

- 30 -OF 78

Engineering, IT, Laboratory Non Stock Purchases and Services

Stock Transfer Order

Asset PO

Service PO

The number ranges will be different for each of the above document types and company code

this will help the user identify the Purchase order at a glance.

The system will create a purchase order number which will be system generated and the series

of the number will based on the document type and Company Code which is specified during

creation of the purchase order.

The PO will be amended for quantity as per the receiving plant on the receipt of the material

before the GRN

Condition types for CVD, Cess on CVD, Basic customs duty, Cess on customs duty and ADC will

be percentage based and in foreign currency for which the invoice verification for delivery costs

will be made in INR.

All the condition types will be copied to the new PO from the old PO along with the percentage

or value or quantity based rate.

The unwanted condition types will be deleted from the new PO.

All the secondary cost conditions will be identified in the PO with some vendor as no condition

can be added nor the value can be changed once a GRN is prepared.

Contracts will be prepared on the secondary vendors for transportation, barging, CHA,

insurance, etc and will be only used as reference; no data will be copied from the contract in the

PO by the system.

The secondary vendors will be changed at the time of GRN if different than that identified in the

PO.

Importing against Advance License: If the import receipts are against an Advance License where

no Custom Duty and CVD has to be paid, the amount liable against the Custom and CVD

conditions will to be identified against a Dummy Vendor in the PO. This vendor number will be

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 31 -PAGE 31 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 31

- 31 -OF 78

same as AL number, which will be same as the Advance License Number. For creation of these

liabilities, all the duties and taxes will be identified in the PO (like any normal import PO). This

vendor will be credited with the duty liability and which will be subsequently settled against an

income clearing account.

On the sales side, a report will be generated to track exports obligations to help Finance create

the necessary entries.

The details of the same is explained in FI Blueprint

4.4.2 Exceptions and Variations

Retrospective Amendments are not available in SAP. The changes made to PO will not affect the

GRN which is posted before the changes. The changes shall be affected only to the subsequent

document posted after the changes.

4.4.3 Forms and reports required

Purchase Order Print layout will be developed

4.4.4 Conditions in Purchase Order

Condition types are the various cost carrier components in P.O that determine the value with

which the Material is valuated & how the reimbursement for the same is being carried out.

Conditions for import and local procurement will be different.

ZZZ will have the following condition

Basic Price

Discount

Surcharge

Freight

Cess i.e. Market Cess for NMMC

Survey Charges

Insurance

Barging

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 32 -PAGE 32 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 32

- 32 -OF 78

Clearing and Forwarding

Wharfage

Pricing procedure is a summation of the condition type in a set sequence which helps the

system calculate the net price

There will two pricing procedure for ZZZ i.e. Local and Imports

4.4.5 Delivery Costs in Purchase Orders

The secondary vendor for freight, Insurance and clearing will be identified in the Purchase order

against the specific condition type. The secondary vendor can be changed during the good

receipt stage also.

The delivery condition charges shall be booked to a separate account code at the time of Goods

receipt. It is necessary to identify the Freight, Clearing, Insurance vendor in the PO for the

proper valuation of the material at the GRN stage. However at the time of preparation of GRN,

the actual vendor to whom the payment is to be made can also be identified. In case if the

transportation charges have to be paid to the material vendor than in delivery condition the

vendor field can be left blank & the freight gets automatically allocated to the Material Vendor

Freight Supplier can be changed at the GRN stage only if the planned delivery conditions

have been identified in PO. However the value of the delivery cost can be changed vat

the time of bill passing only.

Delivery Charges cannot be changed /amended in GRN

Any changes in the value of delivery charges (e.g. freight, Clearing, Insurance) can be

carried out at the time of invoice verification. Thus vendor can be paid based on the

actual invoice amount.

4.4.6 Excise and Sales tax related Details

User shall identify relevant tax codes in PO based on which the Excise Duty and Sales Tax shall

be calculated.

The user needs to select correct tax code in the PO

The user needs to select correct document type (order type) in the PO.

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 33 -PAGE 33 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 33

- 33 -OF 78

The tax code shall be identified at item level in the PO

TDS shall be calculated in the Financial Accounting system. Please refer to the Business

Blueprint of Financial Accounting for details regarding TDS.

Excise and Sales Tax (VAT) will posted to a different account and will not be posted to

the stock account

4.4.7 Account Assigned PO (Consumption Orders)

Account Assigned PO will be used in case of materials which are non-coded e.g. Engineering,

Stationery, Laboratory items, Administration and other consumable where the stock tracking for

such material is not required and a cost centre can be directly debited for its consumption.

Specific requirement of any department can be booked using the account assigned PO and

identifying a cost centre linked to the department in the PO.

At the time of Goods receipt for such materials, stock of the material will not be

updated and directly the total cost of the procured material shall be debited to an

identified account assignment i.e. cost centre Mechanical, Civil, Electrical or internal

order.

4.4.8 Asset Purchase

All the asset purchases shall be linked to the asset class. Such PO shall be account assigned to an

Asset. Finance department shall provide the required details to the purchase department

regarding the Asset class and Asset number, which need to be identified in the asset PO.

All asset purchases shall be account assigned PO with account assignment as Asset. Before

raising Asset PO, FI will provide the Asset number.

4.4.9 Release Procedure for Purchase Order

Release procedures will be defined for the following documents:

Purchase Requisition

Purchase Orders

In case of Purchase Requisitions only Engineering Purchase Requisitions will follow a release

procedure as the engineering specification are to be vetted out.

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 34 -PAGE 34 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 34

- 34 -OF 78

In case of Purchase Order the entire PO will follow a Release Procedure. Release procedure will

be different for each of the Purchasing Groups as per the person responsible (i.e. Imports, Local,

Service, Admin and Plant Purchases). The entire POs will be finally released by the MD. All types

of PO will have a release procedure including STO.

4.4.10 Forms and reports required

Purchase Order Print layout will be developed

4.5 High Sea Sales

ZZZ will use the High Sea Sales scenario for the sale of base oil. The process flow will be as

shown below

Create

Imports PO

Create Sales

Order

PR generated

automatically

Amend the

Imports PO

Post a GRN

Create

invoice in SD

Invoice

Verification

for the PO

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 35 -PAGE 35 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 35

- 35 -OF 78

4.5.1 Exceptions and Variations

The PO has to be amended as the sales order will be prepared after the PO. The existing line

item has to be deleted / modified and new line item will be added with reference to the PR

generated from the Sales Order.

A statistical GRN will be made in the system causing the following accounting entries:

Dr. Cost of Goods Sold

Cr. GR/IR Account

This entry will eliminate the need for taking the material into stock, making customer delivery

and posting goods issue.

Customer invoice can be raised once the statistical GRN and the invoice verification are posted.

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 36 -PAGE 36 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 36

- 36 -OF 78

5.Inventory Management

5.1 Material Receipt

A goods receipt is a goods movement with which the receipt of goods from a vendor or

from production is posted. A goods receipt leads to increase of material stock.

Material shall be received at the plants or the delivery address other than the plant

identified in the PO.

In case of Subcontracting PO, the finished goods shall be received at the plants from

where raw material was issued for processing.

Non - Stock material

Cost centre

Project

Other

Blocked stock ( Valuated ) MVT 101 (S)

Unrestricted Use stock MVT 101

Vendor

Stock

Consumption

Conditional

acceptance

GR blocked stock MVT 103

Goods Receipt

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 37 -PAGE 37 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 37

- 37 -OF 78

5.1.1 Goods Receipt Procedure

In Goods receipt is done using Movement Type 101, Stock is directly posted to

unrestricted stock or quality inspection stock and vendor can be paid after invoice

verification.

Both rejection and acceptance cannot be done for the material on which quality

management is not activated. The system can not allow posting accepted quantity and

rejected quantity simultaneously in single posting and for such condition two step goods

receipt procedure is to be followed.

Irrespective of the procedure followed,

No material shall be received without any reference of the PO

ZZZ can use single step goods for material like spares, regular consumable items etc.

Any changes to the PO shall be reflected before preparation of GR

There shall be only one internal number range for the all types of Goods Receipt across

all the plants.

Goods Receipt for Local Material

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 38 -PAGE 38 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 38

- 38 -OF 78

Create RFQ

WRT PR

Receive Quotations

Create Purchase Order

PR

Through MRP

Manual

YES NO

Create RFQ

Manually

YES

Compare Quotations

Accept Reject

Release Purchase Order

Close Quotation

with Reason

LOCAL PURCHASE ORDER

Scenario IA: Good receipt of Excisable Material

CENVAT related details should be captured by the user before preparing the GR. User

shall enter the Vendors Excise Invoice details in the SAP CIN module. The reference of

the internally generated document shall be given at the time of GR. At the time of GR,

RG23A Part I shall be gets updated if excise invoice has been captured before GRN.

Part II entries will be generated at the time of Excise Invoice Verify and post.

In case if Excise Invoice is captured after GR, Part I and Part II entries will be updated at

the time of Excise Invoice Verify and Post

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 39 -PAGE 39 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 39

- 39 -OF 78

If Excise Invoice has not accompanied the material, the material can be received into

unrestricted stock. Whenever Excise invoice comes, Excise Invoice is captured after GR,

Part I and Part II entries will be updated at the time of Excise Invoice Verify and Post.

Invoice verification can be entered only after the excise invoice verified & posted.

If Vendor has not given the excise invoice for excisable material, then user has to change

the PO as non excisable before posting of goods receipt and vendor invoice.

Scenario IA: Good receipt of Non Excisable Material

If the material is not excisable then user shall prepare the GRN using movement 101

without use of CIN Excise Module.

The following accounting entry will be passed in the Financial Accounts

Dr. RM/PM Stock Account

Cr. GR/IR Account

Cr. Freight Clearing Account

Excise Entry for revenue purchases

Dr. Cenvat BED/ AED/ SED Account

Cr. Cenvat Clearing Account

Excise Entry for Capital purchases

Dr. Cenvat BED/ AED/ SED Account

Dr. Cenvat on hold Account

Cr. Cenvat Clearing Account

Goods Receipt for Import Material

Import good receipts will be carried out either at the outside storage location or directly at the

Manufacturing Plant

Amendments will have to done in the PO, for quantity splitting as per receiving plant and any

other condition if required

The break up of the pricing elements (i.e. freight, Barging, CVD etc) will be copied from the last

PO

If the material is received at Outside Storage location, Stock transfer Order will be used to

transfer the material to the manufacturing plant.

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 40 -PAGE 40 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 40

- 40 -OF 78

Create RFQ

WRT PR

Receive Quotations

Create Purchase Order

PR

Through MRP

Manual

YES NO

Create RFQ

Manually

YES

Compare Quotations

Accept Reject

Release Purchase Order

Close Quotation

with Reason

Invoice Verification for Duties i.e. Planned

Delivery Costs

Capture Part I

Post GRN

Post Part II

Transfer Order

Transfer Order

Confirmation

IMPORTS PURCHASE ORDER

Scenario IIA: Goods Receipt for imports at Outside Storage Locations

Preparation of PO

Release of PO

The invoice verification shall be carried out for CVD before the goods receipt of the

material in the system.

Posting of invoice verification for duty charges as delivery costs

The excise invoice (i.e. CVD) shall be captured and posted in CIN.

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 41 -PAGE 41 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 41

- 41 -OF 78

The GRN shall be prepared with respect to PO.

Posting of part 2 in dummy excise registration

Preparing of Transfer order & confirmation for warehouse

Placing in Bin

Scenario IIB: Goods Receipt for imports directly at Manufacturing Plant

Preparation of PO

Release of PO

The invoice verification shall be carried out for CVD before the goods receipt of the

material in the system.

Posting of invoice verification for duty charges as delivery costs

The excise invoice (i.e. CVD) shall be captured and posted in CIN.

The GRN shall be prepared with respect to PO.

Posting of part 2 in respective plants excise registration

Preparing of Transfer order & confirmation for warehouse

Placing in Bin

Accounting Entry:

Invoice Verification for Custom Duty when material not purchased against Advance License

Dr. Cenvat Clearing Account

Dr. Custom Clearing Account

Cr. Vendor Account

Invoice Verification for Custom Duty when material purchased against Advance License.

Dr. Custom Clearing Account

Cr. License Vendor Account (Recon A/c-adv license receivable A/c)

Goods receipt when the material is not purchased against advance License

Dr. Stock Account

Cr. GR/ IR Account

Cr. Custom Clearing Account

Goods receipt when the material is purchased against advance License

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 42 -PAGE 42 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 42

- 42 -OF 78

Dr. Stock Account

Cr. GR/ IR Account

Cr. Custom Clearing Account

Capture Excise Part II when the material is not purchased against advance License

Dr. BED Account

Dr. Cess Account

Cr. Cenvat Clearing Account

Invoice Verification for Foreign Vendor

On receipt of vendor bill the following entry will be passed:

Dr. GR/IR Account

Cr. Vendor Account

Scenario IIC: Goods Receipt for imports in Manufacturing Plant from Outside Storage

Locations (Stock Transport Order)

Creation of Stock transport order with supplying plant as Outside Storage Location and

receiving Plant as Manufacturing Plant

Creation of Replenishment Delivery

Preparing of Transfer order and Confirmation for warehouse

Creation of Post Good issue to reduce the inventory at Outside Storage Location

Pro-forma Invoice

Excise Invoice at Supplying Plant (i.e. Outside Storage Locations)

Good receipt at Receiving Plant (i.e. Manufacturing Plant)

Preparing of Transfer order and Confirmation for warehouse

Excise Invoice post and capture in receiving plant

Scenario IID: Weigh Bridge Interface

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 43 -PAGE 43 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 43

- 43 -OF 78

Other Good Receipts

Scenario III: Goods Receipt for Assets Material / Spares

The cycle of local /import GRN holds good for capital materials.

The type of material (Asset) shall be specified while capturing the excise invoice.

The GRN shall be prepared with respect to excise invoice. The system shall update

RG23C Part I after the GRN has been posted.

The excise invoice shall be posted and the system shall pass an entry for claiming 50%

Modvat for the current year updating RG23C Part II. In the subsequent year remaining

50% Modvat shall be claimed.

Scenario IV: Goods Receipt for Consumable materials

The regular GRN cycle holds well for the consumable materials with the exception that

system shall not update the stock of the material.

It shall be assumed that the material is consumed after good receipt no separate goods

issue transaction needs to be carried out.

Accounting entries in FI at the time of GRN

Dr. Consumption A/c

Cr. GR/IR Clearing A/c

Scenario V: Goods Receipt for Production Order

Goods shall be received in the concerned plant and storage location with respect to

production order. This shall result into converting of stocks from work in progress to

semi finished material or finished good. This shall result into increase of stocks in the

storage location.

Accounting entries in FI at the time of GRN

Dr. FG inventory A/c

Cr. Factory output A/c / Cost of production A/c

Scenario VI: Goods Receipt against Returnable Gate Pass

Service PO will be created for the repairs to be made along with the charges

The inventory of the asset eg pump or motor will be generated against a non valuated

material code

A transfer posting to the subcontractor stock will be entered in SAP to keep a track of

the stock

The material will be sent out of the gate against a printed copy of Returnable gate pass

from SAP

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 44 -PAGE 44 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 44

- 44 -OF 78

On receipt of the repaired asset the transfer posting made earlier will be reversed

Service entry sheet will be posted for the repair charges and the invoice verification will

be done for the same. The GRN for the services will be posted automatically in the

background.

Scenario VII: Goods Receipt for Subcontracting Purchase Order and Material received in

Plant and transferred to Subcontractor

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 45 -PAGE 45 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 45

- 45 -OF 78

Create RFQ

WRT PR

Receive Quotations

Create Purchase Order

PR

Through MRP

Manual

YES NO

Create RFQ

Manually

YES

Compare Quotations

Accept Reject

Enter Transfer Posting

Close Quotation

with Reason

Create Subcontracting Challan

Reconcile Challan

Post GRN

Complete Challan

SUBCONTRACT PURCHASE ORDER

Scenario VIII: Goods Receipt for Subcontracting Purchase Order material is directly received

at Subcontractor

SAP MM BLUE PRINT_SAMPLE G.V.SHIVAKKUMAR

ZZZ GROUP - 46 -PAGE 46 OF 78AAG

SAP MM BUSINESS BLUE PRINT_SAMPLE

MM MODULE BLUE PRINT_SAMPLE

VENKATESANSIVAKUMAR@YAHOO.CO.IN

PAGE 46

- 46 -OF 78

Creation of PO for

Child Material e.g.

Plastic Granules

Receipt of Material

Direct at the

Subcontractor

Receipt of Parent

Material e.g. Plastic

Containers

Stock Report showing

stock at Subcontractor

Consumption of Child

Material as per BOM

(STD) in Background

Consumption of Child

Material not as per BOM

(STD) in Background

Receipt of Parent

Material

Stock Adjustment of

Child Material e.g.

Plastic Granules

Raise a Credit Note

to Subcontractor

CENVAT credit taken

by Subcontractor. Not

Captured in SAP

CENVAT Credit

Taken by Plant as per

Subcontractor Excise

Challan

Child Material

Valuation at Plant will

be inclusive of Excise

Parent Material