Escolar Documentos

Profissional Documentos

Cultura Documentos

New Technologies in Textile Dyeing

Enviado por

Munazza SohailDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

New Technologies in Textile Dyeing

Enviado por

Munazza SohailDireitos autorais:

Formatos disponíveis

www.fi bre2fashi on.

com

New Technologies in Textile

Dyeing & Finishing

Source: New Cloth Market

www.fi bre2fashi on.com

New Technologies in Textile Dyeing & Finishing

Source: New Cloth Market

The industry is desperately in the need of newer and very efficient dyeing/finishing and

functional treatments of textiles. There is growing awareness and readiness to adapt

new perspective on industrial upgradation of Cleaner Production Programme, such new

technologies help enterprises achieve green production and cost reduction at the same

time. Green Production has become necessary for enterprises under the upgrade and

transformation policy. Therefore there is an urgent need to promote new technologies in

textile dyeing and finishing, injecting new thoughts to the industry.

Electrochemical Process Technology

Electrochemistry refers to the use of electrical energy in initiating chemical reactions,

replacing traditional aid agents in direct chemical reactions. Taking sulphur dyes as

example, in traditional technology, sulphides (such as sodium sulphide, Na

2

S) are used as

reducing agents. Although reduction process is fast and direct, large amount of chemical

energy is wasted and wastewater with high chemical oxygen demand (COD) value is

produced, making long-term operation inefficient. If direct electrochemical reduction is

adopted, no reducing agents are needed and the COD value of wastewater can be largely

reduced, hence lowering the cost of wastewater treatment.

Direct electrochemical reduction is undoubtedly more efficient than the traditional

technology, and the underlying chemical principle is also simple. However, as the stability

and oxidising/reducing power of different chemical substances are not the same, dyes may

not be directly and effectively reduced by electrodes. Hence the scope of utilising direct

electrochemical reduction is quite narrow. The principle of indirect electrochemical

reduction is the same, but in operation another strong oxidising/reducing agent acts as

medium, which makes the technology more applicable to different kinds of dyes. Taking

indigo as example, traditional technology takes sodium dithionite (Na

2

S

2

O

4

) as a reducing

agent, and the product should be re-oxidised in the air afterwards to fix the colour. Just

like traditional reduction of sulphides, large amount of chemical energy is wasted and

wastewater with high COD value is produced.

Enterprises attempt to

reduce the amount of

sodium dithionite used in

order to lower production

cost, but such attempt

produces other difficulties

as well. For example,

injecting nitrogen can

reduce the oxidation of

sodium dithionite but is too

expensive. Adding

aldehydes or directly

powering with electricity

can improve the reducing power of sodium dithionite, but the problem of wastewater

remains.

www.fi bre2fashi on.com

If indirect electrochemical reduction is adopted, the medium can replace sodium

dithionite as the reducing agent. The medium can provide both oxidizing and reducing

substances and can regenerate so that both waste and pollution can be reduced. Past

experiments show that reduction by electrolysis can save about 90 per cent of production

cost when compared with reduction by sodium dithionite.

Apart from reducing dyes, electrochemical process technology can be utilised in other

aspects. Taking bleaching as example, the core principle of electrochemical mercerizing

and bleaching is that bleaching chemicals can be produced by electrical energy and can be

regenerated; hence the process is easily controlled, waste-reducing and energy-saving.

The process can be monitored so that bleaching occurs evenly. Also, the cost and danger of

transportation is greatly reduced, particularly regarding hydrogen peroxide which is

explosive.

Another emerging project is the technology of ozone electrolysis. Ozone is strongly

oxidizing and can be used in decolourising and other waterless dye treatments (e.g. ozone

jets to prevent wearing out of jeans). As ozone can selfdecompose, it will not cause

pollution problems once carefully treated.

Supercritical Fluid Dyeing Technology

Supercritical fluid refers to the phase of a substance with both temperature and pressure

higher than the critical point (the point where liquid and gaseous phases of a substance

become indistinguishable). This phase of a substance enjoys many advantages and can

replace water in the dyeing process. The supercritical fluid normally used is carbon dioxide

(CO

2

), as the critical temperature and pressure are easier to achieve than that of other

substances. Moreover, carbon dioxide is also non-flammable without residues, so it is

suitable for industrial use.

In traditional water-dyeing technology,

textiles should undergo multiple processes

with the help of aid agents, chemical salts,

surfactants and reduction clearing agents.

In contrast, for the supercritical waterless

dyeing technology, only supercritical fluid is

needed for dyeing and circulation, after

which the pressure and temperature can be

lowered and the whole process is finished,

without producing any wastewater. Also, as

carbon dioxide automatically detaches from

textiles and remaining dyes, the latter can

be reused. More importantly, as operation

procedures are reduced, the dyeing cycle is

also shortened from several hours to 15 to 60 minutes; energy is also saved due to the

lower operational temperature.

Regarding the cost, although the equipment required for the process is quite expensive,

the supercritical substance (carbon dioxide) is cheap and the technology enjoys an overall

advantage in cost. On the other hand, although the technology is not mature enough

regarding application in natural fibres, the quality of the end-product made of synthetic

fibres is high. Overall, the effects of interactions between different textiles with

supercritical substances are yet to be fully discovered.

www.fi bre2fashi on.com

Plasma Treatment Technology

When a substance in its gaseous phase absorbs enough energy, the outermost electrons in

the atoms will escape the nucleus control and become free electrons, while the atoms

become positively charged. This chemical status of a substance is called plasma. As it is

volatile, it can discharge electricity under certain physical conditions and react with other

substances (including textiles), leading to various chemical fusions and fissions. These

effects can alter the surface structure of textiles; hence plasma is suitable for surface

treatment.

Since only the surface structure of materials is altered

by plasma, the substrate characteristics of textiles will

not be affected.

Also, as small amount of plasma is enough to produce

profound effect and one set of equipment can

accommodate to different kinds of gaseous chemicals,

the equipment is relatively cost effective and user

friendly.

The kinds of plasma undergoing testing are varied,

including silanes (Si

n

H

2n+2

) (waterproof), freons

(increasing surface tension and oil- and dirt-proof

effects) and phosphoruscontaining organic monomers

(fireproof), etc.

Plasma treatment technology can also improve

existing dyeing technology, including the newly

developed technology of metallised fabrics. On the

other hand, HKPC attempts to integrate plasma

reatment technology and supercritical fluid dyeing

technology, and replace supercritical fluid with

plasma in the dyeing process.

The low pressure plasma dyeing technology is still being developed.

The textile dyeing and finishing industry is considered energy-wasting and highly-

polluting, which will be forced to withdraw under the upgrade and transformation policy.

However, with technological development on a full swing, traditional industries are able to

overcome technical difficulties and revive after the financial crisis.

Or i gi nally Publi shed i n New Cloth Mar ket, J an-2011

Image courtesy: careeroutcome.blogspot.com

Você também pode gostar

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Comprehensive Safety Checklist PNL 6-08Documento23 páginasComprehensive Safety Checklist PNL 6-08fcleong69Ainda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Work Instruction Analytical BalanceDocumento2 páginasWork Instruction Analytical BalanceMunazza SohailAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Achieving Your Goals in LifeDocumento25 páginasAchieving Your Goals in LifeBeaKOKOAinda não há avaliações

- Material Handling Notes 2013Documento198 páginasMaterial Handling Notes 2013taridan100% (1)

- Giz2011 en Exploring Biogas Market Opportunities VietnamDocumento92 páginasGiz2011 en Exploring Biogas Market Opportunities Vietnamlhphong021191Ainda não há avaliações

- Technical Seminar ReportDocumento19 páginasTechnical Seminar Report786 utuberAinda não há avaliações

- Textile TestingDocumento33 páginasTextile TestingMunazza Sohail100% (3)

- Chapter 2 Life Cycle AssessmentDocumento24 páginasChapter 2 Life Cycle AssessmentDaniel SonAinda não há avaliações

- City of TagaytayDocumento18 páginasCity of TagaytayMelodyFranciscoAinda não há avaliações

- Format For EquipmentDocumento1 páginaFormat For EquipmentMunazza SohailAinda não há avaliações

- Munazza Report Dec 2023Documento3 páginasMunazza Report Dec 2023Munazza SohailAinda não há avaliações

- 602-7 List of StaffDocumento1 página602-7 List of StaffMunazza SohailAinda não há avaliações

- PT ActivitiesDocumento1 páginaPT ActivitiesMunazza SohailAinda não há avaliações

- StanderizationDocumento1 páginaStanderizationMunazza SohailAinda não há avaliações

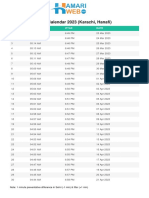

- Karachi Ramadan Calendar 2023 HamariwebDocumento1 páginaKarachi Ramadan Calendar 2023 HamariwebMunazza SohailAinda não há avaliações

- Sohail Reports PDFDocumento2 páginasSohail Reports PDFMunazza SohailAinda não há avaliações

- Rancimat Oxidation Stability Test ApparatusDocumento2 páginasRancimat Oxidation Stability Test ApparatusMunazza SohailAinda não há avaliações

- Rate List-Oils and Fats-2022Documento4 páginasRate List-Oils and Fats-2022Munazza SohailAinda não há avaliações

- Interim Report Fats & Oil R-II 2022 PDFDocumento17 páginasInterim Report Fats & Oil R-II 2022 PDFMunazza SohailAinda não há avaliações

- Scope/ Product Name No. of Sample Location Parameter Required Request For ChargesDocumento2 páginasScope/ Product Name No. of Sample Location Parameter Required Request For ChargesMunazza SohailAinda não há avaliações

- Clause 6.2 Personal FORMSDocumento9 páginasClause 6.2 Personal FORMSMunazza SohailAinda não há avaliações

- Final PSQCA Rate List - Oil and Fats - 2022Documento18 páginasFinal PSQCA Rate List - Oil and Fats - 2022Munazza SohailAinda não há avaliações

- Training Report On Textile Wet ProcessingDocumento38 páginasTraining Report On Textile Wet ProcessingMunazza SohailAinda não há avaliações

- Finance Lafargeholcim Fy Annual Report enDocumento288 páginasFinance Lafargeholcim Fy Annual Report enMatteo GetraliAinda não há avaliações

- Y-Buyers Guide To Screens & BaggersDocumento11 páginasY-Buyers Guide To Screens & BaggersYousef AlipourAinda não há avaliações

- PTP 820C Installation Guide 8.0Documento161 páginasPTP 820C Installation Guide 8.0lufrabaveAinda não há avaliações

- Tabel Rekomendasi Kuesioner Green Metric UIDocumento11 páginasTabel Rekomendasi Kuesioner Green Metric UIBerliana Cahya NingtiasAinda não há avaliações

- Granby Sewer Project ProposalDocumento2 páginasGranby Sewer Project ProposalMassLiveAinda não há avaliações

- Food Service Assessment ChecklistDocumento2 páginasFood Service Assessment Checklistapi-275382998Ainda não há avaliações

- Introduction To Introduction To Cleaner Production (Cleaner Production (CP CP) ) Concepts Concepts and Practice and PracticeDocumento65 páginasIntroduction To Introduction To Cleaner Production (Cleaner Production (CP CP) ) Concepts Concepts and Practice and PracticeprinceAinda não há avaliações

- KigaliecoDocumento162 páginasKigaliecoapi-236125865100% (1)

- MSDS NaphthaDocumento18 páginasMSDS NaphthaPloychompoo HanyanuwatAinda não há avaliações

- CompleteOnsiteManual PDFDocumento277 páginasCompleteOnsiteManual PDFBambang Tutuko SudiroAinda não há avaliações

- Mohtasham 2015 Review Article-Renewable EnergiesDocumento9 páginasMohtasham 2015 Review Article-Renewable EnergiesSasidhar JannuAinda não há avaliações

- 2024.01.26 FILED ComplaintDocumento32 páginas2024.01.26 FILED ComplaintAlexis TarraziAinda não há avaliações

- Steel Mill Scale: Safety Data Sheet 768Documento17 páginasSteel Mill Scale: Safety Data Sheet 768dubravko_akmacicAinda não há avaliações

- Design of Incinerator For The Treatment of BioDocumento11 páginasDesign of Incinerator For The Treatment of Biomubashar husain ansarAinda não há avaliações

- Manual Utilizare Beko DU7133GA0Documento56 páginasManual Utilizare Beko DU7133GA0Madalina BalanAinda não há avaliações

- Kirei Board: Zen ModernDocumento2 páginasKirei Board: Zen Modernapi-58043043Ainda não há avaliações

- MSDS-Suniso3g en InglesDocumento8 páginasMSDS-Suniso3g en InglesGuillermo Jonathan Santana VillavicencioAinda não há avaliações

- Principle 5: Safer Solvents and AuxiliariesDocumento12 páginasPrinciple 5: Safer Solvents and AuxiliariesdeepakangadiAinda não há avaliações

- English LessonDocumento3 páginasEnglish LessonAnnaAinda não há avaliações

- PolystereneDocumento3 páginasPolystereneAlbert Julius VlogsAinda não há avaliações

- London 7 8 London: Instruction ManualDocumento85 páginasLondon 7 8 London: Instruction ManualmxpxaxoAinda não há avaliações

- KR615 "UV BOX" Germicidal Enclosure User's ManualDocumento21 páginasKR615 "UV BOX" Germicidal Enclosure User's ManualRajesh Kumar PuriAinda não há avaliações

- 45096Documento12 páginas45096Halusan MaybeAinda não há avaliações