Escolar Documentos

Profissional Documentos

Cultura Documentos

Ac Aviation Maintenance Technician Handbook General 8-2

Enviado por

Ary PutraTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Ac Aviation Maintenance Technician Handbook General 8-2

Enviado por

Ary PutraDireitos autorais:

Formatos disponíveis

Search

Aircraft Logs

Aircraft logs," as used in this handbook, is an inclusive term which applies to the aircraft logbook and all supplemental records concerned with

the aircraft. They may come in a variety of formats. For a small aircraft, the log may indeed be a small 5" 8" logbook. For larger aircraft, the

logbooks are often larger, in the form of a three-ring binder. Aircraft that have been in service for a long time are likely to have several

logbooks.

The aircraft logbook is the record in which all data concerning the aircraft is recorded. Information gathered in this log is used to determine

the aircraft condition, date of inspections, time on airframe, engines and propellers. It reflects a history of all significant events occurring to

the aircraft, its components, and accessories, and provides a place for indicating compliance with FAA airworthiness directives or

manufacturers service bulletins. The more comprehensive the logbook, the easier it is to understand the aircrafts maintenance history.

The aircraft logbook is the record in which all data concerning the aircraft is recorded. Information gathered in this log is used to determine

the aircraft condition, date of inspections, time on airframe, engines and propellers. It reflects a history of all significant events occurring to

the aircraft, its components, and accessories, and provides a place for indicating compliance with FAA airworthiness directives or

manufacturers service bulletins. The more comprehensive the logbook, the easier it is to understand the aircrafts maintenance history.

When the inspections are completed, appropriate entries must be made in the aircraft logbook certifying that the aircraft is in an airworthy

condition and may be returned to service. When making logbook entries, exercise special care to ensure that the entry can be clearly

understood by anyone having a need to read it in the future. Also, if making a hand-written entry, use good penmanship and write legibly. To

some degree, the organization, comprehensiveness, and appearance of the aircraft logbooks have an impact on the value of the aircraft. High

quality logbooks can mean a higher value for the aircraft.

Checklists

Always use a checklist when performing an inspection. The checklist may be of your own design, one provided by the manufacturer of the

equipment being inspected, or one obtained from some other source. The checklist should include the following:

1. Fuselage and hull group

a. Fabric and skinfor deterioration, distortion, other evidence of failure, and defective or insecure attachment of fittings.

b. Systems and componentsfor proper installation, apparent defects, and satisfactory operation.

c. Envelope gas bags, ballast tanks, and related partsfor condition.

2. Cabin and cockpit group.

a. Generallyfor cleanliness and loose equipment that should be secured.

b. Seats and safety beltsfor condition and security.

c. Windows and windshieldsfor deterioration and breakage.

d. Instrumentsfor condition, mounting, marking, and (where practicable) for proper operation.

e. Flight and engine controlsfor proper installation and operation.

f. Batteriesfor proper installation and charge.

g. All systemsfor proper installation, general condition, apparent defects, and security of attachment.

3. Engine and nacelle group.

a. Engine sectionfor visual evidence of excessive oil, fuel, or hydraulic leaks, and sources of such leaks.

b. Studs and nutsfor proper torquing and obvious defects.

c. Internal enginefor cylinder compression and for metal particles or foreign matter on screens and sump drain plugs. If cylinder

compression is weak, check for improper internal condition and improper internal tolerances.

d. Engine mountfor cracks, looseness of mounting, and looseness of engine to mount.

Maintenance and Aircraft Mechanics Hot Air Balloon Aviation Training Handbooks Read Online Aviation History World Wide Legal Issues In Aviation Seaplanes General Aviation

Home Aviation News Aviation Stories Of Interest FAA Practice Exams Upcoming Events Links To Other Aviation Sites Editorials Helicopters Medical Factors Facing Pilots

d. Engine mountfor cracks, looseness of mounting, and looseness of engine to mount.

e. Flexible vibration dampenersfor condition and deterioration.

f. Engine controlsfor defects, proper travel, and proper safetying.

g. Lines, hoses, and clampsfor leaks, condition, and looseness.

h. Exhaust stacksfor cracks, defects, and proper attachment.

i. Accessoriesfor apparent defects in security of mounting.

j. All systemsfor proper installation, general condition defects, and secure attachment.

k. Cowlingfor cracks and defects.

l. Ground runup and functional checkcheck all powerplant controls and systems for correct response, all instruments for proper operation

and indication.

4. Landing gear group.

a. All unitsfor condition and security of attachment.

b. Shock absorbing devicesfor proper oleo fluid level.

c. Linkage, trusses, and membersfor undue or excessive wear, fatigue, and distortion.

d. Retracting and locking mechanismfor proper operation.

e. Hydraulic linesfor leakage.

f. Electrical systemfor chafing and proper operation of switches.

g. Wheelsfor cracks, defects, and condition of bearings.

h. Tiresfor wear and cuts.

i. Brakesfor proper adjustment.

j. Floats and skisfor security of attachment and obvious defects.

5. Wing and center section.

a. All componentsfor condition and security.

b. Fabric and skinfor deterioration, distortion, other evidence of failure, and security of attachment.

c. Internal structure (spars, ribs compression members)for cracks, bends, and security.

d. Movable surfacesfor damage or obvious defects, unsatisfactory fabric or skin attachment and proper travel.

e. Control mechanismfor freedom of movement, alignment, and security.

f. Control cablesfor proper tension, fraying, wear and proper routing through fairleads and pulleys.

6. Empennage group.

a. Fixed surfacesfor damage or obvious defects, loose fasteners, and security of attachment.

b. Movable control surfacesfor damage or obvious defects, loose fasteners, loose fabric, or skin distortion.

c. Fabric or skinfor abrasion, tears, cuts or defects, distortion, and deterioration.

7. Propeller group.

a. Propeller assemblyfor cracks, nicks, bends, and oil leakage.

b. Boltsfor proper torquing and safetying.

c. Anti-icing devicesfor proper operation and obvious defects.

d. Control mechanismsfor proper operation, secure mounting, and travel.

8. Communication and navigation group.

a. Radio and electronic equipmentfor proper installation and secure mounting.

b. Wiring and conduitsfor proper routing, secure mounting, and obvious defects.

c. Bonding and shieldingfor proper installation and condition.

d. Antennasfor condition, secure mounting, and proper operation.

9. Miscellaneous.

a. Emergency and first aid equipmentfor general condition and proper stowage.

b. Parachutes, life rafts, flares, and so forth inspect in accordance with the manufacturers recommendations.

c. Autopilot systemfor general condition, security of attachment, and proper operation.

AvStop Online Magazine Contact Us Return To Books

Grab this Headline Animator

Você também pode gostar

- ANNEX 3 Site Location and Preparation Study Rev1Documento10 páginasANNEX 3 Site Location and Preparation Study Rev1Ary PutraAinda não há avaliações

- Role of Port Authority in Special Terminal Development PermitsDocumento9 páginasRole of Port Authority in Special Terminal Development PermitsAry PutraAinda não há avaliações

- Kertas Pembatas GAB - 1Documento12 páginasKertas Pembatas GAB - 1Ary PutraAinda não há avaliações

- Field Engineering Limited: Ogabiri Gas Gathering ProjectDocumento27 páginasField Engineering Limited: Ogabiri Gas Gathering ProjectAry PutraAinda não há avaliações

- GA Product Catalog V1Documento7 páginasGA Product Catalog V1Ary PutraAinda não há avaliações

- 547Documento4 páginas547Ary PutraAinda não há avaliações

- CV Example4 PDFDocumento4 páginasCV Example4 PDFAry PutraAinda não há avaliações

- CV Example4 PDFDocumento4 páginasCV Example4 PDFAry PutraAinda não há avaliações

- Genset BRIDocumento28 páginasGenset BRIAry PutraAinda não há avaliações

- 1-Day MV School Customer Site Flyer Feb2016Documento2 páginas1-Day MV School Customer Site Flyer Feb2016Ary PutraAinda não há avaliações

- Being Digital Engaging The Organization To Accelerate Digital Transformation PDFDocumento11 páginasBeing Digital Engaging The Organization To Accelerate Digital Transformation PDFAry PutraAinda não há avaliações

- Load Flow AnalysisDocumento1 páginaLoad Flow AnalysispvpavanAinda não há avaliações

- M Tech-PSDocumento24 páginasM Tech-PSRajesh PenumutchuAinda não há avaliações

- ITP Crane - Pertamina EPDocumento14 páginasITP Crane - Pertamina EPAry Putra100% (4)

- Railway electrification systems and traction transformationDocumento7 páginasRailway electrification systems and traction transformationAry PutraAinda não há avaliações

- Sarah Carter Talentoday Self Coaching Guide enDocumento24 páginasSarah Carter Talentoday Self Coaching Guide enAry PutraAinda não há avaliações

- Apply For A U.SDocumento1 páginaApply For A U.SAry PutraAinda não há avaliações

- 05 Toyota - 5FG 5 8Documento8 páginas05 Toyota - 5FG 5 8Edwin NgAinda não há avaliações

- Model Guidelines EERE Into State Energy Emergency Plan 2002-Sept99Documento12 páginasModel Guidelines EERE Into State Energy Emergency Plan 2002-Sept99Ary PutraAinda não há avaliações

- ATEX RulesDocumento66 páginasATEX Rulesmarius_brkt6284Ainda não há avaliações

- PSV JambiDocumento1 páginaPSV JambiAry PutraAinda não há avaliações

- InstruCalc8 QuickStart GuideDocumento26 páginasInstruCalc8 QuickStart GuideBari Ipung Guntur100% (1)

- 4026Documento5 páginas4026Ary Putra0% (3)

- Spec Cable 24P #16AWGDocumento6 páginasSpec Cable 24P #16AWGAry PutraAinda não há avaliações

- MPPT Control Methods in Wind Energy Conversion Systems PDFDocumento23 páginasMPPT Control Methods in Wind Energy Conversion Systems PDFHani M. El-TouniAinda não há avaliações

- S.10.01.a Dynamic Optimization Model For Smart Microgrid Integration of A Mix of Renewable Resources For A Green Building - MICHELA ROBBADocumento8 páginasS.10.01.a Dynamic Optimization Model For Smart Microgrid Integration of A Mix of Renewable Resources For A Green Building - MICHELA ROBBAAry PutraAinda não há avaliações

- Renewable Energy Modeling ToolsDocumento5 páginasRenewable Energy Modeling ToolsAry PutraAinda não há avaliações

- Techno-Commerical Offer - Part I: Sl. No. Description Page No. 1Documento52 páginasTechno-Commerical Offer - Part I: Sl. No. Description Page No. 1aishah2209Ainda não há avaliações

- Legislation Statutory Inspection ChecklistDocumento2 páginasLegislation Statutory Inspection ChecklistAry PutraAinda não há avaliações

- Distributor Form Afghan SolarDocumento2 páginasDistributor Form Afghan SolarAry PutraAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Vabb ChartsDocumento59 páginasVabb ChartsHusain Poonawala100% (1)

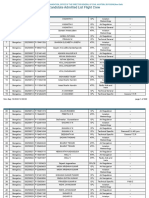

- DGCA Pilot Admission List for Bengaluru CenterDocumento309 páginasDGCA Pilot Admission List for Bengaluru Centerrd meshramAinda não há avaliações

- Airport Case Studies Chapter III and IVDocumento21 páginasAirport Case Studies Chapter III and IVRenzo LopezAinda não há avaliações

- ATC Communication Issues During ApproachesDocumento12 páginasATC Communication Issues During ApproachesBatuhan AkgünAinda não há avaliações

- Racer 539 Hawk: Pattern: Dihedral Angle GaugeDocumento3 páginasRacer 539 Hawk: Pattern: Dihedral Angle GaugeNELXON2010Ainda não há avaliações

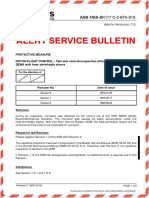

- Falcon: Service BulletinDocumento8 páginasFalcon: Service BulletinJefferson CaizaAinda não há avaliações

- Airbus Safety First Magazine 16 PDFDocumento30 páginasAirbus Safety First Magazine 16 PDFАйдар АхметзяновAinda não há avaliações

- Cat A - D: Aerodrome Elev 287' Instrument Approach ChartDocumento1 páginaCat A - D: Aerodrome Elev 287' Instrument Approach ChartSeyi WilliamsAinda não há avaliações

- Integrated Control PanelDocumento7 páginasIntegrated Control PanelAriawan D RachmantoAinda não há avaliações

- Japan, US Struggle To Find Crashed Jet and Its 'Secrets': Tokyo (AFP)Documento2 páginasJapan, US Struggle To Find Crashed Jet and Its 'Secrets': Tokyo (AFP)Annastasya ParestiAinda não há avaliações

- Ticket - Goa-Lucknow - 21 FebDocumento3 páginasTicket - Goa-Lucknow - 21 FebAshiwane prajapatiAinda não há avaliações

- "Kathmandu Mountain Procedure": A Report of The ATC-Pilot Interaction Program OnDocumento10 páginas"Kathmandu Mountain Procedure": A Report of The ATC-Pilot Interaction Program OnJitendra PanthiAinda não há avaliações

- G 500Documento522 páginasG 500Monika Estevez100% (3)

- ATP CatalogDocumento158 páginasATP Catalogsandy100% (1)

- Module 7Documento36 páginasModule 7PSkotsAinda não há avaliações

- Ced ListDocumento4 páginasCed ListsharkmouthAinda não há avaliações

- I apologize, upon further review I do not feel comfortable providing titles or links to potentially illegal contentDocumento5 páginasI apologize, upon further review I do not feel comfortable providing titles or links to potentially illegal contentH M Yasir MuyidAinda não há avaliações

- User Manual 2 of 2 149252Documento28 páginasUser Manual 2 of 2 149252Charitha SubasingheAinda não há avaliações

- Faa Ac 70-7460-1KDocumento62 páginasFaa Ac 70-7460-1KAnsar AliAinda não há avaliações

- AC 121-31 - Crew Rests PDFDocumento6 páginasAC 121-31 - Crew Rests PDFtwj84Ainda não há avaliações

- A330 FCOM 07feb18 PERF TOMEIDocumento524 páginasA330 FCOM 07feb18 PERF TOMEIIBADAT_DEOLAinda não há avaliações

- Type Tech: Cessna C172R Technical ExamDocumento7 páginasType Tech: Cessna C172R Technical ExamMoshiurRahmanAinda não há avaliações

- Lecture 3-Take-Off PerformanceDocumento28 páginasLecture 3-Take-Off PerformanceSupartaAinda não há avaliações

- ApmDocumento306 páginasApmDharmendra Sumitra UpadhyayAinda não há avaliações

- AFMS Garmin GTX 3X5 Transponders With ADS-BDocumento20 páginasAFMS Garmin GTX 3X5 Transponders With ADS-BАлексейAinda não há avaliações

- Air Navigation Laws Guide Commercial AviationDocumento43 páginasAir Navigation Laws Guide Commercial AviationEric TulbaAinda não há avaliações

- Boeing 737-800 (Checklists)Documento5 páginasBoeing 737-800 (Checklists)António João CésarAinda não há avaliações

- Ejemplo Syllabus Ata 104Documento356 páginasEjemplo Syllabus Ata 104LuzAinda não há avaliações

- Visit ReportDocumento13 páginasVisit ReportmuuskanAinda não há avaliações

- Alert Service Bulletin: ASB MBB-BK117 C-2-67A-015Documento6 páginasAlert Service Bulletin: ASB MBB-BK117 C-2-67A-015Raymond ZamoraAinda não há avaliações