Escolar Documentos

Profissional Documentos

Cultura Documentos

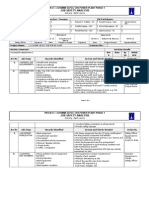

Activity Hazard Analysis Concrete Table, Sidewalk, and Ramp Installation

Enviado por

gunnery020 notas0% acharam este documento útil (0 voto)

70 visualizações2 páginasThis document outlines potential hazards and recommended controls for concrete table, sidewalk, and ramp installation. It identifies hazards such as broken materials, employee injury, tripping, and back strain during transport and placement of materials. When installing forms, hazards include access issues, loss of forms, eye and hand injuries from tools. Repair work presents risks of material in eyes, pinch points, back strain, and lacerations. Recommended controls include use of protective equipment, inspection of equipment and materials, proper lifting techniques, and securing loads.

Descrição original:

concrete table

Título original

Concrete Table JSA

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

DOC, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoThis document outlines potential hazards and recommended controls for concrete table, sidewalk, and ramp installation. It identifies hazards such as broken materials, employee injury, tripping, and back strain during transport and placement of materials. When installing forms, hazards include access issues, loss of forms, eye and hand injuries from tools. Repair work presents risks of material in eyes, pinch points, back strain, and lacerations. Recommended controls include use of protective equipment, inspection of equipment and materials, proper lifting techniques, and securing loads.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOC, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

70 visualizações2 páginasActivity Hazard Analysis Concrete Table, Sidewalk, and Ramp Installation

Enviado por

gunnery02This document outlines potential hazards and recommended controls for concrete table, sidewalk, and ramp installation. It identifies hazards such as broken materials, employee injury, tripping, and back strain during transport and placement of materials. When installing forms, hazards include access issues, loss of forms, eye and hand injuries from tools. Repair work presents risks of material in eyes, pinch points, back strain, and lacerations. Recommended controls include use of protective equipment, inspection of equipment and materials, proper lifting techniques, and securing loads.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOC, PDF, TXT ou leia online no Scribd

Você está na página 1de 2

ACTIVITY HAZARD ANALYSIS

CONCRETE TABLE, SIDEWALK, AND RAMP INSTALLATION

PRINCIPAL STEPS

POTENTIAL HAZARDS

RECOMMENDED CONTROLS

1. Installing concrete tables

and bases

a. loading and transporting

and unloading materials

1. Broken material

1. Inspect for condition of items.

2. Employee injury

1. Inspect slings for wear and tear.

3. Hand, face, foot injury

1. Place cribbing between each section

for ease of unhooking and to keep pinch

points to a minimum.

2. Wear hand protection, eye and foot

protection.

b. placement of materials

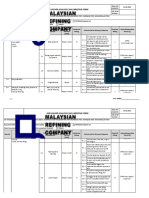

2. Placing form for concrete

sidewalks and ramps

a.

preparing forms

b.

installing forms

1. Loss of materials

1. Distribute, check and secure load.

2. Traffic hazards

1. Inspect vehicle, wench and cable for

safe operation.

3. Back strain

1. Use proper lifting procedures.

2. Do not set alone-use a helper.

4. Tripping

1. Apply housekeeping rules.

5. Falling materials

1. Secure base by using horizontal and

cross braces.

1. Access areas to/from work area

1. Clear debris from walkways.

2. Back strain

1. Long and heavy formsuse helpers

for moving and setting.

3. Loss of forms-personnel safety

1. Use horizontal and vertical bracing

when required.

4. Tripping and/or falling

1. Keep areas neat and orderly.

2. Keep materials stacked.

5. Hand and body injury

1. Replace unserviceable tools-use

correct tools for the job.

6. Electrical shock

1. Inspect and test equipment and cords.

7. Eye and face injury due to flying

wood chips and nails

1. Wear eye and face protection.

8. Head injury

1. Wear head protection.

9. Hand injury

1. Wear hand protection.

3. Repair broken concrete

tables

a.

replacing broken

bench or top

b.

placing new concrete

if needed

c.

transporting repair

materials

1. Material in eyes

1. Wear eye protection equipment.

2. Pinch point

1. Wear safety toe boots.

2. Wear work gloves.

3. Signal persons shall be in full view of

equipment operator.

4. Material shall no be stacked higher

than 20 feet or as less as practical.

5. Material will not be moved over or

suspended above personnel.

6. Person shall not go over, under,

behind, or between operating equipment.

7. Tools, equipment, and material shall

be placed in their proper storage places to

insure displacement or falling is

adequately secured.

8. Person must stand clear of sides of

materials when being untied for

unloading.

3. Back strain

1. Use proper lifting techniques.

4. Laceration, cut, or abrasion to skin

1. Inspect work area and equipment for

hazardous conditions and correct before

continuing work.

2. Wear proper clothing and safety

equipment (gloves, boots, hard hat).

3. Create awareness through active

safety program.

4. Instruction in first aid treatment.

5. Losing load

1. Do not overload capacity of vehicle.

2. Drivers of trucks and similar vehicles

shall leave the cab while a vehicle is

being loaded.

3. No vehicle shall be loaded so as to

obscure the drivers view ahead or to

either side or to interfere with the safe

operation of such vehicle.

4. No part of the load shall extend

beyond the rear or sides of the vehicle

except under unavoidable circumstances

when such loading is necessary.

5. The load on every vehicle shall be

distributed, chocked, tied down, or

secured.

Você também pode gostar

- RA-02 Installation of Aco Tech PanelDocumento7 páginasRA-02 Installation of Aco Tech PanelVaradaraju Thirunavukkarasan100% (1)

- Hazardous Energy Control ProcedureDocumento20 páginasHazardous Energy Control ProcedureRam Kumar BarathanAinda não há avaliações

- Section Q Concrete Masonry-07Documento63 páginasSection Q Concrete Masonry-07MirwaliAinda não há avaliações

- Asbestos Management (Removal, Handling and Disposal)Documento8 páginasAsbestos Management (Removal, Handling and Disposal)Okhwa WangilaAinda não há avaliações

- Hoisting & RiggingDocumento5 páginasHoisting & RiggingRam SinghAinda não há avaliações

- C4M Mivan FormworkDocumento3 páginasC4M Mivan Formworkmanohar reddyAinda não há avaliações

- Explosives in Demolition - Exclusive ZoneDocumento2 páginasExplosives in Demolition - Exclusive ZoneVignesh KmAinda não há avaliações

- Job Safety Analysis FormDocumento4 páginasJob Safety Analysis FormM.Dimas PrakosoAinda não há avaliações

- 014 Commissioning Weekly Report Template PDFDocumento21 páginas014 Commissioning Weekly Report Template PDFali ahmadAinda não há avaliações

- Tracy Asbestos PlanDocumento18 páginasTracy Asbestos PlanidahssAinda não há avaliações

- SWP-SF010A - 6 Daily Vibratory Roller Compactor Rev. ADocumento1 páginaSWP-SF010A - 6 Daily Vibratory Roller Compactor Rev. ACliffordAinda não há avaliações

- STMLK Asbestos Plan - 0Documento18 páginasSTMLK Asbestos Plan - 0idahssAinda não há avaliações

- Scaffolding SafetyDocumento51 páginasScaffolding SafetySatya NaiduAinda não há avaliações

- SECTION 08 14 00 Interior Wood DoorsDocumento8 páginasSECTION 08 14 00 Interior Wood DoorsAlronavee MambajeAinda não há avaliações

- Section 03 Site Clearance N Demolition PDFDocumento11 páginasSection 03 Site Clearance N Demolition PDFlakmalperera1986100% (1)

- SEPR-IC-Q-111 Rev.1 Formwork StrippingDocumento3 páginasSEPR-IC-Q-111 Rev.1 Formwork Strippingengr.s.a.malik6424Ainda não há avaliações

- Standard Lift Plan ChecklistDocumento9 páginasStandard Lift Plan ChecklistPablo Alejandro JrAinda não há avaliações

- Glenbrook Rd. Demolition and Disposal PlanDocumento56 páginasGlenbrook Rd. Demolition and Disposal PlanBruno CarvalheiroAinda não há avaliações

- Green Building Material LeedDocumento4 páginasGreen Building Material Leeddep_vinAinda não há avaliações

- Ayala Triangle Gardens: Roughing Installation (Drop-Off Landscape Lightings)Documento6 páginasAyala Triangle Gardens: Roughing Installation (Drop-Off Landscape Lightings)james alfarasAinda não há avaliações

- Excavation Safety Policy: City of LincolnDocumento11 páginasExcavation Safety Policy: City of LincolnMianAinda não há avaliações

- Method Statement For Gypsum Panels WorkDocumento8 páginasMethod Statement For Gypsum Panels WorkNikita KasyanovAinda não há avaliações

- Jha Lin FillingDocumento6 páginasJha Lin FillingLuqman OsmanAinda não há avaliações

- 2 - Risk Assessment HeightsDocumento15 páginas2 - Risk Assessment HeightsXozanAinda não há avaliações

- SECTION 02221 Trench Excavating and Backfilling: Part 1 GeneralDocumento4 páginasSECTION 02221 Trench Excavating and Backfilling: Part 1 GeneralJojolasAinda não há avaliações

- Checklist Site and Security Fencing SchoolsDocumento2 páginasChecklist Site and Security Fencing Schoolsakshay aryaAinda não há avaliações

- Concrete Mixing and PouringDocumento7 páginasConcrete Mixing and Pouringnewaz2010Ainda não há avaliações

- Demolition Work Audit Checklist: Los Angeles Community College DistrictDocumento6 páginasDemolition Work Audit Checklist: Los Angeles Community College DistrictJaycee PagadorAinda não há avaliações

- 10-F20 Fuel Driven Equipment InspectionDocumento3 páginas10-F20 Fuel Driven Equipment InspectionSn AhsanAinda não há avaliações

- Asbestos Cement Pipes - A Showcase of Underutilized TechnologyDocumento2 páginasAsbestos Cement Pipes - A Showcase of Underutilized Technologyanirbanpwd76Ainda não há avaliações

- Temporary Works RegisterDocumento2 páginasTemporary Works Registerrachel banfieldAinda não há avaliações

- 02 Table of Contents+and+CQM+Specification SEPT2019Documento59 páginas02 Table of Contents+and+CQM+Specification SEPT2019pdyba13Ainda não há avaliações

- Daily Inspection Checklist - SFLBDocumento3 páginasDaily Inspection Checklist - SFLBAdriana EscobarAinda não há avaliações

- Pa Hsec 02 040 002 F03Documento4 páginasPa Hsec 02 040 002 F03Abdul KhaliqAinda não há avaliações

- Method Statements 20 % Week 08-09Documento10 páginasMethod Statements 20 % Week 08-09Sujani MaarasingheAinda não há avaliações

- F04 Site Safety HandbookDocumento40 páginasF04 Site Safety Handbooksalman ahmed0% (1)

- Plumber Remove Bathroom Suite MethodDocumento2 páginasPlumber Remove Bathroom Suite MethodUbah ChigozieAinda não há avaliações

- GRA 2.1.3 Trenches and Pits PDFDocumento22 páginasGRA 2.1.3 Trenches and Pits PDFIrfanullah TunioAinda não há avaliações

- Earth Works JSADocumento4 páginasEarth Works JSARen SalazarAinda não há avaliações

- Erection Method StatementDocumento8 páginasErection Method Statementjones100% (1)

- Contractor Safety Orientation ChecklistDocumento1 páginaContractor Safety Orientation ChecklistJason 'Hogie' HoganAinda não há avaliações

- Fischer Technical DataDocumento6 páginasFischer Technical DataAnonymous CgJzschAinda não há avaliações

- Method StatementDocumento4 páginasMethod StatementNajib GombakAinda não há avaliações

- b4310 Boysen PrimeguardDocumento7 páginasb4310 Boysen Primeguarddep_vin100% (1)

- Documents Checklist For Foundation Plan Submission Typical Items RequirementsDocumento10 páginasDocuments Checklist For Foundation Plan Submission Typical Items RequirementsChan Kin CheungAinda não há avaliações

- Storm Water Construction Checklist FinalDocumento6 páginasStorm Water Construction Checklist FinalWalt FlowersAinda não há avaliações

- UFGS 01 35 30 Safety, Health, and Emergency ResponseDocumento33 páginasUFGS 01 35 30 Safety, Health, and Emergency Responserhunter2010Ainda não há avaliações

- Jha TentDocumento7 páginasJha TentMUHAMAD ROZEE MAT AZMIAinda não há avaliações

- Activity Hazard Analysis FinalDocumento23 páginasActivity Hazard Analysis FinalPedro PereiraAinda não há avaliações

- Access and Egress Dangers of Trenching and ExcavationDocumento2 páginasAccess and Egress Dangers of Trenching and ExcavationMayank RajputAinda não há avaliações

- Cofferdam Construction and Dewatering Taunsa Barrage RehabilDocumento22 páginasCofferdam Construction and Dewatering Taunsa Barrage RehabilAhmed Huessien SuleimanAinda não há avaliações

- Demolition 4 PDFDocumento19 páginasDemolition 4 PDFazrulAinda não há avaliações

- Working at Height PermitDocumento1 páginaWorking at Height PermitharikrishnaAinda não há avaliações

- Activity Hazard Analysis (AHA) : Risk Assessment Code (RAC) Matrix Severity ProbabilityDocumento6 páginasActivity Hazard Analysis (AHA) : Risk Assessment Code (RAC) Matrix Severity ProbabilityAnthony MacatangayAinda não há avaliações

- Excavation Trench Permit Ex 1 F0206Documento5 páginasExcavation Trench Permit Ex 1 F0206emeka2012Ainda não há avaliações

- Method Statement of Installing I-BeamDocumento1 páginaMethod Statement of Installing I-BeamfaizbukhariAinda não há avaliações

- Material Handling - Word DocumentDocumento6 páginasMaterial Handling - Word DocumentE Mohammed IbrahimAinda não há avaliações

- Working at Height Risk AssessmentDocumento7 páginasWorking at Height Risk AssessmentAshish100% (3)

- Behaviour Based Observation ChecklistDocumento3 páginasBehaviour Based Observation ChecklistVaradaraju ThirunavukkarasanAinda não há avaliações

- Risk AssessmentDocumento10 páginasRisk Assessmentalamdar321100% (2)

- Stainless Steels InfoDocumento2 páginasStainless Steels Infogunnery02Ainda não há avaliações

- Waste Duty Care Code Practice 2016Documento16 páginasWaste Duty Care Code Practice 2016gunnery02Ainda não há avaliações

- UrwDocumento319 páginasUrwgunnery02Ainda não há avaliações

- Concrete Risk PDFDocumento32 páginasConcrete Risk PDFkrissregionAinda não há avaliações

- Subpart P: Gayle W. Fratto Manager, Safety Engineering Branch Georgia Tech's OTI Education CenterDocumento59 páginasSubpart P: Gayle W. Fratto Manager, Safety Engineering Branch Georgia Tech's OTI Education Centergunnery02Ainda não há avaliações

- P91 T91 Property Boiler TubesDocumento3 páginasP91 T91 Property Boiler Tubesgunnery02Ainda não há avaliações

- CoalDocumento77 páginasCoalgunnery02Ainda não há avaliações

- Health History Form Adult StrabagDocumento3 páginasHealth History Form Adult Strabaggunnery02Ainda não há avaliações

- Dropped ObjectsDocumento26 páginasDropped Objectsgunnery0250% (2)

- Pest Control Food Industry PDFDocumento52 páginasPest Control Food Industry PDFzknsmknynprzlAinda não há avaliações

- Seatbelts x4Documento2 páginasSeatbelts x4gunnery02Ainda não há avaliações

- Crane Mobile SpecificationDocumento13 páginasCrane Mobile Specificationsancakemre100% (2)

- Rr757 Gasses in Tunnels TTDocumento72 páginasRr757 Gasses in Tunnels TTgunnery02Ainda não há avaliações

- Drill Pipe InfoDocumento6 páginasDrill Pipe Infogunnery02Ainda não há avaliações

- CLC Glossary EnglishDocumento11 páginasCLC Glossary Englishgunnery02Ainda não há avaliações

- LNG HazardsDocumento11 páginasLNG HazardsPrince Israel EboigbeAinda não há avaliações

- 6.1 Reporting & Quality Control Procedures (DOC & SMC)Documento1 página6.1 Reporting & Quality Control Procedures (DOC & SMC)gunnery02Ainda não há avaliações

- Ref6 Australia Code of Practice For Tunnels Under ConstructionDocumento88 páginasRef6 Australia Code of Practice For Tunnels Under Constructionkavya1811Ainda não há avaliações

- Auh Location Map Fugro OfficeDocumento1 páginaAuh Location Map Fugro Officegunnery02Ainda não há avaliações

- API 1160 Pipeline IntegrityDocumento19 páginasAPI 1160 Pipeline Integritygunnery0280% (5)

- Bones of FootDocumento1 páginaBones of Footgunnery02Ainda não há avaliações

- Hazardous Area Classification For Flammable Gases and VapoursDocumento9 páginasHazardous Area Classification For Flammable Gases and Vapoursgunnery02Ainda não há avaliações

- Check List For Roads Buildings WorksDocumento36 páginasCheck List For Roads Buildings Worksgunnery02Ainda não há avaliações

- Forklift Safety Checklist ComprehensiveDocumento7 páginasForklift Safety Checklist Comprehensivegunnery02Ainda não há avaliações

- Crane Inspection ChecklistDocumento1 páginaCrane Inspection Checklistgunnery02100% (3)

- Scaffold ChecklistDocumento4 páginasScaffold Checklistgunnery02100% (1)

- Daily Inspection Checklist For MANLIFTDocumento2 páginasDaily Inspection Checklist For MANLIFTgunnery02100% (3)

- Checklist Env PDODocumento7 páginasChecklist Env PDOgunnery02Ainda não há avaliações

- Combined Cycle Power Plant InfoDocumento2 páginasCombined Cycle Power Plant Infogunnery02Ainda não há avaliações

- Bakkalaureatsarbeit GIDEN Ilhami 0235017Documento37 páginasBakkalaureatsarbeit GIDEN Ilhami 0235017spinsta11Ainda não há avaliações

- Saket District CenterDocumento18 páginasSaket District CenterRohit Tangri100% (2)

- Savelife Foundation & Anr v. Union of India & Anr, Writ Petition (Civil) No(s) - 235 of 2012 (SC)Documento4 páginasSavelife Foundation & Anr v. Union of India & Anr, Writ Petition (Civil) No(s) - 235 of 2012 (SC)Vaishnavi JayakumarAinda não há avaliações

- SAPEM 1 Introduction PDFDocumento30 páginasSAPEM 1 Introduction PDFLuke Jabulani Reid100% (2)

- 7642 2015-2016 RoutesDocumento292 páginas7642 2015-2016 RoutesVijay Kumar100% (1)

- Skippy Tuning Guide 2011 S1Documento26 páginasSkippy Tuning Guide 2011 S1dust1977Ainda não há avaliações

- PCT Sections MapDocumento1 páginaPCT Sections MapKeponugarteAinda não há avaliações

- Cri224 - 1st ExamDocumento161 páginasCri224 - 1st Examr.hoyohoy.531234Ainda não há avaliações

- The High Cost of Free Parking: Donald ShoupDocumento27 páginasThe High Cost of Free Parking: Donald Shoupjaffa99Ainda não há avaliações

- Vibro Replacement Columns For Shipyard Infrastructure at Pipavav - IsGI 2009Documento7 páginasVibro Replacement Columns For Shipyard Infrastructure at Pipavav - IsGI 2009suvraAinda não há avaliações

- Penentuan Kriteria Dalam Pemilihan Jenis Perkerasan Pada Dataran Tinggi Di Kabupaten TrenggalekDocumento8 páginasPenentuan Kriteria Dalam Pemilihan Jenis Perkerasan Pada Dataran Tinggi Di Kabupaten TrenggalekDulsaAinda não há avaliações

- Bridge Engineering: Topic: Construction Methods of Arch Bridges and Cable Stayed BridgesDocumento11 páginasBridge Engineering: Topic: Construction Methods of Arch Bridges and Cable Stayed BridgesTaimoor NasserAinda não há avaliações

- Flagpole Regulations: Zoning Districts SizeDocumento1 páginaFlagpole Regulations: Zoning Districts SizeHossam SeifAinda não há avaliações

- Side Dump Loader 625e - SDLDocumento2 páginasSide Dump Loader 625e - SDLSriram NambiAinda não há avaliações

- 3 Green LightsDocumento4 páginas3 Green LightsTun HanAinda não há avaliações

- Performance Evaluation of Polymer Modified Asphalt MixDocumento39 páginasPerformance Evaluation of Polymer Modified Asphalt MixEnd End100% (1)

- (COMPLETE - Highfields Suburb Added) Property Report For Tim Mortimer PDFDocumento262 páginas(COMPLETE - Highfields Suburb Added) Property Report For Tim Mortimer PDFAll Content Media Digital Content CreatorsAinda não há avaliações

- Dar 05112018Documento5 páginasDar 05112018Fauquier NowAinda não há avaliações

- 9 Physical and Non Physical Determinants of City Form PatternDocumento31 páginas9 Physical and Non Physical Determinants of City Form Patterntanie100% (8)

- Analysis and Design of Arch-Type Pedestrian BridgeDocumento18 páginasAnalysis and Design of Arch-Type Pedestrian BridgeJenrry Montan VizaAinda não há avaliações

- Design of T-Beam Bridge Super Structre Using Limit State MethodDocumento49 páginasDesign of T-Beam Bridge Super Structre Using Limit State MethodGauravAinda não há avaliações

- Traction CONTROLDocumento18 páginasTraction CONTROLkiransideasAinda não há avaliações

- Commercial BanksDocumento8 páginasCommercial BanksEdwin NyamohAinda não há avaliações

- Dec. 1997 Toyota MR2 - Original Beams Redtop' Engine - R671 TKVDocumento1 páginaDec. 1997 Toyota MR2 - Original Beams Redtop' Engine - R671 TKVCalum C CampbellAinda não há avaliações

- Ford Sierra Workshop Manual 1 8 TDDocumento4 páginasFord Sierra Workshop Manual 1 8 TDmarc18950% (2)

- Implementing Rules PD 957Documento68 páginasImplementing Rules PD 957Austin CharlesAinda não há avaliações

- Design and Detailing Concrete Block PavementsDocumento10 páginasDesign and Detailing Concrete Block PavementsBolanle OlaawoAinda não há avaliações

- B2 Alphabetical Wordlist Unit 2Documento7 páginasB2 Alphabetical Wordlist Unit 2Кирие ЭлейсонAinda não há avaliações

- LL Rap 01606016617Documento1 páginaLL Rap 01606016617YaswanthGorantlaAinda não há avaliações

- Agenda: Shoreline City Council Special Workshop Dinner MeetingDocumento13 páginasAgenda: Shoreline City Council Special Workshop Dinner MeetingNeal McNamaraAinda não há avaliações