Escolar Documentos

Profissional Documentos

Cultura Documentos

CMS System Inspection and Observations

Enviado por

arockiyathassDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

CMS System Inspection and Observations

Enviado por

arockiyathassDireitos autorais:

Formatos disponíveis

STANDARD REFERNCE SHEET

SAESJ902

7 Enclosures

7.1 Enclosures for instruments in outdoor plant areas shall

be NEMA Type 4 in accordance with NEMA ICS 6 and

NEMA 250 or IEC 60529 Type IP 65. Enclosures in

severe corrosive environments shall be NEMA Type 4X

or IEC 60529 Type IP 66.

7.2 The field junction box, in a Class I, Zone 2 location

and in non-hazardous areas, shall be a single door NEMA

Type 4X or IEC 60529 Type IP 66 box. The box

construction shall meet the following requirements:

7.2.1 Type 316 stainless steel body, door and

hardware.

7.2.2 Continuously welded seams, finished

smooth.

7.2.3 Stainless steel hinge.

7.2.4 Stainless steel captive clamps.

7.2.5 Data/Print pocket on inside of door.

7.2.6 External mounting brackets.

7.2.7 Collar studs for mounting inside panel.

7.2.8 Ground stud for terminating A/C safety

ground wire.

7.2.9 Removable door

7.3 All field junction boxes shall be mounted

vertically, i.e., the door shall open from left-to-

right or from right-to-left.

7.4 Instrument enclosures and junction boxes having

an internal volume exceeding 2,000 cm shall be

provided with Type 300 Series stainless steel

breather and drain fittings, or a combination

breather and drain fitting.

10.2.10 The terminals shall be mounted on vertical DIN

rails (i.e., horizontal DIN rails are not allowed).

Commentary Note:

This section is specifying vertical DIN rails in 'field junction

boxes'. This section is not intended to apply to ancillary

termination boxes, e.g., smart ZV control stations, GUA fittings,

etc.

10.2.11 The DIN rail shall only be mounted on the inside

panel (back-pan) of the junction box.

16.3 Terminal Reference

16.3.1 Each row of terminals shall be uniquely

identified alphanumerically, e.g., TS-101,

TS-102, etc.

16.3.2 The terminals in each row shall be

sequentially numbered starting at number

one (1).

17.2 Safety Ground

17.2.1 All exposed non-current-carrying metallic

parts that could become energized with hazardous

potentials must be reliably connected to the

equipment grounding circuits. This assures that

hazardous potential differences do not exist between

individual instrument cases or between an instrument

case and ground. Therefore, all metal equipment and

enclosures within a panel or series of panels (i.e.,

instrument cases, hinged doors, racks, etc.) shall be

bonded with bonding jumpers and connected to a

safety ground bus with a minimum copper wire size

of 12 AWG. Two copper conductors, 25 mm

minimum, shall be connected from the safety ground

bus to a single tie point on the safety ground grid in a

closed loop configuration. Safety ground connections

must be made such that when a case-grounded

instrument is removed, the integrity of the rest of the

safety ground system is maintained.

34-SAMSS-820

5.3 Heat dissipation calculations shall be submitted

for any cabinet that houses power supplies, PCs or other

heat generating components. The calculations shall show

that the components installed inside the cabinet will not

be exposed to a temperature above their temperature

rating.

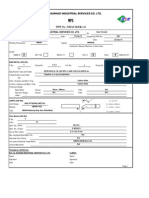

SL.NO Originator Action By Compliance Status Status On

1

2

3

4

5

6

7

1

2

3

4

5

6

1

2

ACCESSFITTINGSJUNCTIONBOX

RS485REPEATERJUNCTIONBOX

CRMSSYSTEMCABINET

TheTerminalMarkingIdentification:TheTerminalsInEachRowShallBeSequentiallyNumbered

StartingatNumber1.(TB2,TB3,TB4..TerminalMarkingShallBeStartFromNo1).

EnclosuresDrain&BreatherMaterialType:InstrumentEnclosureAndJunctionBoxesHavingAn

InternalVolumeExceeding2,000Cm3ShallBeProvidedWithType300StainlessSteelBreather

AndDrainFittings,OrACombinationBreatherAndDrainFitting).(NowDrain&BreatherMaterial

IsPlastic).

HeatDissipationCalculations:HeatDissipationCalculationsShallBeSubmittedForAnyCabinet

ThatHousesPowerSupplies,PCsOrOtherHeatGeneratingComponents.TheCalculationsShall

ShowThatTheComponentsinstalledInsideTheCabinetWIllNotBeExposedToATemperature

AboveTheirTemperatureRating.(NotAvilable).

BackPanMaterial:316StainlessSteelBackPanels.(NowBackPanIsGalvanize).

TheTerminalMarkingIdentification:TheTerminalsInEachRowShallBeSequentiallyNumbered

StartingatNumber1.(TB2TerminalMarkingShallBeStartFromNo1).

HingedDoorSafetyGround:Therefore,AllMetalEquipmentAndEnclosuresWithinAPanelOr

SeriesOfPanelsHingedDoorShallBeBondedWithBondingJumbersAndConnectedToASafety

GroundBus.

DoorLocks:KeyLocksPadlocksAreNotAcceptable.(316StainlessSteelCaptiveScrewsMayBe

UsedInLieuOfCaptiveClampsProvidedThatTheScrewDoNotPenetrateTheDoorGasket).

Data/PrintPocket:Data/PrintPocketOnInsideOfDoor.(Data/PrintPocketMissing).

EnclosuresDoor:StainlessSteelHingeRemovableDoor.(DoorHingeMissing)

HingedDoorSafetyGround:Therefore,AllMetalEquipmentAndEnclosuresWithinAPanelOr

SeriesOfPanelsHingedDoorShallBeBondedWithBondingJumbersAndConnectedToASafety

GroundBus.(NewHingeTypeDoorSafetyGround).

Data/PrintPocket:Data/PrintPocketOnInsideOfDoor.(Data/PrintPocketMissing).

BackPan:TheDINRailShallOnlyBeMountedOntheInsidePanel(BackPan)OfTheJunction

Box.(BackPanelMissing).

BackPanMaterial:TheDINRailShallOnlyBeMountedOntheInsidePanel(BackPan)OfThe

JunctionBox.(TheNewBackPanelMaterialShallBeSS316).

TheTerminalDINRailMountingPosition:TheTerminalsShallBeMountedOnVerticalDINRails

(i.e.,HorizontalDINRailsAreNotAllowed).(NowTerminalsAreInHorizontalPosition).

CRMSSYSTEMINSPECTIONPUNCHLIST

Punch List description Comments

TheTerminalMarkingIdentification:EachRowOfTerminalsShallBeUniquelyIdentified

Alphanumerically(TB1IdentificationMissing)

Você também pode gostar

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsNo Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsNota: 4 de 5 estrelas4/5 (1)

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsNo EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsNota: 3 de 5 estrelas3/5 (2)

- Acalculous Cholecystitis CaseDocumento35 páginasAcalculous Cholecystitis CaseSaada Enok MedtamakAinda não há avaliações

- Technical Specification - MCCDocumento14 páginasTechnical Specification - MCCKunik Swaroop0% (1)

- Grade Control For Australian Open Pit Gold MinesDocumento14 páginasGrade Control For Australian Open Pit Gold Mineswaldo100% (1)

- CMS For Cad WeldingDocumento9 páginasCMS For Cad WeldingarockiyathassAinda não há avaliações

- Capacitor BANKDocumento15 páginasCapacitor BANKalokedas11100% (1)

- Switchgear SpecificationsDocumento29 páginasSwitchgear SpecificationsNandkumar ChinaiAinda não há avaliações

- E21-Control & Relay Panel - 17!05!2013Documento74 páginasE21-Control & Relay Panel - 17!05!2013Shatrughna SamalAinda não há avaliações

- SAIC & SATR - InstrumentationDocumento8 páginasSAIC & SATR - InstrumentationAdel Klk100% (1)

- Types of ProcurementDocumento7 páginasTypes of ProcurementrahulAinda não há avaliações

- Bhel 11kv To 415vDocumento46 páginasBhel 11kv To 415vDeepakJain100% (1)

- Automation Specn - 220kVDocumento88 páginasAutomation Specn - 220kVkiran100% (1)

- QCP Hot TapDocumento9 páginasQCP Hot TaparockiyathassAinda não há avaliações

- Craig & Derricott Isolators & Switch Disconnectors CatalogueDocumento40 páginasCraig & Derricott Isolators & Switch Disconnectors CataloguerocketvtAinda não há avaliações

- Ansi C80 - 3Documento9 páginasAnsi C80 - 3sultanalamoudiAinda não há avaliações

- 200mm 250mm 300 MM: Project Name Location Bill No. - 00 (Rev. 0) Consultant Contractor Buildiong Name DATEDocumento2 páginas200mm 250mm 300 MM: Project Name Location Bill No. - 00 (Rev. 0) Consultant Contractor Buildiong Name DATEganesh gundAinda não há avaliações

- Certificate Hummel AGDocumento5 páginasCertificate Hummel AGTh NattapongAinda não há avaliações

- Lighting SystemDocumento10 páginasLighting SystemJyoti ShekharAinda não há avaliações

- WPS 204 NewDocumento6 páginasWPS 204 Newarockiyathass100% (1)

- Aramco Hot Tap Welding Procedure Rev. 1Documento3 páginasAramco Hot Tap Welding Procedure Rev. 1arockiyathass100% (10)

- Control and Relay PanelsDocumento59 páginasControl and Relay PanelsMrrajesh Rajesh100% (1)

- GAD OrientationDocumento58 páginasGAD OrientationKevin Dalangin100% (2)

- Saudi Aramco Pre-Commissioning Form: Battery SystemDocumento4 páginasSaudi Aramco Pre-Commissioning Form: Battery SystemarockiyathassAinda não há avaliações

- Wika Pressure SensorDocumento4 páginasWika Pressure SensorPratap ValekarAinda não há avaliações

- Spec For 33kv SystemDocumento27 páginasSpec For 33kv SystemkjfenAinda não há avaliações

- Engineering Specification For MV SwitchgearDocumento21 páginasEngineering Specification For MV SwitchgearSundaresan SabanayagamAinda não há avaliações

- QCP-S-000-5520-176 Rev A (Elect - Power & Control Cable)Documento15 páginasQCP-S-000-5520-176 Rev A (Elect - Power & Control Cable)arockiyathassAinda não há avaliações

- Instruction Manual: Model 7SCDocumento52 páginasInstruction Manual: Model 7SCkmpoulos100% (2)

- CRP & SasDocumento93 páginasCRP & Sasbalaeee123Ainda não há avaliações

- Leonard Peikoff-Introduction To LogicDocumento20 páginasLeonard Peikoff-Introduction To Logicbursa07Ainda não há avaliações

- PGCIL - C & R SPECIFICATION Rev - 4 PDFDocumento80 páginasPGCIL - C & R SPECIFICATION Rev - 4 PDFravindren_eee100% (1)

- ST. LUKE'S MEDICAL CENTER EMPLOYEE'S FOUNDATION AFW v. NLRCDocumento3 páginasST. LUKE'S MEDICAL CENTER EMPLOYEE'S FOUNDATION AFW v. NLRCjodelle11Ainda não há avaliações

- Vertical Mills V2 0Documento56 páginasVertical Mills V2 0recai100% (1)

- 04 Electrical SpecificationDocumento49 páginas04 Electrical SpecificationVishal NarkhedeAinda não há avaliações

- IRS S 82-92 With Amd 2 InverterDocumento18 páginasIRS S 82-92 With Amd 2 Invertersourabhcoomar@gmail.comAinda não há avaliações

- Eng TS X SP 0012Documento6 páginasEng TS X SP 0012Robert LiraAinda não há avaliações

- Grounding and Lighthing ProtectionDocumento7 páginasGrounding and Lighthing ProtectionAdhyartha KerafAinda não há avaliações

- Types of LV Switchboard: SwitchboardsDocumento10 páginasTypes of LV Switchboard: SwitchboardscRi SocietyAinda não há avaliações

- SECTION 16160 PanelboardsDocumento7 páginasSECTION 16160 Panelboardsno nameAinda não há avaliações

- Atex3171 PDFDocumento12 páginasAtex3171 PDFAnonymous skZysXxAinda não há avaliações

- 11kv and 33KVDocumento43 páginas11kv and 33KVArun KumarAinda não há avaliações

- Q EsvDocumento4 páginasQ Esvknotship.comAinda não há avaliações

- Electrical Revamp Cahier de Charge ENDocumento20 páginasElectrical Revamp Cahier de Charge ENben sanAinda não há avaliações

- 1vga673004 - General Specification (Unigear Family)Documento10 páginas1vga673004 - General Specification (Unigear Family)Riza Ibn AdriansyahAinda não há avaliações

- Description: Specification For Low Voltage Switchboard SenDocumento5 páginasDescription: Specification For Low Voltage Switchboard Senwaseem kausarAinda não há avaliações

- Instruction Manual: Model 7SL High/Low LimitrolDocumento48 páginasInstruction Manual: Model 7SL High/Low LimitrolkmpoulosAinda não há avaliações

- 21-28 - EtaDocumento5 páginas21-28 - EtaModern DesignsAinda não há avaliações

- SECTION 16470 Panelboards Part 1 - GeneralDocumento5 páginasSECTION 16470 Panelboards Part 1 - GeneraljosemartinpenatorresAinda não há avaliações

- DB Tech Specs - BDDocumento5 páginasDB Tech Specs - BDDarshit VyasAinda não há avaliações

- Sem210 Series: Programmable In-Head Universal Temperature TransmitterDocumento5 páginasSem210 Series: Programmable In-Head Universal Temperature TransmitterjhuskanovicAinda não há avaliações

- Moxa Imc 101 Series Qig v9.3Documento13 páginasMoxa Imc 101 Series Qig v9.3Stéphane SintesAinda não há avaliações

- Enclosures TechnicalDocumento16 páginasEnclosures TechnicalAnonymous rYZyQQot55Ainda não há avaliações

- (India) PVT LTD: FJ5705 1/6 - SS 75 6008/I 140597101Documento22 páginas(India) PVT LTD: FJ5705 1/6 - SS 75 6008/I 140597101netsavy71Ainda não há avaliações

- Tech Spec SS - IIDocumento253 páginasTech Spec SS - IIkrcdewanewAinda não há avaliações

- Document No PCPL-0532-4-407-04-06 Contol & Relay Panel Section - 4 PAGE: 1 of 6 ScopeDocumento6 páginasDocument No PCPL-0532-4-407-04-06 Contol & Relay Panel Section - 4 PAGE: 1 of 6 ScopetceterexAinda não há avaliações

- Technicall Specification of 630 KVA, 11-0.415 KV Dry Type Outdoor Transformers.......... Dated. 31.08.2015Documento25 páginasTechnicall Specification of 630 KVA, 11-0.415 KV Dry Type Outdoor Transformers.......... Dated. 31.08.2015spidervinoAinda não há avaliações

- Volume I I Technical Specification Part I I IDocumento239 páginasVolume I I Technical Specification Part I I IMohit Patel100% (1)

- Specification For 2000Hp Ac Draw Works, Drives and Controls: QTY Description 1 E-2000 DrawworksDocumento22 páginasSpecification For 2000Hp Ac Draw Works, Drives and Controls: QTY Description 1 E-2000 DrawworksSunil GandhiAinda não há avaliações

- 60.30-069 - 1994specification For Differential PressureDocumento5 páginas60.30-069 - 1994specification For Differential PressurepradeepAinda não há avaliações

- Waha Oil Company: Engineering Specification Air-Cooled Transformer / Rectifier Units For Cathodic Protection SystemsDocumento5 páginasWaha Oil Company: Engineering Specification Air-Cooled Transformer / Rectifier Units For Cathodic Protection SystemsRobert LiraAinda não há avaliações

- EG 15-6-1.1 Installation of Field Instrumentation: ScopeDocumento6 páginasEG 15-6-1.1 Installation of Field Instrumentation: Scopeamin100% (1)

- 1.4 Installation PrerequisitesDocumento22 páginas1.4 Installation PrerequisitespulloagAinda não há avaliações

- Aislador Digital Input 8DIDocumento1 páginaAislador Digital Input 8DIEduardo_77Ainda não há avaliações

- Equipment Ring Main Unit Sno Spec Clause No. Query / Clarification Required Bidder's Response Resolution Technical Resolution Project: Name of ManufacturerDocumento4 páginasEquipment Ring Main Unit Sno Spec Clause No. Query / Clarification Required Bidder's Response Resolution Technical Resolution Project: Name of Manufacturersyedabuthahir_mAinda não há avaliações

- PanelboardsDocumento3 páginasPanelboardsCristina Marie BatoAinda não há avaliações

- LT AcdbDocumento44 páginasLT Acdbanu2013Ainda não há avaliações

- RAK TR.1000S H DatabladDocumento4 páginasRAK TR.1000S H DatabladPhuc HuynhAinda não há avaliações

- 372 - Catalog Cedaspe 22 PDFDocumento7 páginas372 - Catalog Cedaspe 22 PDFAndrei BădiţăAinda não há avaliações

- LV Power Cable Specification - 06.11.2009Documento10 páginasLV Power Cable Specification - 06.11.2009ErAkashAryanAinda não há avaliações

- Abb FusesDocumento124 páginasAbb FusesJC InquillayAinda não há avaliações

- Volume 3 Sec 3 22Documento205 páginasVolume 3 Sec 3 22saravananAinda não há avaliações

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142No EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142Ainda não há avaliações

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsAinda não há avaliações

- CRMS ItpDocumento2 páginasCRMS Itparockiyathass100% (1)

- Wescosa Site Test Procedure STP - DL Services Department Title: Distribution ListDocumento2 páginasWescosa Site Test Procedure STP - DL Services Department Title: Distribution ListarockiyathassAinda não há avaliações

- Attachment 1 - Microcor® Transmitter: Inspection ChecklistDocumento1 páginaAttachment 1 - Microcor® Transmitter: Inspection ChecklistarockiyathassAinda não há avaliações

- QCP 040 QCP CrmsDocumento7 páginasQCP 040 QCP Crmsarockiyathass100% (1)

- Ehtcl 001 1Documento1 páginaEhtcl 001 1arockiyathassAinda não há avaliações

- Data Sheet Increased Safety Dpe Breather Drain 0912 PDFDocumento2 páginasData Sheet Increased Safety Dpe Breather Drain 0912 PDFarockiyathassAinda não há avaliações

- Standardization 1 PDFDocumento7 páginasStandardization 1 PDFmazharul HasanAinda não há avaliações

- Artifact 7 - Superannuation Pension Calculator-GuidelinesDocumento2 páginasArtifact 7 - Superannuation Pension Calculator-GuidelinesSai RamAinda não há avaliações

- Dingenen 2017Documento14 páginasDingenen 2017pedro.coleffAinda não há avaliações

- Manual Servicio Soxte 2050Documento46 páginasManual Servicio Soxte 2050Quimica JordanlabAinda não há avaliações

- Neicchi 270 ManualDocumento33 páginasNeicchi 270 Manualmits2004Ainda não há avaliações

- Fosroc Conplast SP335: Multi-Range Water Reducing AdmixtureDocumento2 páginasFosroc Conplast SP335: Multi-Range Water Reducing AdmixtureVincent JavateAinda não há avaliações

- Targets: Chris Paul P. Pagaoa, LPT, Msc. Biology - InstructorDocumento4 páginasTargets: Chris Paul P. Pagaoa, LPT, Msc. Biology - InstructorVince RetutaAinda não há avaliações

- Child Abuse Lesson PlanDocumento7 páginasChild Abuse Lesson PlanIrvie manalacAinda não há avaliações

- Multicultural Aspects of Communication Disorders - CH 12Documento21 páginasMulticultural Aspects of Communication Disorders - CH 12Maitry PatelAinda não há avaliações

- Book Summary - I Hear You Summary Michael Sorensen - Read in 7 MinutesDocumento10 páginasBook Summary - I Hear You Summary Michael Sorensen - Read in 7 MinutesNogüey JoseAinda não há avaliações

- Different Types of FermentationDocumento26 páginasDifferent Types of FermentationCats and DogAinda não há avaliações

- Good Boys Go To Heaven, Bad Boys Go EverywhereDocumento32 páginasGood Boys Go To Heaven, Bad Boys Go Everywherealcantaravic2006Ainda não há avaliações

- Daily 500 Maximum 2500 Minimum 1000 Lead Time 15 Days EOQ 1200 Emergency Lead Time 3 DaysDocumento5 páginasDaily 500 Maximum 2500 Minimum 1000 Lead Time 15 Days EOQ 1200 Emergency Lead Time 3 DaysM Noaman AkbarAinda não há avaliações

- Should Beauty Pageants Be BannedDocumento2 páginasShould Beauty Pageants Be BannedHastin Dilipbhai BagthariyaAinda não há avaliações

- Yuasa NPL Range: VRLA BatteriesDocumento2 páginasYuasa NPL Range: VRLA BatteriesVuro BegaAinda não há avaliações

- Formula Sheet Pre-MidDocumento4 páginasFormula Sheet Pre-MidUzair KhanAinda não há avaliações

- Joey Agustin (Price Tag)Documento2 páginasJoey Agustin (Price Tag)AGUSTIN JOENALYN MAE M.Ainda não há avaliações

- What Is A Walkable Place The Walkability Debate inDocumento20 páginasWhat Is A Walkable Place The Walkability Debate inBADR HAMDAN ALATEBEAinda não há avaliações

- Modelling The Effects of Condensate Banking On High CGR ReservoirsDocumento11 páginasModelling The Effects of Condensate Banking On High CGR ReservoirslikpataAinda não há avaliações

- What Is Primary Health Care and Its Relation To Universal Health Care? As A Medical Student, What Impact Can I Create in Implementing PHC and UHC?Documento2 páginasWhat Is Primary Health Care and Its Relation To Universal Health Care? As A Medical Student, What Impact Can I Create in Implementing PHC and UHC?Aubrey Unique EvangelistaAinda não há avaliações

- Liquid Fertilizer PresentationDocumento17 páginasLiquid Fertilizer PresentationAnna RothAinda não há avaliações

- Human Nutritional RequirementsDocumento3 páginasHuman Nutritional RequirementsAgnesMagadiaAinda não há avaliações