Escolar Documentos

Profissional Documentos

Cultura Documentos

Biaxially Voided Bubble Deck Slab System and Other Conventional Floor Slab Systems

Enviado por

Umange RanasingheDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Biaxially Voided Bubble Deck Slab System and Other Conventional Floor Slab Systems

Enviado por

Umange RanasingheDireitos autorais:

Formatos disponíveis

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

Chapter 1

INTRODUCTION

Department of Civil Engineering, M.S.R.I.T. Page 1

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

1.1 OVERVIEW

Reinforced concrete slabs are relatively thin, flat, structural elements, whose main

function is to transmit loading acting normal to their plane. Slabs are used as floors and

roofs of buildings, as walls in tanks and buildings, and as bridges to transmit relatively

heavy concentrated loading.

Reinforced concrete slabs are among the most common structural elements, but despite

the large number of slabs design and built, the details of the elastic and plastic behavior of

slabs are not always appreciated or properly taken into account. This occurs at least

partially because of the mathematical complexities of dealing with elastic equations,

especially for support conditions which realistically approximate those in building floor

slabs.

Regardless of which design method is used, the resulting slab must be serviceable at the

working load level, with deflections and cracking remaining within acceptable limits .slab

design methods are concerned largely with flexure, but the shear forces may also be a

limiting factor .The particular problem of shear is in beamless slabs, especially when

acting in combination with transfer of unbalanced moments from slabs to columns.

The bi-axially voided bubble deck technology is based upon the patented integration

technique - the direct way of linking air and steel. The bubble deck technology comprises

of a bi axial carrying hollow slab in which plastic balls serves the purpose of eliminating

concrete that has no carrying effect. n other words, it removes the non working dead

load, while maintaining bi axial strength.

This pro!ect report contains the details of innovative design, detailing and estimation of bi

axially voided bubble deck slab and a comparative study with conventional slab systems,

namely, beam slab and conventional flat slab.

Department of Civil Engineering, M.S.R.I.T. Page 2

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

1.2 OBJECTIVES

The main ob!ective of this pro!ect is to design and compare structural, economic, and

environmental panorama of the following floor slab systems "

#onventional beam slab system

#onventional flat slab system

$i-axially voided bubble deck system

n order to accomplish the advantages of the new bi-axially voided bubble deck floor slab

systems over other conventional floor slab systems.

1.3 Project Outl!e"

There are eight chapters in this pro!ect report. #hapter one gives introduction and

ob!ectives of this pro!ect. #hapter % provides literature review for this pro!ect. This chapter

gives the theory behind this pro!ect. #hapter & gives the information related to design and

detailing of flat slab system. #hapter ' gives the information about design and detailing of

conventional beam slab system. #hapter ( gives the information about design and

detailing of bi-axially voided bubble deck floor slab system. #hapter ) contains material

and economic estimation of all above mentioned floor slab systems. #hapter * contains

results and discussions. #hapter + gives conclusions on the experimental outcome and

the scope for future work.

Department of Civil Engineering, M.S.R.I.T. Page 3

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

C#$PTER 2

%ITER$TURE REVIEW

2.1 C%$SSI&IC$TION O& S%$BS

Department of Civil Engineering, M.S.R.I.T. Page 4

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

,ifferent types of load patterns and support conditions require different types of floor slab

systems. To accomplish this, the different types of floor slab systems used can be broadly

grouped into the following four classes "

a - #onventional beam slab system

b- .lat slab system

c- /ollow core floor slab system

d- $i-axially voided bubble deck floor slab system

Slabs can be classified as follows0

2.2 BE$' S%$B

Slabs supported on beams on all sides or selected sides of each poannel are generally

termed as beam slabs. n a beam slab system, it is quite easy to visuali1e the path from

load point to columns as being from slab to beam to column and them to compute realistic

moments and shears for the design of all members. 2 conventional beam slab system can

be classified as 0

3ne way slab

Two way slab

2 typical beam slab is shown in figure %.4

Department of Civil Engineering, M.S.R.I.T. Page 5

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

2.2 &%$T S%$BS

Department of Civil Engineering, M.S.R.I.T. Page 6

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

The term flat slab means a reinforced concrete slab with or without drops, supported

generally without beams, by columns with or without flared column heads. 2 flat slab may

be a solid slab or may have recesses formed on the soffit so that the soffit comprises a

series of ribs in two direction.

The following two methods are recommended by the code for determining the bending

moments in the slab panel0

1 ,irect design method 5,,6-

2 7quivalent frame method 57.6-

These methods are applicable only for two way rectangular slabs.

2.2.1 DIRECT DESI(N 'ET#OD

Department of Civil Engineering, M.S.R.I.T. Page !

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

,irect design method is a simplified procedure of determining the negative and positive

design moment at critical section in the slab. The code specifies that the following

conditions must be satisfied by the two way slab system for the application of direct

design method0

4- There must be at least three continuous spans in each direction.

%- 7ach panel must be rectangular, with the long to short span ratio not exceeding

%.8

3 The columns must not be offset by more than ten percent of span from either axis

between centre lines of successive columns. 2s shown in figure %.&.

4 The successive span length in each direction must not differ by more than 49&

rd

of

longer span.

(- The factored live load must not exceed three times the factored dead load.

Department of Civil Engineering, M.S.R.I.T. Page "

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

2.2.2. E)UIV$%ENT &R$'E 'ET#OD

The equivalent frame method 57.6- of design of two way beam supported slabs, flat

slabs, flat plates and waffle slab is a more general and more rigorous method than ,,6,

and is not sub!ected to the limitations of ,,6.

The equivalent frame concept simplifies the analysis of three dimensional reinforcement

concrete building by sub dividing it into a series of two dimensional frames centered on

column lines in longitudinal as well as transverse direction. The 7.6 differs from ,,6 in

Department of Civil Engineering, M.S.R.I.T. Page #

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

the determination of total :negative: and :positive: design moments in the slab panel for

the condition of gravity loading. /owever, the apportioning of the moments to column strip

and middle strip is common for both methods.

2.3 #O%%OW CORE S%$B

/ollow core slabs are pre fabricated, one way spanning, concrete elements with hollow

cylinders.

&I( 2.*

,ue to the pre fabrication, these are inexpensive and reduce building time, but can be

used only in one way spanning construction and must be supported by beams and9or

walls.

2.3.1 %I'IT$TIONS O& #O%%OW CORE S%$B

6anufactured

t requires higher capacity cranes

;revalence of post construction inflexibility

t has one way action

Department of Civil Engineering, M.S.R.I.T. Page 1$

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

t is suitable only for certain applications

2.+ BI,$-I$%%. VOIDED BUBB%E DEC/ S%$B S.STE'

The bi-axially voided bubble deck technology is based upon the patented integration

technique - the direct way of linking air and steel.

The bubble deck technology comprises of a bi axial carrying hollow slab in which plastic

balls serves the purpose of eliminating concrete that has no carrying effect. n other

words, it removes the non working dead load, while maintaining bi axial strength.

$y adopting the geometry of the ball in the mesh, an optimi1ed concrete construction is

obtained, with simultaneous maximum utility of both moment and shear 1ones.

The construction literally creates itself as a result of the geometry of two well known

components0

a Reinforcement

% /ollow plastic balls

Department of Civil Engineering, M.S.R.I.T. Page 11

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

<hen the top and bottom reinforcement are linked in the usual way, a geometrical and

statically stable bubble deck bubble-unit evolves.

The reinforcement catches, distributes and locks the balls in exact position, while the balls

shape the air volume, control the level of reinforcement and at the same time stabili1e the

spatial lattice. <hen the steel lattice unit is concreted, a monolithic bi-axial hollow slab is

obtained.

2.+.1 (ENER$% T#EOR.

2 bubble deck behaves like a solid slab, with true bi axial behavior, uniform in arbitrary

direction.

Tension and compression 1one is not influenced by the voids.

.orces can be distributed freely, with no singularities, in the three dimensional structure,

hence, making all concrete effective.

&01 2.2

Department of Civil Engineering, M.S.R.I.T. Page 12

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

<hen cutting out holes, the difference between the two deck types becomes obvious.

<ith one way span it is necessary to place beams around the hole to transport the forces

to principle beams.

Department of Civil Engineering, M.S.R.I.T. Page 13

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

Two way spans can be completely without beams.

&I( 2.3

2.+.2 TESTS $ND STUDIES

The bubble deck technology has been tested thoroughly. Results confirm that a bubble

deck slab behaves like a solid slab in every way.

2.+.2.1 S#E$R STREN(T#

Tests confirm that all concrete in the slab can be taken into account when calculating any

type of forces. .or safety reasons, it is recommended to use a factor of 8.) compared to

values of a solid slab of same height.

Department of Civil Engineering, M.S.R.I.T. Page 14

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

2.+.2.2 BENDIN( STREN(T# $ND DE&%ECTION BE#$VIOUR

2 bubble deck slab has the same bending strength as a solid slab of same height. The

bending stiffness is 8.=, compared to a solid slab. $ut since the weight of the slab is only

8.)( of a solid slab, the deflection will be considerably less.

2.+.2.3 $NC#ORIN(

Tests confirm that the balls have no influence on the anchoring values. The values are

exactly the same s for a solid slab.

2.+.2.+ &IRE

2 bubble deck slab can be tailored to meet any requirements by optimi1ing the actual

concrete cover.

The bubbles only slightly influence the patterns of heat transfer through the cover after a

certain time and distance from the bottom,. 2gain, a bubble deck behaves like a solid

slab.

T$B%E 2.1

2.+.2.* SOUND

Department of Civil Engineering, M.S.R.I.T. Page 15

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

>alues for air borne, impact sound 5vertical or hori1ontal- exists. $elow are the

representative values.

T$B%E 2.2

2.+.3 $u44le 5ec6 "la4 7er"o!"

The appropriate bubble deck slab version is engineered to suit building configuration,

span length between supports, applied loadings and vertical alignment of supports.

T$B%E 2.3

2.+.+ E%E'ENT T.PES

$ubble deck can be manufactured in three types of manufactured elements0

Department of Civil Engineering, M.S.R.I.T. Page 16

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

T?;7 2 " .@AR77 7@76BTS

<hen the bottom of the bubble reinforcement sandwich includes a *8mm thick pre cast

concrete layer acting as formwork within part of the finished slab depth replacing the need

for soffit shuttering. The elements are placed on temporary propping, loose !oint, the shear

and edge reinforcement added, perimeter and tolerance shuttered and then the remaining

slab depth concreted.

6ost commonly specified being suitable for the ma!ority of new-build pro!ects. Requires

fixed or mobile crane to lift into position due to weight of manufactured elements as

delivered to site.

T?;7 $-R7B.3R#767BT 63,C@7S

#omprising pre-fabricated Dbubble reinforcementE sandwiched elements. The modules are

placed on traditional site formwork, loose !oint, shear and edge reinforcement added and

then concrete in two stage to the full slab depth. Suitable for suspended ground floor slabs

and alteration9refurbishment pro!ects, particularly where site access is extremely

restricted. #an be manually lifted into position.

Department of Civil Engineering, M.S.R.I.T. Page 1!

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

T?;7 #-.BS/7, ;@2BFS

,elivered to the building site as complete pre-cast factory made slab elements with full

concrete thickness . These span in one direction only and require the inclusion of

supporting beams or walls within the structure.

2.+.* POST,TENSION

<hen mega spans are required 5above 4( meter- we can provide a post tension 5;T-

bubble deck solution. The above deflection limits can be increased by up-to &8 percent

with post-tension bubble deck slab.

2.+.2 (REEN CREDENTI$%S

$y virtually eliminating concrete in the middle of a slab bubble deck makes a significant

contribution to reducing environmental impact. Auidance from the 3,;6 requires the

direct environmental effects of building to be considered, including usage of natural

resources and emission resulting from construction. Bot only is concrete usage reduced

up-to (8 percent within a building structure but knock-on benefits can be reali1ed through

reduced foundation side. $ubble deck can make a a big contribution towards achieving

$R772B targets.

7very (888 m

%

of bubble deck floor slab can save0

4888 m

%

site concrete

4)) ready mix lorry trips

4*=+ tonnes of foundation loads "or 4= less piles

4*'( AG energy used in concrete production and haulage

%*+ tonnes of #3%- green house gases-emission

Department of Civil Engineering, M.S.R.I.T. Page 1"

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

C#$PTER 3

DESI(N O& &%$T S%$BS

$N$%.TIC$% P%$N

Department of Civil Engineering, M.S.R.I.T. Page 1#

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

&I( 3.1

3. DESI(N O& &%$T S%$B

8USIN( E)UIV$%ENT &R$'E 'ET#OD9

3.1 Sla4 thc6!e""

.or deflection control

d H

l

n 9 %) IS-'(), #lause %&.%.4J

Since drop is not provided

d H

l

n95%)K8.=- IS-'(), #lause %&.%.4J

d H )(8895%)K8.=-

d H %**.** mm

2pprox. d L %*( mm

Department of Civil Engineering, M.S.R.I.T. Page 2$

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

Therefore , M d N %( 5clear cover-

, M %*( N %(

, M &88 mm

3.2 %oa5 Calculato!

Self weight of slab M %( K 8.& M *.( FB 9 m

%

.loor finish M 4 FB 9 m

%

@ive load M %.' FB 9 m

%

Total M 48.= FB 9 m

%

.actored load M 4.( K 48.= M 4).&( FB 9 m

%

3.3 E:u7ale!t &ra;e $!al<""

2long B-S direction

6iddle strip

Department of Civil Engineering, M.S.R.I.T. Page 21

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

&0 3.2

.ixed end moment

6f-ab M w K l

%

9 4%

M - =+.4 K ).(

%

9 4%

M - &'(.&= FB-m

I,ue to symmetry fixed end moments are same for all spansJ

,istribution factor 5,. Table-

Span F OF ,. M F 9 OF

2

%

$

%

9 ).( 8.4( 4

$

%

2

%

$

%

#

%

9 ).(

9 ).(

8.&

8.(

8.(

,

%

#

%

,

%

7

%

9 ).(

9 ).(

8.&

8.(

8.(

7

%

.

%

9 ).(

8.&

8.(

Department of Civil Engineering, M.S.R.I.T. Page 22

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

7

%

,

%

9 ).( 8.(

.

%

7

%

.

%

A

%

9 ).(

9 ).(

8.&

8.(

8.(

A

%

.

%

9 ).( 8.4( 4

T$B%E 3.1

6oment ,istribution Table

Goint 2

%

$

%

#

%

,

%

7

%

.

%

A

%

Span 2

%

$

%

$

%

2

%

$

%

#

%

#

%

$

%

#

%

,

%

,

%

#

%

,

%

7

%

7

%

,

%

7

%

.

%

.

%

7

%

.

%

A

%

A

%

.

%

,. 4 8.( 8.( 8.( 8.( 8.( 8.( 8.( 8.( 8.( 8.( 4

.76 -&'( &'( -&'( &'( -&'( &'( -&'( &'( -&'( &'( -&'( &'(

.inal

6ome

nt

-&'( &'( -&'( &'( -&'( &'( -&'( &'( -&'( &'( -&'( &'(

T$B%E 3.2

Since 2 and A are fixed ends and also due to symmetry, all moments are balanced,

hence fixed end moments are equal to final moments

.or edge strip

Department of Civil Engineering, M.S.R.I.T. Page 23

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

&0 3.3

.ixed end moment

6f-ab M w K l

%

9 4%

M - '=.8( K ).(

%

9 4%

M - 4*%.*8 FB - m

I,ue to symmetry fixed end moments are same for all spansJ

,istribution factor 5,. Table-

Span F OF ,. M F 9 OF

2$ 9 ).( 8.4( 4

$2

$#

9 ).(

9 ).(

8.&

8.(

8.(

,#

,7

9 ).(

9 ).(

8.&

8.(

8.(

7.

7,

9 ).(

9 ).(

8.&

8.(

8.(

.7

.A

9 ).(

9 ).(

8.&

8.(

8.(

A. 9 ).( 8.4( 4

Ta4le 3.3

6oment ,istribution Table

Goint 2 $ # , 7 . A

Span 2$ $2 $# #$ #, ,# ,7 7, .7 A.

Department of Civil Engineering, M.S.R.I.T. Page 24

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

7. .A

,. 4 8.( 8.( 8.( 8.( 8.( 8.( 8.( 8.( 8.( 8.( 4

.76 -4*% 4*% -4*% 4*% -4*% 4*% -4*% 4*% -4*% 4*% -4*% 4*%

.inal

6omen

t

-4*% 4*% -4*% 4*% -4*% 4*% -4*% 4*% -4*% 4*% -4*% 4*%

T$B%E 3.+

Since 2 and A are fixed ends and also due to symmetry, all moments are balanced,

hence fixed end moments are equal to final moments

2long 7-< direction

7,A7 STR;

&0 3.*

.ixed 7nd 6oment

6f-a4a% M w K l

%

9 4%

M - (&.4& K )

%

9 4%

M -4(&.&= FB - m

I,ue to symmetry fixed end moments are same for all spansJ

,istribution factor 5,. Table-

Department of Civil Engineering, M.S.R.I.T. Page 25

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

Goint Span F =F ,. M F 9 OF

2

4

2

4

2

%

9 ) 8.4)) 4

2

%

2

%

2

4

2

&

2

%

9 )

9 )

8.&&

8.(

8.(

2

&

2

&

2

%

9 ) 8.4)) 4

Ta4le 3.*

6oment ,istribution Table

Since 24 and 2& are fixed ends and also due to symmetry, all moments are balanced,

hence fixed end moments are equal to final moments

Ta4le 3.2

6, STR;

&0 3.2

.ixed 7nd 6oment

6.-$4$% M < K l

% 9

4%

M -48).%* K )

%

9 4%

M -&4+.+%( FB " m

I,ue to symmetry fixed end moments are same for all spansJ

Department of Civil Engineering, M.S.R.I.T. Page 26

Goint 2

4

2

%

2

&

Span 2

4

2

%

2

%

2

4

2

%

2

&

2

&

2

%

,. 4 8.( 8.( 4

.76 -4(=.&= 4(=.&= -4(=.&= 4(=.&=

.inal 6oment -4(=.&= 4(=.&= -4(=.&= 4(=.&=

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

,istribution factor 5,. Table-

Goint Span F =F ,. M F 9 OF

$

4

$

4

$

%

9 ) 8.4)) 4

$

%

$

%

$

4

$

&

$

%

9 )

9 )

8.&&

8.(

8.(

$

&

$

&

$

%

9 ) 8.4)) 4

Ta4le 3.3

6oment ,istribution Table

Ta4le 3.>

,ue to symmetry of span and supports, maximum positive moment will occur at centre

&0 3.3

6

Nive

M w K l

%

9 +

M =+.4 K ).(

%

9 +

M (4+.8= FB " m

Department of Civil Engineering, M.S.R.I.T. Page 2!

Goint $

4

$

%

$

&

Span $

4

$

%

$

%

$

4

$

%

$

&

$

&

$

%

,. 4 8.( 8.( 4

.76 -&4+.%( &4+.%( - &4+.%( &4+.%(

.inal 6oment -&4+.%( &4+.%( -&4+.%( &4+.%(

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

3.+ 'o;e!t Calculato!

B-S direction

Begative moment calculation 5for mid strip along B-S dir-

.rom left support , 6

-ive

M 6l " 5=+.4 K 8.&(

%

9 %-

M -&'(.&= - ).88+

M -&(4.&= FB " m

5Since all the spans are symmetrical, moment from right support will be equal to moment

from left support-

Total design moment, for span 5face to face- , 6o M w K ln 9 +

M =+.4 K (.+ 9 +

M *4.4%( FB - m

#alculation of 2st 5B-S direction-

2dopting 6

Nive

for calculation of 2st, since its value is highest and reducing it by 48P in

accordance with clause &4.'.&.' of S " '().

6u M 8.=8 K (4+.8=

M ')).%+ FB " m

6u 9 bd

%

M ')).%+ K 48 Q ) 9 5)888 K %*(

%

-

M 4.8(

5Csing .ck M &8, from table ' of S; " )-

pt M 8.&8'

#onsidering 4m strip

2st M pt K b K d 9 488

M 8.&8' K 4888 K %*( 9 488

M +&) mm

%

Csing 4)mm bars

Spacing M 5R K 4)

%

9 '- K 4888 9 +&)

Department of Civil Engineering, M.S.R.I.T. Page 2"

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

M %'8 mm

7-< ,irection

,ue to symmetry, maximum positive moment will occur at centre

6

Nive

M w K l

%

9 +

M 48).%* K )

%

9 +

M '*+.%4 FB " m

6aximum negative moment,

.rom left support , 6

-ive

M 6l " w K l

%

9%

M -&4+.+% " 548).%* K 8.&(

%

9 %-

M -&%(.&& FB " m

Total design moment, 6o M w K ln 9 +

M 48).%*( K (.& 9 +

M *8.'4 FB " m

#alculation of 2st 57-< direction-

2dopting 6

Nive

for calculation of 2st, since its value is highest and reducing it by 48P in

accordance with clause &4.'.&.' of S " '().

6C M .=8K'*+.%4

M '&8.&= FB-m

6C9bKd

%

M '&8.&=K48Q)95)(88K%*(-

M 8.=8

5Csing .ck M &8, from table ' of S; " )-

pt M 8.%(=

Department of Civil Engineering, M.S.R.I.T. Page 2#

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

#onsidering 4m strip

2st M pt K b K d 9 488

M 8.%(=K4888K%*(9488

M *4%.%( mm

%

Csing 4)mm bars

Spacing M 5R K 4)

%

9 '- K 4888 9 *4%.%(

M %+8mm

&.'.4 Shear check

v M >C 9bKd

M5 &4+.+% K % K 48

&

-95 )888K %*(-

M 8.&+ B9mm

%

.or 4882st9bd M 8.&8'

Referring to table 4= of S-'()

# M 8.'8

/ence # S v

Therefore S2.7

Detal!0 o? ?lat "la4

Department of Civil Engineering, M.S.R.I.T. Page 3$

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

&0 3.>

Department of Civil Engineering, M.S.R.I.T. Page 31

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

C#$PTER +

DESI(N O& CONVENTION$%

BE$' S%$B

+. De"0! o? Co!7e!to!al Bea; Sla4

8U"!0 l;t "tate ;etho59

+.1 De"0! o? "la4

+.1.2 Chec6 &or o!e @a< A t@o @a< t<pe o? "la4

Ratio of longer span to shorter span M ly 9 lx M ).(9)

Department of Civil Engineering, M.S.R.I.T. Page 32

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

M 4.8+ S %

Therefore slab is designed as two way slab.

@x M )m

@y M ).(m

#onsider 4m strip

2ssume slab thickness M4(8mm

Csing 4(mm clear cover with 48mm bar

d M 4(8-4(-489% M 4&8mm

+.1.3 loa5 calculato!

,ead load M 8.4(K%( M &.*( FB9m

%

@ive load M %.' FB9m

%

.loor finish M 4 FB9m

%

Total load M *.4( FB9m

%

Cltimate load M 4.( K *.4( M 48.*%( FB9m

%

+.1.+ Calculato! o? ;o;e!t co,e??ce!t

4.8 4.8+ 4.4

B

C

8.8)% 8.8*4) 8.8*'

B

<

8.8)% 8.8)4% 8.8)4

Ta4le +.1

+.1.* Calculato! o? ;o;e!t"

6T M 8.8*4) K 48.*%( K )

%

M %*.)' FB-m

6y M 8.8)4% K 48.*%( K )

%

M %&.)& FB-m

6 max M %*.)' FB-m

+.1.2 Chec6 ?or 5epth

Department of Civil Engineering, M.S.R.I.T. Page 33

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

6C M 58.&) K Tu-max 5 4-8.'%5Tu-max 9d--bKd

%

fck -9 d

%*.)' K48

)

M 8.&)K8.'+5 4-8.'%K8.'+-K4888Kd

%

K %8

d M +4.*%mm U 4(8mm

/ence safe

;rovide , M4(8mmV d M4&8mm

.rom S-'() V ;g *)

6 M %=.)) FB-m

Spacing M 448mm

;rovide 48mm bar W 448mm c9c along long direction and short direction

+.2 DESI(N O& BE$'S

2R72 3. 4 N % M %K55).( N 8.(-9%K&-

M %4 m

&

>olume M %4 K 8.4(

M &.4( m

&

<eight M %( K &.4(

M *+.*( FB

Cniformly distributed load M *+.)( 9 ).(

M 4%.4% FB 9 m

+.2.1 Depth Calculato!

.or simply supported beam 5clause %&.%.% of S - '()-

@ 9 d M %8

d M )(88 9 %8

2pprox. d L &%( mm

Therefore , M d N (8 5clear cover-

Department of Civil Engineering, M.S.R.I.T. Page 34

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

, M &%( N (8

, M &*( mm

2ssuming width, b M %&8mm

+.2.2 %oa5 Calculato!

Self weight of slab M %( K 8.&*( K 8.%& M %.4) FB 9 m

%

,ead load due to slab M 4%.4% FB 9 m

%

.loor finish M 4 FB 9 m

%

@ive load M %.' FB 9 m

%

Total M 4*.)+ FB 9 m

%

.actored load M 4.( K 4*.)+ M %).(% FB 9 m

%

6oment 6u M w K l

%

9 +

M %).(% K ).(

%

9 +

M 4'8.8) FB "m

Shear force at support, >u M w K l 9 %

M %).(% K ).( 9 %

M +).4= FB

@imiting value of moment,

6ulim M 8.&) K Tumax K54- 8.'%Tumax9d-bd

%

fck 9d

Referring to clause &+.4 of S " '()

.or .e '4(, Tumax9d M 8.'+

6ulim M 8.&) K 8.'+ 54-8.'%K8.'+-K%&8K&%(

%

K%8

M )*.8&& FB " m

6u S 6ulim, hence design as doubly reinforced section

Tumax M 8.'+ K &%(

M 4() mm

Department of Civil Engineering, M.S.R.I.T. Page 35

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

+.2.3 Calculato! o? area

#ompression steel

Strain M 8.88&( 5Tumax " d:-9Tumax

M 8.88&( 54() " (8-94()

M%.&* K 48

-&

.rom S; 4), figure &

Stress, .sc M &+8 B9mm

%

6u - 6ulim M .sc K 2sc 5d-d:-

48Q

)

54'8.8) " )*.8&- M &+8 K 2sc 5&%( - (8-

2scM )=+.+( mm

%

Csing %8mm bars

Bumber of bars M )=+.+( 9 5R K %8

%

9 '-

M %.%& L & bars

/ence provide & bars of %8mm as compression steel

Tension steel

Tu 9 d M Tumax 9 d M5 8.+* fy2st4- 958.&) fck bd-

8.'+ M 58.+* K '4( K 2st4- 9 58.&) K %8 K %&8 K &%( -

2st4M*4(.(4mm

%

2st% M 2sc K fsc 958.+* fy-

M )=+.+( K &+8 9 58.+* K '4(-

M *&(.(& mm

%

Total area of tension steel , 2sc M 2sc4 N 2st%

M *4(.(4 N *&(.(&

M 4'(4.8' mm

%

Csing %%mm bars

Bo of bars M 4'(4.8' 9 5R K %%

%

9 '-

M &.+4 L ' bars

Department of Civil Engineering, M.S.R.I.T. Page 36

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

;rovide ' bars of %%mm as tension steel

+.2.+ De"0! ?or "hear

X

>u M +).4= FB

b M %&8 mm

d M &%( mm

2ctual steel M ' K R K%%

%

9 '

M 4(%8.(& mm

%

v M >u 9 bd

M +).4= K 48 Q

&

95 %&8 K &%(-

M 4.4* B 9 mm

%

488 2st 9 bd M 488 K 4(%8.(& 9 5%&8 K &%8-

M %.8&

Referring to table 4= of S '(), for 6%8,

c M 8.*=

c U v

/ence provide shear reinforcement

Csing >us M 8.+* K fy K 2sv K d 9 Sv

Csing % legged , + mm stirrups,

2sv M % K R K +

%

9 '

M 488.(& mm

%

>us M >u - c bd

M +).4= K 48Q

&

"58.*= K %&8 K &%(-

M %*.4& K 48 Q

&

B

%*.4& K 48 Q

&

M 8.+* K '4( K 488.(& K &%( 9 S>

Sv M '&'.)+ mm

Department of Civil Engineering, M.S.R.I.T. Page 3!

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

$ut, 2s per S '(), maximum spacing M 8.*( K d

M 8.*( K &%(

M %'&.*( mm

3R &88 mm

/ence provide % @ +mm W &88mm c9c stirrups

Detal!0 o? co!7e!to!al 4ea; "la4

Department of Civil Engineering, M.S.R.I.T. Page 3"

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

&0 +.1

Department of Civil Engineering, M.S.R.I.T. Page 3#

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

&0 +.2

Department of Civil Engineering, M.S.R.I.T. Page 4$

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

C#$PTER *

DESI(N O& BUBB%E DEC/ S%$B

*. De"0! O? Bu44le Dec6 Sla4

Department of Civil Engineering, M.S.R.I.T. Page 41

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

*.1Sla4 thc6!e""

.or deflection control

6odifying l 9 d ratio by 8.( I$S+448, product introductionJ

d H

l

n 9 5%)K8.=K4.(- IS-'(), #lause %&.%.4J

d H )(88 9 5&(.4-

d H 4+(.4= mm

2pprox. d L 4=8 mm

Therefore , M d N %8 5clear cover- considering

, M 4=8 N %8

, M %48 mm

;rovide , M %&8 mm 5considering slab version $, %&8-

/ence , d M %&8 " %( M %8( mm

5%(mm cover provides )8 min of fire resistance-

*.2 %oa5 Calculato!

Self weight of slab M %( K 8.%& K%9 & M &.+& FB 9 m

%

.loor finish M 4 FB 9 m

%

@ive load M %.' FB 9 m

%

Total M *.%& FB 9 m

%

.actored load M 4.( K *.%& M 48.+'( FB 9 m

%

*.3 E:u7ale!t &ra;e $!al<""

Department of Civil Engineering, M.S.R.I.T. Page 42

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

2long B-S direction

.or middle strip

&0 *.1

.ixed end moment

6f-ab M w K l

%

9 4%

M - )(.8* K ).(

%

9 4%

M - %%=.4 FB-m

I,ue to symmetry fixed end moments are same for all spansJ

,istribution factor 5,. Table-

Span F OF ,. M F 9 OF

2

%

$

%

9 ).( 8.4( 4

$

%

2

%

$

%

#

%

9 ).(

9 ).(

8.&

8.(

8.(

,

%

#

%

,

%

7

%

9 ).(

9 ).(

8.&

8.(

8.(

7

%

.

%

7

%

,

%

9 ).(

9 ).(

8.&

8.(

8.(

.

%

7

%

.

%

A

%

9 ).(

9 ).(

8.&

8.(

8.(

A

%

.

%

9 ).( 8.4 4

Ta4le *.1

Department of Civil Engineering, M.S.R.I.T. Page 43

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

6oment ,istribution Table

Goint 2

%

$

%

#

%

,

%

7

%

.

%

A

%

Span 2

%

$

%

$

%

2

%

$

%

#

%

#

%

$

%

#

%

,

%

,

%

#

%

,

%

7

%

7

%

,

%

7

%

.

%

.

%

7

%

.

%

A

%

A

%

.

%

,. 4 8.( 8.( 8.( 8.( 8.( 8.( 8.( 8.( 8.( 8.( 4

.76 -%%= %%= -%%= %%= -%%= %%= -%%= %%= -%%= %%= -%%= %%=

.inal

6ome

nt

-%%= %%= -%%= %%= -%%= %%= -%%= %%= -%%= %%= -%%= %%=

Ta4le *.2

Since 2 and A are fixed ends and also due to symmetry, all moments are

balanced, hence fixed end moments are equal to final moments

.or edge strip

&0 *.2

.ixed end moment

6f-ab M w K l

%

9 4%

M - &%.(&( K ).(

%

9 4%

M - 44'.(( FB - m

I,ue to symmetry fixed end moments are same for all spansJ

,istribution factor 5,. Table-

Department of Civil Engineering, M.S.R.I.T. Page 44

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

Span F OF ,. M F 9 OF

2$ 9 ).( 8.4( 4

$2

$#

9 ).(

9 ).(

8.&

8.(

8.(

,#

,7

9 ).(

9 ).(

8.&

8.(

8.(

7.

7,

9 ).(

9 ).(

8.&

8.(

8.(

.7

.A

9 ).(

9 ).(

8.&

8.(

8.(

A. 9 ).( 8.4( 4

Ta4le *.3

6oment ,istribution Table

Goint 2 $ # , 7 . A

Span 2$ $2

$#

#$

#,

,#

,7

7,

7.

.7

.A

A.

,. 4 8.( 8.( 8.(

8.(

8.(

8.(

8.(

8.(

8.(

8.(

4

.76 -44'.( 44'.(-

44'.(

44'.(-

44'.(

44'.(-

44'.(

44'.(-

44'.(

44'.(-

44'.(

44'.(

.inal

6oment

-44'.( 44'.(-

44'.(

44'.(-

44'.(

44'.(-

44'.(

44'.(-

44'.(

44'.(-

44'.(

44'.(

Ta4le *.+

Since 2 and A are fixed ends and also due to symmetry, all moments are

balanced, hence fixed end moments are equal to final moments

2long 7-< direction

7,A7 STR;

Department of Civil Engineering, M.S.R.I.T. Page 45

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

&0 *.3

.ixed 7nd 6oment

6f-a4a% M w K l

%

9 4%

M - &(.%' K )

%

9 4%

M -48(.*% FB - m

I,ue to symmetry fixed end moments are same for all spansJ

,istribution factor 5,. Table-

Goint Span k =F ,. M F 9 OF

2

4

2

4

2

%

9 ) 8.4)) 4

2

%

2

%

2

4

2

&

2

%

9 )

9 )

8.&&

8.(

8.(

2

&

2

&

2

%

9 ) 8.4)) 4

Ta4le *.*

6oment ,istribution Table

Ta4le *.2

Since 24 and 2& are fixed ends and also due to symmetry, all moments are balanced,

hence fixed end moments are equal to final moments

Department of Civil Engineering, M.S.R.I.T. Page 46

Goint 2

4

2

%

2

&

Span 2

4

2

%

2

%

2

4

2

%

2

&

2

&

2

%

,. 4 8.( 8.( 4

.76 -48(.*% 48(.*% -48(.*% 48(.*%

.inal 6oment -48(.*% 48(.*% -48(.*% 48(.*%

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

6, STR;

&0 *.+

.ixed 7nd 6oment

6.-$4$% M < K l

%

9 4%

M -*8.'=K )

%

9 4%

M -%44.'* FB " m

I,ue to symmetry fixed end moments are same for all spansJ

,istribution factor 5,. Table-

Goint Span F =F ,. M F 9 OF

$

4

$

4

$

%

9 ) 8.4)) 4

$

%

$

%

$

4

$

&

$

%

9 )

9 )

8.&&

8.(

8.(

$

&

$

&

$

%

9 ) 8.4)) 4

Ta4le *.*

6oment ,istribution Table

Department of Civil Engineering, M.S.R.I.T. Page 4!

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

Ta4le *.2

,ue to symmetry of span and supports, maximum positive moment will occur at centre

&0 *.*

>a M )(.8'K).(9%

M%44.'* FB

6

Nive

M w K l

%

9 +

M =+.4 K ).(

%

9 +

M (4+.8= FB " m

*.+ 'o;e!t Calculato!

B-S direction

Begative moment calculation 5for mid strip along B-S dir-

.rom left support , 6

-ive

M 6l " 5)(.8* K 8.&(

%

9 %-

M -%%=.4- &.=+

M -%&&.8+ FB " m

5Since all the spans are symmetrical, moment from right support will be equal to moment

from left support-

Department of Civil Engineering, M.S.R.I.T. Page 4"

Goint $

4

$

%

$

&

Span $

4

$

%

$

%

$

4

$

%

$

&

$

&

$

%

,. 4 8.( 8.( 4

.76 -%44.'* %44.'* - %44.'* %44.'*

.inal 6oment -%44.'* %44.'* - %44.'* %44.'*

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

Total design moment, for span 5face to face- , 6o M w K ln 9 +

M )(.8* K (.+ 9 +

M '*.4* FB - m

#alculation of 2st 5B-S direction-

2dopting 6

Nive

for calculation of 2st, since its value is highest and reducing it by 48P in

accordance with clause &4.'.&.' of S " '().

6u M 8.=8 K &'&.8+

M &8+.**% FB " m

6u 9 bd

%

M &8+.**% K 48 Q ) 9 5)888 K %8(

%

-

M 4.%(

5Csing .ck M &8, from table ' of S; " )-

pt M 8.&)(

#onsidering 4m strip

2st M pt K b K d 9 488

M 8.&)( K 4888 K %8( 9 488

M *'+.%( mm

%

Csing 4)mm bars

Spacing M 5R K 4)

%

9 '- K 4888 9 *'+.%(

M %*8 mm

7-< ,irection

,ue to symmetry, maximum positive moment will occur at centre

6

Nive

M w K l

%

9 +

M *8.'= K )

%

9 +

M &4*.%8 FB " m

6aximum negative moment,

.rom left support , 6

-ive

M 6l " w K l

%

9%

Department of Civil Engineering, M.S.R.I.T. Page 4#

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

M -%44.'* " 5*8.'=K 8.&(

%

9 %-

M -%4(.*+ FB " m

Total design moment, 6o M w K ln 9 +

M *8.'=K (.& 9 +

M ').)= FB " m

#alculation of 2st 57-< direction-

2dopting 6

Nive

for calculation of 2st, since its value is highest and reducing it by 48P in

accordance with clause &4.'.&.' of S " '().

6C M .=8K&4*.%

M %+(.'+ FB-m

6C9bKd

%

M %+(.'+K48Q)95)(88K%8(-

M 4.8(

5Csing .ck M &8, from table ' of S; " )-

pt M 8.&8'

#onsidering 4m strip

2st M pt K b K d 9 488

M 8.&8'K4888K%8(9488

M )%&.% mm

%

Csing 4)mm bars

Spacing M 5R K 4)

%

9 '- K 4888 9 )%&.%

M &%( mm

Department of Civil Engineering, M.S.R.I.T. Page 5$

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

Detal!0 o? 4u44le 5ec6

&0 *.2

Department of Civil Engineering, M.S.R.I.T. Page 51

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

C#$PTER 2

COSTIN( $ND ESTI'$TION

2.1 &%$T S%$B

).4.4 Reinforcement

2long B-S ,irection

Department of Civil Engineering, M.S.R.I.T. Page 52

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

@ength of main reinforcement

@M l N % K 8.(Kd- %c

M &=*88N %K8.(K4.( " %K%(

M &=))) mm

@ength of crank bar

@ M l-%c N% K8.(d N% K=d4 5d4 M , -%c-d M &88-(8-4) M%&' mm-

M &=*88- %K%( N%K8.(K4)N%K=K%&'

M '&+*+mm

Bumber of main reinforcement M 55span9spacing-N4-9%

M 554%.*98.%'9%-N4-9%

M %* bars

Bumber of cranked bars M ('-%*

M %* bars

2long 7-< direction

@ength of main reinforcement,

@ M l N %K8.(d-%c

M4%*88 N %K8.(K4) -%K%(

M4%))) mm

@ength of cranked bar,

@ M l " %c N %K8.(Kd N%K=Kd4

M 4%*88 -(8 N%K8.(K4) N%K=K%&'

M 4)+*+mm

Bumber of main reinforcement M 55span9spacing-N4-9%

M 55&=.*98.%'-N4-9%

Department of Civil Engineering, M.S.R.I.T. Page 53

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

M +' bars

Bumber of cranked bars M 4)*-+'

M +& bars

Ta4le 2.1

Reinforcement Bumber @ength

5m-

<eight9meter

8.)4)d

%

M8.)4)K4.)

%

Total weight

5kilogram, kg-

B-S direction

6ain

#ranked

%*

%*

&=.*

''

4.(*

4.(*

4)+&

4+)(

7-< direction

6ain

#ranked

+'

+&

4%.*

4).=

4.(*

4.(*

4)*(

%%8%

T3T2@ M *'%(

).4.% #3B#R7T7

>olume M4%*88 K&=*88 K&88

M 4(4.& m

&

Ta4le 2.2

;articular Yuantity Rate 5Rs- 2mount 5Rs-

Steel *.'%( 6 Ton '%888 &,44,=(8

#oncrete 4(4.& m

&

&(88 (,%=,((8

T3T2@ M +,'4,(88

2.1 BUBB%E DEC/ S%$B

).%.4 $ottom Reinforcement

2long B-S ,irection

Department of Civil Engineering, M.S.R.I.T. Page 54

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

@ength of main reinforcement

@M l N % K 8.(Kd- %c

M &=*88N %K8.(K4.( " %K%(

M &=))) mm

@ength of crank bar

@ M l-%c N% K8.(d N% K=d4 5d4 M , -%c-d M %&8-(8-4) M4)' mm-

M &=*88- %K%( N%K8.(K4)N%K=K4)'

M '%)4+mm

2long 7-< direction

@ength of cranked bar,

@ M l " %c N %K8.(Kd N%K=Kd4

M 4%*88 -(8 N%K8.(K4) N%K=K4)'

M 4()4+mm

).%.% Top Reinforcement

2long B-S direction

@ength of main reinforcement,

@ M l N % K 8.(Kd- %c

M &=*88N %K8.(K) " %K%(

M &=)() mm

@ength of crank bar

@ M l-%c N% K8.(d N% K=d4 5d4 M , -%c-d M %&8-(8-)M4*' mm-

M &=*88- %K%( N%K8.(K)N%K=K4*'

M '%*++mm

Department of Civil Engineering, M.S.R.I.T. Page 55

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

2long 7-< direction

@ength of main reinforcement,

@ M l N % K 8.(Kd- %c

M 4%*88N %K8.(K) " %K%(

M 4%)() mm

@ength of crank bar

@ M l-%c N% K8.(d N% K=d4 5d4 M , -%c-d M %&8-(8-)M4*' mm-

M 4%*88- %K%( N%K8.(K)N%K=K4*'

M 4(*++mm

Bumber of bars

2long B-S direction 5bottom reinforcement-

Bumber of main reinforcement M 55span9spacing- N 4-9%

M 554%.*98.%*-N4-9%

M %' bars

Bumber of #ranked bar M '+-%'

M%' bars

2long 7-< direction 5bottom reinforcement-

Bumber of main reinforcement M 55span9spacing-N4-9%

M 55&=.*98.%*-N4-9%

M *' bars

Bumber of cranked bar M 4'+-*'

M*' bars

2long B-S direction 5top reinforcement-

Bumber of main reinforcement M55span9spacing-N4-9%

M 55&=.*98.%-N4-9%

M 4== bars

Department of Civil Engineering, M.S.R.I.T. Page 56

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

2long 7-< direction 5top reinforcement-

Bumber of main reinforcement M 55span9spacing-N4-9%

M 554%.*98.%-N4-9%

M )' bars

,etails of bottom reinforcement 5 using fe'4( steel-

Ta4le 2.3

Reinforcement Bumber @ength

5m-

<eight9meter

8.)4)d

%

M8.)4)K4.)

%

Total weight

5kilogram, kg-

B-S direction

6ain '+ &=.* 4.(* %==%

7-< direction

6ain 4'+ 4%.* 4.(* %=(8

T3T2@ M (='%

,etails of top reinforcement 5using fe%(8steel-

Table ).'

Reinforcement Bumber @ength

5m-

<eight9meter

8.)4)d

%

M8.)4)K8.)

%

Total weight

5kilogram, kg-

B-S direction

6ain )' &=.) 8.%% ((+

7-< direction

6ain 4== 4%.) 8.%% ((%

Department of Civil Engineering, M.S.R.I.T. Page 5!

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

T3T2@ M 4448

).%.& #oncrete

Total volume M 4%*88 K&=*88K%&8

M 44(.=) m

&

Bumber of balls

2long B-S direction M 5span 9 spacing--4

M 5&=.*98.%--4

M 4=*.(

L 4=+ balls

2long 7-< direction M 5span9spacing--4

M 54%.*98.%--4

M )%.(

L )& balls

Total M 4=*K)%

M 4%,%4' balls

Reduction at column

Solid slab is to be provided for areas of high shear that is 49)

th

of the distance from centre

to centre of column.

Therefore, area of 4 column M %888 K%4)).

Bumber of balls M 5%888K%4)).)-95%888 K%888-

M %8.+&

L %4 balls

Bumber of equivalent columns units M 4K(N8.(K4% N8.%(K'

M (N)N4

Department of Civil Engineering, M.S.R.I.T. Page 5"

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

M 4%

Bumber of balls to be reduced M4%K %4

M %(% balls

Therefore, total number of balls actually provided

M 4%,%4' "%(%

M 44,=)%

>olume of one ball M 5' KR Kr

&

-9&

M 5'K R K8.8=8

&

-9&

M &.8( K 48

-&

m

&

/ence, volume of concrete M 44(.=) -&).(&

M *=.'& m

&

2bstract

Ta4le 2.*

;articular Yuantity Rate 5Rs- 2mount 5Rs-

Steel 5fe

'4(

- (.='% 6 Ton '%888 %,'=,()'

Steel 5fe

%(8

- 4.44 6 Ton '%888 '),)%8

#oncrete *=.'& m

&

&(88 %,*+,88(

$alls 44,=)% @ump-sump &8,888

T3T2@ M ),8',4+=

2.3 BE$' S%$B

2.3.1 S%$B

#oncrete

>olume of concrete M ).%(K (.*( K8.4(

M (.&= m

&

Total M 4% K (.&=

M )'.)+ m

&

Reinforcement

2long B-S direction

Department of Civil Engineering, M.S.R.I.T. Page 5#

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

Bumber of main bars M 55span9spacing-N4-9%

M 55(.*(98.44-N4-9%

M %* bars

#ranked M ('-%*

M %* bars

@ength of main reinforcement

@ M l N % K 8.(Kd- %c

M )%(8N %K8.(K4 " %K%(

M )%48 mm

@ength of crank bar

@ M l-%c N% K8.(d N% K=d4

5d4 M , -%c-d M 4(8-(8-48M =8 mm-

M )%(8- %K%( N%K8.(K48N%K=K=8

M *+&8mm

2long 7-< direction

Bumber of main bars M 55span9spacing-N4-9%

M 55).+(98.44-N4-9%

M %= bars

#ranked M (=-%=

M &8 bars

@ength of main reinforcement

@ M l N % K 8.(Kd- %c

M (*(8N %K8.(K48 " %K%(

M (*48 mm

Department of Civil Engineering, M.S.R.I.T. Page 6$

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

@ength of crank bar

@ M l-%c N% K8.(d N% K=d4

5d4 M , -%c-d M 4(8-(8-48M =8 mm-

M (*(8- %K%( N%K8.(K48N%K=K=8

M *&&8mm

2.3.2 Bea;

2long B-S direction

@ength of main reinforcement

@ M l N % K 8.(Kd- %c

M )(88N %K8.(K48 " %K%(

M )')8 mm

@ength of the stirrups

@ M % 5 l4 N l% - N % K =Kd

M %54+8N%*(- N%K=K+

M 48(' mm

Bumber of stirrups M 5).(98.&-N4

M %&

2long 7-< direction

@ength of main reinforcement

@ M l N % K 8.(Kd- %c

M )888N %K8.(K48 " %K%(

M (=)8 mm

Bumber of stirrups M 5)98.&- N 4

M %4

Department of Civil Engineering, M.S.R.I.T. Page 61

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

>olume of concrete for beam M 4+5).(K8.%&K8.&*(-

M 4'5)K8.%&K8.&*(-

M 4*.'& m

&

,etails of reinforcement

Ta4le 2.2

Reinforcement Bumber @ength

5m-

<eight9meter Total weight

5kilogram, kg-

Sla4

B-S direction

6ain

#ranked

7-< direction

6ain

#ranked

4%K%*M&%'

4%K%*M&%'

4%K%=M&'+

4%K&8M&)8

).%

*.+

(.*

*.&

8.)4)

8.)4)

8.)4)

8.)4)

4%&)

4()8

4%%%

4)4=

Bea;

B-S direction

Top 4+K&M(' ).( %.') +)(

Department of Civil Engineering, M.S.R.I.T. Page 62

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

$ottom

7-< direction

Top

$ottom

Stirrup

4+K'M*%

4'K&M'%

4'K'M()

*8+

).(

)

)

4.8(

%.=+

%.')

%.=+

8.&=

4&=(

)%4

4884

%=8

T3T2@ M =+8=

Total quantity of concrete M4*.&' N)'.)+

M +%.8% m

&

2bstract

Ta4le 2.3

;articular Yuantity Rate 5Rs- 2mount 5Rs-

Steel =.+ 6 Ton '%888 ',44,)88

#oncrete +%.8% m

&

&(88 %,+*,8*8

T3T2@ M ),=+,)*8

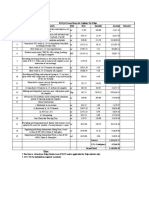

2.+ $BSTR$CT

T?;7 >3@C67 R2T7 263CBT5 RS-

&%$T S%$B

Steel

#oncrete

*.'%( 6-Ton

4(4.& m

&

'%888

&(88

&,44,+(8

(,%=,((8

BE$' S%$B

Steel =.+ 6-Ton '%888 ',44,)88

Department of Civil Engineering, M.S.R.I.T. Page 63

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

#oncrete +%.8% m

&

&(88 %,+*,8*8

BUBB%E DEC/S%$B

Steel 5fe

'4(

-

#oncrete

Recycled plastic

Steel 5fe

%(8

-

(.=' 6-Ton

*=.'& m

&

44,=)%

4.44 6-Ton

'%888

&(88

@ump-sump

'%888

%,'=,'+8

%,*+,88(

&8,888

'),)%8

Ta4le 2.>

C#$PTER 3

Department of Civil Engineering, M.S.R.I.T. Page 64

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

RESU%TS $ND DISCUSSION

*.1 IINTRODUCTION

,esign and analysis of three types of slabs was done using their respective design

considerations. #osting and estimation was carried out to compute and compare the

structural, economic and environmental results. The outcome of the comparison is

presented in this chapter.

3.2 T#IC/NESS O& S%$B

$ased on the design outcome 5given in chapter &,',(- comparison of thickness of slab for

the different type of floor slab systems is plotted in the figure *.4.

Department of Civil Engineering, M.S.R.I.T. Page 65

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

&0 3.1

Araph shows that bubble deck slab has considerably less thickness as compared to

conventional flat slab. Tough the conventional beam slab has least thicknessV the addition

of beam nullifies the advantage.

3.3 )U$NTIT. O& CONCRETE

$ased on the design outcome 5given in chapter )- comparison of quantity of concrete

used in slab for the different type of floor slab systems is plotted in the figure *.%.

&0 3. 2

Araph shows, the conventional flat slab system uses highest amount of concrete and

conventional beam slab system and bubble deck slab uses equal amount of concrete. $ut

addition of beams in conventional beam slab system nullifies this advantage.

3.+ )U$NTIT. O& STEE%

$ased on the design outcome 5given in chapter )- comparison of quantity of steel used in

slab for the different type of floor slab systems is plotted in the figure *.&

& 03.3

Department of Civil Engineering, M.S.R.I.T. Page 66

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

.rom the graph we conclude that the bubble deck slab used least amount of steel and

usage of steel in conventional beam slab is maximum.

3.* TOT$% )U$NTIT. 2B, 7#3B36#S O& '$TERI$%S

.igure *.' shows the diagrammatic comparison of quantity of steel as well as quantity of

concrete used in different type of slab systems

&0 3.+

&0 3.*

.igure *.( shows the comparison of cost of concrete and cost of steel in slabs for different

types of floor slab systems. t can be seen that the bubble deck slab has least cost of both

steel and concrete as compared to conventional flat slab and conventional beam slab

3.2 ENVIRON'ENT$% CO'P$RISON

Table *.4 shows the #3% emissions for different types of slabs at given slab thickness

The table gives relevant data with reference to designed slabs as the thickness of slabs in

table are identical to the slabs designed

Department of Civil Engineering, M.S.R.I.T. Page 6!

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

Ta4le 3.1

.rom table *.4 we conclude that #3% emission for bubble deck slab is least and that for

conventional flat slab is most. .igure *.' shows the diagrammatic comparison of quantity

of steel as well as quantity of concrete used in different type of slab systems

Department of Civil Engineering, M.S.R.I.T. Page 6"

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

C#$PTER >

CONC%USIONS $ND SCOPE &OR &UTURE WOR/

Department of Civil Engineering, M.S.R.I.T. Page 6#

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

>.1 CONC%USIONS

2 floor slab was designed using three different floor slab systems, namely conventional

beam slab system, conventional flat slab system, new bubble deck floor slab system.

,esign and estimation was carried out for all the three types of slab systems. 3n the basis

of this work the following conclusions are drawn.

').& P of #oncrete was saved by using bubble deck slab instead of conventional

flat slab system

&+.* P of steel was saved in bubble deck slab system as compared to

conventional beam slab system.

2lmost %8 6.tones of #3% emission was reduced by use of bubble deck

technology

ntangibles " other intangible benefits derived from the use of bubble deck

technology are "

4- ncrease in number of floors due to less slab thickness

2 Reduction in foundation depth and si1e, which alsoi reduces the earthwork

excavation.

&- Reduction in number of columns used and larger spans are possible

Department of Civil Engineering, M.S.R.I.T. Page !$

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

>.2 SCOPE &OR &UTURE WOR/

The present study on bi-axially voided bubble deck slab system has the following scope

for further improvement

,esign can be improved so as to provide bubbles at the areas of high punching

shear

The technology can be extended to design of rigid pavements and design of

foundation slabs.

Department of Civil Engineering, M.S.R.I.T. Page !1

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

$PPENDI- $

Department of Civil Engineering, M.S.R.I.T. Page !2

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

.ig 2.4 $all diameter

.ig 2.% $ending strength design

Department of Civil Engineering, M.S.R.I.T. Page !3

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

.ig 2.& $ending stiffness

.ig 2.' Shear capacity

.ig 2.( Shear capacity

Department of Civil Engineering, M.S.R.I.T. Page !4

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

.ig 2.) Bominal cover to meet specified period of fire resistance

.ig 2.* 6inimum permissible values of Zc

Department of Civil Engineering, M.S.R.I.T. Page !5

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

.ig 2.+ ,esign shear strength of concrete

.ig 2.= 6aximum shear stress

Department of Civil Engineering, M.S.R.I.T. Page !6

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

.ig 2.48 $ending moment coefficient for slab spanning in two directions at right angles,

simply supported on four sides

Department of Civil Engineering, M.S.R.I.T. Page !!

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

BIB%O(R$P#.

RE&ERENCES

Department of Civil Engineering, M.S.R.I.T. Page !"

BIAXIALLY VOIDED BUBBLE DECK SLAB SYSTEM AND OTHER CONVENTIONAL FLOOR SLAB

SYSTEMS

I4J S CBBFRS/B2 ;@@2, ,7>,2S 67B3B 54===- Reinforced concrete design, Tata

6cgraw /ill.

I%J ;.#. >arghese 5%88=- ,esign of Reinforced #oncret .oundations, ; / ndia.

I&J S.S. $havikatti 5%88=- 2dvanced R## ,esign 5R## >olume-ii-, Bew 2ge nternational

;ublishers.

I'J ndian Standard ;lain and Reinforced #oncrete " #ode of ;ractice 5.3CRT/

R7>S3B- S '()0%888.

I(J 2# code &4+-8%,%88%.

I)J Bederlands $>-YR code.

I*J $ubbledeck >oided .lat slab solutions Technical 6anual and ,ocuments 5Gune, %88+-

I+J $ritish Standard code +448.

Department of Civil Engineering, M.S.R.I.T. Page !#

Você também pode gostar

- Wind Load CalcsDocumento10 páginasWind Load CalcsUmange RanasingheAinda não há avaliações

- Worked Example 2 Concrete CantileverDocumento18 páginasWorked Example 2 Concrete CantileverJaime A Gutierrez VAinda não há avaliações

- Retaining Wall DesignDocumento55 páginasRetaining Wall DesignMohit Kohli100% (1)

- PCI Architectural Precast Concrete Design ManualDocumento609 páginasPCI Architectural Precast Concrete Design ManualAsraf Muidin100% (1)

- BS 4466Documento25 páginasBS 4466Umange Ranasinghe100% (5)

- Eb204 1Documento337 páginasEb204 1alikaroutAinda não há avaliações

- Total Station Setup and OperationDocumento33 páginasTotal Station Setup and OperationMaskusHaryadiAinda não há avaliações

- IEI Rules of Thumb Line Card 03012016Documento2 páginasIEI Rules of Thumb Line Card 03012016Anonymous 4ItkiwIAinda não há avaliações

- BS 4466Documento25 páginasBS 4466Umange Ranasinghe100% (5)

- Ground SlabDocumento199 páginasGround Slabramuzen100% (1)

- Earthquake Design by DR Vinod Hosur PDFDocumento144 páginasEarthquake Design by DR Vinod Hosur PDFUmange RanasingheAinda não há avaliações

- Soil Compaction TestsDocumento116 páginasSoil Compaction TestsUmange RanasingheAinda não há avaliações

- CE 437/537 Retaining Wall Design ExampleDocumento8 páginasCE 437/537 Retaining Wall Design ExampleJefferson Nobleza67% (3)

- Design of Reinforcement in Piles by J.P. Tyson PDFDocumento62 páginasDesign of Reinforcement in Piles by J.P. Tyson PDFUmange RanasingheAinda não há avaliações

- Standard Structural Designs For Low Rise Residential BuildingsDocumento125 páginasStandard Structural Designs For Low Rise Residential BuildingsUmange RanasingheAinda não há avaliações

- Code of Pactice For Dead and Imposed Loads 2011Documento30 páginasCode of Pactice For Dead and Imposed Loads 2011iyhkAinda não há avaliações

- S&T Dimentions & Properties HandbookDocumento118 páginasS&T Dimentions & Properties HandbookDedyBarokahSetiawan100% (1)

- Basics of Retaining Wall DesignDocumento229 páginasBasics of Retaining Wall Designsalahaddinsharif100% (1)

- Design of Reinforced Concrete Structures M.L Gambhir 2008Documento193 páginasDesign of Reinforced Concrete Structures M.L Gambhir 2008Ramachandra Sahu75% (32)

- Chapter 6.0 Slab Design TheoryDocumento19 páginasChapter 6.0 Slab Design TheoryMohd Afzal100% (1)

- PileIntegrityTestingAndAnalysis PDFDocumento5 páginasPileIntegrityTestingAndAnalysis PDFUmange RanasingheAinda não há avaliações

- Waterproofing in Swimming PoolsDocumento40 páginasWaterproofing in Swimming PoolsUmange RanasingheAinda não há avaliações

- Structural TestingDocumento55 páginasStructural TestingUmange RanasingheAinda não há avaliações

- Basic Hi Wy Plan ReadingDocumento141 páginasBasic Hi Wy Plan ReadingmodarthAinda não há avaliações

- Survey Made Easy PDFDocumento36 páginasSurvey Made Easy PDFUmange RanasingheAinda não há avaliações

- Form Work Scafoldings PDFDocumento155 páginasForm Work Scafoldings PDFUmange RanasingheAinda não há avaliações

- Reinforced Concrete Deep Beams - Prof. F.KDocumento299 páginasReinforced Concrete Deep Beams - Prof. F.Kward_civil036694100% (5)

- Bridge and Structural DesignDocumento217 páginasBridge and Structural DesignMrAgidasAinda não há avaliações

- Bangladesh Concrete CodeDocumento34 páginasBangladesh Concrete CodeXaid IbrahimAinda não há avaliações

- Junior MathsDocumento17 páginasJunior MathsUmange RanasingheAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Clay & Concrete Block Fire ResistanceDocumento4 páginasClay & Concrete Block Fire ResistanceMeganathan MegaAinda não há avaliações

- Structure and Properties of Hardened Portland Cement PasteDocumento7 páginasStructure and Properties of Hardened Portland Cement PasteRudiele Schankoski0% (1)

- m2 Materials Code of Procedure Construction Quality ControlDocumento165 páginasm2 Materials Code of Procedure Construction Quality ControlThuthuka KoloaneAinda não há avaliações

- Utilization of Red Mud As FillerDocumento12 páginasUtilization of Red Mud As FillerRam VermaAinda não há avaliações

- VARIO GT 24 Standard PanelsDocumento57 páginasVARIO GT 24 Standard PanelsdonnyervinAinda não há avaliações

- Damages of Buildings On Expansive SoilsDocumento9 páginasDamages of Buildings On Expansive SoilsLuisSalazarRomeroAinda não há avaliações

- Steel column base plate designDocumento68 páginasSteel column base plate designAmirul Asyraf Bin Mohd BekeriAinda não há avaliações

- Zaha Hadid's Sheikh Zayed Bridge: An Architectural and Engineering MarvelDocumento6 páginasZaha Hadid's Sheikh Zayed Bridge: An Architectural and Engineering MarvelJohn Aaron BlancoAinda não há avaliações

- Design of Aspects of CC Roads PDFDocumento12 páginasDesign of Aspects of CC Roads PDFviharikapavuluri1290100% (1)

- Tekban LampiranDocumento3 páginasTekban LampiranIndra PanjaitanAinda não há avaliações

- Ahad-Ur - Rahman - CV 201122Documento5 páginasAhad-Ur - Rahman - CV 201122Ahad-Ur RahmanAinda não há avaliações

- Nanoparticles From Construction Wastes A Problem To Health and TheDocumento8 páginasNanoparticles From Construction Wastes A Problem To Health and TheSC TagleAinda não há avaliações

- Material Testing Laboratory ManualDocumento22 páginasMaterial Testing Laboratory ManualSamirHashimAinda não há avaliações

- Master Emaco P210Documento2 páginasMaster Emaco P210Gavriel NgAinda não há avaliações

- Performance of Concrete Paving Blocks Reinforced Withbamboo and Rice Husk Ash As Partial Replacement ForcementDocumento7 páginasPerformance of Concrete Paving Blocks Reinforced Withbamboo and Rice Husk Ash As Partial Replacement ForcementFolorunsho AyomideAinda não há avaliações

- 506.1r 08 Guide To Fiber Reinforced ShotcreteDocumento18 páginas506.1r 08 Guide To Fiber Reinforced Shotcreteerika guerrero100% (1)

- Sika Group Report 2012 eDocumento66 páginasSika Group Report 2012 eRomualdo Cavassana Jr.Ainda não há avaliações

- Plastic Mixed Reinforced Concrete - BehaviourDocumento4 páginasPlastic Mixed Reinforced Concrete - BehaviourThiaga RajanAinda não há avaliações

- Construction and Building Materials: F. Pacheco-Torgal, S. JalaliDocumento7 páginasConstruction and Building Materials: F. Pacheco-Torgal, S. JalaliAndrew PiAinda não há avaliações

- Build Pro Quality Brick WallDocumento11 páginasBuild Pro Quality Brick WallMoe Zaw OoAinda não há avaliações

- IS 4995 (Part 2) 1974Documento25 páginasIS 4995 (Part 2) 1974Nagaraju ChintaAinda não há avaliações

- techNOTE 13 - GRC TolerancesDocumento4 páginastechNOTE 13 - GRC TolerancesJoseph JayakanthanAinda não há avaliações

- Building Technology 4 Week 4Documento42 páginasBuilding Technology 4 Week 4Xette FajardoAinda não há avaliações

- P&ID LegendDocumento29 páginasP&ID LegendEmmanuel Cervantes VelázquezAinda não há avaliações

- Aci Design PDFDocumento91 páginasAci Design PDFSufyan SafiAinda não há avaliações

- Protective Concrete Coating GuideDocumento3 páginasProtective Concrete Coating GuideTori SmallAinda não há avaliações

- Screen House (211 SQM)Documento9 páginasScreen House (211 SQM)avs kfleAinda não há avaliações

- Circular TanksDocumento42 páginasCircular TanksDipak BorsaikiaAinda não há avaliações

- Article1 KHATIB NabilDocumento9 páginasArticle1 KHATIB NabilNabilAinda não há avaliações

- Proposed Renovation of Commercial BuildingDocumento3 páginasProposed Renovation of Commercial BuildingLimar SetatraAinda não há avaliações