Escolar Documentos

Profissional Documentos

Cultura Documentos

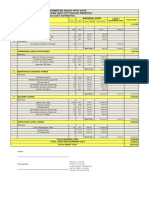

Checklist With Checkpoints For Diagrams: Title Block

Enviado por

safaldTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Checklist With Checkpoints For Diagrams: Title Block

Enviado por

safaldDireitos autorais:

Formatos disponíveis

Checklist with checkpoints for diagrams

TITLE BLOCK

Check with respect to the:

Project plan

Document list

the following:

Name client

Name project

Title drawing

Drawing number

Revision date, number, description, initials

rder number

ffice and discipline

EQUIPMET

!essels"col#mns

Check with respect to the:

!"uipment list

#Process$ Datasheets%Re"uisitions

the following:

Title

Diameter

&eight

Design pressure

Design temperature

'olume

No((les #diameter and number$

)anholes%hand holes

)aterial

*nternals: gasket%plates%vorte+ breaker%demister%baffles%spra, balls%dip pipes%packing%supports%inlet

devices%tra,s%split bottom plates etc-

.lind flanges on spare no((le

P!D Product classification

Area of attention

Drain facilit,

/ample points

Protection against overpressure #e+plosion, fire, outlet pressure pump, pressure utilities, etc-$

Protection against under pressure #condensing steam, suction pressure pump, etc-$

/econdar, containment #drip tra,, tank pit etc-$

verflow protection

'enting #flame arrester re"uired0$

1tilit, connections #purge, steam, e+haust$

2nti s,phon hole

3i"uid seal height

3i"uid level in connection with re"uired NP/&

4interising #tracing, insulation etc-$

2rching #when dealing with solids$

Cleaning, spra, balls, bottom slope, flush connections, manhole etc-

)easuring devices, level pressure

)aterial, cold flashing, corrosion, erosion #no((les$, etc-

Conse"uences of human error

P#mps$ compressors$ agitators

Check with respect to the:

!"uipment list

#Process$ Datasheets%Re"uisitions

the following:

Title

Capacit, #normal and rated$

&,drostatic head

Design pressure, Temperature

)aterial

*nstalled power

Diameters

Reducers #avoid air traps in suction line$

Drain%vents

/eal connections%t,pe of seal

/peed%fre"uenc,

T,pe

1tilit, connections

Area of attention

/uction and discharge protection #most important: positive displacement pumps need protection

against blocked suction and discharge lines$

/tart5up strainer%permanent filter

Pressure gouge, check valve, block valves #connection for cleaning$

)inimum flow protection

&igh temperature protection

NP/& #6or boiling li"uids indicate the re"uired static head$

No pockets in suction line

Conse"uences of human error

%eat e&changer

Check with respect to the:

!"uipment list

#Process$ Datasheets%Re"uisitions

the following:

Title

T,pe, fouling, cleanabilit,, dT fi+ed tube heat e+changer

Dut,

&eat e+change area

&eat transfer coefficient

Pressure drop%available pressure drop

Design pressure #both sides$

Design temperature #both sides$

Diameter connections

Tube vibration anal,sis, impingement plates

)aterial

Crevice corrosion, etc-

Product shell or tube side

Tube la,5out #shell diameter large enough for tubes 7 tie rods 7 re"uired free envelope space$

*nstalled power #air5cooled%electric$

Area of attention

Cleaning possibilit,

Thermal relief #both shell and tube side$, 'ent re"uirement

Pipe rupture #correct usage of safet, devices$

Thermowell

Conse"uences of human error

PIPI'$ (PPE)('E*

Check with respect to the:

3ine list%line designation table #P!D$

the following:

Diameter

3ine number

)edium code

Piping specification code

Tracing #winteri(ing or condensation%cr,stalli(ation risk$

*nsulation #heat%cold conservation, personnel protection-

Area of attention

Pockets #if not permissible$

)inimum distance

Reducers #eccentric%concentric$

6low direction

2ccessibilit, of pipe cleaning devices

/lope #low point$ drains and #high point$ vents, drop tra,s

'alve position: locked open%closed #3%3C$8 normall, open%closed #N%NC$

Correct velocit, #electrostatic charging, erosion, settling bio fouling$

Pressure drop in lines with gravit, flow

1tilit, connections #flushing, steaming, purging$

)inimum re"uired static head #standpipe, anti siphon, NP/&$

3ist of tie5ins

.atter, limits

Thermal relief

References to%from other drawings

.linds %spectacle blinds

T,pe of valve #gate, ball, diaphragm valve, etc-$

!longation stems of valve in relation to insulation thickness

*nsulation thickness in line list for piping supports etc-

Connecting drain and%or vent s,stems to process s,stem #consider pressure, mutual reactions of

chemicals, etc-$

6ast5acting valves %flow limiters#restriction orifices$%slow5acting valves #water hammer$

Conse"uences of human error

*(+ET, )E!ICE*"-UPTU-E )I*C*

Check with respect to the:

Datasheets /afet, Devices

the following:

/et pressure

Diameter inlet and outlet

/i(e of orifice

Tag number

Pressure class inlet%outlet

Area of attention

Relation set pressure%operating pressure #for rupture discs$

Relation set pressure%back pressure in relief line

Relation set pressure%design pressure

Relation set pressure%pressure alarm

Pressure drop in lead and tail line #less than 9: of set pressure$

No((le on e"uipment to be protected has to be larger than or e"ual to the inlet diameter of the safet,

device

The operabilit, of the safet, device ma, not be impeded b, the nature of the medium #corrosion,

h,drate formation, solidification, free(ing, cr,stalli(ation, etc-$

No valves in inlet and outlet line, unless with permission

2larm%notification between rupture disc and safet, device

Relief s,stem #relieving a safet, device into a s,stem with a lower pressure$

Drainage location, weep hole #drainage of condensate valves, self closing drain valves, stem position

indicator, etc-$

Conse"uences of human error

P-OCE** COT-OL

!erification checks ./ other disciplines

'erif, that the responsible discipline !lectrical and Process Control has checked the diagrams-

!;PC checks with respect to the:

*nstrument Datasheets%re"uisitions

the following:

Correct processing of specification data in the diagrams

Connections of instrumentation

Correct measuring circumstances like dela, time and minimum distances

Tag number

Pressure class inlet%outlet

One0s own checks

Check with respect to the:

Process Protection )emorandum

Process description

the following:

Principle of the control%safet, device

6unction and s,mbols

Tag number

/et pressure of controllers

Closing%opening of automaticall, controlled valves, in the event of a au+iliar, power failure #fail

position$

.lock valves #b,5pass, drain, vents$ e-g- for maintenance

*ndication #local%local panel%central panel%graphic interface$

Correct presentation of instrumentation

Area of attention

/tart5up, testing

/hut5down

!mergenc, stop

/afeguard of the au+iliar, power suppl,

6ailure of pumps, agitators

6ailure of utilit, s,stems

1ndesired chemical reactions #due to wrong dosage, etc-$

Reaction process medium with water #e-g- in the event of fire$

6ailure inert gas s,stem #blanketing s,stem$

perabilit,, location local indicators and control devices

Conse"uences of human error

)-(1I'*

!erification checks ./ other disciplines

'erif, that the responsible discipline )echanical !ngineering has checked the diagrams-

)echanical !ngineering checks with respect to the:

The diagrams #to be drawn$ submitted b, Process

The valid standards for drawing work

the following:

Correct processing of all drawing work

Correct application of the standards

Correct processing of data from the following documents in the diagrams:

o diagrams tracing and insulation

o list of tie5ins

o list of appendages, safet, valves

o demolition schemes%drawings

o plot plans

o piping route drawings

o isometrics

Você também pode gostar

- Flange Leakage Checking in Caesar II Using ASME Section VIII MethodDocumento10 páginasFlange Leakage Checking in Caesar II Using ASME Section VIII MethodMichael RobinsonAinda não há avaliações

- Basic Piping Training: A. Piping Skill DevelopmentDocumento8 páginasBasic Piping Training: A. Piping Skill DevelopmentMuhammad KhurramAinda não há avaliações

- Trac Iii Production LogDocumento48 páginasTrac Iii Production LogLuffy01Ainda não há avaliações

- Instrumentation Questions and AnswersDocumento45 páginasInstrumentation Questions and AnswersSajid RazaAinda não há avaliações

- Pca - Engine Room - vg822 - January 14Documento1 páginaPca - Engine Room - vg822 - January 14api-236510386Ainda não há avaliações

- Piping Inspector QuestionsDocumento7 páginasPiping Inspector Questionsnike_y2k100% (1)

- Procedure For Hydro Test of BoilerDocumento7 páginasProcedure For Hydro Test of Boilervai123_bodAinda não há avaliações

- HYDROTEST - JeevaDocumento68 páginasHYDROTEST - JeevaJayaraman KamarajAinda não há avaliações

- Silo Data Sheet PDFDocumento4 páginasSilo Data Sheet PDFMohamed ElfawalAinda não há avaliações

- Electronics Assembly Electronics Assembly: Surface Surface Mount Mount Technology Technology SMT: SMTDocumento24 páginasElectronics Assembly Electronics Assembly: Surface Surface Mount Mount Technology Technology SMT: SMTbibicul1958Ainda não há avaliações

- Swyd Comm STDDocumento14 páginasSwyd Comm STDjunfaAinda não há avaliações

- Bechtel France S.A.S.: Reliance Petroleum Limited Jamnagar Export Refinery ProjectDocumento22 páginasBechtel France S.A.S.: Reliance Petroleum Limited Jamnagar Export Refinery Projectravi00098Ainda não há avaliações

- Old Hot InsulationDocumento9 páginasOld Hot InsulationNehal VaghelaAinda não há avaliações

- FM Global Loss Prevention Visit Protocol - Non-USDocumento7 páginasFM Global Loss Prevention Visit Protocol - Non-USFederico MattsonAinda não há avaliações

- Silo Data SheetDocumento4 páginasSilo Data SheetZoran Danilov100% (1)

- Pressure Equipment Inspection Requirements: Upstream-Unit 82 U-A8300 Condensate Pre-CoolerDocumento1 páginaPressure Equipment Inspection Requirements: Upstream-Unit 82 U-A8300 Condensate Pre-CoolerSiva KumarAinda não há avaliações

- Heat ExchangerDocumento36 páginasHeat ExchangerUsman MansuriAinda não há avaliações

- 001-Sample Method Statement Piping Pre-ShutdownDocumento4 páginas001-Sample Method Statement Piping Pre-ShutdownS.C.Satish ChanderAinda não há avaliações

- Hvacr Designer Tips: Design Review and Startup ChecklistDocumento1 páginaHvacr Designer Tips: Design Review and Startup ChecklistsajuhereAinda não há avaliações

- Hydro TestDocumento35 páginasHydro TestSumedh SinghAinda não há avaliações

- API 570 Questions 06Documento22 páginasAPI 570 Questions 06Ravindra S. Jivani75% (4)

- Hydro TestDocumento36 páginasHydro TestAayush PandeyAinda não há avaliações

- Valves: Section 7Documento11 páginasValves: Section 7Emad SaadAinda não há avaliações

- Module 3 (KTU)Documento129 páginasModule 3 (KTU)Muhammed AfnazAinda não há avaliações

- Hvacr Designer Tips: Design Review and Startup ChecklistDocumento1 páginaHvacr Designer Tips: Design Review and Startup ChecklistsajuhereAinda não há avaliações

- Pressure Equipment Inspection Requirements: Upstream-Unit 82 U-C8300 Condensate Stripper ColumnDocumento1 páginaPressure Equipment Inspection Requirements: Upstream-Unit 82 U-C8300 Condensate Stripper ColumnSiva KumarAinda não há avaliações

- Hydro TestDocumento36 páginasHydro TestAhmed AshourAinda não há avaliações

- Control Valve Failure Relief Rate - Liquid ServiceDocumento2 páginasControl Valve Failure Relief Rate - Liquid ServiceSaeid Rahimi MofradAinda não há avaliações

- Pressure Equipment Inspection Requirements: Train-3 Unit-82 03-S8203A Sea Water FilterDocumento1 páginaPressure Equipment Inspection Requirements: Train-3 Unit-82 03-S8203A Sea Water FilterSiva KumarAinda não há avaliações

- API 520 PresentationDocumento31 páginasAPI 520 PresentationLISTUS1100% (2)

- 6 WI LP1-4 Surface Downhole Equipment FI 2003Documento49 páginas6 WI LP1-4 Surface Downhole Equipment FI 2003Karwan Dilmany100% (1)

- Final CompilitionDocumento116 páginasFinal CompilitionNilesh GohelAinda não há avaliações

- Fabrication NotesDocumento76 páginasFabrication NotesnicekhanAinda não há avaliações

- Pressure Equipment Inspection Requirements: Train2 - Unit 07 03-E0707 Debutanizer CondenserDocumento1 páginaPressure Equipment Inspection Requirements: Train2 - Unit 07 03-E0707 Debutanizer CondenserSiva KumarAinda não há avaliações

- Hydro Testing in Crosscountry PipelineDocumento22 páginasHydro Testing in Crosscountry Pipelinemadhunikhil50% (8)

- Minor Loss Coefficients in Pipes and Tubes ComponentsDocumento2 páginasMinor Loss Coefficients in Pipes and Tubes ComponentsSurendra ReddyAinda não há avaliações

- Astm ArticlesijjbDocumento36 páginasAstm ArticlesijjbKaushik FalduAinda não há avaliações

- Introduction and FlowchartingDocumento67 páginasIntroduction and FlowchartingSusanth SunilAinda não há avaliações

- Method of Statement Plumbing WorksDocumento3 páginasMethod of Statement Plumbing Workshasan_6764896160% (1)

- SealedTankPresentation by IEEEDocumento5 páginasSealedTankPresentation by IEEESupratik MukherjeeAinda não há avaliações

- NAF ProCap Capping Valves For Pulp DigestersDocumento8 páginasNAF ProCap Capping Valves For Pulp DigestersUday GokhaleAinda não há avaliações

- Commissioning ProcedureDocumento18 páginasCommissioning ProcedureToniMelo100% (1)

- Es Hvacdesigntips0603Documento1 páginaEs Hvacdesigntips0603sajuhereAinda não há avaliações

- Blast Furnace: Standard Operating Procedures For Top FiringDocumento7 páginasBlast Furnace: Standard Operating Procedures For Top FiringNishant BandaruAinda não há avaliações

- Eliminate The Guesswork!: Cardinal Surveys CompanyDocumento49 páginasEliminate The Guesswork!: Cardinal Surveys CompanyNghiêm Xuân ĐạtAinda não há avaliações

- Inspection of Heat ExchangerDocumento83 páginasInspection of Heat ExchangerRaghavanAinda não há avaliações

- Guidelines Aid TroubleshootingDocumento13 páginasGuidelines Aid TroubleshootingaminAinda não há avaliações

- Flow Measurement Lecture 1Documento37 páginasFlow Measurement Lecture 1Rahul KalraAinda não há avaliações

- Tuboscope Drill PipeDocumento6 páginasTuboscope Drill PipeOscar CarrascoAinda não há avaliações

- Overpressure Protection & Relief ValvesDocumento72 páginasOverpressure Protection & Relief Valvesankitalalwani100% (1)

- Underwater TreadmillDocumento25 páginasUnderwater TreadmillangeltandinganAinda não há avaliações

- Reventive Maintenance and ChecklistDocumento8 páginasReventive Maintenance and ChecklistkicchasandeepAinda não há avaliações

- Downhole Corrosion Survey ToolsDocumento34 páginasDownhole Corrosion Survey ToolsabyAinda não há avaliações

- Pressure Vessel Fabrication & Inspection: Poyyara ConsultantsDocumento76 páginasPressure Vessel Fabrication & Inspection: Poyyara ConsultantsgopidhanAinda não há avaliações

- Quality ManualDocumento11 páginasQuality Manualdosprem100% (1)

- Process Controller - Treatment 2Documento1 páginaProcess Controller - Treatment 2api-236510386Ainda não há avaliações

- Qdoc - Tips - General Guidelines of Pump Piping LayoutDocumento8 páginasQdoc - Tips - General Guidelines of Pump Piping LayoutAmjadali ChoudhariAinda não há avaliações

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNo EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNota: 4.5 de 5 estrelas4.5/5 (10)

- Valve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationNo EverandValve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationNota: 4.5 de 5 estrelas4.5/5 (21)

- Steam Tracing CalculationDocumento44 páginasSteam Tracing CalculationsafaldAinda não há avaliações

- 4 GEN 8602 DOC - Vendor's Documentation RequirementsDocumento7 páginas4 GEN 8602 DOC - Vendor's Documentation RequirementssafaldAinda não há avaliações

- Steam TracingDocumento18 páginasSteam TracingSyed Mujtaba Ali Bukhari100% (2)

- Receipt - Nusatrip Online TravelDocumento1 páginaReceipt - Nusatrip Online TravelsafaldAinda não há avaliações

- List of Tender PackagesDocumento25 páginasList of Tender PackagessafaldAinda não há avaliações

- Vendors Info (2015!04!09) SsssssDocumento49 páginasVendors Info (2015!04!09) SssssssafaldAinda não há avaliações

- Restrictive Orifice Calc For Tube FinalDocumento12 páginasRestrictive Orifice Calc For Tube FinalsafaldAinda não há avaliações

- Piping PDFDocumento46 páginasPiping PDFGORO43100% (1)

- 3182xxx - PDS For Rupture DiskDocumento2 páginas3182xxx - PDS For Rupture DisksafaldAinda não há avaliações

- Pressure Control Valve (PV) : Process Data Sheet ForDocumento1 páginaPressure Control Valve (PV) : Process Data Sheet ForsafaldAinda não há avaliações

- 3182xxx - Restriction OrificeDocumento2 páginas3182xxx - Restriction OrificesafaldAinda não há avaliações

- Process Data Sheet For Temperature Gauge: XXX XXX XXX XXX XX of XXDocumento2 páginasProcess Data Sheet For Temperature Gauge: XXX XXX XXX XXX XX of XXsafaldAinda não há avaliações

- 3182xxx - Flow Instruments - FT, FC, FIDocumento5 páginas3182xxx - Flow Instruments - FT, FC, FIsafaldAinda não há avaliações

- 3182xxx - Level Switch, Transmitter, IndicatorDocumento4 páginas3182xxx - Level Switch, Transmitter, IndicatorsafaldAinda não há avaliações

- Process Data Sheet For Tank / Vessel: XXX XXX XXX XXX XXX XXXDocumento2 páginasProcess Data Sheet For Tank / Vessel: XXX XXX XXX XXX XXX XXXsafaldAinda não há avaliações

- New Microsoft Excel WorksheetDocumento6 páginasNew Microsoft Excel WorksheetsafaldAinda não há avaliações

- 3181xxx - PDS For FilterDocumento1 página3181xxx - PDS For FiltersafaldAinda não há avaliações

- 3181xxx - PDS For PumpDocumento1 página3181xxx - PDS For PumpsafaldAinda não há avaliações

- 3181xxx - PDS For Mixer - AgitatorDocumento1 página3181xxx - PDS For Mixer - AgitatorsafaldAinda não há avaliações

- Design of AgitatorDocumento3 páginasDesign of AgitatorManish PatelAinda não há avaliações

- Agitator DesignDocumento7 páginasAgitator DesignTint Tiger100% (4)

- 2011-08 Newsletter TNBVDocumento3 páginas2011-08 Newsletter TNBVsafaldAinda não há avaliações

- EDS DisciplineDocumento7 páginasEDS DisciplinesafaldAinda não há avaliações

- Pressure Vessel Nozzle Calc - ASME VIII Div 1Documento20 páginasPressure Vessel Nozzle Calc - ASME VIII Div 1aauppal100% (1)

- Ex Reactor DesignDocumento10 páginasEx Reactor DesignsafaldAinda não há avaliações

- Heat Transfer Coeficient in ReactorDocumento2 páginasHeat Transfer Coeficient in ReactorDavid LambertAinda não há avaliações

- Gas Linesizing Rev1Documento9 páginasGas Linesizing Rev1safaldAinda não há avaliações

- 8.62 Bars 45.6 C 8.62 Bars: Condenser Expansion CompressorDocumento16 páginas8.62 Bars 45.6 C 8.62 Bars: Condenser Expansion Compressorduazo2009100% (1)

- Styrene Acrylic LatexDocumento4 páginasStyrene Acrylic LatexsafaldAinda não há avaliações

- Styrene Acrylic LatexDocumento4 páginasStyrene Acrylic LatexsafaldAinda não há avaliações

- Kouga MaintainanceDocumento28 páginasKouga MaintainancematshonaAinda não há avaliações

- Creamery Juice HACCP PlanDocumento27 páginasCreamery Juice HACCP PlanDavid ChanAinda não há avaliações

- PS Plugs and Connectors Brochure 2013Documento16 páginasPS Plugs and Connectors Brochure 2013Bruno SantosAinda não há avaliações

- Polymer Degradation and Stability: Sumit K. Singh, Yogesh Kumar, Sham S. RavindranathDocumento12 páginasPolymer Degradation and Stability: Sumit K. Singh, Yogesh Kumar, Sham S. RavindranathAnonymous x7VY8VF7Ainda não há avaliações

- Manufacture of Alum PDFDocumento450 páginasManufacture of Alum PDFKimberly ConleyAinda não há avaliações

- Insulation Condition During Transformer Manufacturing: by Study Committee A2Documento4 páginasInsulation Condition During Transformer Manufacturing: by Study Committee A2Pruthvi KrishnaAinda não há avaliações

- Analysis of A Centrifugal Pump: Pumping Head Curves: CM3215 Fundamentals of Chemical Engineering LaboratoryDocumento7 páginasAnalysis of A Centrifugal Pump: Pumping Head Curves: CM3215 Fundamentals of Chemical Engineering Laboratoryshadowblader9Ainda não há avaliações

- Service Manual - Siau282005ea - Rza(s) - C (1) (2) V (Y) 1Documento298 páginasService Manual - Siau282005ea - Rza(s) - C (1) (2) V (Y) 1jpj54ktqjdAinda não há avaliações

- Ipg 2016 Investor Day PresentationDocumento122 páginasIpg 2016 Investor Day PresentationyaacovAinda não há avaliações

- GAS - by BASF - 1 PDFDocumento12 páginasGAS - by BASF - 1 PDFD K SAinda não há avaliações

- Tinosorb S Aqua OPPDocumento1 páginaTinosorb S Aqua OPPPRINCESS ALYSSA PASAJOLAinda não há avaliações

- First Monthly Test in TVLDocumento2 páginasFirst Monthly Test in TVLEpoyIrish BongaisAinda não há avaliações

- American Woodworker - 129 (July 2007)Documento68 páginasAmerican Woodworker - 129 (July 2007)Emilian Baluta100% (3)

- NZ Container-PartsDocumento32 páginasNZ Container-PartsNagendra PratapAinda não há avaliações

- Outgassing Versus Flashing - What Are The Differences?: Issue 2Documento4 páginasOutgassing Versus Flashing - What Are The Differences?: Issue 2Ashok SankarAinda não há avaliações

- P 07Documento1 páginaP 07Kamarul NizamAinda não há avaliações

- Distribution ReservoirsDocumento14 páginasDistribution ReservoirsBinyam KebedeAinda não há avaliações

- DEVISE - Industrial HIGH-RATE - Brochure - r1Documento2 páginasDEVISE - Industrial HIGH-RATE - Brochure - r1mesratiAinda não há avaliações

- Maraging Steel Data SheetDocumento2 páginasMaraging Steel Data SheetdavideAinda não há avaliações

- Hollow Bars (ISO2938)Documento8 páginasHollow Bars (ISO2938)suku maranAinda não há avaliações

- Flanged Series: Flow-TekDocumento8 páginasFlanged Series: Flow-Teklcs2006mvAinda não há avaliações

- Freedom SW 2000 Owners Guide (975-0528!01!01 - Rev-D)Documento48 páginasFreedom SW 2000 Owners Guide (975-0528!01!01 - Rev-D)MatthewAinda não há avaliações

- Hipon 20 DechloDocumento3 páginasHipon 20 DechloLopez GardoAinda não há avaliações

- Sae Ams 4027 SheetmetalDocumento7 páginasSae Ams 4027 Sheetmetaljuan100% (5)

- TDS - 4S Service ManualDocumento271 páginasTDS - 4S Service ManualLeonardo Alvarez100% (4)

- Man Made FibreDocumento23 páginasMan Made FibreKhushboo ThakurAinda não há avaliações

- EstimateDocumento1 páginaEstimateAlemar Soriano MalintadAinda não há avaliações

- Tata Steel en 15804 Verified EPD ProgrammeDocumento16 páginasTata Steel en 15804 Verified EPD Programmeashutosh mishraAinda não há avaliações

- Husky HRPG enDocumento136 páginasHusky HRPG envdj85Ainda não há avaliações

- HighNote4 U6E Vocabulary Quiz BDocumento1 páginaHighNote4 U6E Vocabulary Quiz BZuza StarońAinda não há avaliações