Escolar Documentos

Profissional Documentos

Cultura Documentos

Bell Method Example 7 5

Enviado por

jnmanivannan0 notas0% acharam este documento útil (0 voto)

92 visualizações9 páginasBell Method Example 7 5

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

XLS, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoBell Method Example 7 5

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato XLS, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

92 visualizações9 páginasBell Method Example 7 5

Enviado por

jnmanivannanBell Method Example 7 5

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato XLS, PDF, TXT ou leia online no Scribd

Você está na página 1de 9

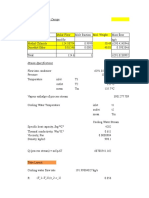

This worksheet allows calculation of the Overall Heat Transfer Coefficient and pressure drops in a TEMA type E shell

and tubes heat exchanger using Bell-Delaware method.

Data input corresponds to yellow cells and the tube array must be selected in the list box. Results are shown in cells K48 to K50

Process Data

(see drawing at right)

tube side shell side N= Number of tubes per shell

Ntw= Number of tubes in window

Flowrate (kg/s) 38.88 33.33 AUX NCL=Number of tubes in central row

Inlet Temp. (C) 40 104 44 NBT= Number of tubes crossing

Outlet Temp. (C) 60 85 45 the baffle

Inlet Pressure (bar abs) 4 3 NC= Number of tubes rows between

Q= Heat Duty (W) 1664064 1671833 consecutives baffles edges

Thermal Balance sigma=separation between rows

check OK- error <2% DS= Shell Diameter

DB=Baffle Diameter

Density (kg/m3) 716 578 BC= Baffle cut

Viscosity (cp) 0.62 0.16 A= Baffle central angle in degrees

Specific Heat. (J/kg.K) 2140 2640 Do= Tubes external diameter

Thermal Conduct. (W/m.K) 0.129 0.0917 Di= Tubes internal diameter

Visc at wall temperature (cp) 0.59 0.16 DBT=Baffle holes diameter

Pr 10.29 4.61 Pt= Tubes separation (Pitch)

c= clearance between tubes

Tube side Calculations n= number of tube passes

NB= Number of baffles

at= Flow Area 0.0401 m2 NS= Number of sealing strips pairs

Gt= mass velocity 970.2 kg/m2/s L= tubes length

Ret= Reynolds Number 24568 B= Baffles spacing

hi= internal coeff. 1327 W/m2K

hio= 1096 W/m2K

friction factor 0.00758 Internal fouling ressistance(m2.K/W)

Pressure drop 16099 N/m2 External fouling ressistance

Shell side calculations- Bell method

effective number of tubes rows 334 Select the tubes array

Total number of tubes rows correction 1

Sm=Cross flow area 0.0491 m2

Gm= Mass velocity 678.3 kg/s.m2

Rem 80544

j=Colburn Coefficient 3.76E-03

FBP=By pass fraction 0.390

alfa 1.35

by pass correction for h 0.8426 Ns/0.5*Nc

r 0.1812 0.307692

Sw 0.0356 m2

window correction factor 1.1251

STB=tube-baffle leakage area 0.0083 m2

SSB=shell baffle leakage area 0.0030 m2

SL= total leakage area 0.0112 m2 U= Overall heat transfer coefficient calculated

SL/Sm= 0.2288 Tubeside pressure drop per shell

(1-hL/hNL)o 0.2029 Shellside pressure drop per shell

1-hL/hNL 0.2567

hL/hNL 0.7433 Wall temperature calculation

ho 1714.8 W/m2K

shell side friction factor 0.0908 1/(1/hio+Rfi)=

alfa2 4 1/(1/ho+Rfo)=

by pass correction for deltap 0.602

(deltap)BP 1131.3 N/m2 Wall mean temp

vZ 1.38 m/s

Nw 5.54

(deltap)w 2921 N/m2 Number of shells

(1-deltapL/deltapNL)o 0.398 in series 1

(1-deltapL/deltapNL) 0.503

deltapL/deltapNL 0.497 Heat transfer

deltap shell 36886 N/m2 Total area 105.4

LMTD 44.5

Q 1894475

% Overdesign 14%

This worksheet allows calculation of the Overall Heat Transfer Coefficient and pressure drops in a TEMA type E shell and tubes heat exchanger using Bell-Delaware method.

Data input corresponds to yellow cells and the tube array must be selected in the list box. Results are shown in cells K48 to K50

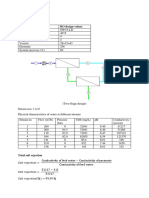

GEOMETRIC DATA

(see drawing at right)

N= Number of tubes per shell 414

Ntw= Number of tubes in window 75

NCL=Number of tubes in central row 21

NBT= Number of tubes crossing

339

NC= Number of tubes rows between

consecutives baffles edges 13

sigma=separation between rows 0.022 m

0.609 m

0.6043 m

0.15225 m

A= Baffle central angle in degrees 120

Do= Tubes external diameter 0.019 m

de tubos 0.0157 m

DBT=Baffle holes diameter 0.0198 m

Pt= Tubes separation (Pitch) 0.0254 m

c= clearance between tubes 0.0064

n= number of tube passes 2

17

NS= Number of sealing strips pairs 2

4.267 m

0.234 m

Internal fouling ressistance(m2.K/W) 0.0005

External fouling ressistance 0.0004

U= Overall heat transfer coefficient calculated 417.5 W/m2K

Tubeside pressure drop per shell 16099 N/m2

Shellside pressure drop per shell 36886 N/m2

Wall temperature calculation

708 W/m2K Ts=shell side fluid mean temp. 94.5 C

1017 W/m2K Tt=Tubeside fluid mean temp. 50 C

76.24 C

DPt 16099 Pa

0.217 DPc 36886 Pa

m2

C Ft 0.97 MTD 43.0 C

W

LMTD Correction factor Ft Ft

T1 104

T2 85.0

t1 40

t2 60.0

R 1.0

S 0.31

Number of shells Numero de carcasas 1

Tube passes 2

FT 0.967152

Rem<100

j=a*Rem^b

a

array

1 triangle (30) Pt/D= 1.25 1.81

2 Square Pt/D=1.25 0.97

3 Rotated Square Pt/D=1.25 1.81

4 triangle (30) Pt/D= 1.5 1.34

5 Square Pt/D=1.5 0.88

3 Selected array 1.81

For Rem = 80544.11 j =

Coefficients for f calculation - ln(f)=a+blnRem+c*(lnRem)^2+d*(lnRem)^3

a

arreglo

1 tringulo (60) Pt/D= 1.25 4.376

2 Cuadrado Pt/D=1.25 3.923

3 Cuadro rotado Pt/D=1.25 3.923

4 tringulo (60) Pt/D= 1.5 3.196

5 Cuadrado Pt/D=1.5 3.04

3 Arreglo seleccionado 3.923

Coefficients for Rem 80544.11

Calculation of friction factor and J factor

coefficients for J calculation

100<Rem<3000 Rem>3000

j=a*Rem^b lnj=a+b*lnRem+c(lnRem)^2 j=aRem^b

b a b c a b

-0.72 1.7 -1.25 0.065 0.275 -0.38

-0.62 3.29 -1.9 0.121 0.275 -0.38

-0.72 0.32 -0.76 0.025 0.275 -0.38

-0.68 0.37 -0.56 0.0087 0.275 -0.38

-0.64 1.61 -1.34 0.082 0.275 -0.38

-0.72 0.32 -0.76 0.025 0.275 -0.38

3.76E-03

Coefficients for f calculation - ln(f)=a+blnRem+c*(lnRem)^2+d*(lnRem)^3

Rem<100 100<Rem<1300 1300<Rem<3000

b c d a b c d a b

-1.025 0 0 5.293 -1.864 0.1584 -0.00472 5.293 -1.864

-0.984 0 0 3.871 -0.498 -0.2052 0.0221 3.871 -0.498

-0.984 0 0 6.3 -2.403 0.226 -0.00721 6.3 -2.403

-1.176 0.0557 0 3.472 -1.547 0.1425 -0.00454 3.472 -1.547

-1.13 0.031 0 -8.015 5.152 -1.166 0.0771 -6.666 1.152

-0.984 0 0 6.3 -2.403 0.226 -0.00721 6.3 -2.403

a = 6.3

b = -2.403 f = 0.090804

c = 0.226

d = -0.00721

1300<Rem<3000 Rem>3000

c d a b c d

0.1584 -0.00472 5.293 -1.864 0.1584 -0.00472

-0.2052 0.00221 -7.907 1.774 -0.16 0.00407

0.226 -0.00721 6.3 -2.403 0.226 -0.00721

0.1425 -0.00454 3.472 -1.547 0.1425 -0.00454

-0.0981 0.00237 -6.666 1.152 -0.0981 0.00237

0.226 -0.00721 6.3 -2.403 0.226 -0.00721

Você também pode gostar

- Practice Problems For Modulus and Logarithm Section-I: FiitjeeDocumento8 páginasPractice Problems For Modulus and Logarithm Section-I: FiitjeePratham SharmaAinda não há avaliações

- Brain Alchemy Masterclass PsychotacticsDocumento87 páginasBrain Alchemy Masterclass Psychotacticskscmain83% (6)

- Emiss Calc HotmixDocumento37 páginasEmiss Calc HotmixjnmanivannanAinda não há avaliações

- Heat Conduction Pipe InsulationDocumento1 páginaHeat Conduction Pipe InsulationJogender DhayalAinda não há avaliações

- Dfmea TeamDocumento2 páginasDfmea TeamjnmanivannanAinda não há avaliações

- Chapter 5 - Shear and Diagonal Tension On Beams PDFDocumento55 páginasChapter 5 - Shear and Diagonal Tension On Beams PDFJhe Taguines100% (1)

- Design HeatexchangerDocumento15 páginasDesign HeatexchangerMayurMahajan100% (1)

- Checklist Code ReviewDocumento2 páginasChecklist Code ReviewTrang Đỗ Thu100% (1)

- Hitungan PPDocumento30 páginasHitungan PPHamdan ShdAinda não há avaliações

- FEMA Equip ScheduleDocumento14 páginasFEMA Equip SchedulejnmanivannanAinda não há avaliações

- GEMI Equations ToolDocumento10 páginasGEMI Equations TooljnmanivannanAinda não há avaliações

- GEMI Equations ToolDocumento10 páginasGEMI Equations TooljnmanivannanAinda não há avaliações

- CPI DesignDocumento6 páginasCPI Designprasad336Ainda não há avaliações

- Structural Sections SpreadsheetDocumento74 páginasStructural Sections Spreadsheetpiper1985Ainda não há avaliações

- Water PropertiesDocumento4 páginasWater Propertiesaw_aeAinda não há avaliações

- Packed Column DesignDocumento6 páginasPacked Column Designyamen-691904Ainda não há avaliações

- Cooling Tower ComparisonDocumento4 páginasCooling Tower ComparisonKiran DasAinda não há avaliações

- Long Span PrattDocumento36 páginasLong Span PrattCarmel Buniel SabadoAinda não há avaliações

- Samudra-Pasai at The Dawn of The European AgeDocumento39 páginasSamudra-Pasai at The Dawn of The European AgemalaystudiesAinda não há avaliações

- Tube Rupture (Two Phase-Omega Method) PDFDocumento1 páginaTube Rupture (Two Phase-Omega Method) PDFAmin RoisAinda não há avaliações

- Multiphase Flow 1995No EverandMultiphase Flow 1995A. SerizawaAinda não há avaliações

- Heat CapacityDocumento2 páginasHeat CapacityAbhijit MokashiAinda não há avaliações

- Shell Tube Heat Exchanger DesignDocumento7 páginasShell Tube Heat Exchanger DesignAbhijeet JhaAinda não há avaliações

- Pressuredrop Calculations by Kern Method SRRDocumento18 páginasPressuredrop Calculations by Kern Method SRRrajeev50588Ainda não há avaliações

- Design of Heat ExchangersDocumento23 páginasDesign of Heat ExchangersKhalid Turki100% (2)

- JR Heat Exchanger DesignDocumento14 páginasJR Heat Exchanger Designjanelle ramdahinAinda não há avaliações

- Perancangan CycloneDocumento20 páginasPerancangan CycloneDavid LambertAinda não há avaliações

- Chimney Design CalcDocumento5 páginasChimney Design CalcDenny ThomasAinda não há avaliações

- Pipe Rack Design Wind Forces: Z F F Z ZT D 2Documento7 páginasPipe Rack Design Wind Forces: Z F F Z ZT D 2jnmanivannanAinda não há avaliações

- Restriction Orifice Diamater CalculationDocumento1 páginaRestriction Orifice Diamater CalculationkodeesAinda não há avaliações

- Double FdexchangerDocumento8 páginasDouble FdexchangerBoško IvanovićAinda não há avaliações

- Calculo HP K-60 AbDocumento23 páginasCalculo HP K-60 Abgustavo barbozaAinda não há avaliações

- Mass Balance (Final)Documento26 páginasMass Balance (Final)Adeel AhmedAinda não há avaliações

- Mixer CalcDocumento10 páginasMixer CalchadiAinda não há avaliações

- Vapor Line Sizing-Mpp6Documento10 páginasVapor Line Sizing-Mpp6Nitin KurupAinda não há avaliações

- Timah - Open Spray - Tower - For - Flue - Gas - Scrubbing - Design 56870 NCMHDocumento1 páginaTimah - Open Spray - Tower - For - Flue - Gas - Scrubbing - Design 56870 NCMHAyahKenzie100% (1)

- Process Calculations Scenario A Cattle Manure Maize Silage: 4 3 CH4 ODM - 1 - 3 - 1 - 1Documento18 páginasProcess Calculations Scenario A Cattle Manure Maize Silage: 4 3 CH4 ODM - 1 - 3 - 1 - 1SabariyantoAinda não há avaliações

- Gas Liquid Separator DesignDocumento3 páginasGas Liquid Separator DesignSoheil MoradiAinda não há avaliações

- Distillation Column: Major Equipment DesignDocumento45 páginasDistillation Column: Major Equipment Designrubesh_rajaAinda não há avaliações

- Vertical SeparatorDocumento38 páginasVertical SeparatorSaidFerdjallahAinda não há avaliações

- Flash CalculationsDocumento10 páginasFlash CalculationsHamza AliAinda não há avaliações

- Cyclone CalculatorDocumento19 páginasCyclone CalculatornarsingrameshAinda não há avaliações

- Shell&Tube TEMAsheet 1Documento1 páginaShell&Tube TEMAsheet 1Rikiya FebriyanAinda não há avaliações

- DesignDocumento2 páginasDesignhmxAinda não há avaliações

- Water Transmission Oil (Type-H) : Cold FluidDocumento6 páginasWater Transmission Oil (Type-H) : Cold FluidPassmore DubeAinda não há avaliações

- Design II Mannual CFDocumento71 páginasDesign II Mannual CFarulrakk100% (1)

- Energy BalanceDocumento11 páginasEnergy BalanceBharat VaajAinda não há avaliações

- Mixer (So3 Jadi H2so4)Documento6 páginasMixer (So3 Jadi H2so4)Evi SiswantoAinda não há avaliações

- Qaverage Phase-1 Phase-2 Qpeak Phase-1 Phase-2 m3/d m3/d m3/hr m3/hr M3/sec M3/secDocumento7 páginasQaverage Phase-1 Phase-2 Qpeak Phase-1 Phase-2 m3/d m3/d m3/hr m3/hr M3/sec M3/secHemantk8731100% (1)

- Handbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4No EverandHandbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4Nota: 5 de 5 estrelas5/5 (1)

- 11.3 KernDocumento78 páginas11.3 KernChou ChouAinda não há avaliações

- RELATIVE CLAUSES 1º Bachillerato and KeyDocumento3 páginasRELATIVE CLAUSES 1º Bachillerato and Keyrapitanoroel0% (2)

- Process Calculation For FREYLIT CPI Oil SeparatorDocumento4 páginasProcess Calculation For FREYLIT CPI Oil SeparatorRajdeepsinhAinda não há avaliações

- HX Design v1Documento12 páginasHX Design v1mansourotaibiAinda não há avaliações

- Heat Exchanger Input Correction FactorDocumento11 páginasHeat Exchanger Input Correction FactorTrần Tuấn VũAinda não há avaliações

- Hydroulics Calculation and Gas PropertiesDocumento3 páginasHydroulics Calculation and Gas PropertiesSteve WanAinda não há avaliações

- Peng Robinson MixturesDocumento1 páginaPeng Robinson MixturesdckristantoAinda não há avaliações

- Tube Rupture (Two Phase-Omega Method)Documento1 páginaTube Rupture (Two Phase-Omega Method)Saeid Rahimi MofradAinda não há avaliações

- Mathematical Method For Physicists Ch. 1 & 2 Selected Solutions Webber and ArfkenDocumento7 páginasMathematical Method For Physicists Ch. 1 & 2 Selected Solutions Webber and ArfkenJosh Brewer100% (3)

- L.3.1. EVAPORATOR - 01 (EV-01) : 1 o o o oDocumento9 páginasL.3.1. EVAPORATOR - 01 (EV-01) : 1 o o o omedias indah monica sariAinda não há avaliações

- h-101 TwiceDocumento20 páginash-101 TwiceAdela ShofiaAinda não há avaliações

- Nirma University Heat Exch AssignmentDocumento16 páginasNirma University Heat Exch AssignmentSarvagyaAinda não há avaliações

- Design: of Shell & Tube Heat ExchangerDocumento27 páginasDesign: of Shell & Tube Heat ExchangerBalamurugan SakthivelAinda não há avaliações

- Appendixs ADocumento188 páginasAppendixs ABurhanudin MuizAinda não há avaliações

- Bell Method Example 7 5Documento9 páginasBell Method Example 7 5Amin FarukiAinda não há avaliações

- Type k1 (Re 1) NP (Re 10 5) : Anchor 0.7 LaminarDocumento3 páginasType k1 (Re 1) NP (Re 10 5) : Anchor 0.7 LaminarRobinAinda não há avaliações

- 4.4 Heat Ex ChangersDocumento7 páginas4.4 Heat Ex Changersmukesh kaushikAinda não há avaliações

- Vent Dispersion Calc - OptionalDocumento4 páginasVent Dispersion Calc - OptionalPeddy Nesa0% (1)

- 6 Crystallizer Design and Operation1Documento22 páginas6 Crystallizer Design and Operation1Dhrumil GandhiAinda não há avaliações

- Jet Impingement CoolingDocumento9 páginasJet Impingement CoolingDanish AbbasAinda não há avaliações

- Design Calculation For Gaseous SystemsDocumento16 páginasDesign Calculation For Gaseous Systemsshashi ranjanAinda não há avaliações

- DP Calc 1Documento3 páginasDP Calc 1Manjunath HardcheeseAinda não há avaliações

- Sparger Calc MotDocumento5 páginasSparger Calc MotRajesh NareAinda não há avaliações

- Jumadiao, Yra Marielle M. Exercise 9: Heat Balance and Theoretical Flame Temperature GivenDocumento4 páginasJumadiao, Yra Marielle M. Exercise 9: Heat Balance and Theoretical Flame Temperature GivenJanelle M. JumadiaoAinda não há avaliações

- High Pressure Phase Behaviour of Multicomponent Fluid MixturesNo EverandHigh Pressure Phase Behaviour of Multicomponent Fluid MixturesAinda não há avaliações

- 04 DEC1 A DatabaseDocumento46 páginas04 DEC1 A DatabasejnmanivannanAinda não há avaliações

- Final Load List 30 04 12Documento14 páginasFinal Load List 30 04 12jnmanivannanAinda não há avaliações

- Steam Trap EstimatorDocumento9 páginasSteam Trap EstimatorjnmanivannanAinda não há avaliações

- 22268Documento290 páginas22268jnmanivannanAinda não há avaliações

- Dola Char AnalysisDocumento3 páginasDola Char AnalysisS V NAGESHAinda não há avaliações

- EI2009Documento717 páginasEI2009jnmanivannanAinda não há avaliações

- AHU Supply Front PackageDocumento10 páginasAHU Supply Front PackagejnmanivannanAinda não há avaliações

- Soil Resistivity1Documento12 páginasSoil Resistivity1jnmanivannanAinda não há avaliações

- Chimney Qty ReinforcementDocumento25 páginasChimney Qty ReinforcementjnmanivannanAinda não há avaliações

- GiwlistDocumento1 páginaGiwlistjnmanivannanAinda não há avaliações

- Plant SpecificationsDocumento4 páginasPlant SpecificationsjnmanivannanAinda não há avaliações

- EI2009Documento717 páginasEI2009jnmanivannanAinda não há avaliações

- EH GPR Checklist v1-2Documento8 páginasEH GPR Checklist v1-2jnmanivannanAinda não há avaliações

- Normality Acid, N Sample Vol: ML PHDocumento10 páginasNormality Acid, N Sample Vol: ML PHjnmanivannanAinda não há avaliações

- H 2 EauDocumento4 páginasH 2 EaujnmanivannanAinda não há avaliações

- H 2 EauDocumento4 páginasH 2 EaujnmanivannanAinda não há avaliações

- Journal of Engineering Physics and Thermophysics Volume 47 Issue 1 1984 (Doi 10.1007 - bf00832588) E. N. Pis'Mennyi - Study of Flow On The Surface of Fins On Cross-Finned TubesDocumento5 páginasJournal of Engineering Physics and Thermophysics Volume 47 Issue 1 1984 (Doi 10.1007 - bf00832588) E. N. Pis'Mennyi - Study of Flow On The Surface of Fins On Cross-Finned TubesjnmanivannanAinda não há avaliações

- 보온재두께계산Documento2 páginas보온재두께계산Sharon LambertAinda não há avaliações

- Calculation Form CombustionDocumento2 páginasCalculation Form CombustionjnmanivannanAinda não há avaliações

- Fluid HeatDocumento83 páginasFluid HeatjnmanivannanAinda não há avaliações

- Busbar Size Calculation (22.8.12)Documento16 páginasBusbar Size Calculation (22.8.12)Jeya KannanAinda não há avaliações

- Chapter 1Documento20 páginasChapter 1Li YuAinda não há avaliações

- Fix LHA Whole PagesDocumento81 páginasFix LHA Whole PagesvuonghhAinda não há avaliações

- Grounding & Bonding - The Foundation For Effective Electrical Protection PDFDocumento76 páginasGrounding & Bonding - The Foundation For Effective Electrical Protection PDFFabian Nina Aguirre100% (1)

- LLB IV Sem GST Unit I Levy and Collection Tax by DR Nisha SharmaDocumento7 páginasLLB IV Sem GST Unit I Levy and Collection Tax by DR Nisha Sharmad. CAinda não há avaliações

- Defence QuestionnaireDocumento2 páginasDefence QuestionnaireSumitt SinghAinda não há avaliações

- Copy - of - Commonlit - Meet The Fearless Cook Who Secretly Fed and Funded The Civil Rights Movement - StudentDocumento6 páginasCopy - of - Commonlit - Meet The Fearless Cook Who Secretly Fed and Funded The Civil Rights Movement - Studentlilywright08Ainda não há avaliações

- FloodDocumento9 páginasFloodapi-352767278Ainda não há avaliações

- T-61.246 Digital Signal Processing and Filtering T-61.246 Digitaalinen Signaalink Asittely Ja Suodatus Description of Example ProblemsDocumento35 páginasT-61.246 Digital Signal Processing and Filtering T-61.246 Digitaalinen Signaalink Asittely Ja Suodatus Description of Example ProblemsDoğukan TuranAinda não há avaliações

- Hung201 PDFDocumento14 páginasHung201 PDFMua Dong Tuyet RoiAinda não há avaliações

- MY-SDK-10000-EE-005 - Method Statement For Concrete Pole Installation - GVB Rev1Documento7 páginasMY-SDK-10000-EE-005 - Method Statement For Concrete Pole Installation - GVB Rev1Seeths NairAinda não há avaliações

- Atmosphere Study Guide 2013Documento4 páginasAtmosphere Study Guide 2013api-205313794Ainda não há avaliações

- CAKUTDocumento50 páginasCAKUTsantosh subediAinda não há avaliações

- Red Hat Ceph Storage-1.2.3-Ceph Configuration Guide-en-US PDFDocumento127 páginasRed Hat Ceph Storage-1.2.3-Ceph Configuration Guide-en-US PDFJony NguyễnAinda não há avaliações

- Poster@IcepeDocumento1 páginaPoster@IcepeAakash NawabAinda não há avaliações

- What Is A Timer?Documento12 páginasWhat Is A Timer?Hemraj Singh Rautela100% (1)

- 10.ULABs Presentation Camiguin FinalDocumento55 páginas10.ULABs Presentation Camiguin FinalKaren Feyt MallariAinda não há avaliações

- S L Dixon Fluid Mechanics and Thermodynamics of TurbomachineryDocumento4 páginasS L Dixon Fluid Mechanics and Thermodynamics of Turbomachinerykuma alemayehuAinda não há avaliações

- List of Every National School Walkout PDF LinksDocumento373 páginasList of Every National School Walkout PDF LinksStephanie Dube Dwilson100% (1)

- Generalised Ultimate Loads For Pile GroupsDocumento22 páginasGeneralised Ultimate Loads For Pile GroupsValerioAinda não há avaliações

- Med Error PaperDocumento4 páginasMed Error Paperapi-314062228100% (1)

- Making Sense of The Future of Libraries: Dan Dorner, Jennifer Campbell-Meier and Iva SetoDocumento14 páginasMaking Sense of The Future of Libraries: Dan Dorner, Jennifer Campbell-Meier and Iva SetoBiblioteca IICEAinda não há avaliações

- Topic 3 Module 2 Simple Annuity (Savings Annuity and Payout Annuity)Documento8 páginasTopic 3 Module 2 Simple Annuity (Savings Annuity and Payout Annuity)millerAinda não há avaliações

- WP05 - ACT 01 - Development 1909Documento53 páginasWP05 - ACT 01 - Development 1909ramesh9966Ainda não há avaliações