Escolar Documentos

Profissional Documentos

Cultura Documentos

Welding Calculation

Enviado por

MaqsoodDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Welding Calculation

Enviado por

MaqsoodDireitos autorais:

Formatos disponíveis

Weld Stress Calculations

http://www.roymech.co.uk/Useful_Tables/Form/Weld_strength.html[11/14/2013 10:13:55 AM]

Disclaimer: The information on this page has not been checked by an independent person. Use this information at your own risk.

ROYMECH

Clickarrowstopageadverts

These Pages include various standards. To confirm the status of any standard, identify the replacement standard if it is obsolete and/or

purchase the standard please use.

BSI Shop

It is also possible to become a BSI member and obtain copies of the Standards at much reduced prices.

Home

Formulae_Index

Nomenclature

Wel d St r engt h Cal c ul at i ons

Introduction.....RelevantStandards.....VariablesAssociatedWithWelds.....

GuidancePrinciples.....TableBasicWeldCalcs......AssessmentofFilletWelds.....

ExamplesofFilletWeldsCalcs.....PropertiesofFilletWeldsaslines.....

Exampleoftorsionweldcalc.usingvectors.....CapacitiesofFilletWelds.....DesignStrengthofFilletWelds.....

ImportantNote:ThenotesbelowgenerallyrelatetomethodsgenerallyprovidedinrelevanttextbooksandthetheBritishStandardBS5950.

TheEurocodeBSEN1993-8hassupersededthisstandard.. I believethatthemethodsandexamplesprovidedbelowaregenerallyinline

withthestandard.I haveprovidednotesonthislatestcodeStructural connections-welds. Thesenotesprovidesufficientinformationto

enablecorrectionstothemethodsprovidedbelow:Actions,Resistance,limitstatedesignetc.I shallmodifythispagebeforeJune2013to

identifythesefactorsindetail.

Introduction

Thefollowingnotesaregeneralguidancenotesshowingmethodsofcalculationofthestrengthandsizeofwelds.Weldedjointsare

oftencruciallyimportantaffectingthesafetyofthedesignsystems.Itisimportantthatthenotesanddatabelowareonlyusedfor

preliminarydesignevaluations.Finaldetaildesignshouldbecompletedinaformalwayusingappropriatecodesandstandardsand

qualityreferencedocuments

RelevantStandards

BS5950-1:2000..Structuraluseofsteelworkinbuilding.Codeofpracticefordesign.Rolledandweldedsections

BSEN10025-1:2004-Hotrolledproductsofstructuralsteels.General technicaldeliveryconditions

BSEN1993-1-8:2005-Eurocode3:Designofjoints..ReplacesBS449-2,BS4604-1,BS4604-2,BS5400-3andBS5950-1

Variablesrelatedtoweldedjoints

1. Strengthofdepositedweldmaterial

2. Typeofjointandweld..important

3. Sizeofweld..important

4. Locationofweldinrelationtopartsjoined..important

5. Typesofstresstowhichtheweldissubjected

6. Conditionsunderwhichweldiscarriedout

7. Typeofequipmentusedforwelding

8. Skillofwelder

Ecoscape Consultants

www.ecoscapeconsultants.com

Irrigation Designers, Consultants Landscape Artchitects

Weld Stress Calculations

http://www.roymech.co.uk/Useful_Tables/Form/Weld_strength.html[11/14/2013 10:13:55 AM]

GuidancePrinciples

Agenerousfactorofsafetyshouldbeused(3-5)andiffluctuatingloadsarepresentthenadditionaldesignmarginsshouldbeincluded

toallowforfatigue

Usetheminimumamountoffillermaterialconsistentwiththejobrequirement

Trytodesignjointsuchthatloadpathisnotnotthroughtheweld

Thetablebelowprovidesprovidesapproximatestressesin,hopefully,aconvenientway.

Forthedirectloadingcasethebuttweldstressesaretensile/compressive?

t

forthefilletweldsthestressesareassumedtobeshear

?

s

appliedtotheweldthroat.

Forbuttweldedjointssubjecttobendingthebuttweldstressesresultfromatensile/compressivestress?

b

andadirectshearstress?

s

.

Inthesecasesthedesignbasisstressshouldbe?

r

=Sqrt(?

b

2

+4?

s

2

)

ForFilletweldedjointssubjecttobendingthestressesinthefilletweldsareall shearstresses. Frombending?

b

andfromshear?

s

Inthesecasesthedesignbasisstressisgenerally?

r

=Sqrt(?

b

2

+?

s

2

)

Thestressesfromjointssubjecttotorsionloadingincludeshearstressfromtheappliedloadandshearstressesfromthetorque

loading.Theresultingstressesshouldbeaddedvectoriallytakingcaretochoosethelocationofthehigheststresses.

Tableofbracket weldsubjecttodirectandbendingstresses

MethodofLoading Weldment

Stressin

Weld

?

b

?

s

Weldsize

(h)

Weldment

StressinWeld

?

b

?

s

Weldsize(h)

Weldment

StressinWeld

?

b

?

s

Weldsize(h)

Weld Stress Calculations

http://www.roymech.co.uk/Useful_Tables/Form/Weld_strength.html[11/14/2013 10:13:55 AM]

AssessmentofFilletWeldGroupsrefnotesandtablePropertiesofFilletWeldsaslines

Importantnote:ThemethodsdescribedbelowisbasedonthesimplemethodofcalculationofweldstressasidentifiedinBS5950-

clause6.7.8.2. TheothermethodidentifedinBS5950-1clause6.7.8.3asthedirectionmethodusesthemethodofresolvingthe

forcestransmittedbyunitthicknessweldsperunitlengthintotraverseforces(F

T

)andlongitudinalforces(F

L

).I have,tosomeextent,

illustratedthismethodinmyexamplesbelow

Themethodofassessingfilletweldsgroupstreatingweldsaslinesisreasonablysafeandconservativeandisveryconvenienttouse.

a)Weldsubjecttobending....SeetablebelowfortypicalunitareasandunitMomentsofInertia

Afilletweldsubjecttobendingiseasilyassessedasfollows.

1)TheareaofthefilletweldA

u

..(unitthickness)iscalculatedassumingtheweldisoneunitthick..

2)The(unit)MomentofInertiaI

u

iscalculatedassumingtheweldisoneunitthick..

3)Themaximumshearstressduetobendingisdetermined...?

b

=M.y/I

u

4)Themaximumshearstressduetodirectshearisdetermined..?

s

=P/A

5)Theresultantstress?

r

=Sqrt(?

b

2

+?

s

2

)

6)Bycomparingthedesignstrengthp

w

withtheresultantstress?

r

thevalueoftheweldthroatthicknessiscalculatedandthenthe

weldsize.

i.e.ifthe?

r

/p

w

=5thenthethroatthickesst =5unitsandtheweldlegsizeh=1,414t

a)Weldsubjecttotorsion...SeetablebelowfortypicalunitareasandunitPolarmomentsofInertia

Afilletweldsubjecttotorsioniseasilyassessedasfollows.

1)TheareaofthefilletweldA

u

(unitthickness)iscalculatedassumingtheweldisoneunitthick

2)The(unit)PolarMomentofInertiaJ

u

iscalculatedassumingtheweldisoneunitthick..ThepolarmomentofinertiaJ=I

xx

+I

yy

3)Themaximumshearstressduetotorsionisdetermined...?

t

=T.r/J

u

4)Themaximumshearstressduetodirectshearisdetermined..?

s

=P/A

u

5)Theresultantstress?

r

isthevectorsumof?

t

and?

s

. rischosentogivethehighestvalueof?

r

6)Bycomparingthedesignstrengthp

w

withtheresultantstress?

r

thevalueoftheweldthroatthicknessiscalculatedandthenthe

weldsize.

i.e.ifthe?

r

/p

w

=5thenthethroatthickesst =5unitsandtheweldlegsizeh=1,414.t

Weld Stress Calculations

http://www.roymech.co.uk/Useful_Tables/Form/Weld_strength.html[11/14/2013 10:13:55 AM]

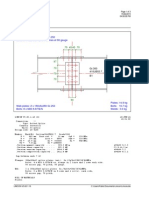

ExamplesofFilletWeldCalculations

Example of Weld in Torsion..

P =Applied load =10 000N

P

w

=Design Strength =220 N/mm

2

(Electrode E35 steel S275) Design Strength

b =120mm.

d =150 mm

x =b

2

/ 2(b+d) =27mm.. (From table below)

y =d

2

/ 2(b+d) =42mm..(From table below)

SimpleMethodasBS5950clause6.8.7.2

..The vector sum of the stresses due to forces and moments should

not exceed the design strength P

w

A

u

=Unit Throat Area

=(From table below) b +d =(120 +150) =270mm

2

To obtain radius of Force from weld centre of gravity

A =250-27 =223mm

Moment M =P.r =10000.223 =2,23.10

6

N.mm

J

u

=[(b+d)

4

- 6b

2

d

2

] /12 (b+d) =1,04.10

6

..(From Table)

It is necessary to locate the point subject to the highest shear

stress..For a weld subject to only torsion this would be simply at the

point furthest from the COG. However because the weld is subject to

torsion and direct shear the problem is more complicated. A normal

method of determining the stresses in these cases is to use vector

addition.

It is generally prudent to calculate the total shear stress at both

positions, using the method below, and select the highest.. For this

example the method used is to resolve the stresses in the x and y

directions

First considering point Z

Horizontal distance from centroid r

zh

=120-27=93mm

Vertical distance from centroid r

zv

=42mm

The vertical stress ?

v

=?

sv

+?

tv

?

sv

=P /A

u

=10000/270 =37 N/mm

2

?

tv

=M.r

zh

/J

u

=2,23.10

6

.93/1,04.10

6

=199 N/mm

2

?

v

=236,45 N/mm

2

The horizontal stress ?

h

=?

sh

+?

th

?

sh

=0

DirectionMethodasBS5950clause6.8.7.3

L =Length of weld 1 unit thick =

(From table below) b +d =(120 +150) =270mm

To obtain radius of Force from weld Centre of Gravity (Cog) .

A =250-27 =223mm

Moment M =P.r =10000.223 =2,23.10

6

N.mm

J

u

=Polar Moment of inertia for weld 1unit(mm) thick.

=[(b+d)

4

- 6b

2

d

2

] /12 (b+d) =1,04.10

6

mm

4

/mm..(From Table)

It is necessary to locate the point subject to the highest shear

stress..For a weld subject to only torsion this would be simply at the

point furthest from the COG. However because the weld is subject to

torsion and direct shear the problem is more complicated. A normal

method of determining the stresses in these cases is to use vector

addition.

It is generally prudent to calculate the total shear stress at both

positions, using the method below, and select the highest.. For this

example the method used is to resolve the stresses in the x and y

directions

First considering point Z

Horizontal distance from centroid r

zh

=120-27=93mm

Vertical distance from centroid r

zv

=42mm

The vertical force /mm run F

v

=F

sv

+F

tv

F

sv

=P /L =10000/270 =37 N/mm run

F

tv

=M.r

zh

/J

u

=2,23.10

6

.93/1,04.10

6

=199 N/mm run

F

v

=236,45 N/mm run

The horizontal force /mm run for unit(mm) weld width F

h

=F

sh

+F

th

F

sh

=0

F

th

=M.r

zv

/J

u

=2,23.10

6

.42/1,04.10

6

=90 N/mm run

F

h

=90 N/mm run

Weld Stress Calculations

http://www.roymech.co.uk/Useful_Tables/Form/Weld_strength.html[11/14/2013 10:13:55 AM]

?

th

=M.r

zv

/J

u

=2,23.10

6

.42/1,04.10

6

=90 N/mm

2

?

h

=90 N/mm

2

The resultant stress on the weld at z

?

r

=Sqrt (?

h

2

+?

v

2

) =253 N/mm

2

Now considering point w

Horizontal distance from centroid r

wh

=27mm

Vertical distance from centroid r

wv

=150-42=108mm

The vertical stress ?

v

=?

sv

- ?

tv

?

sv

=P /A

u

=10000/270 =37 N/mm

2

?

tv

=M.r

wh

/J

u

=2,23.10

6

.27/1,04.10

6

=57,9 N/mm

2

?

v

=20,86 N/mm

2

The horizontal stress ?

h

=?

sh

+?

th

?

sh

=0

?

th

=T.r

wv

/J

u

=2,23.10

6

.108/1,04.10

6

=231,6 N/mm

2

?

h

=231,6 N/mm

2

The resultant stress on the weld at w

?

r

=Sqrt (?

h

2

+?

v

2

) =232,5 N/mm

2

The maximum stress is similar but greatest at z ....

The design strength p

w

for the weld material is 220 N/mm

2

The weld throat thickness should be 253 /220 =1,15mm .

The weld size is therefore 1,414. 1,15 =1,62mm use 3mm fillet weld

The resultant force on the weld/mm run at z

F

r

=Sqrt (F

h

2

+F

v

2

) =253 N/mm run

Now considering point w

Horizontal distance from centroid r

wh

=27mm

Vertical distance from centroid r

wv

=150-42=108mm

The vertical forces per mm run F

v

=F

sv

- F

tv

F

sv

=P /L =10000/270 =37 N/mm run

F

tv

=M.r

wh

/J

u

=2,23.10

6

.27/1,04.10

6

=57,9 N/mm run

F

v

=20,86 N/mm run

The horizontal force /mm run =F

h

=F

sh

+F

th

F

sh

=0

F

th

=M.r

wv

/J

u

=2,23.10

6

.108/1,04.10

6

=231,6 N/mm run

F

h

=231,6 N/mm run

The specific force on the weld at w

F

r

=Sqrt (F

h

2

+F

v

2

) =232,5 N/mm run

The maximum specific is greatest at z =253 N/mm run....

Referring to weld capacities for longitudinal stresses P

L

for fillet welds

Capacities of Fillet Welds the weld capacity for a 3mm weld with and

E35 Electrode S275 Steel is 462N /mm run. This weld would be more

than sufficient.

Example of Weld in Bending..

P=30000 Newtons

d=100mm

b=75mm

y =50mm

Design Stress p

w

=220 N/mm

2

(Electrode E35 steel S275) Design Strength

Moment =M =30000*60=18.10

5

Nmm

SimpleMethodasBS5950clause6.8.7.2

Unit Weld Area =A

u

=2(d+b) =2(100+75) =350mm

2

Unit Moment of Inertia =I

u

=d

2

(3b+d) / 6 =100

2

(3.75 +100) / 6 =5,42.10

5

mm

4

DirectionMethodasBS5950clause6.8.7.3

Length of Weld of unit thickness =L =2(d+b) =2(100+75) =350mm

Moment of Inertia / mm throat thickness =I

u

/ mm

=d

2

(3b+d) / 6 =100

2

(3.75 +100) / 6 =5,42.10

5

mm

4

/ mm

Weld Stress Calculations

http://www.roymech.co.uk/Useful_Tables/Form/Weld_strength.html[11/14/2013 10:13:55 AM]

?

r

=Sqrt(?

s

2

+?

b

2

)

?

s

=P / A

u

=30000/350 =85,71 N/mm

2

?

b

=M.y / I

u

=18.10

5

. 50 / 5,42.10

5

=166,05 N/mm

2

?

r

=Sqrt(85,71

2

+166.05

2

) =186,86 N/mm

2

?

r

/ p

w

=186,86 / 220 =0,85 =Throat Thickness.....

( Throat thickness for ?<sub="">=220 N/mm

2

)

Leg Length =Throat thickness *1,414 =1,2mm use 3mm

weld thickness

Note : If a leg length h=1,2mm is used in the equations in

relevant part of the "Table of bracket weld subject to direct

and bending stresses" above a value of ?

b

=198 N/mm

and a value of ?

s

=100 N/mm

2

results with a resultant

stress of Sqrt (?

b

2

+?

s

2

) =222N/mm

2

..Which is in

general agreement with the above result

<>

F

r

=Resultant force per unit length of weld.

F

s

=Shear force per unit length of weld.

F

b

=Bending force per unit length of weld.

F

r

=Sqrt(F

s

2

+F

b

2

)

F

s

=P / L =30000/350 =85,71 N per mm length of weld

F

b

=M.y / I

u

=18.10

5

. 50 / 5,42.10

5

=166,05 N per mm length of weld

F

r

=Sqrt(85,71

2

+166.05

2

) =186,86 N per mm length of weld.

For this case for the welds under greatest loading the type of loading is

traverse loading. The bending stress is in line with horizontal element and the

shear stress is in line with vertical member.

The angle of the resulting specific load to the horizontal element

=arctan(85,71/166,5)=27,5

o

.

This is an angle with the weld throat ? =45

o

+27,5

o

=72,5

o

Referring to weld capacities table below.Weld Capacities K is calculated at

1,36 for this resultant direction of forces.

P

T

=a.K.p

w

for a E35 Weld electrode used with S275 steel

p

w

=220 N/mm

2

and therefore P

T

=a*300N/mm

2

..

A 3mm weld (a =2,1mm) therefore will therefore have a design capacity of

630 N/mm run and will easily be able to support the load of 186,86 N per mm

run

Propertiesofweldgroupswithweldstreatedaslines-

Itisacceptedthatitisreasonablyaccuratetousepropertiesbasedonunitweldthicknessincalculationtodeterminethestrengthof

weldsasshownintheexamplesonthispage.TheweldpropertiesI

xx

I

yy

andJareassumedtobeproportional totheweldthickness.

Thetypicalaccuracyofthismethodofcalculationisshownbelow...

Thisisillustratedinthetabledvaluesbelow

Weld Stress Calculations

http://www.roymech.co.uk/Useful_Tables/Form/Weld_strength.html[11/14/2013 10:13:55 AM]

d b h I

xx

I

yy

J =I

xx

+I

yy

Accurate 3 60 50 955080 108000 1063080

Simple 3 60 50 900000 108000 1008000

Error 6% 0 5%

Note:Theerroridentifiedwiththismethodislowerashincreasesrelativetod.Thiserrorissuchthattheresultingdesignsare

conservative.

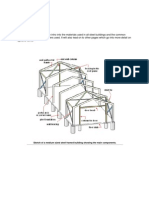

Exampleillustratinguseofstressvectors

Cal c ul at i on based on r eal w el d si zes

1)Theareaofthewelds

(basedonthroatweldthicknessat0,707.5=3,5mm)

Area=(57.3,5+2.55.3,5)=584,5mm

2

2)Themomentofareaaboutx-x=

MofArea=(57.3,5.3,5/2+2.55.3,5.(27.5+3,5))=12284mm

3

3)Thecentroidv=MomentofArea/Area

MofArea/ Area=21mm

4)Theradiir

A

, r

B

, r

C

&r

D

arecalculated..

r

A

=r

B

=Sqrt((58,5-21)^2+28,5^2)=47,1

r

C

=r

D

=Sqrt((21)^2+28,5^2)=35,40...

5)Theangles?

A

, ?

B

, ?

C

&?

D

arecalculated..

?

A

=?

B

=tan

-1

((58,5-21)/28,5)=52,7

o

?

C

=?

D

=tan

-1

((21)/28,5)=36,4

o

...

6)Thedirectshearstressonthearea=Force/Area

?

S

=5000/584=8,56N/mm

2

7)TheMomentontheweldgroup=Force.Distancetocentroid

M=5000.(100+21)=6,05.10

5

Nmm

8)Thepolarmomentofinertiaoftheweldgroup=J=I

xx

+I

yy

I

yy

=2.[55.3,5

3

/12+3,5.55.(50/2+3,5/2)

2

]

+57

3

.3,5/12=3,3.10

5

mm

4

I

xx

=2.[55

3

.3,5/12+3,5.55.(55/2+3,5-21)

2

]

+3,5

3

57/ 12+3,5.57.(21-3,5/2)

2

=2,097.10

5

mm

4

J=I

xx

+I

yy

=5,4.10

5

mm

4

9)Thestressduetotorsion

Cal c ul at i ons based on uni t val ues

This calculation uses equations from table below

for Area, centroid, and J

u

1)Areaofweld=0,707.5.(2b+d)

Area=0,707.5.(2.55+50)=565.6mm

2

2)ThereisnoneedtocalculatetheMomentofAreawiththismethod

3)Thecentroidv=b

2

/(2b+d)

v=55

2

/(2.55+50)=18,9mm

4)Theradiir

A

, r

B

, r

C

&r

D

arecalculated..

r

A

=r

B

=Sqrt((55-18,9)^2+25^2)=43,9

r

C

=r

D

=Sqrt(18,9^2+25^2)=31,34

5)Theangles?

A

, ?

B

, ?

C

&?

D

arecalculated..

?

A

=?

B

=tan

-1

((55-18,9)/25)=55,29

o

?

C

=?

D

=tan

-1

((18,9)/25)=37

o

...

6)Thedirectshearstressonthearea=Force/Area

?

S

=5000/565,5=8,84N/mm

2

7)TheMomentontheweldgroup=Force.distancetocentroid

M=5000.(100+18,9)=5.94.10

5

Nmm

8)TheUnitPolarmomentofinertiaoftheweldgroup=

J

u

=0.707.5.(8.b

3

+6bd

2

+d

3

)/12+b

4

/(2b+d)

J

u

=0,707.5.(8.55

3

+6.55.50

2

+50

3

)/12-55

3

/(2.55+50)=4,69.10

5

9)Thestressduetotorsion

?

TA

=?

TB

=M.r

A

/J..and..?

TC

=?

TD

=M.r

C

/J

Weld Stress Calculations

http://www.roymech.co.uk/Useful_Tables/Form/Weld_strength.html[11/14/2013 10:13:55 AM]

?

TA

=?

TB

=M.r

A

/J..and..?

TC

=?

TD

=M.r

C

/J

?

TA

=6.05

5

Nmm.47,1mm/ 5,4.10

5

mm

4

=52,8N/mm

2

?

TC

=?

TD

=6.05

5

Nmm.35,4mm/ 5,4.10

5

mm

4

=39,70N/mm

2

10)Theresultantstresses?

RA

, =?

RB

and?

RA

, =?

RB

areobtainedbyaddingthestressvectosgraphicallyasshownbelow

?

RA

=?

RB

=46,29N/mm

2

?

RC

=?

RD

==45,31N/mm

2

?

TA

=5,94.10

5

Nmm.43,9mm/ 4,69.10

5

mm

4

=55,6N/mm

2

?

TC

=?

TD

=5,94

5

Nmm.31,34mm/ 4,69.10

5

mm

4

=39,69N/mm

2

10)Theresultantstresses?

RA

, =?

RB

and?

RA

, =?

RB

areobtainedbyaddingthestressvectosgraphicallyasshownbelow

?

RA

=?

RB

=48,59N/mm

2

?

RC

=?

RD

=45,56N/mm

2

Note:Theexampleabovesimplyillustratesthevectormethodaddingdirectandtorsionalshearstressesandcomparesthedifference

inusingtheunitweldwidthmethodandusingrealweldsizes.Theexamplecalculatesthestresslevelsinanexistingweldgroupitis

clearthattheweldisoversizedfortheloadingscenario.Thedifferenceintheresultingvaluesareinlessthan4%.Iftheweldswere

smalleri.e3mmthenthedifferenceswouldbeevensmaller.

Tablepropertiesofarangeoffilletweldgroupswithweldstreatedaslines-

Weld

ThroatArea

UnitArea

LocationofCOG

x

y

I

xx

-(unit)

J-(Unit)

-

Weld Stress Calculations

http://www.roymech.co.uk/Useful_Tables/Form/Weld_strength.html[11/14/2013 10:13:55 AM]

-

TableOfWeldCapacities

Thefilletweldcapacitytablesrelatedtothetypeofloadingontheweld.Twotypesofloadingareidentifiedtraverseloadingand

longitudinalloadingasshowbelow

Theweldloadingshouldbesuchthat

{(F

L

/P

L

)

2

+(F

T

/P

T

)

2

}?1

ThefollowingtableisinaccordwithdatainBS5950part1.Basedondesignstrengthsasshownintablebelow...DesignStrength

P

L

=a.p

w

P

T

=a.K.p

w

a=weldthroatsize.

K=1,25v(1,5/ (1+Cos

2

?)

P

T

basedonelementstransmittingforcesat90

o

i.e?=45

o

andK=1,25

WeldCapacityE35ElectrodeS275Steel WeldCapacityE42ElectrodeS355Steel

Leg

Length

Throat

Thickness

Longitudinal

Capacity

Transverse

Capacity Leg

Length

Throat

Thickness

Longitudinal

Capacity

Transverse

Capacity

P

L

(kN/mm) P

T

(kN/mm) P

L

P

T

mm mm kN/mm kN/mm mm mm kN/mm kN/mm

3 2,1 0,462 0,577 3 2,1 0,525 0,656

4 2,8 0,616 0,720 4 2,8 0,700 0,875

Weld Stress Calculations

http://www.roymech.co.uk/Useful_Tables/Form/Weld_strength.html[11/14/2013 10:13:55 AM]

5 3,5 0,770 0,963 5 3,5 0,875 1,094

6 4,2 0,924 1,155 6 4,2 1,050 1,312

8 5,6 1,232 1,540 8 5,6 1,400 1,750

10 7,0 1,540 1,925 10 7,0 1,750 2,188

12 8,4 1,848 2,310 12 8,4 2,100 2,625

15 10,5 2,310 2,888 15 10,5 2,625 3,281

18 12,6 2,772 3,465 18 12,6 3,150 3,938

20 14,0 3,08 3,850 20 14,0 3,500 4,375

22 15,4 3,388 4,235 22 15,4 3,850 4,813

25 17,5 3,850 4,813 25 17,5 4,375 5,469

DesignStrengthp

w

offilletwelds

Electrodeclassification

Steel Grade

35 43 50

N/mm

2

N/mm

2

N/mm

2

S275 220 220 220

S355 220 250 250

S460 220 250 280

Usef ul Rel at ed Li nk s

1. Gowelding..ARealFind..thissitehaslotsofInformationoncalculatingthestrengthofWelds

2. WeldDesignNotes..Asetofexcellentdesignnotes

ThisPageisbeingdeveloped

Home

Formulae_Index

Nomenclature

SendCommentstoRoyBeardmore

LastUpdated17/02/2013

Pipe Welding

Stress

Weld On

Você também pode gostar

- DesignManualAUGUST2014 Watermarked PDFDocumento35 páginasDesignManualAUGUST2014 Watermarked PDFAbdelaziz BrakhliaAinda não há avaliações

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNo EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityAinda não há avaliações

- Bolt Design For Steel Connections As Per AISCDocumento24 páginasBolt Design For Steel Connections As Per AISCDjordjeDj100% (1)

- AE21!06!01 - Steel Grating Load Class-D400Documento40 páginasAE21!06!01 - Steel Grating Load Class-D400nithya sudheeshAinda não há avaliações

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsAinda não há avaliações

- FEA-DM-ST-2020-SB01 Rev 2 ReviseDocumento13 páginasFEA-DM-ST-2020-SB01 Rev 2 ReviseMohd Azali IshakAinda não há avaliações

- Offshore construction Complete Self-Assessment GuideNo EverandOffshore construction Complete Self-Assessment GuideAinda não há avaliações

- Study & Analysis of Transportation SkidDocumento10 páginasStudy & Analysis of Transportation SkidJay PAinda não há avaliações

- V Q 0.0473 X 10 K K K V I: Calculation of Wind Load As Per SBC 301-2007 (Chapter 6)Documento2 páginasV Q 0.0473 X 10 K K K V I: Calculation of Wind Load As Per SBC 301-2007 (Chapter 6)SuvankarAinda não há avaliações

- How Do You Calculate Chequered Plate WeightDocumento2 páginasHow Do You Calculate Chequered Plate Weightssr11700% (1)

- Imp Design GuideDocumento32 páginasImp Design GuideRahulAinda não há avaliações

- Calculation Software of WeldingDocumento1 páginaCalculation Software of WeldinghaharameshAinda não há avaliações

- Cural Steel Material Takeoff ChecklistDocumento2 páginasCural Steel Material Takeoff ChecklistbillAinda não há avaliações

- Zamil PEB BrochureDocumento40 páginasZamil PEB BrochureAlbert Ericson DelfinoAinda não há avaliações

- ComFlor Manual October08 CorusDocumento72 páginasComFlor Manual October08 CorusevilaigilAinda não há avaliações

- Fillet Weld Strength (AISC)Documento8 páginasFillet Weld Strength (AISC)shadab521Ainda não há avaliações

- Structural Analysis of Pipe Rack Structures - FinalDocumento205 páginasStructural Analysis of Pipe Rack Structures - FinalJasna Trifković MešićAinda não há avaliações

- AEFAC Anchor DesignDocumento56 páginasAEFAC Anchor DesignNickAinda não há avaliações

- Seafastening For Pelikan - 12mm Thickness PlateDocumento12 páginasSeafastening For Pelikan - 12mm Thickness PlateHafidAinda não há avaliações

- NSTS-08307 (Criteria For Preloaded Bolts)Documento38 páginasNSTS-08307 (Criteria For Preloaded Bolts)ffontanaAinda não há avaliações

- ASte Purlins MLDocumento56 páginasASte Purlins MLzgroupro100% (1)

- Structural CalculationsDocumento112 páginasStructural Calculationsmechpandian100% (1)

- X388allegato1 2X Offshore Cranes BDocumento15 páginasX388allegato1 2X Offshore Cranes BMostafa BatourAinda não há avaliações

- Shipping G Force Memorandum DocumentDocumento24 páginasShipping G Force Memorandum Documentscribduser9999Ainda não há avaliações

- Circular WeldDocumento12 páginasCircular WeldJohn Paul UmaliAinda não há avaliações

- Remark Calculation Sheet: Pipe PropertiesDocumento4 páginasRemark Calculation Sheet: Pipe Propertiesmoseslugtu6324Ainda não há avaliações

- Weigh BridgeDocumento1 páginaWeigh BridgeMdnor RahimAinda não há avaliações

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 13Documento1 páginaASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 13Anonymous 0x2pwMCWgjAinda não há avaliações

- Seismic DesignDocumento74 páginasSeismic DesignnathychidazAinda não há avaliações

- 1990 - 03 - Mar - Design of Tower Foundations-NS and VasanthiDocumento7 páginas1990 - 03 - Mar - Design of Tower Foundations-NS and VasanthierjuniorsanjipAinda não há avaliações

- 8c4e1df9481dcc6b372d92439770bfcbDocumento63 páginas8c4e1df9481dcc6b372d92439770bfcbWansyah Putra SiregarAinda não há avaliações

- Kirby Erection ManualDocumento42 páginasKirby Erection ManualAburvaraj100% (1)

- Anchor Design HILTIDocumento14 páginasAnchor Design HILTIRohit GadekarAinda não há avaliações

- Rev - Office Proposal - 6.11.2014-ModelDocumento1 páginaRev - Office Proposal - 6.11.2014-ModelChandra ShekarAinda não há avaliações

- 3.1 - General Principles of Dynamic DesignDocumento36 páginas3.1 - General Principles of Dynamic DesignKevin OzAinda não há avaliações

- Welders Visual Inspection Handbook-2013 WEB PDFDocumento77 páginasWelders Visual Inspection Handbook-2013 WEB PDFketanAinda não há avaliações

- Pad Eye DesignFDocumento8 páginasPad Eye DesignFRajasekar MeghanadhAinda não há avaliações

- Capacity of Bolts in Bearing Connection Based On AISC-ASD 9th EditionDocumento1 páginaCapacity of Bolts in Bearing Connection Based On AISC-ASD 9th EditionThiha KyawAinda não há avaliações

- Temporary StructuresDocumento65 páginasTemporary StructuresnisfibolahenkAinda não há avaliações

- Spreadsheets To BS 8110: Carrefour PC 2Documento48 páginasSpreadsheets To BS 8110: Carrefour PC 2orode franklynAinda não há avaliações

- Lifting Lug Stress AnalysisDocumento10 páginasLifting Lug Stress AnalysisChaitanya Sai TAinda não há avaliações

- Anchor BoltDocumento4 páginasAnchor BoltAhmed Shaban0% (1)

- S 000 5310 001 (Structual)Documento33 páginasS 000 5310 001 (Structual)Midhun K ChandraboseAinda não há avaliações

- European Codes - Steel Design To Eurocode 3 (EN 1993-1-1:2005)Documento7 páginasEuropean Codes - Steel Design To Eurocode 3 (EN 1993-1-1:2005)Chong Ting Sheng100% (1)

- Limcon SpliceDocumento3 páginasLimcon SpliceconorkellysligoAinda não há avaliações

- POS CAL TP No10 Vb2 C200x80x7 - 5 CVR Bolt R0 20180731Documento26 páginasPOS CAL TP No10 Vb2 C200x80x7 - 5 CVR Bolt R0 20180731Nguyễn Duy QuangAinda não há avaliações

- Beam FLexureDocumento4 páginasBeam FLexureNikitaBhattaraiAcharyaAinda não há avaliações

- Mezz Portal 10 StoriesDocumento4 páginasMezz Portal 10 StoriesthiệnAinda não há avaliações

- HE-A Steel BeamsDocumento2 páginasHE-A Steel BeamsAbdul BasitAinda não há avaliações

- Bill of Material, Gas Injection Header, LBDPDocumento2 páginasBill of Material, Gas Injection Header, LBDPSoumya KumarAinda não há avaliações

- Rak Surge Vessel FoundationDocumento11 páginasRak Surge Vessel Foundationlayaljamal2Ainda não há avaliações

- Example 2a: All-Round Fillet Weld Connection Between I Beam and Plate (Simple)Documento6 páginasExample 2a: All-Round Fillet Weld Connection Between I Beam and Plate (Simple)Imran SaikatAinda não há avaliações

- Design of Lifting LugsDocumento3 páginasDesign of Lifting LugsSaravan KumarAinda não há avaliações

- Shear Strength of High-Strength BoltsDocumento61 páginasShear Strength of High-Strength Boltsloox600Ainda não há avaliações

- N F N A: Input Data & Design SummaryDocumento9 páginasN F N A: Input Data & Design SummaryOswaldo SuárezAinda não há avaliações

- Single V Butt Weld With Both Plates Prepped at Same Angle: Select ProcessDocumento1 páginaSingle V Butt Weld With Both Plates Prepped at Same Angle: Select ProcessKiukStaksAinda não há avaliações

- Beam Column ConnectionDocumento2 páginasBeam Column ConnectionHAZIRACFS SURATAinda não há avaliações

- Structural Steel Design Project: Calculation SheetDocumento14 páginasStructural Steel Design Project: Calculation SheetJoey Johnson100% (2)

- Design Guide For Metal Roofing and Cladding To Comply With Energy Requirements of Uk Building REGULATIONS (2006)Documento36 páginasDesign Guide For Metal Roofing and Cladding To Comply With Energy Requirements of Uk Building REGULATIONS (2006)MaqsoodAinda não há avaliações

- Pad Footing Analysis & Design (BS8110)Documento6 páginasPad Footing Analysis & Design (BS8110)Maqsood100% (1)

- Strength of Materials - Quick ReviewDocumento7 páginasStrength of Materials - Quick ReviewMaqsood100% (2)

- Design Guide For Metal Roofing and Cladding To Comply With Energy Requirements of Uk Building REGULATIONS (2006)Documento36 páginasDesign Guide For Metal Roofing and Cladding To Comply With Energy Requirements of Uk Building REGULATIONS (2006)MaqsoodAinda não há avaliações

- SSB04 Detailed Design of Portal Frames 2010-05-24 PDFDocumento135 páginasSSB04 Detailed Design of Portal Frames 2010-05-24 PDFSebastian PopAinda não há avaliações

- Spiral StaircasesDocumento16 páginasSpiral Staircasesvrajan1988100% (1)

- BS5950 Load CasesDocumento46 páginasBS5950 Load CasesthespecifierAinda não há avaliações

- Structural Steel Construction ManualDocumento23 páginasStructural Steel Construction ManualMaqsoodAinda não há avaliações

- Steel Sheds IntroductionDocumento9 páginasSteel Sheds IntroductionMaqsood100% (1)

- Design of Beams in Structural SteelDocumento15 páginasDesign of Beams in Structural SteelMaqsood92% (13)

- Structural Steel Engineering Basic ConceptsDocumento40 páginasStructural Steel Engineering Basic ConceptsMaqsood100% (17)

- Physics Grade 10Documento228 páginasPhysics Grade 10Jan92% (26)

- Shear and Moment in Beams CH No 4Documento48 páginasShear and Moment in Beams CH No 4Maqsood86% (7)

- Design of Columns and Struts in Structural SteelDocumento20 páginasDesign of Columns and Struts in Structural SteelMaqsood83% (18)

- Design of Beams in Structural SteelDocumento15 páginasDesign of Beams in Structural SteelMaqsood92% (13)

- 40 Item Test Science 6with Key To CorrectionDocumento5 páginas40 Item Test Science 6with Key To CorrectionvinnAinda não há avaliações

- IntegralDocumento4 páginasIntegralprasenjitsayantanAinda não há avaliações

- HTR India - Products - Current Sense Resistors - Ceramic Encased Resistor - BR (English)Documento4 páginasHTR India - Products - Current Sense Resistors - Ceramic Encased Resistor - BR (English)crplzAinda não há avaliações

- HS-C0964SA3 / HS-C1264SA4 HS-C1865SA4 / HS-C2465SA1: FeaturesDocumento1 páginaHS-C0964SA3 / HS-C1264SA4 HS-C1865SA4 / HS-C2465SA1: FeaturesklseklseAinda não há avaliações

- Difference Between Bonding in Ceramics and MetalsDocumento2 páginasDifference Between Bonding in Ceramics and MetalsQamarShafiqAinda não há avaliações

- Hydrcolloids 2Documento24 páginasHydrcolloids 2nakshatra1714Ainda não há avaliações

- ASTM Casting MaterialsDocumento1 páginaASTM Casting Materialschy_81Ainda não há avaliações

- PAB 3053 Project 2Documento9 páginasPAB 3053 Project 2Fierdaus Zaharin100% (1)

- Toxic Run ExportDocumento3 páginasToxic Run ExportOH CHEN XI MoeAinda não há avaliações

- What Is Atmospheric PressureDocumento10 páginasWhat Is Atmospheric Pressurenidyashree100% (1)

- Ahsanullah University of Science and TechnologyDocumento60 páginasAhsanullah University of Science and TechnologyazwarAinda não há avaliações

- Influence of Blanching On Antioxidant, Nutritional and Physical Properties of Bamboo ShootDocumento11 páginasInfluence of Blanching On Antioxidant, Nutritional and Physical Properties of Bamboo ShootSharin Julia Krista SuniAinda não há avaliações

- Tempering MartensiteDocumento21 páginasTempering Martensitejardel de matosAinda não há avaliações

- NDT1 220K Ultrasonic TransducerDocumento4 páginasNDT1 220K Ultrasonic TransducerJose Miguel Madrid ReinaAinda não há avaliações

- Flotation Frother Mixtures - Decoupling The Sub-Processes of Froth Stability, Froth Recovery and EntrainmentDocumento8 páginasFlotation Frother Mixtures - Decoupling The Sub-Processes of Froth Stability, Froth Recovery and EntrainmentJose Luis Barrientos RiosAinda não há avaliações

- Des Case PML Manual DigitalDocumento195 páginasDes Case PML Manual DigitalFraz Ahmad0% (1)

- Sci Oly Practice QuestionsDocumento5 páginasSci Oly Practice QuestionsJessica JimenezAinda não há avaliações

- Stilling BasinDocumento5 páginasStilling Basinale hopeju2009100% (1)

- AIIMS 2019 Chemistry Sample Question PaperDocumento10 páginasAIIMS 2019 Chemistry Sample Question PapermisostudyAinda não há avaliações

- Chemistry Investigatory Project: Study The Change in E.M.F of A Daniel CellDocumento20 páginasChemistry Investigatory Project: Study The Change in E.M.F of A Daniel CellrahuhlAinda não há avaliações

- Hyundai Welding Co., LTDDocumento4 páginasHyundai Welding Co., LTDGerry Dan ChanliongcoAinda não há avaliações

- ALS Recommended Holding Times and Preservations For WatersDocumento3 páginasALS Recommended Holding Times and Preservations For WatersasdfAinda não há avaliações

- Pile Capacity PrecastDocumento38 páginasPile Capacity Precastbasum matAinda não há avaliações

- Test Panel Preparation Method No. 1: SSPC: The Society For Protective CoatingsDocumento2 páginasTest Panel Preparation Method No. 1: SSPC: The Society For Protective CoatingsRinush SinagaAinda não há avaliações

- ColaTeric CBSDocumento1 páginaColaTeric CBSmndmattAinda não há avaliações

- Crystal Growth TechnologyDocumento8 páginasCrystal Growth TechnologyEtienne HouleAinda não há avaliações

- Biology Peka Sharifah Nadia Binti Syed Muhammad Naquib 4 Saidina Abu Bakar Activity 6.1 Determining The Energy Value in Food SamplesDocumento4 páginasBiology Peka Sharifah Nadia Binti Syed Muhammad Naquib 4 Saidina Abu Bakar Activity 6.1 Determining The Energy Value in Food SamplesNadia AldrsAinda não há avaliações

- DT Series Digital TachometerDocumento3 páginasDT Series Digital TachometerMamani JesusAinda não há avaliações

- Tutorial On Scale UpDocumento18 páginasTutorial On Scale Uphafizi naim IsmailAinda não há avaliações

- Lead Acid vs. Lithium-Ion Battery ComparisonDocumento5 páginasLead Acid vs. Lithium-Ion Battery ComparisonRasbihari SharmaAinda não há avaliações

- Arizona, Utah & New Mexico: A Guide to the State & National ParksNo EverandArizona, Utah & New Mexico: A Guide to the State & National ParksNota: 4 de 5 estrelas4/5 (1)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensNo EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensAinda não há avaliações

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoNo EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoNota: 5 de 5 estrelas5/5 (1)

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptNo EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptNota: 5 de 5 estrelas5/5 (1)

- New York & New Jersey: A Guide to the State & National ParksNo EverandNew York & New Jersey: A Guide to the State & National ParksAinda não há avaliações