Escolar Documentos

Profissional Documentos

Cultura Documentos

Profibus Master: User Manual For The

Enviado por

Vander SiqueiraDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Profibus Master: User Manual For The

Enviado por

Vander SiqueiraDireitos autorais:

Formatos disponíveis

User Manual for the

HE693PBM100

PROFIBUS MASTER

22 June 2000

MAN0001-02

MAN0001-02 22 JUN 2000 PAGE 3

PREFACE

PREFACE

This manual explains how to use the Horner APGs Profibus Master Module (HE693PBM100).

Copyright (C) 2000 Horner APG, LLC., 640 North Sherman Drive, Indianapolis, Indiana 46201. All rights

reserved. No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval

system, or translated into any language or computer language, in any form by any means, electronic,

mechanical, magnetic, optical, chemical, manual or otherwise, without the prior agreement and written

permission of Horner APG, Inc.

All software described in this document or media is also copyrighted material subject to the terms and

conditions of the Horner Software License Agreement.

Information in this document is subject to change without notice and does not represent a commitment on

the part of Horner APG, Inc.

Profibus is a trademark of Siemens.

Series 90-30 PLC are trademarks of GE Fanuc.

Alspa 8000 and P8 are trademarks of CEGELEC.

For user manual updates, contact Horner APG, Technical Support

Division, at (317) 916-4274 or visit our web site at www.heapg.com.

PAGE 4 22 JUN 2000 MAN0001-02

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Horner APG, LLC. (HE-APG) warrants to the original purchaser that the HE693PBM100 Profibus Master

manufactured by HE-APG is free from defects in material and workmanship under normal use and

service. The obligation of HE-APG under this warranty shall be limited to the repair or exchange of any

part or parts which may prove defective under normal use and service within two (2) years from the date

of manufacture or eighteen (18) months from the date of installation by the original purchaser whichever

occurs first, such defect to be disclosed to the satisfaction of HE-APG after examination by HE-APG of

the allegedly defective part or parts. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER

WARRANTIES EXPRESSED OR IMPLIED INCLUDING THE WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR USE AND OF ALL OTHER OBLIGATIONS OR LIABILITIES AND HE NEITHER

ASSUMES, NOR AUTHORIZES ANY OTHER PERSON TO ASSUME FOR HE-APG, ANY OTHER

LIABILITY IN CONNECTION WITH THE SALE OF THIS HE693PBM100. THIS WARRANTY SHALL

NOT APPLY TO THIS HE693PBM100 OR ANY PART THEREOF WHICH HAS BEEN SUBJECT TO

ACCIDENT, NEGLIGENCE, ALTERATION, ABUSE, OR MISUSE. HE-APG MAKES NO WARRANTY

WHATSOEVER IN RESPECT TO ACCESSORIES OR PARTS NOT SUPPLIED BY HE-APG. THE

TERM "ORIGINAL PURCHASER", AS USED IN THIS WARRANTY, SHALL BE DEEMED TO MEAN

THAT PERSON FOR WHOM THE HE693PBM100 IS ORIGINALLY INSTALLED. THIS WARRANTY

SHALL APPLY ONLY WITHIN THE BOUNDARIES OF THE CONTINENTAL UNITED STATES.

In no event, whether as a result of breach of contract, warranty, tort (including negligence) or otherwise,

shall HE-APG or its suppliers be liable of any special, consequential, incidental or penal damages

including, but not limited to, loss of profit or revenues, loss of use of the products or any associated

equipment, damage to associated equipment, cost of capital, cost of substitute products, facilities,

services or replacement power, down time costs, or claims of original purchaser's customers for such

damages.

To obtain warranty service, return the product to your distributor with a description of the

problem, proof of purchase, post paid, insured and in a suitable package.

ABOUT PROGRAMMING EXAMPLES

Any example programs and program segments in this manual or provided on accompanying diskettes are

included solely for illustrative purposes. Due to the many variables and requirements associated with any

particular installation, Horner APG cannot assume responsibility or liability for actual use based on the

examples and diagrams. It is the sole responsibility of the system designer utilizing the HE693PBM100 to

appropriately design the end system, to appropriately integrate the HE693PBM100 and to make safety

provisions for the end equipment as is usual and customary in industrial applications as defined in any

codes or standards which apply.

Note: The programming examples shown in this manual are for illustrative

purposes only. Proper machine operation is the sole responsibility

of the system integrator.

MAN0001-02 22 JUN 2000 PAGE 5

PREFACE

TABLE OF CONTENTS

CHAPTER 1: INTRODUCTION................................................................................................................7

1.1 Product Description................................................................................................................... 7

1.1.1 General ................................................................................................................................. 7

1.1.2 Pseudo Slave Feature of the HE693PBM100 ...................................................................... 7

1.2 Profibus Overview..................................................................................................................... 7

1.3 System Requirements: .............................................................................................................. 8

1.4 Physical Layout of HE693PBM100: ........................................................................................... 8

CHAPTER 2: INSTALLATION..................................................................................................................9

2.1 Mounting Requirements ............................................................................................................ 9

2.2 Profibus DP Connector.............................................................................................................. 9

2.3 RS-232 Connector .................................................................................................................... 9

2.4 LED Operation of HE693PBM100: ...........................................................................................10

2.5 PBM101 Status Error/Reporting ...............................................................................................11

2.5.1 PLC Status Bit Definition ......................................................................................................11

CHAPTER 3: CONFIGURATION...........................................................................................................13

3.1 Configuring the HE693PBM100................................................................................................13

CHAPTER 4: WIRING DIAGRAMS........................................................................................................19

4.1 Profibus Wiring:........................................................................................................................19

4.2 Other considerations when wiring the Profibus network: ...........................................................20

4.3 Recommended Part numbers:..................................................................................................21

APPENDIX A: IMPLEMENTATION OF THE HE693PBM100 PSEUDO SLAVE...................................23

1.1 General....................................................................................................................................23

2.1 Pseudo Slave Description......................................................................................................23

3.1 Adding the Pseudo Slave to the Cimplicity Control Configuration............................................23

4.1 Accessing Additional Functions of the HE693PBM100..............................................................24

4.1.1 SYNC/FREEZE Control ........................................................................................................24

4.1.2 Slave Status .........................................................................................................................25

4.1.3 Master Firmware Version......................................................................................................25

PAGE 6 22 JUN 2000 MAN0001-02

NOTES

MAN0001-02 22 JUN 2000 PAGE 7

CH. 1

CHAPTER 1: INTRODUCTION

1.1 Product Description

1.1.1 General

Horner APGs Profibus Master Module (HE693PBM100) functions as a Profibus DP network master

capable of controlling up to 64 slave devices. The Profibus DP application allows for the connection of

I/O devices and simple field devices to an automation system via a Profibus network. Emphasis is on

fast transmission of small data volumes. The HE693PBM100 operates as Profibus DP module only

and does not support other types of Profibus (FMS, PA).

Profibus uses a Master-Slave type of communication with the HE693PBM100 functioning as the

master device. The HE693PBM100 communicates with slave devices such as input/output devices,

drives, valves, and measuring transmitters via a Profibus network. The HE693PBM100 (when used

with HE Profibus Slave Modules) also allows communication between modules located in different

PLC racks via the Profibus network. (For information covering HE-APG Slave Modules, see the User

Manuals for the HE693PBS105 and the HE693PBM106.)

1.1.2 Pseudo Slave Feature of the HE693PBM100

The Pseudo Slave feature of the HE693PBM100 enables users to access three additional functions

that are not available using the normal configuration procedure in Chapter 3. If the functions are

desired, users must perform additional configuration procedures as indicated in Appendix A.

The Pseudo Slave is neither a physical device nor is it true slave device. The Pseudo Slave

is simply a part of the software which allows the HE693PBM100 to access specific information from a

PLC, and thus, provides the additional functions. Appendix B covers the following functions in more

detail.

a. SYNC/FREEZE Control Allows the Logic to control the data flow to and from the inputs and

outputs of the slaves.

b. Additional slave system diagnosis status information

c. Firmware Release information

1.2 Profibus Overview

Profibus, a token-passing network, supports one master controlling the network and writing to the

slave devices. Multiple masters, however, can read information simultaneously off the Profibus

network. Master devices (HE693PBM100) are used to determine the data communication on the bus.

Slave devices are peripherals such as input/output devices, valves, drives, and measuring

transmitters, etc. Slaves devices also include HE-APG Profibus Slave Modules located in PLCs that

the HE693PBM100 reads or writes to over the Profibus network. Slaves do not have bus access rights

and can only acknowledge received messages or send messages to the master when requested to do

so. Data from the slave devices can be read by any master. All connected Slaves have the same

priority.

Up to 32 devices (masters or slaves) can be connected in one segment without using repeaters or up

to 64 devices can be connected using repeaters.

For further information, refer to the following web site: http:\\www.profibus.com.

PAGE 8 22 JUN 2000 MAN0001-03

CH. 1

1.3 System Requirements:

Important requirement information:

a. The HE693PBM100 requires a CPU351 (or higher) with Firmware Version 8.0 (or better).

b. CIMPLICITY Control Version 2.0 or higher is required to configure the modules.

c. Logicmaster software and earlier versions of CPU Firmware can NOT support these

modules.

1.4 Physical Layout of HE693PBM100:

Figure 1.1 - Front Cover Figure 1.2 Side View

H693PBM100

PROFIBUS DP

OK

RUN

PWR

P

R

O

F

I

B

U

S

D

P

P

O

R

T

R

S

-

2

3

2

S

E

R

V

I

C

E

P

O

R

T

PROFIBUS DP

MASTER

MAN0001-02 22 JUN 2000 PAGE 9

CH. 2

CHAPTER 2: INSTALLATION

2.1 Mounting Requirements

The HE693PBM100 Module is designed to plug into any Series 90-30 local slot. The

HE693PBM100 requires at least a CPU351 model or higher with Firmware Revision 8. The

HE693PBM100 will not operate correctly with a lower version Firmware. Please refer to the 90-

30 Installation manual (GFK-0356E) for information on installing the module.

2.2 Profibus DP Connector

The 9-pin Profibus DP connector is for physical connection between the slaves and the master.

For further information on the cable and connectors, see Chapter 4 in this manual.

2.3 RS-232 Connector

The RS-232 Service Port is used to upgrade the firmware specific to the slave. This port uses a

standard RS-232 9-pin connector.

5

4

3

2

1

9

8

7

6

RI

DTR

RTS

RXD

CTS

TXD

DSR

DCD

Figure 2.1- Pin-out for the RS-232

PAGE 10 22 JUN 2000 MAN0001-02

CH. 2

2.4 LED Operation of HE693PBM100:

There are three visible LEDs on the HE693PBM100, the OK LED, RUN LED, and the POWER

LED. Various combinations of these LEDs will indicate different states of the master. See Table

2.1 for the states indicated by the LEDs. Table 2.2 indicates fault conditions.

Table 2.1 LED Operation

OK LED RUN LED POWER LED Meaning

Off Off Off Module not receiving any power.

Yellow Red Green Module has good power, but has not received valid

configuration from CPU and is not communicating on

the Profibus-DP network.

Green Red Green Module has good power, has received valid

configuration from CPU but is not communicating on

the Profibus-DP network. This may be due to the

CPU being in STOP mode.

Green Yellow Green Module has good power, has received valid

configuration from CPU and is communicating on the

Profibus-DP network ,but one or more configured

slaves is not responding.

Green Green Green Module has good power, has received valid

configuration from CPU and is communicating on the

Profibus-DP network.

Red Blinking

between yellow

and green

Yellow A fault has occurred. Refer to the following

description to determine fault.

Table 2.2 Fault Conditions *

Pulse Count Meaning

2 An error was encountered receiving configuration from the PLC CPU.

3 An error was encountered creating the Profibus-DP network

configuration.

4 An internal error was encountered while communicating with the

Profibus hardware

10-23 Internal Error Codes. If witnessed, record value and report to GE

Fanuc.

* The blinking RUN light indicates a fault. To determine the fault, simply count the number of

green pulses (the LED will pause for 2 seconds, pulse green a number of times, then repeat

the cycle) Table 1-2 will describe the fault as represented by the number of green pulses.

MAN0001-02 22 JUN 2000 PAGE 11

CH. 2

2.5 PBM101 Status Error/Reporting

2.5.1 PLC Status Bit Definition

The PBM101 has 64 bits of status information reported to the PLC CPU. The bits are defined as

follows:

Table 2.3 PLC Status Bit Definition *

Name Byte Offset Bit Offset Values

Area 1 Slave Active

Indication (This

corresponds to the Slave 1

definition in the Slave

Information tab of the

PBM100 configuration).

0 0

1= Slave actively

communicating on network

with no errors.

0= Problem with Slave.

Either the slave is not in

data exchange or the slave

has a fault (ERROR).

Area 2 Slave Active

Indication (This

corresponds to the Slave 2

definition in the Slave

Information tab of the

PBM100 configuration)

0 1

1= Slave actively

communicating on network

with no errors.

0= Problem with Slave.

Either the slave is not in

data exchange or the slave

has a fault (ERROR).

: :

: :

Area 64 Slave Active

Indication (This

corresponds to the Slave

64 definition in the Slave

Information tab of the

PBM100 configuration

7 7

1= Slave actively

communicating on network

with no errors.

0= Slave not active on

network, (possibly due to

no config, bad config or

bad network connection.

Bits do not represent slave addresses. Bits 0-63 are the slave status bits ordered by

the slave areas of the master configuration in Cimplicity Control

In order to determine which slave is not properly functioning, the user must:

1. First, identify the affected bit using this table;

2.Second, determine the area (See Figure 3.5 Data Area of Master Parameters screen)

The area is indicated in the first column of the screen.

3. Third, the slave address is located next to the appropriate Data Area column.

Example: bit 0 = area 1 (as seen in Figure 3.5)

bit 1 = area 2

thru bit 63 = area 64

PAGE 12 22 JUN 2000 MAN0001-02

CH. 2

NOTES

MAN0001-02 22 JUN 2000 PAGE 13

CH. 3

CHAPTER 3: CONFIGURATION

WARNING: Do not use the load function of Cimplicity Control for Profibus.

Cimplicity is unable to disassemble binary data to information that it can use itself.

Using the Load function will result in a corrupt Cimplicity data file.

NOTE: The Pseudo Slave Feature of the HE693PBM100

The Pseudo Slave feature of the HE693PBM100 enables users to access three additional

functions that are not available using the normal configuration procedure in Chapter 3. If the

functions are desired, users must perform additional configuration procedures as

indicated in Appendix A.

NOTE: The Pseudo Slave is neither a physical device nor is it true slave device.

The Pseudo Slave is simply a part of the software which allows the HE693PBM100 to access

specific information from a PLC, and thus, provides the additional functions. Appendix B covers

the following functions in more detail.

3.1 Configuring the HE693PBM100

CIMPLICITY Control Version 2.0 or higher is required in order to configure the HE693PBM100.

The following is a step by step methodology on configuring the HE693PBM100 using

CIMPLICITY Control.

Step 1: Get into CIMPLICITY Control and select Create New Equipment Folder at the

opening window. Give the new folder a name.

Step 2: Select Hardware Configuration. A screen similar to Figure 3.1 should appear.

Step 3: If the rack type is not correct, place the mouse cursor (arrow) on the rack, press the right

mouse button (right clicking) and select Change Rack Type.

Figure 3.1

PAGE 14 22 JUN 2000 MAN0001-02

CH. 3

Step 4: Highlight the slot where the HE693PBM100 is to be placed by left clicking (pressing the

left mouse button) on that spot.

Step 5: Right click on the highlighted slot and select Add Module. The following screen

appears (Figure 3.2).

Step 6: Click on the Bus Controller tab and select HE693PBM100. The empty slot on the

virtual PLC is replaced with the PBM module. The following screen appears (Fig. 3.3).

FIGURE 3.2

Figure 3.3

MAN0001-02 22 JUN 2000 PAGE 15

CH. 3

The following table briefly describes the fields on the Settings Tab.

Table 3.1 Fields on the Settings Tab

Bus Address This refers to the Profibus-DP bus address.

Status Reference Type Location of Status Bits (see Table 1.3 of this document) in

PLC memory. (8 bytes)

Status Length Number of Status Bits (Fixed at 64)

Baud Rate Baud Rate of data transmissions on the Profibus network.

(range between 9.6K - 12M)

Min. Slave Interval (.1ms) Smallest allowed period of time between two successive poll

cycles of a particular slave. It is in .1ms units and has a

range of 1-65535.

Target Rotation Time (t_bits) Allowable cycle time in which all slaves will be polled by this

master. It is in t_bits and has a range of 1-65535.

Step 7: Set the Bus Address, Status Reference Type, Baud rate, Min. Slave Interval and Target

Rotation Time.

Step 8: After the above parameters are set, click on the Slave Information tab. The following

Screen should appear (Figure 3.4). (See Appendix A if Pseudo Slave functions are

desired.)

a. The GSD File contains mapping information from the Master to the Slave. This file is

imported from the GSD directory.

Note: The GSD Files can be found on the Horner APGs Web site at

www.heapg.com.

b. The BUS Addr field refers to the bus address of the slaves that are being mapped to this

Master.

FIGURE 3.4

PAGE 16 22 JUN 2000 MAN0001-02

CH. 3

c. The Flags field sets a bit mask denoting operating characteristics of the particular slave.

Table 3.2

Bit 0-2 Reserved

Bit 3 1 = Watchdog Control Activated; 0 = Not Activated

Bit 4 1 = Operate in Freeze mode, 0 = No Freeze Control

Bit 5 1 = Operate in Sync Mode, 0 = No Sync Mode

Bit 6-7 Lock Control 00 = Tsdr can change only, 10=slave

will be unlocked for other masters, 01=slave is locked

for other masters, all parameters accepted except

Tsdr; 11=slave is unlocked for other masters

d. The Ident High field sets the High byte Ident Number of the DP-Slave device as assigned

by the Profibus Trade Organization.

e. The Ident Low field sets the Low byte Ident number of the DP-Slave device as assigned

by the Profibus Trade Organization.

f. The Grp Mask field sets the Bit Mask denoting group control for Freeze and Sync

Functions. Each bit identifies a particular group. Group Control is only possible if bit 7 in

the above Operating Flags is set to 1.

Step 9: Next Click on the Data Area tab, the following screen should appear (Figure 3.5).

Figure 3.5

MAN0001-02 22 JUN 2000 PAGE 17

CH. 3

a. This tab is where the configuration for the mapping of the Profibus-DP network data to

PLC memory locations is completed. The order that the data is configured must be

identical to that of the DP-Slave. If configuration mismatches exist, no data is exchanged

with that particular slave. For the HE693PBS105 Slave Module, output data must be

configured first on the list for each slave. For example, if there is a slave at bus address

3 with an input configuration and an output configuration, the output must be configured

before the input.

b. To configure the slave at bus address 3, start on the next available unused line (in Figure

2-5 this is the very first line, represented by Area 1), Enter in the bus address (for this

example it will be 3). Enter a 1 for the module number. The module type will be

Output so left click on the field with the mouse and select output from the pull down

menu. The Length Type is either a byte or a word, and the data length is the desired

length. The remainder of the lines are used to map the input and outputs to the slave.

c. To configure the input, tab down to the next line (area 2 in Figure 3.5). Enter a 3 for the

Slave Address. The module type is a 2. Since the slave is configured for both inputs and

outputs, it is looked at by the master as two modules with the same bus address.

Configure the type, length, and mapping as before. The master is now configured for a

slave at bus address 3 and as both in input device and an output device.

NOTE: It is important to remember that an input to the Slave is an Output to the Master

and vise-versa.

Table 3.3 Fields on the Data Area Tab

Area

Memory area being defined within the PLC. It is not configurable. The master currently supports

configuring 64 unique areas.

Slave Address

Bus address of the particular slave for which you are adding a data area mapping. It must be

equal to a corresponding value set in the Slave n Settings tab.

Module #

Particular module ID which is being configured for the given slave address. The number of

modules used must be identical to the slave configuration for proper data exchange to occur.

For example, if the slave to which communication is desired is a GE Fanuc Field Control Profibus

BIU which has an input module followed by an output module, the number of modules would be

three. The Module # of the area mapped to the BIU would be 1; the Module # of the input

module would be 2; and the Module # of the output module would be 3.

Type

Data Type of module being defined. Possible types are: Input, Output, I/O (both input and

output), Special input, Special output, Special I/O, and Empty.

Length Type Specifies whether data is of type Byte or Word.

Data Length

Length of data. This value is expressed in units according to the Length Type field. If the Type

field is set to I/O, this value is both the length of the input and the length of the output. Range is

0-16. A value of 0 implies that this area is not defined.

Input Offset

Memory location in PLC where input data will be mapped. This field must be set if the Type

value is Input or I/O.

Output Offset

Memory location in PLC where output data will be mapped. This field must be set if the Type

value is Output or I/O.

Consistency

Consistency Option Flag. Possible choices are: Byte/Word and Entire Length. (Not used for

Special Types)

Special In Byte

Data Byte used for Types Special Input and Special I/O. This byte (range 0-ff) represents a

special input identifier as defined by a particular slave.

Special Out

Byte

Data Byte used for Types Special Output and Special I/O. This byte (range 0-ff) represents a

special output identifier as defined by a particular slave.

d. The Power Consumption Tab is used to display power consumption characteristics of

the module. No fields are editable on this tab.

e. After the configuration is complete download the configuration to the PLC. Complete

details on how to do so can be found in GE Fanuc manual GFK-1295A, using

CIMPLICITY CONTROL.

PAGE 18 22 JUN 2000 MAN0001-02

CH. 3

NOTES

MAN0001-02 22 JUN 2000 PAGE 19

CH. 4

CHAPTER 4: WIRING DIAGRAMS

4.1 Profibus Wiring:

Assembling the cable for use with the DP port on the HE693PBM100 and PBS105.

a. The HE693PBM100 uses a 9-pin D-sub plug connector for its DP port. The pin

assignment of the plug connector and the wiring are shown below (Figure 4.1).

b. It is necessary to terminate both ends of the network. Both terminations must have

power to them to insure proper operation of the network. The following diagram (Figure

4.2) illustrates the correct connection for the termination resistors.

NOTE: The above wiring diagram (Fig. 4.2) is for illustrative purposes only. Cabling and

connectors must be PTO approved to achieve the desired performance results. See

Section 4.3 for recommended part numbers.

Figure 4.1

(Already on

Profibus

Mainboard)

Figure 4.2

VP(6)

B-Line (3)

A-Line (8)

GND(5)

390 Ohm

220 Ohm

390 Ohm

Line Termination

Line B

Line A

PAGE 20 22 JUN 2000 MAN0001-02

CH. 4

c. The shield braiding and, if present, the shield foil should be connected to protective

ground on both sides and with good conductivity via shield clamps covering as large an

area as possible. In addition, it is recommended that the data lines be kept separate from

all high-voltage cables.

4.2 Other considerations when wiring the Profibus network:

a. In the Profibus network, up to 32 stations (master or slaves) can be connected per

segment without the addition of repeaters. If more that 32 stations are desired repeaters

must be used. The repeaters are used to connect individual bus segments together.

b. The maximum cable length depends on the transmission speed. The specified cable

length can be increased by the use of repeaters. However, the use of more than three

repeaters in series is not recommended.

c. The following cable length specifications are based on type-A cable with a 135 to 165

Ohm impedance, less than 30 pf/m capacity, a loop resistance of 110 Ohms/Km, a wire

gauge of .64mm, and a conductor area of 0.34mm.

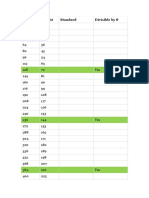

Table 4.1 - Baud/Distance Rates

Baud Rate(bit/sec) 9.6K 19.2K 93.75K 187.5K 500K 1.5M 12M

Distance/Segment 1200m 1200m 1200m 600m 200m 200m 100m

d. For data transmission speeds of greater than 500 kbit/sec, Stub lines (free hanging ends

of the cable) should be avoided. There are plug connectors available on the market that

permit data line A and data line B to be connected directly to the plug connector.

MAN0001-02 22 JUN 2000 PAGE 21

CH. 4

4.3 Recommended Part numbers:

It is highly recommended that the following cable and connectors be used for high speed data

transmissions. Both Cable and Connector part numbers are Siemens part numbers.

a. Connectors:

b. Cable: Part Number 6XV1-830-OAH10

6ES7-972-0BB10-0XAO 6ES7-972-0BA10-0XAO

Figure 4.3 - Connectors

Extra 9-pin DSUB for easy

cable stacking.

PAGE 22 22 JUN 2000 MAN0001-02

CH. 4

NOTES

MAN0001-02 22 JUN 2000 PAGE 23

APPENDIX A

APPENDIX A: IMPLEMENTATION OF THE HE693PBM100 PSEUDO SLAVE

1.1 General

The Pseudo Slave feature of the HE693PBM100 enables users to access the following three

functions that are not available using the normal configuration procedure in Chapter 3.

a. SYNC/FREEZE Control - The Sync/Freeze controls allow the Logic to control the data flow to

and from the inputs and outputs of the slaves.

b. Additional slave System Diagnosis status information.

c. Firmware release information

If the above functions are desired, the user must perform additional configuration procedures as

indicated herein Appendix B.

2.1 Pseudo Slave Description

The Pseudo Slave is neither a physical device nor is it true slave device. The Pseudo Slave

is simply a part of the software which allows the HE693PBM100 to obtain specific information from a

PLC, and thus, provides three additional functions. The Pseudo Slave is designed strictly for use by

the HE693PBM100.

3.1 Adding the Pseudo Slave to the Cimplicity Control Configuration

Although the Pseudo Slave is added to the Cimplicity Control Configuration in the same manner as a

true slave device, the slave information is not passed to the Profibus network and does not affect

network traffic. The Pseudo Slave is simply an extension of the HE693PBM100s I/O.

1. While configuring the Master Module, select the Slave information tab. This will allow the

addition of slaves to the Master configuration.

2. In the desired line (Slave 1 - 64) click on the GSD File field, type a space character followed

by the ENTER, this will bring up a file selection dialog. (See Chapter 3, Figure 3.4.)

3. Select the HEMASTIO.GSD from the directory that contains it. Cimplicity Control will then

import the GSD data and insert the I/O modules into the next available fields in the Data

Area. The needed Slave Information fields will also be filled.

4. After the import is finished, the Slave address must be assigned. Enter any valid unused

address into the Slave Information Bus Address field. This address must be used to

update the Data Area Slave Address fields of the modules added by the Import. The Data

Area Modules # fields will also need to be updated so that they are numbered sequentially

from 1 to 8. (See Chapter 3, Figure 3.5.)

5. The HEMASTIO.GSD contains data to setup the slave as follows:

Slave Ident = 0x0008 Special Reserved Ident Number

1

st

module = 0x23 - 4 bytes of Output

2

nd

module = 0x11 - 2 bytes of Input

3

rd

module = 0x17 - 8 bytes of Input

Module 1 is used to pass Sync/Freeze control data, module 2 is used to pass firmware version

information, and module 3 is used to pass the additional slave status data.

PAGE 24 22 JUN 2000 MAN0001-02

APPENDIX A

6. Although Cimplicity Control assigns Data Offset values to each module, these can be changed

by the user to optimize their use in logic. These offsets can be referenced as %I, %Q, %AI,

%AQ and %R types.

4.1 Accessing Additional Functions of the HE693PBM100

4.1.1 SYNC/FREEZE Control

The following explanation describes the SYNC/FREEZE function and indicates the information needed

to setup the SYNC/FREEZE parameters in the program language being used (such as Ladder Logic,

C-Programming, etc.).

a. The SYNC/FREEZE controls allow the Logic to control the data flow to and from the inputs

and outputs of the slaves. The FREEZE control can be used to synchronize the slave inputs

and the SYNC command is used to synchronize the slaves outputs.

b. The FREEZE control freezes the physical input data existing on one or more slaves

simultaneously, like taking a snap shot. The selected slave(s) will stay in the frozen state until

an UNFREEZE control is issued.

c. The SYNC control works in much the same way, it will lock the physical output data existing

on one or more slaves simultaneously. This data will remain static until an UNSYNC control or

new SYNC control is issued. Additional SYNC controls will update the output data.

d. The slaves can be selected individually or in groups. To use the group functions, the Slaves

must have been configured for a group. The Slave Information dialog screen contains the

Grp Mask fields for each slave. This field can contain a group number of 0 - 8. The zero

group is a global group.

e. The format of the SYNC/FREEZE control data is as follows:

Byte 0 = Group data

Bit 0 = Group 1

Bit 1 = Group 2

Bit 2 = Group 3

Bit 3 = Group 4

Bit 4 = Group 5

Bit 5 = Group 6

Bit 6 = Group 7

Bit 7 = Group 8

data FFH = Group 0, Global group

Byte 1 = Slave Address (7FH = broadcast, all addresses)

Byte 2 = Control type

01H = UNFREEZE

02H = FREEZE

04H = UNSYNC

08H = SYNC

Byte 3 = Transmit Control command

This can be any data, as any change in this byte will trigger a Control update.

MAN0001-02 22 JUN 2000 PAGE 25

APPENDIX A

4.1.2 Slave Status

The following explanation describes the Slave Status and indicates the information needed to setup

the Slave Status parameters in the program language being used (such as Ladder Logic, C-

Programming, etc.).

a. The Slave Status inputs contain additional information about the slaves which is useful for

system diagnosis. This data is contained in 8 bytes with each bit containing the system

diagnosis state for each slave.

b. A true bit indicates that the Slave has a fault or has diagnostic information available. These

bits correspond to the slaves in the same format as the Master Status Reference. Bit 0 of Byte

0 is the indicator for Slave number 1 of the Slave Information dialog, Bit 1 of Byte 0 is the

indicator for Slave number 2 and so on. The 64 bits represent the 64 available slaves.

4.1.3 Master Firmware Version

The Master Firmware Version function allows a user to determine which firmware version is being

used by the HE693PBM100. The following indicates the information needed to setup the parameters

for determining firmware version:

The two input bytes of the master Firmware version have to following format:

Byte 0 = High nibble = Major revision number

Low nibble = Minor revision number

Byte 1 = future use

PAGE 26 22 JUN 2000 MAN0001-02

APPENDIX A

NOTES

Você também pode gostar

- Manual Horner Ocs He-Xe102Documento112 páginasManual Horner Ocs He-Xe102Martin Velasco GarciaAinda não há avaliações

- Instructions Reference Manual (W474) CPU CJ2MDocumento1.314 páginasInstructions Reference Manual (W474) CPU CJ2Mjoseluisrosglz100% (1)

- KPD Series MPEG4 DVR 616 616F 608 608F 604 604F Manual V1.5Documento73 páginasKPD Series MPEG4 DVR 616 616F 608 608F 604 604F Manual V1.5l1f3b00kAinda não há avaliações

- Enderby 1990Documento96 páginasEnderby 1990Fadjar MulyaAinda não há avaliações

- Mindwave MobileDocumento46 páginasMindwave MobileRodrigo AlexanderAinda não há avaliações

- User Manual For: HE-QX351 / HEQX351C103Documento109 páginasUser Manual For: HE-QX351 / HEQX351C103Douglas FernandoAinda não há avaliações

- Manual PLC HornerDocumento82 páginasManual PLC HornerMiguel GcAinda não há avaliações

- Horner PLC ManualDocumento84 páginasHorner PLC ManualChepe Chepe MartinezAinda não há avaliações

- MAN0883-03 XL6eDocumento130 páginasMAN0883-03 XL6ecatalin_1972Ainda não há avaliações

- Horner PLC XLe Series Programming ReferenceDocumento204 páginasHorner PLC XLe Series Programming ReferenceVinc PanAinda não há avaliações

- 05 CsCAN Connectivity PagesDocumento106 páginas05 CsCAN Connectivity PagescucuAinda não há avaliações

- Xle Ocs: User Manual ForDocumento82 páginasXle Ocs: User Manual ForRafael Pertile CarneiroAinda não há avaliações

- Cscape Programming and Reference Manual: 1-888-55-OMEGADocumento204 páginasCscape Programming and Reference Manual: 1-888-55-OMEGAacnofsingerAinda não há avaliações

- Horner Manual Básico Programación CsCape y XLe PDFDocumento112 páginasHorner Manual Básico Programación CsCape y XLe PDFUlises100% (2)

- NX Ocs Hardware: User Manual ForDocumento78 páginasNX Ocs Hardware: User Manual ForJaime Igor ViegasAinda não há avaliações

- PT-60Users Manual WinCE50 en Version11 090901Documento86 páginasPT-60Users Manual WinCE50 en Version11 090901Alex Almeida LeonardoAinda não há avaliações

- Migration Guide From CPM2A To CP1EDocumento40 páginasMigration Guide From CPM2A To CP1EAlberto LazoAinda não há avaliações

- User Manual For XL-J1939Documento23 páginasUser Manual For XL-J1939RegisAinda não há avaliações

- VSP 198CVS - User Manual - EN - V1.1 - 20150819 PDFDocumento122 páginasVSP 198CVS - User Manual - EN - V1.1 - 20150819 PDFRene CastilloAinda não há avaliações

- Galaxy EPS 6000 InstallationDocumento72 páginasGalaxy EPS 6000 InstallationFernando PrietoAinda não há avaliações

- EI Manifold Pressure ManualDocumento12 páginasEI Manifold Pressure Manualjkloepping_634367970Ainda não há avaliações

- Manual PactronicDocumento102 páginasManual Pactronicfrancisco HernandezAinda não há avaliações

- XL4 User ManualDocumento122 páginasXL4 User ManualDavid Serrano LopezAinda não há avaliações

- I924 From 3g3jx To 3g3mx2 Replacement Guide enDocumento32 páginasI924 From 3g3jx To 3g3mx2 Replacement Guide enfarich putraAinda não há avaliações

- Man MCPDocumento121 páginasMan MCPKen Lau Boun KongAinda não há avaliações

- Aegis 7000P-2011 ManualDocumento26 páginasAegis 7000P-2011 ManualjcnespoliAinda não há avaliações

- DPR 100 C - DPR 100 D: Product ManualDocumento232 páginasDPR 100 C - DPR 100 D: Product ManualkmpoulosAinda não há avaliações

- hrt1 Hoffer Flow ControlsDocumento52 páginashrt1 Hoffer Flow ControlsSohaib ButtAinda não há avaliações

- LPG Premier LPG Premier Midflow LPG Premier Hiflow: 21-Stage Pump Section 17-Stage Pump Section 24-Stage Pump SectionDocumento0 páginaLPG Premier LPG Premier Midflow LPG Premier Hiflow: 21-Stage Pump Section 17-Stage Pump Section 24-Stage Pump SectionBato TomicAinda não há avaliações

- REEMPLAZO SERVOS I868 Ac Servomotor Servo Drives - Replace Guide Replacement Guide enDocumento98 páginasREEMPLAZO SERVOS I868 Ac Servomotor Servo Drives - Replace Guide Replacement Guide enkevin18jmsAinda não há avaliações

- Digiguard Manual v0.9Documento84 páginasDigiguard Manual v0.9lundiexAinda não há avaliações

- 05959-3344 6030-1-2-5A Service Nov99Documento139 páginas05959-3344 6030-1-2-5A Service Nov99István BujákiAinda não há avaliações

- 700XA Rev CDocumento248 páginas700XA Rev CMiguel I. Roman BarreraAinda não há avaliações

- From CP1E To CP2E: Replace GuideDocumento26 páginasFrom CP1E To CP2E: Replace GuideZANGA TORREZ WILBERAinda não há avaliações

- OMRON Corporation: Authorized DistributorDocumento100 páginasOMRON Corporation: Authorized DistributorMạnh VũAinda não há avaliações

- MGE UPS Systems EPS 6000 User Manual PDFDocumento84 páginasMGE UPS Systems EPS 6000 User Manual PDFlyax1365Ainda não há avaliações

- Mixrack Getting Started Guide: Dm32, Dm48, Dm64Documento14 páginasMixrack Getting Started Guide: Dm32, Dm48, Dm64David KaazAinda não há avaliações

- I573 E1 03 - r88m K - r88d KN - Ect RDocumento484 páginasI573 E1 03 - r88m K - r88d KN - Ect RjoeAinda não há avaliações

- OPTIFLUX Handbook For Electromagnetic FlowmetersDocumento36 páginasOPTIFLUX Handbook For Electromagnetic FlowmetersRoyalty GouldAinda não há avaliações

- Setup Manual: Programmable TerminalsDocumento241 páginasSetup Manual: Programmable Terminals滕鼎Ainda não há avaliações

- Sysmac NJ FINS TechnicalGuide en 201205 W518-E1-01Documento40 páginasSysmac NJ FINS TechnicalGuide en 201205 W518-E1-01Luigi FaccioAinda não há avaliações

- MR 198CVS Video Processor User Manual V1.0 20140505 PDFDocumento120 páginasMR 198CVS Video Processor User Manual V1.0 20140505 PDFMauricio DiazAinda não há avaliações

- Zed-10 User Guide: Publication AP7880Documento32 páginasZed-10 User Guide: Publication AP7880LincolnAinda não há avaliações

- DG Ps1010uDocumento78 páginasDG Ps1010uSuraj GeorgeAinda não há avaliações

- CPM2A To CP1E Replacement GuideDocumento40 páginasCPM2A To CP1E Replacement Guideedtatel73Ainda não há avaliações

- G5-Servos UsersManual en 201509 I571-E1-05 tcm871-112685Documento632 páginasG5-Servos UsersManual en 201509 I571-E1-05 tcm871-112685microsoda8Ainda não há avaliações

- Model 700 GCDocumento334 páginasModel 700 GCFerry BudiAinda não há avaliações

- Command Plus 43004-016D ManualDocumento56 páginasCommand Plus 43004-016D ManualBob FayAinda não há avaliações

- Model ACC2500 Audio Control Center User and Installation ManualDocumento56 páginasModel ACC2500 Audio Control Center User and Installation ManualJonathan MoralesAinda não há avaliações

- Qu Mixer Reference Guide AP9372 8ADocumento91 páginasQu Mixer Reference Guide AP9372 8ATatty GonçalvesAinda não há avaliações

- PLC Omron Zen Z184-E1-04Documento95 páginasPLC Omron Zen Z184-E1-04Moody ToemAinda não há avaliações

- CPC 100 Reference ManualDocumento370 páginasCPC 100 Reference ManualDaniela Emilia Insuaste Correa0% (1)

- AggRAM Op Man D6500094D PDFDocumento108 páginasAggRAM Op Man D6500094D PDFDewi ArisandyAinda não há avaliações

- Qu Mixer User Guide 12-8-2014 5Documento72 páginasQu Mixer User Guide 12-8-2014 5ozamaroAinda não há avaliações

- E2rl f2 L 0 0 ManualDocumento100 páginasE2rl f2 L 0 0 ManualDarshan RavalAinda não há avaliações

- Manual PirometruDocumento85 páginasManual PirometruMunteanu SimonaAinda não há avaliações

- TurbineDocumento57 páginasTurbineSantiago Mateo Enciso AvilaAinda não há avaliações

- Zen SoftwareDocumento95 páginasZen SoftwareJimmy ChanAinda não há avaliações

- Electrician''s Guide to Control and Monitoring Systems: Installation, Troubleshooting, and MaintenanceNo EverandElectrician''s Guide to Control and Monitoring Systems: Installation, Troubleshooting, and MaintenanceAinda não há avaliações

- Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid DriveNo EverandBosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid DriveRobert Bosch GmbHAinda não há avaliações

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualNo EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualAinda não há avaliações

- SAABO StiprintuvasDocumento6 páginasSAABO StiprintuvasTomasAleknaAinda não há avaliações

- Voltage Monitoring Series SM 501Documento5 páginasVoltage Monitoring Series SM 501srinivasgateAinda não há avaliações

- ABB - TechNotes - 2.2 - Overvoltages - Protective Distance 1HC0138872 EN AADocumento11 páginasABB - TechNotes - 2.2 - Overvoltages - Protective Distance 1HC0138872 EN AADeoudrafAinda não há avaliações

- Silo Weight & Volume CalculationDocumento18 páginasSilo Weight & Volume CalculationYogesh PatilAinda não há avaliações

- Calibration of Linear Displacement Sensor Systems Used To Measure MicromotionDocumento4 páginasCalibration of Linear Displacement Sensor Systems Used To Measure MicromotionAhmad Zubair RasulyAinda não há avaliações

- 2004, TDEI, Leakage Current Characterization For Estimating The Conditions of Ceramic and Polymeric Insulating SurfacesDocumento10 páginas2004, TDEI, Leakage Current Characterization For Estimating The Conditions of Ceramic and Polymeric Insulating SurfacesMansoor AsifAinda não há avaliações

- 01B-ElectSchematics Feb2015Documento19 páginas01B-ElectSchematics Feb2015Alive100% (2)

- ListOf PHD Students OngoingDocumento5 páginasListOf PHD Students OngoingBiswajit DebnathAinda não há avaliações

- QP THC-Q5713 Multi Skilled TechnicianDocumento101 páginasQP THC-Q5713 Multi Skilled TechnicianABIR ADHIKARIAinda não há avaliações

- SChapter13 The Adams MotorGeneratorDocumento14 páginasSChapter13 The Adams MotorGeneratorpranalar100% (1)

- Precision Micropower, Low Dropout Voltage References: Nominal Output Number Voltage (V)Documento24 páginasPrecision Micropower, Low Dropout Voltage References: Nominal Output Number Voltage (V)Jorge Centeno RamosAinda não há avaliações

- Report ProjectDocumento17 páginasReport ProjectMAGUDESWARAN PAinda não há avaliações

- Eee589 Analog-ic-Design Eth 2.00 Ac29Documento2 páginasEee589 Analog-ic-Design Eth 2.00 Ac29dileshwarAinda não há avaliações

- Instrumentation (Chapter 2)Documento7 páginasInstrumentation (Chapter 2)Yab TadAinda não há avaliações

- Technical Specification For Isolators: Odisha Power Transmission Corporation LimitedDocumento15 páginasTechnical Specification For Isolators: Odisha Power Transmission Corporation LimitedRAKESH CHANDRA PATRAAinda não há avaliações

- Uniconn Operation Manual Addendum Subject: Operation of Phoenix Select Gauge With Uniconn Firmware: 1.200R1 Wellview Version 2.400R1Documento11 páginasUniconn Operation Manual Addendum Subject: Operation of Phoenix Select Gauge With Uniconn Firmware: 1.200R1 Wellview Version 2.400R1ahmed elsheikhAinda não há avaliações

- Computer Systems ServicingDocumento17 páginasComputer Systems Servicingmarvin aguban75% (4)

- The Electromagnetic Spectrum by Cindy GriggDocumento2 páginasThe Electromagnetic Spectrum by Cindy GriggMae Dil G. Tirariray - PaladAinda não há avaliações

- Latest Pricelist PDFDocumento4 páginasLatest Pricelist PDFSha Edd'sAinda não há avaliações

- DP LAN Others 13115 DriversDocumento2.284 páginasDP LAN Others 13115 DriversSyed AliAinda não há avaliações

- Prac. Summer 2014Documento19 páginasPrac. Summer 2014Praful KakdeAinda não há avaliações

- MKP 18-10000 Rev 6 YPS PDFDocumento48 páginasMKP 18-10000 Rev 6 YPS PDFMalek AbourawiAinda não há avaliações

- Temperature Controls K57 Series: Features and BenefitsDocumento2 páginasTemperature Controls K57 Series: Features and BenefitsmaresliviuAinda não há avaliações

- List of True 16 9 ResolutionsDocumento19 páginasList of True 16 9 ResolutionsryuAinda não há avaliações

- KWXTI5500 501 EngDocumento6 páginasKWXTI5500 501 EngDaniel HallbergAinda não há avaliações

- M28 BluetoothModulesDocumento5 páginasM28 BluetoothModulessouwestrubiAinda não há avaliações

- Distribution Safety InstructionDocumento12 páginasDistribution Safety InstructionShakeb RahmanAinda não há avaliações

- Ade Lab ManualDocumento73 páginasAde Lab ManualAshutosh PatilAinda não há avaliações