Escolar Documentos

Profissional Documentos

Cultura Documentos

Wing Analysis FLUENT

Enviado por

asbadgTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Wing Analysis FLUENT

Enviado por

asbadgDireitos autorais:

Formatos disponíveis

1 | P a g e

TUT 8: Aerofoil Analysis in

Fluent

CFD 814

Adhikar Hariram (18121004)

2013

2 | P a g e

Contents

Table of figures ....................................................................................................................................... 3

Introduction ............................................................................................................................................ 4

Technical Section .................................................................................................................................... 4

Problem Description ........................................................................................................................... 4

Problem Setup .................................................................................................................................... 4

Results ................................................................................................................................................. 7

Simulation 1 .................................................................................................................................... 7

Simulation 2 .................................................................................................................................. 11

Simulation 3 .................................................................................................................................. 15

Simulation 4 .................................................................................................................................. 19

Conclusion ............................................................................................................................................. 24

References ............................................................................................................................................ 25

3 | P a g e

Table of figures

Figure 1: Geometrical Description of Problem ....................................................................................... 4

Figure 2: Fine Mesh Generated............................................................................................................... 6

Figure 3: Residuals k-epsilon ................................................................................................................... 8

Figure 4: Drag Coefficient k-epsilon ........................................................................................................ 8

Figure 5: Lift Coefficient k-epsilon .......................................................................................................... 9

Figure 6: Axis Transformation for Drag and Lift ...................................................................................... 9

Figure 7: y+ k-epsilon ............................................................................................................................ 10

Figure 8: Velocity Contour Plot k-epsilon ............................................................................................. 11

Figure 9: Residuals k-omega ................................................................................................................. 12

Figure 10: Drag Coefficient k-omega .................................................................................................... 12

Figure 11: Lift Coefficient k-omega ....................................................................................................... 13

Figure 12: y+ k-omega ........................................................................................................................... 14

Figure 13: Velocity Contour Plot k-omega ............................................................................................ 15

Figure 14: Residuals RSM ...................................................................................................................... 16

Figure 15: Drag Coefficient RSM ........................................................................................................... 16

Figure 16: Lift Coefficient RSM ............................................................................................................. 17

Figure 17: y+ RSM ................................................................................................................................. 18

Figure 18: Velocity Contour Plot RSM ................................................................................................... 19

Figure 19: Rough Mesh Generated ....................................................................................................... 20

Figure 20: Residuals Rough Mesh ......................................................................................................... 21

Figure 21: Drag Coefficient Rough Mesh .............................................................................................. 21

Figure 22: Lift Coefficient Rough Mesh ................................................................................................. 22

Figure 23: y+ Rough Mesh .................................................................................................................... 23

Figure 24: Velocity Contour Plot Rough Mesh ...................................................................................... 24

4 | P a g e

Introduction

One of the most common applications in the field of CFD is in the aeronautics industry with a large

amount of work having being done on the analysis of aerofoils. Amongst the many types and series

of aerofoils, the Joukowski aerofoil is one who's shape is steeped in mathematics and as a result the

streamlines around such a profile are well understood. There also exists empirical data on the lift

and drag characteristics for this series of aerofoil and hence it provides an ideal shape for CFD

analysis and verification of results. Thus, the CFD analysis of a Joukowski aerofoil profile with known

lift and drag characteristics has been undertaken.

Technical Section

Problem Description

The problem modelled consisted a Joukowski 558 aerofoil profile at an angle of attack of that is

travelling at a velocity equivalent to Mach 0.4. A geometrical description of the problem is shown in

figure 1.

Figure 1: Geometrical Description of Problem

The value for , as well as the other variables used in the simulation can be found in table 1. All of

the values used were derived from the student number 18121004.

Table 1: Values used in Simulation

Property/Dimension Value

3+4

0

T 0

0

C

H (altitude) 4000m

It should be noted that the fluid properties were left as the database values for air in FLUENT.

Problem Setup

The first step of the problem setup was to create the geometry for the domain, which was done

using the ANSYS Design modeller. The first step was to create a sketch for the flow domain that

would accurately represent the flow being simulated. As was found in both the FLUENT Tutorial

guide, as well as in other online tutorials for the analysis of an aerofoil, the domain was made to be

curved at the inlet with a semi-circle with the rest of the downstream domain being made up of a

5 | P a g e

simple rectangle. It should also be noted that the trailing edge of the aerofoil was made to be in-line

with the end points of the semi-circle. This is illustrated further on in figure 2, which shows the

meshed domain. The domain was also made sufficiently large to ensure that the boundary

conditions could be accurately prescribed. Once the domain was sketched; a 2-D surface was

created from it as the analysis to be undertaken was a pure 2-D simulation. In order to accurately

capture flow phenomenon close to the aerofoil body, the coordinates of the aerofoil were scaled up

twice and imported into the Design modeller. From these scaled coordinates, line bodies were

created and projected onto the created domain. This split the domain into three parts which allowed

for much greater mesh control especially near to the aerofoil body. The next step then required the

domain to be meshed using the ANSYS Meshing facility.

Once the domain was in the meshing facility, all previous line bodies were suppressed as only the

domain needed to be meshed and not these line bodies. The next step was to apply separate face

sizing's onto the two separate regions closest to the aerofoil body as this would allow the flow to be

accurately captured in this region. Finally, inflation was applied to the surface of the aerofoil in order

to capture the boundary layer effects along its surface. When inserting the inflation layer, the

specification was changed to first layer thickness as this would allow for an adequate y+ value to be

achieved at the wall. This y+ value was achieved using a flat plate approximation and the total

number of layers was determined from the boundary layer thickness, , also determined from a flat

plate approximation. The details of the equations used to calculate these values for a turbulent flow

can be found in (1). The velocity used in the equations given in (1) was determined from the mach

number and the speed of sound. For flow in air, this is given as :

where c is the speed of the fluid concerned, is the ratio of specific heats, is the gas constant

divided by the fluid's molecular weight and T is in Kelvin. From this equation, the speed of the fluid

was found to be 146.02 m/s which resulted in a y of 1 mm at the end of 2 m long plate for a y+ of 60,

and a value of 26.48mm at a length of 1.8m along a 2m long plate. The y+ of 60 was chosen as this

is within the range of 30<y+<300 for which the wall treatment equations used in FLUENT are valid.

The length of 1.8 m was also chosen due to flow separation being expected to occur before the

trailing edge of the aerofoil. This meant that the maximum boundary layer thickness that was

required occurred at a point before 2m along the flat plate approximation. Using the mentioned

sizing's and inflation specifications, the mesh that had been generated can be seen in figure 2. It

should be noted that the named selections for the boundaries were also created in the meshing

application. These selections were namely: 'inlet', 'outlet', 'symmetry' and 'wing'.

6 | P a g e

Figure 2: Fine Mesh Generated

Once the mesh had been generated; the problem then needed to be setup and solved in FLUENT.

The first step of setting up the problem was to change the viscosity model from laminar to turbulent,

with the specific turbulence model being changed for each simulation in order to investigate the

effects of the turbulence model on the results. Next, the operating pressure for the domain needed

to be set, and this was a function of altitude as described as follows:

where P

0

is the pressure at ground level, h

0

is the height of the atmosphere, which is taken as 7km

and h is the altitude of concern which, in this specific simulation, was 4km. This resulted in the

operating pressure being 57220 Pa. Next, the inlet conditions needed to be set. When setting the

velocity; it was specified using components by splitting the total velocity into x and y components

where the total velocity was at an angle of 7

0

to the x axis. At the inlet the turbulence had to also be

specified and this was done using turbulence intensity along with hydraulic diameter. This method

was chosen as the hydraulic diameter can be approximated more accurately than the other

specification methods. The turbulence intensity was set to 7% as common values used in simulations

are between 5% and 10% with values over 10% being highly turbulent and fairly rare in simulations.

The hydraulic diameter was set to that of the flat plate approximation of 2 m. The same turbulence

conditions were also set at the pressure outlet whilst the gauge pressure at the outlet was set to 0

Pa. Next, the reference values were computed from the inlet and the temperature and pressure was

changed accordingly to the values previously mentioned. The next step was to select the solver

methods. Due to the effect of the turbulence model being the only variable of concern, the solution

methods selected were used in every simulation and thus had to be chosen correctly.

7 | P a g e

For the pressure-velocity coupling, the Coupled solver was used. The coupled algorithm solves both

the momentum and pressure based continuity equation simultaneously (2). This scheme was chosen

as it was found, from past experience, to give results similar to that of the SIMPLE solver whilst

having greatly reduced convergence times. This meant that the solution would converge fairly

quickly whilst providing as accurate as possible results. For the spatial discretisation, the Second

Order Upwind scheme was chosen. With the upwind differencing scheme, cell face values upwind of

the centroid is taken to be the same as the value of the cell centroid upwind of the cell concerned

(3). With the second order upwind scheme, the cell face values are computed using a Taylor series

expansion of the cell-centred solution about the cell centroid (2). The Second Order Upwind scheme

was chosen as it was found, in previous simulations, to provide the most accurate results for the

widest range of simulations. It also has increased accuracy over the First Order Upwind scheme,

especially in cases where flow separation is expected as was found in (4). The QUICK scheme was

also found to provide accurate results, however was not as robust as the Second Order Upwind

scheme in terms of the range of problems that the QUICK scheme could be applied to. This was

especially evident for natural convection problems as found in (5). Thus, for these reasons the

Second Order Upwind scheme was determined to be the most appropriate spatial discretisation

scheme for this problem. Next, in order to accurately judge convergence, both a monitor for the

drag and lift coefficient on the wing was created as these plots would become constant when the

solution has converged. The lower limit on the residuals were then set to 0.0001 in order to obtain

greater accuracy in the results. The next step was to then initialise the solution and this was done

using hybrid initialisation which solves the Laplace equation to produce a velocity field and smooth

pressure distribution in the domain (2). Once initialised, the solution was run and the results were

extracted and analysed.

Results

When conducting the various simulations, the most important effects that were of concern were the

following:

1. Effect of various turbulence models

2. Mesh independence of the solution

Before analysing the results of each simulation, it was important to establish the results as predicted

by the empirical data provided. Using this data, for an aerofoil with an angle of attack of 7

0

, the

coefficient of lift was approximately 1.18 and the coefficient of drag was approximately 0.175. The

equation governing the drag force and lift force for an aerofoil flow is given as follows:

where the area A is the plan area of the aerofoil which is the projected area of the aerofoil as seen

from above or below. This equation applies to both lift and drag and the values predicted for a 1 m

wing span with chord length 2 m was: Drag force = 4537.02 N, Lift Force = 30592.49 N.

Simulation 1

The first simulation that had been conducted using the aforementioned setup information was done

using the standard k-epsilon (k-) turbulence model with standard wall functions. This standard k-

epsilon model is based on model transport equations for the turbulence kinetic energy and its

8 | P a g e

dissipation rate (2). These equations and further detail on this model can be found in (2). The results

of the simulations run using this model are presented here. First, the convergence nature of the

solution can be seen in figures 3, 4 and 5.

Figure 3: Residuals k-epsilon

Figure 4: Drag Coefficient k-epsilon

9 | P a g e

Figure 5: Lift Coefficient k-epsilon

From figures 4 and 5 it can be seen that convergence may have occurred in the region of 1600

iterations. It should also be noted that these plots were used simply as a guide to judge convergence

and do not represent the true drag and lift coefficients for the given aerofoil. This is due to the

vector direction in which FLUENT measures them being different to the actual direction in which

they should be measured. This is illustrated in figure 6 where the direction of measurement is the x

and y axis', whereas the actual direction they should be measured in is the x1, y1 axis' due to the

manner of the flow direction relative to the domain.

Figure 6: Axis Transformation for Drag and Lift

Using the new direction vectors, as represented in figure 6, it was found that with the standard k-

epsilon model, the total lift force per 1 m wingspan was found to be 22702.50N. Similarly the total

drag force was found to be 2310.18N. Both these values are found to be lower than the predicted

values and this could be a result of the different conditions under which the coefficients were

10 | P a g e

obtained for the predicted results. Due to no information being available concerning the conditions

under which the coefficients; used to predict the results; were obtained, it is likely a cause for the

difference in the simulated and predicted results. As an example, the viscosity of the fluid would

have an effect on the total drag force on the aerofoil thus differences in the values used in the

simulation and prediction could result in differences in the total drag force. It could also be that the

coefficients may have been obtained using a different working fluid in which case there may be

inaccuracies when converting the values to air. Another contributing factor is that for flows over a

mach number of 0.3, the fluid would generally need to be modelled as compressible, which was not

done in this case. As a result of these arguments, it can be said that for this specific flow scenario;

the simulated values are more accurate as a result of the direct nature in which they solve the

governing equations. This is especially true for slightly more complex geometries, such as that of an

aerofoil. This being said, in order to check that the solution was in fact accurate, the y+ value along

the surface of the wing was plotted in order to ensure that it fell between 30 and 300 as this would

validate the use of the wall functions. These wall functions in term determine the wall shear stress

which are indicative of the drag force on the cylinder. This y+ plot can be seen in figure 7.

Figure 7: y+ k-epsilon

From figure 7 it can be seen that majority of the surface of the aerofoil contains a y+ value in the

range mentioned, which validates the use of the wall functions. As previously mentioned, flow

separation was also expected to occur at some point along the aerofoil's surface. In order to judge

where this separation occurs; the velocity contour plot was investigated and at a point where the

boundary layer along the aerofoil stops growing as expected; it was determined that separation

occurs at that point. This contour plot can be seen in figure 8.

11 | P a g e

Figure 8: Velocity Contour Plot k-epsilon

From figure 8, the point of separation of the flow was judged to be in the region of 1.9m

downstream of the leading edge of the aerofoil. This was found to be fairly close to the predicted

value of 1.8m that was used to determine the boundary layer thickness.

Simulation 2

The second simulation that was run was done using the SST-k-omega (SST-k-) model. This model is

a blend of the robust and accurate formulation of the k-omega model near the wall with the free-

stream independence of the k-epsilon model in the far field (2). More information, as well as the

governing equations for this model can be found in (2). As with the first simulation, the convergence

behaviour is presented first with the same monitors in place. These can be seen in figures 9, 10 and

11.

12 | P a g e

Figure 9: Residuals k-omega

Figure 10: Drag Coefficient k-omega

13 | P a g e

Figure 11: Lift Coefficient k-omega

From figures 10 and 11, it can be seen that the k-omega model converges much faster than the k-

epsilon model with convergence occurring in the region of 500 iterations. Using this turbulence

model the lift and drag force was found to be: Drag force = 1617.26 N, Lift force = 24466.13 N. Again,

these values were found to be greatly different to the predicted values. The arguments presented

for the first simulation however still apply and provide an explanation for the differences in

predicted and simulated results. It should be noted that the SST-k-omega turbulence model is the

recommended model for analysis of aerofoils and this model achieves greater accuracy in a greater

class of flows (2). Thus it can be said that the results found with this turbulence model is of greater

accuracy than those achieved with the k-epsilon model. Again, however, in order to validate the use

of the wall functions for this model, the y+ plot was used and can be seen in figure 12.

14 | P a g e

Figure 12: y+ k-omega

From figure 12 it can be seen that y+ value is within the required range for a larger portion of the

aerofoil when using the k-omega turbulence model. This shows that the use of the wall functions are

valid. It can also be seen that y+ falls within the required range for a greater proportion of the wing

when using the k-omega model as compared with the k-epsilon model. This proves that, for this

specific flow scenario, the k-omega method is the more accurate of the two. Finally, in order to

judge flow separation; the velocity contour plot was once again used. This is seen in figure 13.

15 | P a g e

Figure 13: Velocity Contour Plot k-omega

Investigation of the velocity contour plot revealed that flow separation again only occurs in a region

approximately 1.9 downstream of the leading edge of the aerofoil.

Simulation 3

The third simulation that was run using the fine mesh was done using the Reynolds Stress Transport

model (RSM). The RSM closes the Reynolds-averaged Navier-Stokes equations by solving transport

equations for the Reynolds stresses, together with an equation for the dissipation rate (2). More

detail can be found in (2). As with the previous simulations, the convergence behaviour has been

presented in figures 14, 15 and 16.

16 | P a g e

Figure 14: Residuals RSM

Figure 15: Drag Coefficient RSM

17 | P a g e

Figure 16: Lift Coefficient RSM

From figures 14, 15 and 16, it can be seen that convergence only occurs in the region of 900

iterations. Using the RSM, the drag and lift forces were found to be: Drag force = 1513.09 N, Lift

force = 23669.56 N. Once again these values are found to be different to the predicted values with

the differences already having been explained for the previous simulations. In comparison to the

other turbulence models, the RSM is the most elaborate model and has greater potential to provide

more accurate solutions. However this model does employ certain assumptions to close the

transport equations and still relies on scale equations (epsilon; omega), both of which are a source

of inaccuracy for this scheme. The results for this simulation can be said to be more accurate than

the other two, simpler models, however not so much so to warrant the additional computational

cost. In order to confirm the accuracy of the solution, again the wall y+ value was checked along the

surface of the aerofoil. This can be seen in figure 17 which shows the wall y+ value along the length

of the aerofoil.

18 | P a g e

Figure 17: y+ RSM

From figure 17 it can be seen that y+ falls within the appropriate range; for the RSM model; over as

much of the aerofoil as with the k-omega model. Due to this being the large majority of the aerofoil

surface, it can again be said that the use of wall functions for this model are indeed accurate. Once

again, in order to judge the separation of the flow the velocity contour plot was investigated and this

can be seen in figure 18.

19 | P a g e

Figure 18: Velocity Contour Plot RSM

From investigation of figure 18 it was again found that the flow separation occurred in the region of

1.9m downstream of the leading edge of the aerofoil. This shows that all three turbulence models

produce the same velocity profiles.

Simulation 4

The final simulation that was conducted was done using a rougher mesh than for the first three

simulations. This was done due to the first mesh having in the region of 60000 cells and thus much

further refinement could not be done due to the cell limit in the FLUENT academic licence. The

rough mesh was in the region of half the mesh density of the first three simulations in all the regions

of the domain and can be seen in figure 19.

20 | P a g e

Figure 19: Rough Mesh Generated

The simulation run with the rough mesh was done using the SST-k-omega turbulence model alone

due to this model being recommended for aerofoil analysis. This model was also found to converge

much faster than the other two and thus provided the best platform to compare the results from the

fine and rough mesh simulations.

As with the previous simulations, the convergence nature of the simulation run with the rough mesh

has been represented in figures 20, 21 and 22.

21 | P a g e

Figure 20: Residuals Rough Mesh

Figure 21: Drag Coefficient Rough Mesh

22 | P a g e

Figure 22: Lift Coefficient Rough Mesh

From the convergence plots presented it can be seen that the rough mesh converged much faster

than any previous simulation. This is a direct result of having fewer cells and thus faster solving

times. It can be seen however that the residuals do not converge as smoothly as with the fine mesh.

This is most likely due to the larger cells resulting in the solver having to overcompensate to satisfy

the governing equations and this continues to loop over itself around the converged value. It may

have been possible to overcome this fluctuation by setting the under-relaxation factors even smaller

in order to avoid the overcompensation of the solver. With the rough mesh, the resultant forces on

the aerofoil were found to be: Drag force = 1616.54 N, Lift force = 24371.26 N. From these results it

can be said the result is fairly mesh independent as these results are extremely close to those

achieved with the fine mesh. However it can be seen that due to the way in which the mesh was

constructed, the mesh density close to the aerofoil was still fairly high which still results in an

accurate solution. Again, to check this accuracy the y+ value along the wall surface has been plotted

in figure 23 as this would validate the wall functions.

23 | P a g e

Figure 23: y+ Rough Mesh

From figure 23 it can be seen that the y+ value along the wall falls within the required range almost

everywhere along the aerofoils surface. This validates that the wall functions are indeed valid, even

for this lowered mesh density. Finally, for the rougher mesh the flow separation again needed to be

checked against the previous results, and this was done with the use of the velocity contour plot as

before. This is seen in figure 24.

24 | P a g e

Figure 24: Velocity Contour Plot Rough Mesh

For the rough mesh it was found that the flow separation occurred slightly closer to the leading edge

of the aerofoil at a distance of around 1.8m. Thus, overall the only major difference between the

fine and rough mesh results are the rates of convergence and the velocity profiles that are

developed.

Conclusion

From the simulations conducted it can be concluded that when analysing an aerofoil profile that the

most appropriate turbulence model is the SST-k-omega model. This is due to it having the cheapest

computational cost whilst having fairly accurate results compared to the expensive RSM model.

Another conclusion that can be drawn is that the different turbulence models result in similar

velocity profiles yet due to differences in the stress modelling of the flow; each turbulence model

produces different values of lift and drag. It can also be concluded that when comparing the results

of a simulation and empirical data, it is vital that the conditions under which the simulation is run

matches the conditions used when obtaining the empirical data. It can also be concluded that for

flows with Mach numbers greater than 0.3, compressibility effects likely need to be taken into

account else the results of the simulation will be inaccurate. It can also be concluded that for the

specific aerofoil shape analysed at the specific angle of attack analysed; the flow remains fairly well

structured over majority of the length of the aerofoil as the flow only separates around 0.1m

upstream of the trailing edge. Finally it can be concluded that the result is fairly mesh independent

as long as the mesh remains fairly fine in the regions close to the aerofoil.

25 | P a g e

References

1. Hariram, A V. Tut 7: Flow Over a Flat Plate. Stellenbosch : University of Stellenbosch, 2013.

2. Ansys-Help. Ansys FLUENT Theory Guide. Ansys FLUENT Theory Guide. s.l. : ANSYS, 2011.

3. HK, Versteeg and W, Malasekera. 5.6 The upwind differencing scheme. An Introduction to

Computational Fluid Dynamics The Finite Volume Method. Essex : Pearson Education Limited, 2007.

4. Hariram, A V. Tut 6: Vortex Shedding in Fluent. Stellenbosch : University of Stellenbosch, 2013.

5. . Tut 5: Natural Convection Heat Transfer in Fluent. Stellenbosch : University of Stellenbosch,

2013.

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Bombardier Aerospace 20140716 Business Aircraft Market Forecast - 2014 33Documento43 páginasBombardier Aerospace 20140716 Business Aircraft Market Forecast - 2014 33asbadgAinda não há avaliações

- Flow Through A Circular TubeDocumento8 páginasFlow Through A Circular TubeAnas Iqmal0% (1)

- 2016 Year End: General Aviation Aircraft Shipment ReportDocumento7 páginas2016 Year End: General Aviation Aircraft Shipment ReportasbadgAinda não há avaliações

- As 5045Documento2 páginasAs 5045asbadgAinda não há avaliações

- 2013 Year End: General Aviation Aircraft Shipment ReportDocumento6 páginas2013 Year End: General Aviation Aircraft Shipment ReportasbadgAinda não há avaliações

- 2016 GAMA Databook - ForwebDocumento60 páginas2016 GAMA Databook - ForwebAnton100% (1)

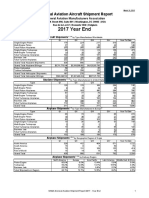

- 2017 Year End: General Aviation Aircraft Shipment ReportDocumento7 páginas2017 Year End: General Aviation Aircraft Shipment ReportasbadgAinda não há avaliações

- C 141 ADocumento2 páginasC 141 AasbadgAinda não há avaliações

- Brochura Legacy 600Documento17 páginasBrochura Legacy 600jtonetiAinda não há avaliações

- 2015 Year End: General Aviation Aircraft Shipment ReportDocumento7 páginas2015 Year End: General Aviation Aircraft Shipment ReportasbadgAinda não há avaliações

- 2018 Year-End Report: General Aviation Aircraft Shipment ReportDocumento7 páginas2018 Year-End Report: General Aviation Aircraft Shipment ReportasbadgAinda não há avaliações

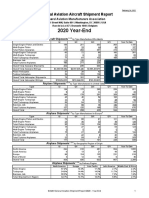

- 2020 Year-End: General Aviation Aircraft Shipment ReportDocumento7 páginas2020 Year-End: General Aviation Aircraft Shipment ReportasbadgAinda não há avaliações

- C 141 FDocumento2 páginasC 141 FasbadgAinda não há avaliações

- 2014 Year End: General Aviation Aircraft Shipment ReportDocumento7 páginas2014 Year End: General Aviation Aircraft Shipment ReportasbadgAinda não há avaliações

- 2017 Year End: General Aviation Aircraft Shipment ReportDocumento7 páginas2017 Year End: General Aviation Aircraft Shipment ReportasbadgAinda não há avaliações

- Gulfstream G550 Specifications SheetDocumento4 páginasGulfstream G550 Specifications Sheetasbadg100% (1)

- S102SDocumento2 páginasS102SasbadgAinda não há avaliações

- S102BDocumento2 páginasS102BasbadgAinda não há avaliações

- G550Performance ENG GS530EDocumento8 páginasG550Performance ENG GS530Easbadg100% (1)

- N 64215Documento1 páginaN 64215asbadgAinda não há avaliações

- Airbus FMCDocumento89 páginasAirbus FMCceparis100% (2)

- E 864Documento2 páginasE 864asbadgAinda não há avaliações

- E 561Documento2 páginasE 561asbadgAinda não há avaliações

- C 5 ADocumento2 páginasC 5 AasbadgAinda não há avaliações

- Airbus FMCDocumento89 páginasAirbus FMCceparis100% (2)

- Gulfstream G550 BrochureV3Documento26 páginasGulfstream G550 BrochureV3RAC1100% (1)

- C 141 CDocumento2 páginasC 141 CasbadgAinda não há avaliações

- C 141 DDocumento2 páginasC 141 DasbadgAinda não há avaliações

- Ah 79100 CDocumento2 páginasAh 79100 CasbadgAinda não há avaliações

- Bacj 1Documento2 páginasBacj 1asbadgAinda não há avaliações

- BacjDocumento2 páginasBacjasbadgAinda não há avaliações

- Europe Merchant Hydrogen Plants 112015Documento3 páginasEurope Merchant Hydrogen Plants 112015totpityiAinda não há avaliações

- 22 Piston Rings e PDFDocumento12 páginas22 Piston Rings e PDFBhumin PatelAinda não há avaliações

- 2017 Winter Question Paper PDFDocumento4 páginas2017 Winter Question Paper PDFJanardan JakhadAinda não há avaliações

- Dynamic Surface Tension - KRÜSS ScientificDocumento4 páginasDynamic Surface Tension - KRÜSS ScientificRamirez FrancisAinda não há avaliações

- Book 2: Chapter 4 - Fluid Flow: Application LimitationsDocumento20 páginasBook 2: Chapter 4 - Fluid Flow: Application LimitationsVaniya GoelAinda não há avaliações

- Daily Air Compressor Inspection ChecklistDocumento1 páginaDaily Air Compressor Inspection Checklistarunjith rAinda não há avaliações

- Airliquide Ec Handbook v1.3Documento96 páginasAirliquide Ec Handbook v1.3John DalkiaAinda não há avaliações

- LPG TanksDocumento48 páginasLPG TanksdlebreromAinda não há avaliações

- SINGLE STAGE AIR COMPRESSOR LabDocumento5 páginasSINGLE STAGE AIR COMPRESSOR LabLetarbor de'GhettoGuyAinda não há avaliações

- Pipes and FittingsDocumento9 páginasPipes and FittingsRaquel MonsalveAinda não há avaliações

- Line Identification Line P&Id Size Pipe No. Line No. (In.) Spec Service (PD-) FromDocumento56 páginasLine Identification Line P&Id Size Pipe No. Line No. (In.) Spec Service (PD-) Fromsamer8saifAinda não há avaliações

- Unit 2 PumpsDocumento11 páginasUnit 2 PumpsThuy TranAinda não há avaliações

- Lecture 2-Hydraulic / PumpDocumento23 páginasLecture 2-Hydraulic / PumpyujAinda não há avaliações

- 9A03501 Thermal Engineering - IIDocumento1 página9A03501 Thermal Engineering - IIsivabharathamurthyAinda não há avaliações

- List F1929 - StocktypeDocumento37 páginasList F1929 - StocktypeRizki HardiansyahAinda não há avaliações

- Combustion Ratio ControlDocumento8 páginasCombustion Ratio ControlMourougapragash SubramanianAinda não há avaliações

- Rising MainDocumento2 páginasRising MainJitesh KumarAinda não há avaliações

- Tutorial: Water Flooding and WAG Application Builder Grid Properties (Field Units)Documento5 páginasTutorial: Water Flooding and WAG Application Builder Grid Properties (Field Units)Erick Morales SánchezAinda não há avaliações

- Assignmnet 2 Solutions 2011Documento4 páginasAssignmnet 2 Solutions 2011nedian_2006Ainda não há avaliações

- RESONANCE ALP Sol P Fluid Mechanics EDocumento6 páginasRESONANCE ALP Sol P Fluid Mechanics EChandrakant Bokade100% (1)

- DOLE Rule 1170 - Unfired Pressure VesselsDocumento16 páginasDOLE Rule 1170 - Unfired Pressure VesselsCrislene CruzAinda não há avaliações

- Laddomat 21 ManualDocumento8 páginasLaddomat 21 ManualAlonso CoradoAinda não há avaliações

- Impulse Tubing InstrumentsDocumento2 páginasImpulse Tubing InstrumentssuhailfarhaanAinda não há avaliações

- Greenhouse Gases and Human Activities: Snc2DDocumento7 páginasGreenhouse Gases and Human Activities: Snc2DdaramdasAinda não há avaliações

- Reporte Examen A Junior Valente Cansino PerezDocumento1 páginaReporte Examen A Junior Valente Cansino PerezCesar Alberto Cansino PerezAinda não há avaliações

- IBU-SMO-DC D002 Barrier Guidelines - Revision 3.1 (2020)Documento51 páginasIBU-SMO-DC D002 Barrier Guidelines - Revision 3.1 (2020)Boedi Syafiq100% (1)

- MAnual de Servicio Bomba CAT 2DXDocumento8 páginasMAnual de Servicio Bomba CAT 2DXKetzadilis Johana PérezAinda não há avaliações

- Abu Dhabi Oil Co., LTD (Japan)Documento3 páginasAbu Dhabi Oil Co., LTD (Japan)Anonymous AdofXEYAgEAinda não há avaliações

- Introduction GmawDocumento6 páginasIntroduction GmawNur' AyuniAinda não há avaliações