Escolar Documentos

Profissional Documentos

Cultura Documentos

083 AppOpt31 7219

Enviado por

Jacqueline Didier0 notas0% acharam este documento útil (0 voto)

24 visualizações7 páginas1. An absolute cryogenic radiometer (ACR) operating at 2-4K has been developed as a standard detector for measuring radiant fluxes from 20 nW to 100 μW with an uncertainty of ±1%.

2. The ACR has a flat absorption efficiency over 99% from visible to long-wavelength IR. It has been installed in a cryogenic chamber at NIST for testing cryogenic sources, detectors, and optics.

3. Characterization measurements of the ACR's time constant, responsivity, and nonequivalence error agree with design predictions. Comparisons with a photodiode detector found agreement within 0.5% uncertainty.

Descrição original:

083

Título original

083_AppOpt31_7219

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documento1. An absolute cryogenic radiometer (ACR) operating at 2-4K has been developed as a standard detector for measuring radiant fluxes from 20 nW to 100 μW with an uncertainty of ±1%.

2. The ACR has a flat absorption efficiency over 99% from visible to long-wavelength IR. It has been installed in a cryogenic chamber at NIST for testing cryogenic sources, detectors, and optics.

3. Characterization measurements of the ACR's time constant, responsivity, and nonequivalence error agree with design predictions. Comparisons with a photodiode detector found agreement within 0.5% uncertainty.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

24 visualizações7 páginas083 AppOpt31 7219

Enviado por

Jacqueline Didier1. An absolute cryogenic radiometer (ACR) operating at 2-4K has been developed as a standard detector for measuring radiant fluxes from 20 nW to 100 μW with an uncertainty of ±1%.

2. The ACR has a flat absorption efficiency over 99% from visible to long-wavelength IR. It has been installed in a cryogenic chamber at NIST for testing cryogenic sources, detectors, and optics.

3. Characterization measurements of the ACR's time constant, responsivity, and nonequivalence error agree with design predictions. Comparisons with a photodiode detector found agreement within 0.5% uncertainty.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 7

Characterization of an absolute cryogenic

radiometer as a standard detector

for radiant-power measurements

R. U. Datla, K. Stock, A. C. Parr, C. C. Hoyt, P. J. Miller, and P. V. Foukal

An active cavity radiometer of the electrical substitution type with a cone receiver that operates at 2-4 K

has been developed for measuring radiant fluxes in the dynamic range of 20 nW to 100 puW within an

uncertainty of 1% (2a level). It is a broadband absolute detector with a flat overall absorption efficiency

that is > 99% for radiation from the visible to long-wavelength IR. The system is designed based on

thermal modeling and experimental measurements of concepts. It has been installed in the cryogenic

chamber for low-background infrared radiation calibrations at the National Institute of Standards and

Technology (NIST) for testing cryogenic blackbody sources, detectors, and optical components. Its time

constant, responsivity, and nonequivalence error have been measured. They are in agreement with

design predictions. Radiant power measurements of an amplitude-stabilized He-Ne laser beam with the

radiometer and an industry standard photodiode detector, QED-200, have been intercompared and found

to be in agreement. The intercomparison ratio of the measurements with the absolute cryogenic

radiometer and QED-200 was 1.004 in the 75-100-puW range with an uncertainty of 0.5% (the 3 level).

Key words: Radiant power, absolute cryogenic radiometer, radiometry, electrical substitution radiom-

eter, visible to long-wavelength IR radiation, photodiode detector intercomparison, low-background IR

radiation.

1. Introduction

Absolute cryogenic radiometers (ACR's) are being

used increasingly as the standard detectors for abso-

lute radiometry. A review of the historical develop-

ment of absolute radiometers can be found in Ref. 1.

Electrical substitution had been the principal tech-

nique for measuring absolute optical power since the

original experiments of Kurlbaum and Angstrom

nearly a century ago.' The technique involves the

application of electrical heating to keep the receiver of

the radiometer at a constant temperature. When

radiation falls on the receiver, to keep the receiver at

the same temperature the electrical heater power is

reduced by an amount that is equal to the optical

power. Therefore the optical power is measured as

the difference between the electrical power applied

R. U. Datla, K. Stock, and A. C. Parr are with the National

Institute of Standards and Technology, Gaithersburg, Maryland

20899. C. C. Hoyt, P. J. Miller, and P. V. Foukal are with,

Cambridge Research and Instrumentation, Inc., 21 Erie Street,

Cambridge, Massachusetts 02139.

Received 27 January 1992.

0003-6935/92/347219-07$05.00/0.

i 1992 Optical Society of America.

before and after the radiation is permitted to fall on

the receiver. In the past two decades cryogenic

radiometers have gained acceptance as the primary

means for radiometry in standards laboratories be-

cause of their improved accuracy."

2

A cryogenic

radiometer was built at the National Institute of

Standards and Technology (NIST) and was used

successfully in a liquid helium-cooled cryochamber

until early 1985 for measuring the radiant-power

output of cryogenic blackbodies.

3

It became unser-

viceable with age, and a more modern cryogenic

radiometer with improved accuracy was built re-

cently for more general calibration and research

activity in the IR spectral region of 2-30 m. A

large (60-cm-diameter by 152-cm-long) stainless-steel

chamber with its internal copper cryoshield cooled to

20 K by a closed-cycle He refrigerator was built

especially to house the radiometer and provide a

low-background environment for calibrations and

research. The laboratory is called the Low Back-

ground Infrared Radiation (LBIR) calibration facility.

The physical features and design considerations of

the radiometer and the cryochamber are described in

recent publications.

3

In Sections 2-5 the features

of this radiometer are illustrated further from its

1 December 1992 / Vol. 31, No. 34 / APPLIED OPTICS 7219

design point of view, and its experimental character-

ization is described.

Silicon photodiodes have been developed for use as

standard detectors.

6

In Section 6 we compare the

performance of the NIST LBIR ACR with that of the

QED-200 silicon photodiode by measuring the output

beam of a He-Ne laser beam at 632.8 nm.

2. NIST LBIR ACR Specifications

The design specifications of this radiometer are an

outgrowth of the earlier radiometer at NIST that was

operated before 1985. The diameter of the cavity

entrance aperture is set to 3.0 cm to maximize the

radiative flux collected. A conical cavity with a

45-deg full apex angle is chosen to provide the inci-

dent rays at least four reflections inside the cavity to

increase the effective absorption of radiation. The

receiver can resolve radiative fluxes down to a 0.2-nW

level. The sensitivity is limited by only the tempera-

ture stabilities of 5 p.K rms achieved under feedback

control when digital temperature controllers are used.

The time constant of the receiver is specified to be as

low as possible (i.e., within a few tens of seconds) to

have a fast response. The numerical model used to

design the ACR with these specifications is described

briefly below.

3. Description of the Numerical Model Used to Design

the ACR

The thermal response of the cryogenic cavity of the

radiometer was modeled with a computer program

called the Lumped Parameter Numerical Code. The

program used data about the geometry together with

temperature-dependent models of the specific heats

and conductivities of the various materials. The

appropriate heat capacities and thermal impedances

are generated as output by the program to describe

the radiometer in terms of parameters such as the

diameter, the vertex angles, and the thickness of the

ACR cone.

The following conditions are used in developing the

final design. The receiver is taken to be operated at

2.2 K, which is determined by a pressure-controlled

He bath. The He bath is taken to be a fixed-

temperature boundary, as is the ambient temperature.

The requirement that the receiver resolution be at

the 0.2-nW level implied with a 5-piK thermometer

noise that the responsivity should exceed 25 K/mW.

To achieve this goal, we considered receiver designs of

25-K/mW responsivity.

Finally, we chose the parameters that entered into

the design based on our experience at CRI, Inc.

constructing cyrogenic receivers and from the results

of the lumped parameter numerical code. We also

studied the nonequivalence terms by using the lumped

parameter model. Figure 1 shows the nodes of

principal interest in the model. The temperatures at

these nodes are the values shown in tabular columns

(a) and (b) in Fig. 1, which were obtained by running

the model at 10 pLW or electrical heating power and an

equal radiative power input, respectively. The key

TEMPERATURE (K)

Node (a) Electrical Heating (b) Radiative Heating

paint 2.432668 2.432736

cone 2.432668 2.432636

heater windings (htr) 2.432757 2.432601

heat sink (h/s) 2.200284 2.200284

GRT 2.432670 2.432635

Fig. 1. Nodes in the lumped parameter model: GRT's, Ge

resistance thermometers.

result from the modeling is that the cavity thermom-

eter and the cone are isothermal to within 1

1

uK, thus

implying a nonequivalence error of 4.0 x 10-1" W,

which is negligible in the use of the instrument.

The calculated time behavior of the receiver in

response to a 10-pLW pulse is illustrated in Fig. 2(a).

The predicted time constant to a 50% response is 22

s. The time constant increases significantly at higher

input power. The response to a 100-,uW pulse is

shown in Fig. 2(b). Figure 3 shows the calculated

responsivity (in kelvins per watt) plotted as a function

of input power in watts. The responsivity is highest

for small signals since the heat-link thermal conduc-

tivity drops with temperature. Its peak marginal

(a)

2

LU

CL

:

c.

2.6 -

2.5 -

2.4 -

2.3-

2.2.

6

2

LU

(b)

a.

LU

I-

Fig. 2. Calculated

100i.LW input power.

5

4

3

2

1 0 tW CONE RESPONSE

0 100 200 300 400 500

Seconds

600

100 LW CONE RESPONSE

I I I I I 2

0 100 200 300 400 500 600

Seconds

response of the ACR receiver for 10- and

7220 APPLIED OPTICS / Vol. 31, No. 34 / 1 December 1992

I I l

-

50

40

> 30

z

0

() 20

10

C0 0.05 0.1 0.15 0.2

POWER (mW)

0.25 0.3

Fig. 3. Calculated responsivity of the ACR receiver.

responsivity is 30 K/mW for input power levels below

10 RW. Figure 4 shows the rising cone temperature

with increasing input power. At power levels ap-

proaching 1 mW the cone temperature exceeds 8 K

and the heater leads will lose their superconducting

properties. This and the general drop of responsiv-

ity illustrated in Fig. 3 suggest the loss of advantages

when this particular cryogenic radiometer for high

powers, i.e., powers above 0.1 mW, is used.

4. Physical Description of the ACR Receiver Assembly

Many of the physical features of the ACR have been

described in earlier publications.

2 4 5

The receiver

subassembly is illustrated in Fig. 5. The receiver

cavity is a cone with a 3.2-cm aperture diameter.

The inner surface of the cone is coated with specu-

larly reflective black paint. The cavity is con-

structed of electrodeposited O-free high-conductivity

Cu (OFHC) with a 0.127-mm wall thickness. The

cylindrical lip is brazed to a stainless-steel tube with a

3.81-cm outer diameter and a 3.04-cm-long and

0.05-mm thick wall, which provides the heat link

between the cavity and an OFHC heat sink. Two Ge

resistance thermometers (GRT's) are attached sym-

metrically on the cone outer surface. One is used for

measurements, and the other one is a spare. The

heat sink is an OFHC tube, the base of which is flange

mounted to the back wall of the receiver chamber.

The heat-sink temperature is also measured by two

GRT's that are located symmetrically as shown in

Fig. 5; again one GRT is kept as a spare. The

receiver GRT and the heat-sink GRT are monitored

by separate temperature controllers located outside

the chamber. The GRT's also operate as the temper-

2

LU

-

z

!R

0c

0U

6

5

4

3

2

0 50 100 150 200

INCIDENT POWER (pW)

250 300

Fig. 4. Variation of the temperature of the ACR receiver cone

with incident power.

Fig. 5. ACR receiver subassembly.

ature sensors of servo loops that control electrical

heaters on the receiver and the heat sink. The

controllers provide temperature stabilities of 4-5 pIK

rms at the receiver and heat sink. The menu-driven

computer software controls, monitors, and collects

the data of power supplied to the heaters.

5. Experimental Characterization of the ACR

The main objective of the characterization is the

evaluation of the aspects of the radiometer that affect

the overall accuracy, such as aperture area, receiver

absorptance, and nonequivalence effects. These ef-

fects have been measured, and the results are used to

produce an uncertainty budget, which gives the sys-

tematic uncertainty of the radiometric measurement.

A. ACR Aperture

The radiometer is designed to provide an extremely

accurate measurement of the irradiance at a given

distance from a blackbody along the optical axis.

An accurately machined 3.0-cm-diam circular aper-

ture made of Invar is mounted on the heat sink as

shown in Fig. 5. It is important that the area of the

aperture at operating temperatures is known as

accurately as possible. Invar (an Fe-Ni alloy, 36 Ni

by weight, not to be confused with age-hardenable

Invar or zero-crossing Invar) is chosen as the aper-

ture material because it has been'shown to have a

low-thermal-expansion coefficient throughout the

range from 300 to 2 K. The data indicate that the

36% Ni Invar has an average expansion coefficient of

1x 10-6 between 300 and 0 K.

7

The determination of the aperture area consists of

a measurement of diameter and roundness at room

temperature and then an extrapolation of the diame-

ter to operating temperatures based on the thermal

expansion data for 36% Ni Invar. Precise measure-

ments of the diameter of the aperture were performed

at room temperature by the precision metrology

group at NIST. Two different coordinate measuring

machines were used. The measured values for the

aperture diameter are 29.9573 and 29.9565 mm.

Measurements were also made by comparing the

diameter of the aperture to a gage block combination.

The value that we obtained for the diameter with this

method is 29.9584 mm. The average of the three

quoted values for the diameter is 29.95740 mm with a

standard deviation of 1.17 x 10-4. The corrected

diameter of the aperture at 2.2 K is 29.94212 mm.

1 December 1992 / Vol. 31, No. 34 / APPLIED OPTICS 7221

I I I~~~~~~~~~~~~~~~~~

I I I I

I

I I I

I

1.

The determination of the uncertainty of the aper-

ture area at 4.2 and 2 K was determined with a

worst-case analysis. According to the Invar thermal

expansion data, the coefficient is always between 0

and 2 x 10-6 and averages - 1 x 10-6. The two

extreme area changes (zero contraction and 2 x 10-6

linear contraction throughout the temperature range)

are 0.05% on either side of the number 7.050 cm

2

.

Thus the uncertainty assigned to the aperture area at

4.2 and 2 K is 0.05%.

B. Receiver Absorptance

The internal cone surface is coated with a specular

carbon black called chemglaze Z302. We character-

ized the absorptance of this paint by measuring the

single reflection at an incidence angle of 45 deg with a

spectrophotometer for wavelengths from 0.3 to 40

pm. The results are plotted in Fig. 6. It shows the

specular reflectance to be < 10.5% over this wave-

length range. Separate tests showed diffuse reflec-

tance to be < 1%. The four reflections expected in

this 45-deg cone yield a calculated overall absorptance

of > 99%. A measurement test

5

on the receiver cone

at 632.8 nm when an expanded He-Ne laser beam

was used showed an absorptance of 99.88 0.1%.

C. Measurements of ACR Parameters

1. Time Constant

The time constant of the receiver is measured in a

small test chamber where a pulse of 10

1

uW of heater

power is used. A time constant of 18.4 s is observed

for a 50% response compared with a calculated value

of 22 s. The time constant is not a critical figure of

merit for the extended measurements of relatively

stable sources. However, the long time constant

SPECULAR REFLECTANCE (0.3 - 2.0)

84

8.

8 7

. 7.8

o 7.4

7

. 6.8

8.6

D 6.4

, 6.2

5.8

5.8

5.4

11

; 10

R 9

rc

Iu

8

7

61

5

K

3 .4 .5 .6 .7 .8 .9 1 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 2

Wavelength (micrometers)

SPECULAR REFLECTANCE (2.0 - 40.0)

2 4 6 8 10121416182022242628303234363840

Wavelength (micrometers)

Fig. 6. Absorptanco measuromonts of Chomglazo.

indicates that the receiver should be permitted to

stabilize in response to radiant input after the shutter

is opened for at least three time constants before the

measurements are started.

2. Responsivity

We measured the responsivity using the following

procedure. After we cooled the LBIR chamber to

maintain a temperature of 20 K inside by using the

closed-cycle He refrigerator system, the radiometer

cryostat is filled with liquid He and evacuated to cool

the heat sink to a temperature of 2 K. The heat-sink

temperature controller is set to maintain a constant

temperature at slightly above 2 K by the ac bridge in

its active mode controlled by the heat-sink tempera-

ture sensor. The temperature sensor is a GRT.

The receiver temperature controller is set to operate

the receiver in the open mode as a bolometer. A set

value of heater power is provided to the receiver by

one of its heaters, and the resulting temperature is

measured by the receiver temperature sensor (GRT).

The heater power is changed to a different value, and

the resulting change in the temperature of the re-

ceiver is noted. The responsivity is given by

responsivity = (temperature change)/(power change).

The measured value of the responsivity is 29.7 K/mW

(0.1% lo) for the receiver operation at 2 K.

3. Measurement of Nonequivalence Error

The radiometer has been designed to reduce the

nonequivalence term to a negligible level. Nonequiv-

alence, such as the difference in the isotherms achieved

under electrical and radiative heating and heat losses

in the heater leads, has been minimized in the ACR

through the use of high-diffusivity Cu and supercon-

ducting heater leads made of Nb.

We tested this nonequivalence contribution by

sequentially applying a constant electrical power to

the two heaters mounted at opposite extremities of

the receiver. Equal power inputs should produce

equal temperatures at the receiver temperature sen-

sor. If a different temperature results, this differ-

ence is an upper limit to the magnitude of the effect

present in normal operating conditions. We can

translate the temperature difference to a nonequiva-

lence error by dividing the temperature change by the

product of the receiver responsivity and power of the

heat applied to perform the test. The results of a

nonequivalence test are summarized in Table 1.

D. Radiometer Equation and the Uncertainty Budget

The electrical substitution principle is illustrated in

Fig. 7. We obtained the flux F falling on the receiver

aperture by measuring the equivalent electrical power

to maintain the receiver at a constant temperature.

The equation to calculate the radiometric power is

electrical power = radiative power,

V

1

(V

2

/R) = FAN, (1)

7222 APPLIED OPTICS / Vol. 31, No. 34 / 1 December 1992

. .. .. .. .. ......

Table 1. Nonequivalence Measurementa

Temperature

Electrical Measured

Power with the

Receiver Supplied Receiver GRT

Heater (11W) (K)

Heater 1 0.0 2.3034

10.0 2.6095

Heater 2 0.0 2.3034

10.0 2.6094

aNonequivalence = (temperature change)/(responsivity) x (pow-

er) x 100 (0.0001 K)/(29.7 K/mW) x (0.010 mW) x (100) =

0.034%.

where V

1

is the voltage across the heater,

V

2

is the voltage across the current sense resis-

tor,

R is the current sense resistance,

F is the radiant flux,

A is the receiver absorptance, and

N is the nonequivalence.

By solving for the power F, we obtain from Eq. (1)

F = VI(V

2

/R)(1/A)(1/N). (2)

We determined the total uncertainty of the radiom-

eter characterization by taking into account the

uncertainties of individual measurements for each

term of Eq. (2). The uncertainty budget is shown in

Table 2. The overall systematic uncertainty (bias) is

0.12% (1cr). It is calculated as the square root of the

sum of squares (SRSS) of the components listed in

Table 2.

E. Measuring the Minimum Sensitivity (Noise Level)

The noise level of the radiometer had to be minimized

to achieve a signal-to-noise ratio of 100 for a flux of 20

nW. The ACR is a thermal detector, and the noise

level is dependent on the temperature stabilities of

the receiver and the heat sink. Thus minimizing the

noise level is partially a task of reducing electrical

noise in the temperature sensors and optimizing the

control parameters. We measured a noise level of

0.2 nW by operating the ACR in a small liquid

He-cooled Dewar at 4 K in a controlled experimental

setup.

6. Comparison of the ACR Performance with a

QED-200 Photodiode

We tested the performance of the ACR by measuring

the power of a He-Ne laser beam and intercomparing

Aperture

R

Flux, F-*_

ACR Receiver

Fig. 7. Electrical substitution principle.

Table 2. Uncertainty Budget for ACR Characterization,

Uncertainty

(1 Standard

Deviation

of the

Mean)

Measurement Method Magnitude (%)

(a) Current NIST calibra- Depends on 0.01

sense resistor tion ohmme- range

ter

(b) Voltage NIST calibra- Depends on 0.05

tion voltmeter range

(c) Receiver Integrating (0.9988) 0.1

absorptance sphere at

632.8 nm

(d) Nonequiva- Dual heaters 0.03% 0.03

lence

aTotal systematic uncertainty given as the SRSS of individual

components (a)-(d) (=0.12%).

it with a measurement by using a QED-200 photo-

diode. A QED-200 has a near-unity quantum effi-

ciency because of the alignment of the three silicon

photodiodes in the package in a light-trapping config-

uration, which results in a near-complete absorption

of incident radiation. The ratio of the output cur-

rent to incident radiation can be calculated on the

basis of one electron per incident photon according to

the equation.

6

R = wavelength/1239.5, (3)

where R is the responsivity in amperes per watt and

the wavelength is in nanometers. It has been estab-

lished through experiments

6

that the response is

near-unity quantum efficiency without an applied

bias from 450 to 550 nm. Above 550 nm a bias

voltage is necessary to bring the quantum efficiency

to near 1 and avoid saturation nonlinearity. In the

present experiment the QED-200 detector is checked

at 632.8 nm by comparing it with another QED-200

reference standard detector at NIST, and it was

adjusted to bring the quantum efficiency to near 1

and eliminate nonlinearity with a 20-V reverse bias

for incident radiant powers of 75-100 pIW. The

upper limit for power measurements with the ACR is

100 ,uW because of its falling responsivity to higher

incident powers, and consequently the intercompari-

son of the ACR with QED-200 is performed at 75 and

100 W of incident power from a He-Ne laser.

We obtained the incident He-Ne laser beam power

P in watts from the measurement of the QED-200

photocurrent response S in amperes by using Eq. (3)

(P = S/R). We measured the photocurrent S by

converting to voltage by using a transimpedance

amplifier. The voltages are measured with a voltme-

ter. The calibration of the transimpedance of the

amplifier circuit yielded a value of 99,896 V/A with an

uncertainty of 0.007%. The calibration of the digital

voltmeter quoted by the manufacturer and tested at

NIST is unity with an uncertainty of 0.014%. The

1 December 1992 / Vol. 31, No. 34 / APPLIED OPTICS 7223

systematic uncertainty when Eq. (3) is used to charac-

terize a commercial QED response is 0.1% as quoted

by the manufacturers based on tests reported in the

literature.

6

The total systematic uncertainty is 0.1%

for the QED-200 measurements. It is calculated as

the SRSS of the three uncertainties.

The experimental setup is shown in Fig. 8. We

obtain a beam of vertically polarized light from a

He-Ne laser by aligning its polarization with that of a

vertical polarizer. The beam was amplitude stabi-

lized by a laser intensity stabilizer.

9

It consisted of

an electro-optic modulator [Fig. 8(A)] and a thermally

controlled monitor photodiode with a beam splitter

[Fig. 8(B)]. These units connected to an electronic

servo system stabilized the laser intensity. Long-

term fluctuations of laser power are reduced to within

0.05% of output power. The beam is spatially fil-

tered to reduce scattered light. A beam expander, an

aperture, and a focusing lens shown in Fig. 8 steered

the beam into the receiver cone of the ACR with a

spot size of 5 mm. A fused silica glass set at a

Brewster angle of 57 deg for vertically polarized light

is used as a window at the entrance port to the LBIR

chamber to reduce laser power losses caused by

reflections. Leakage of the ambient background ra-

diation into the chamber is minimized when nonlimit-

ing apertures are used at the inner and outer cryo-

genic shields and at a place close to the ACR cone.

To simplify the schematic, we do not show the

apertures in Fig. 8. Measured values of the back-

ground flux levels at the ACR aperture are found to be

< 0.1% of the laser power.

To compare the ACR power measurement with the

QED-200, we had to measure the ratio of the laser

power outside the LBIR chamber to inside the cham-

ber as a first step in the experiment. We used the

QED-200 detector to measure the ratio at the ambi-

ent conditions of the temperature and pressure by

interchanging its position from outside to inside the

chamber and vice versa as shown in Fig. 8. At each

position of the QED-200 the beam power is measured

for 3 min with a data point recorded every second.

We measured the background by blocking the beam

with a solid obstruction both before and after the

Mirror

He-Ne LASER Iroflt surlace)

Polarizer

Laser Power

Controller

Module A

LBIR CHAMBER - Spatial Filter

Q~n | ED LENS Beam Expander

K/ I I a I I ~ bra Laser Power

I I ~~~~~~~~~~~~~~~~~~~~~Controiier

< L=L_. < o Module B

Mirror

Window (Iront surface)

(Brewster Angle)

Aperture

Mirror

(front surface)

Fig. 8. Experimental setup for the intercomparison of the ACR

and QED-200.

Table 3. Comparison of QED-200 Measurements of Laser Power

Between Inside and Outside the Chamber

Outside- Inside-

the-Chamber the-Chamber Ratio(1)

QED-200 QED-200 QED-200(Outside)

(1pW) (,.W) QED-200(Inside)

92.13 0.16 90.56 0.13 1.017 0.002

92.81 + 0.13 90.79 0.11 1.022 0.002

91.33 + 0.16 89.58 0.16 1.020 0.003

94.92 0.17 93.05 0.17 1.020 0.003

73.68 0.14 71.93 0.12 1.024 0.003

76.66 0.13 74.93 0.13 1.023 0.003

Weighed mean, 1.021

Standard deviation of the weighed mean, 0.09%

beam power measurements. The background sig-

nals are averaged and subtracted from the average

signals for beam power measurements. The data

are collected for eight such repetitions at various

times over several days and for two arbitrarily se-

lected powers of the laser beam, i.e., 75 and 100 [uW.

The data averages at each power level and the ratios

of powers measured internal to the chamber and

external to the chamber are shown in Table 3. The

uncertainty quoted for each measurement in the

table is the SRSS of the systematic (0.1%) and the

random components. Column 4 shows the ratios of

laser power measured by the QED-200 between its

outside-the-chamber and inside-the-chamber posi-

tions. The deviation of the ratios from unity is

attributed to losses and scatter at the Brewster

window. The uncertainty in each ratio is calculated

by the propagation of errors from power measure-

ments. As a second step of the experiment the same

ratio is measured with the ACR as the detector inside

the chamber and the QED-200 as the detector outside

the chamber. We cooled the LBIR chamber to 20 K

and the radiometer to 2 K to make the measurements.

The data are collected every second for 3 min each on

the QED-200 and the ACR. We alternated between

them using the same laser beam. The background is

measured on each device in the same way as described

above. The measured values at 75- and 100-[LW

power levels are shown in Table 4. The quoted

uncertainties are the SRSS of the systematic and

random components. The systematic uncertainty in

the ACR measurement is taken from Table 2, i.e.,

0.12%, and the ratios of powers measured by the ACR

internal to the chamber and the QED-200 external to

Table 4. Comparison of QED-200 (Outside) and ACR (Inside)

Outside- Inside-

the-Chamber the-Chamber Ratio(2)

QED-200 ACR QED-200(Outside)

(GMW) (GW) ACR(Inside)

91.86 0.24 89.51 0.22 1.026 0.004

76.38 0.22 74.56 0.33 1.024 0.005

Weighed mean, 1.025

Standard deviation of the weighed mean, 0.12%

7224 APPLIED OPTICS / Vol. 31, No. 34 / 1 December 1992

Table 5. Intercomparison of ACR and OED-200

ACR(Inside) Ratio(2)

QED-200(Inside) = Ratio(1) = 1.004 0.0015

the chamber are shown in the third column of Table

4. Again we calculated the uncertainty in each ratio

by the propagation of errors from power measure-

ments. The weighed mean values of the ratios are

shown at the bottom of Tables 3 and Table 4. The

weight factor is taken to be the inverse square of the

standard deviation. Table 5 shows the intercompar-

ison of measurements when the ACR and the QED-

200 are used. The ratio is 1.004 with an uncertainty

of 0.15% (1r level).

7. Summary

The ACR used for the measurements of radiation

from cryogenic blackbody sources was built to NIST

specifications and tested and characterized at the

NIST LBIR user facility. We have compared its

response with an industry standard solid-state QED-

200 by using both devices to measure the beam power

from an intensity-stabilized He-Ne laser. The agree-

ment is within 0.5% (a 3cr level).

The authors appreciate the technical support of S.

Ebner and J. Proctor in running the experiment.

The able assistance of J. Fowler and P. Tobin in the

early phase of the LBIR facility is acknowledged.

K. Stock was a visiting scientist from Physikalisch-

Technische, Bundesanstalt, Braunschweig, Germany.

References and Notes

1. F. Hengstberger, "The absolute measurement of radiant power,"

in Absolute Radiometry: Electrically Calibrated Thermal De-

tectors of Optical Radiation, F. Hengstberger, ed. (Academic,

San Diego, Calif., 1989), pp. 1-117.

2. P. V. Foukal, C. Hoyt, H. Kochling, and P. Miller, "Cryogenic

absolute radiometers as laboratory irradiance standards, re-

mote sensing detectors, and pyroheliometers," Appl. Opt. 29,

988-993 (1990).

3. C. R. Yokely, "Long wave infrared testing at NBS," in Applica-

tions of Optical Metrology: Techniques and Measurements II,

J. J. Lee, ed., Proc. Soc. Photo-Opt. Instrum. Eng. 416, 2-7

(1983).

4. A. C. Parr, J. Fowler, and S. Ebner, "Low background infrared

calibration facility at the National Bureau of Standards," in

Infrared Scene Simulation: Systems, Requirements, Calibra-

tion, Devices, and Modeling, R. B. Johnson and M. J. Triplett,

eds., Proc. Soc. Photo-Opt. Instrum. Eng. 940, 26-33 (1988).

5. S. C. Ebner, A. C. Parr, and C. C. Hoyt, "Update on the low

background IR calibration facility at the National Institute of

Standards and Technology," in Imaging Infrared: Scene Sim-

ulations, Modeling, and Real Image Tracking, A. J. Huber,

M. J. Triplett, and J. R. Wolverton, eds., Proc. Soc. Photo-Opt.

Instrum. Eng. 1110, 49-60 (1989).

6. E. F. Zalewski and C. R. Duda, "Silicon photodiode device with

100% external quantum efficiency," Appl. Opt. 22, 2867-2873

(1983).

7. A. F. Clark, "Thermal expansion," in Materials at Low Temper-

atures, P. R. Reed and A. F. Clark, eds. (American Society for

Metals, Metals Park, Ohio, 1983), pp. 75-128.

8. Product of Lord Corporation, Industrial Coatings Division,

2000 West Grandview Boulevard, Erie, Pa. 16514-0038.

9. Laser Power Controller system, Models LPC-VIS and RD-40,

manufactured by Cambridge Research and Instrumentation,

Inc., 21 Erie Street, Cambridge, Mass. 02139.

1 December 1992 / Vol. 31, No. 34 / APPLIED OPTICS 7225

Você também pode gostar

- Icycler Thermal Service Manual Rev E-2 PDFDocumento135 páginasIcycler Thermal Service Manual Rev E-2 PDFCarlos González100% (2)

- Metal Core PCBDocumento30 páginasMetal Core PCBonafetsAinda não há avaliações

- LG 22ls2100-Ta Chassis ld93q mfl67529901 PDFDocumento32 páginasLG 22ls2100-Ta Chassis ld93q mfl67529901 PDFAlfatah Dan AryaAinda não há avaliações

- HINLJR00BUA-ED00002a DC Cable Sizing CalculationDocumento18 páginasHINLJR00BUA-ED00002a DC Cable Sizing CalculationBADRI VENKATESHAinda não há avaliações

- Design Calculation and Performance Testing of Heating Coil in Induction Surface Hardening Machine PDFDocumento5 páginasDesign Calculation and Performance Testing of Heating Coil in Induction Surface Hardening Machine PDFMohammedAinda não há avaliações

- Earthing CalucaltionsDocumento8 páginasEarthing CalucaltionsGarmangh GersAinda não há avaliações

- HouseTuttle CurrentCarryingCapacityofACSR 1959ID633VER39Documento5 páginasHouseTuttle CurrentCarryingCapacityofACSR 1959ID633VER39VIKAS SINGH BAGHELAinda não há avaliações

- 0-30 V DC Stabilized Power Supply With Current Control 0.002-3 ADocumento8 páginas0-30 V DC Stabilized Power Supply With Current Control 0.002-3 AWaseem AhmadAinda não há avaliações

- WRS Brochure PDFDocumento8 páginasWRS Brochure PDFlutfi_ismailAinda não há avaliações

- Delta VE Fault Code Info and MaintenanceDocumento5 páginasDelta VE Fault Code Info and Maintenancehino_kaguAinda não há avaliações

- FM3A UserManual PDFDocumento56 páginasFM3A UserManual PDFJacqueline DidierAinda não há avaliações

- Material SelectionDocumento22 páginasMaterial Selectionyogi100% (1)

- A Simple and Inexpensive Laser PowerDocumento2 páginasA Simple and Inexpensive Laser Poweroscar_sm77Ainda não há avaliações

- Modeling of Radiation Intensity in An EAFDocumento6 páginasModeling of Radiation Intensity in An EAFmehran1364Ainda não há avaliações

- 4.26μm sensor CO2Documento9 páginas4.26μm sensor CO2JindraAinda não há avaliações

- A Peak Hold Energy Readout Circuit For Use With Pyroelectric Laser Energy MonitorsDocumento3 páginasA Peak Hold Energy Readout Circuit For Use With Pyroelectric Laser Energy Monitorspasargad135106Ainda não há avaliações

- 18PYB101J Manual PDFDocumento37 páginas18PYB101J Manual PDFbhuvan8hopkinsAinda não há avaliações

- 18PYB101J ManualDocumento38 páginas18PYB101J ManualRohit SinghAinda não há avaliações

- 9 766 393 Capacitive Voltage Divider ForDocumento7 páginas9 766 393 Capacitive Voltage Divider FortaiyawutAinda não há avaliações

- H&MT Lab Manual.Documento47 páginasH&MT Lab Manual.Adil AhmedAinda não há avaliações

- Design and Operation of Pegasus Thermionic CathodeDocumento2 páginasDesign and Operation of Pegasus Thermionic CathodeParticle Beam Physics LabAinda não há avaliações

- Temperature Compensation of Total Power RadiometersDocumento6 páginasTemperature Compensation of Total Power RadiometersJoh IgnacioAinda não há avaliações

- A SQUID-based Microwave Cavity Search For Dark-Matter AxionsDocumento4 páginasA SQUID-based Microwave Cavity Search For Dark-Matter AxionsSatya kaliprasad vangaraAinda não há avaliações

- Ece481-Microwave and Optical Communication Laboratory ManualDocumento44 páginasEce481-Microwave and Optical Communication Laboratory Manualeceklu100% (1)

- PhysRevB 109 L081403Documento6 páginasPhysRevB 109 L081403TECHNICAZAinda não há avaliações

- Thermal Transfer Simulation For Concentrator Photovoltaic Receiver Under Concentration ConditionDocumento5 páginasThermal Transfer Simulation For Concentrator Photovoltaic Receiver Under Concentration ConditioncoltallbAinda não há avaliações

- 1AO.3.4 PaperDocumento3 páginas1AO.3.4 PaperDavid Garcia0% (1)

- Aderhold 2010 Innovative Methods Wood Based PanelDocumento28 páginasAderhold 2010 Innovative Methods Wood Based PanelMariana DiasAinda não há avaliações

- DielectricDocumento3 páginasDielectricJoshua DuffyAinda não há avaliações

- Mar 427Documento5 páginasMar 427Юлиян ЛазаровAinda não há avaliações

- Studies of A Pyroelectric Crystal To Develop A Tabletop Neutron SourceDocumento9 páginasStudies of A Pyroelectric Crystal To Develop A Tabletop Neutron SourceDavid TurnerAinda não há avaliações

- Parametric Analysis of A Concentrated Solar Receiver With Scheffler ReflectorDocumento8 páginasParametric Analysis of A Concentrated Solar Receiver With Scheffler ReflectorTJPRC PublicationsAinda não há avaliações

- RT GUide TrainingDocumento13 páginasRT GUide Trainingnaoufel1706Ainda não há avaliações

- Physics Practical BookDocumento23 páginasPhysics Practical BookgauravAinda não há avaliações

- Parison FullDocumento7 páginasParison FullTJPRC PublicationsAinda não há avaliações

- Electronics For A Martian Water Vapor Detection System (August 15, 1967)Documento20 páginasElectronics For A Martian Water Vapor Detection System (August 15, 1967)AlMackenzieAinda não há avaliações

- Dual-Frequency Modified C/V Technique: 150 125 100 7 5 1 50 25 / I 15MW/600nmDocumento2 páginasDual-Frequency Modified C/V Technique: 150 125 100 7 5 1 50 25 / I 15MW/600nmkurabyqldAinda não há avaliações

- Calculation of The Fault Level Contribution of Distributed Generation According To Iec Standard 60909Documento4 páginasCalculation of The Fault Level Contribution of Distributed Generation According To Iec Standard 60909str69d46Ainda não há avaliações

- Fluxgate Magnetometer For Temperatures Up To 180°C: Patrick Sebbes Frank Ludwig Meinhard SchillingDocumento3 páginasFluxgate Magnetometer For Temperatures Up To 180°C: Patrick Sebbes Frank Ludwig Meinhard SchillingKouriba AhmedAinda não há avaliações

- 18PYB101J ManualDocumento36 páginas18PYB101J Manualviswa tejaAinda não há avaliações

- Photodetctor Designs PDFDocumento8 páginasPhotodetctor Designs PDFgeorgesmaccarioAinda não há avaliações

- Test Station For Frequency-Domain Dielectric Spectroscopy of Nanocomposites and SemiconductorsDocumento6 páginasTest Station For Frequency-Domain Dielectric Spectroscopy of Nanocomposites and SemiconductorsOleksandr BoikoAinda não há avaliações

- Paper MNFDocumento10 páginasPaper MNFBRICKTOP000Ainda não há avaliações

- High Power Microwave Generation From Virtual Cathode Oscillator (Vircator)Documento11 páginasHigh Power Microwave Generation From Virtual Cathode Oscillator (Vircator)ChAmirShokatGujjarAinda não há avaliações

- Chopping Frequency Optimizing in The Nir Moisture MeterDocumento6 páginasChopping Frequency Optimizing in The Nir Moisture MeterGENTILINAinda não há avaliações

- Ailure Analysis Sub-Micrometer Devices and Structures Using Scanning Thermal MicrosDocumento4 páginasAilure Analysis Sub-Micrometer Devices and Structures Using Scanning Thermal Microsss626Ainda não há avaliações

- Electrical Power Transmission: Cep ProjectDocumento22 páginasElectrical Power Transmission: Cep ProjectVinay MakhijaniAinda não há avaliações

- Comparison Solar CollectorsDocumento15 páginasComparison Solar CollectorsCatalin FilipAinda não há avaliações

- Experiment No: 7 Obtain The Operational Characteristics of The Light and Temperature Transducer For Control ApplicationsDocumento14 páginasExperiment No: 7 Obtain The Operational Characteristics of The Light and Temperature Transducer For Control ApplicationsYAKALA RAVIKUMARAinda não há avaliações

- Heat Transfer in High-Voltage Surge ArrestersDocumento4 páginasHeat Transfer in High-Voltage Surge Arresterscik_sya87Ainda não há avaliações

- Electrical Properties of SB and Cr-Doped Pbzro - Pbtio - PBMG NB O CeramicsDocumento8 páginasElectrical Properties of SB and Cr-Doped Pbzro - Pbtio - PBMG NB O CeramicsrachnaselvamanigmailAinda não há avaliações

- LONG PULSE 95 GHZ GYROTRON WITH ROOMDocumento7 páginasLONG PULSE 95 GHZ GYROTRON WITH ROOMroeybmAinda não há avaliações

- Study of TransducersDocumento11 páginasStudy of TransducersSrg Perumal NamasivayamAinda não há avaliações

- Calibration of Cryogenic Thermometers For The LHC: Ch. Balle J. Casas-Cubillos N. Vauthier J. P. ThermeauDocumento9 páginasCalibration of Cryogenic Thermometers For The LHC: Ch. Balle J. Casas-Cubillos N. Vauthier J. P. ThermeauSrinivasa MuralidharaAinda não há avaliações

- Applications - Flash - Method Programa ComsolDocumento8 páginasApplications - Flash - Method Programa Comsolivan fernandezAinda não há avaliações

- Antenna-Coupled Niobium Bolometers For Mm-Wave Imaging ArraysDocumento8 páginasAntenna-Coupled Niobium Bolometers For Mm-Wave Imaging ArraysClenaAinda não há avaliações

- RF Power Measurements Basic PrinciplesDocumento27 páginasRF Power Measurements Basic PrinciplesHector Velasco100% (1)

- DC Arc FlashDocumento9 páginasDC Arc FlashNels OdrajafAinda não há avaliações

- CSE 23 Dynamic Current Rating Thermal Transient ResponseDocumento14 páginasCSE 23 Dynamic Current Rating Thermal Transient ResponseThi Thanh Tam NguyenAinda não há avaliações

- Sam ReportDocumento9 páginasSam ReportMahima mpAinda não há avaliações

- Chip-Scale Absolute Scalar Magnetometer For Space ApplicationsDocumento2 páginasChip-Scale Absolute Scalar Magnetometer For Space ApplicationsDoceigenAinda não há avaliações

- Numerical Analysis of The Temperature Field in Luminaires: J. Murín, M. Kropáč, R. FricDocumento6 páginasNumerical Analysis of The Temperature Field in Luminaires: J. Murín, M. Kropáč, R. FricPop Mihai AdrianAinda não há avaliações

- Nanoscale, Phonon-Coupled Calorimetry With Sub-Attojoule/Kelvin ResolutionDocumento4 páginasNanoscale, Phonon-Coupled Calorimetry With Sub-Attojoule/Kelvin ResolutionemediageAinda não há avaliações

- Analysis of MWIR Infrared Pyroelectric DDocumento5 páginasAnalysis of MWIR Infrared Pyroelectric DbjsimardAinda não há avaliações

- Deflection Sensitivity Calibration of Heated Microcantilevers Using Pseudo-GratingsDocumento2 páginasDeflection Sensitivity Calibration of Heated Microcantilevers Using Pseudo-GratingsAnjireddy ThatiparthyAinda não há avaliações

- Modern Devices: The Simple Physics of Sophisticated TechnologyNo EverandModern Devices: The Simple Physics of Sophisticated TechnologyAinda não há avaliações

- SPIE 2007 BidaultDocumento16 páginasSPIE 2007 BidaultJacqueline DidierAinda não há avaliações

- Proc 5455 55 wp-2Documento7 páginasProc 5455 55 wp-2Jacqueline DidierAinda não há avaliações

- A MEMS Ultrasonic Transducer For Monitoring of Steel StructuresDocumento9 páginasA MEMS Ultrasonic Transducer For Monitoring of Steel StructuresJacqueline DidierAinda não há avaliações

- Canadiens Broadcast Schedule: More Channels, and More BlackoutsDocumento3 páginasCanadiens Broadcast Schedule: More Channels, and More BlackoutsJacqueline DidierAinda não há avaliações

- CNR2 Net Radiometer: Revision: 5/10Documento20 páginasCNR2 Net Radiometer: Revision: 5/10Jacqueline DidierAinda não há avaliações

- Laura (L-Band Automatic Radiometer) Instrument. IntroductionDocumento32 páginasLaura (L-Band Automatic Radiometer) Instrument. IntroductionJacqueline DidierAinda não há avaliações

- Cavatina John Williams NotesDocumento1 páginaCavatina John Williams NotesJacqueline DidierAinda não há avaliações

- 11 3082 01 Dowsil TC 5080 Thermal GreaseDocumento2 páginas11 3082 01 Dowsil TC 5080 Thermal GreasePRATHAMESH CHAUDHARIAinda não há avaliações

- Tep75wi ApplicationDocumento69 páginasTep75wi Applicationgowtham raju buttiAinda não há avaliações

- Enhancement TechniquesDocumento13 páginasEnhancement TechniquesThavanayagam EalasukanthanAinda não há avaliações

- K1JD Homebrew Amplifier v1.0Documento10 páginasK1JD Homebrew Amplifier v1.0Manuel Costa MoreiraAinda não há avaliações

- STRW6000 Series PDFDocumento14 páginasSTRW6000 Series PDFmunjaAinda não há avaliações

- 18 Document of Part Wise Inspection ProcessDocumento111 páginas18 Document of Part Wise Inspection ProcessQAD LotusAinda não há avaliações

- AF2ZP0EA (ACE2-2uC-datasheet)Documento5 páginasAF2ZP0EA (ACE2-2uC-datasheet)Ethan GilAinda não há avaliações

- NTE931 Integrated Circuit 3-Terminal Positive Voltage Regulator 5V, 3ADocumento2 páginasNTE931 Integrated Circuit 3-Terminal Positive Voltage Regulator 5V, 3AWilfredo MolinaAinda não há avaliações

- Final Lab ReportDocumento18 páginasFinal Lab Reportapi-622339925Ainda não há avaliações

- Design of Optimum HeatsinkDocumento9 páginasDesign of Optimum Heatsinkbitconcepts9781Ainda não há avaliações

- TDA8359JDocumento21 páginasTDA8359JCesar HernandezAinda não há avaliações

- High Performance Thermal Solutions Heat-Pipes & Engineering Systems For Power ElectronicsDocumento12 páginasHigh Performance Thermal Solutions Heat-Pipes & Engineering Systems For Power ElectronicscivicbladeAinda não há avaliações

- h1 O03eg0 ICDocumento131 páginash1 O03eg0 ICEned ÇelajAinda não há avaliações

- Boost Follower PFCDocumento3 páginasBoost Follower PFCฉัตรชัย เพ็ชรจั่นAinda não há avaliações

- Cte 214 Pratical 1 and 5Documento4 páginasCte 214 Pratical 1 and 5Mac world TrustAinda não há avaliações

- B Proact Digital P Version 2015Documento110 páginasB Proact Digital P Version 2015KawarauAinda não há avaliações

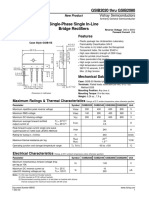

- GSIB 2080 Bridge Rectifiers 20A 200-800VDocumento2 páginasGSIB 2080 Bridge Rectifiers 20A 200-800VZxdIaminxXzlovewithzxXzyouzxAinda não há avaliações

- LM 1117Documento19 páginasLM 1117Juan BravoAinda não há avaliações

- Bonitron M3575T ManDocumento36 páginasBonitron M3575T ManVimal KumarAinda não há avaliações

- Heat Dissipation of LED Lamp - Pin Fin Heat Sink - LED Heat Sink - LED CoolerDocumento2 páginasHeat Dissipation of LED Lamp - Pin Fin Heat Sink - LED Heat Sink - LED CoolermingfaAinda não há avaliações

- Schema Sursa 5vDocumento30 páginasSchema Sursa 5vAndrei PetriciAinda não há avaliações

- Power AmpDocumento12 páginasPower AmpJose Carlo CamposAinda não há avaliações