Escolar Documentos

Profissional Documentos

Cultura Documentos

Enerlux M Software Module Users' Manual Rev.3: Timisoara

Enviado por

Muhammad Faisal Khan0 notas0% acharam este documento útil (0 voto)

65 visualizações35 páginasMM

Título original

EnerluxMSEonliMMb

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoMM

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

65 visualizações35 páginasEnerlux M Software Module Users' Manual Rev.3: Timisoara

Enviado por

Muhammad Faisal KhanMM

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 35

1

ENERLUX M SOFTWARE MODULE

USERS MANUAL

Rev.3

AEM branch of SC - L.L.C. SA Phone: +40-256- 22 22 00

26 Calea Buziasului Fax: +40-256-49 09-28

T I M I S O A R A

2

CONTENTS

GENERAL

FOLDERS AND FILES

METER PROGRAM

Operating program creating, editing, and writing

Program view property page

Time program property page

Special data property page

Hour changing rule property page

Other parameters property page

Display sequence property page

METERS ACCESS

Meters reading

Reading dialogs behaviour

Meters programming

Meter internal clock programming

Operating program

Program quick writing

Clock quick writing

Special commands

Maximum demand reset

One step programming

Scripts editing and running

Meter calibration

Operating mode changing

Meter configuration

Direct access to the measuring circuit

Direct access to the meter memory

Meter calibration

Calibration start property page

Gain calibration property page

Offset calibration property page

Phase displacement property page

Checking and adjustment property page

Calibration end property page

3

GENERAL

EnerluxM.mpl module is a software library, which operates together with

Opticom2K program and enables single-phase EnerluxM meters reading, programming,

and calibration. The description is made for the maximum number of the functions that

the software can perform. Restrictions are possible regarding the rights of the current user

as they are defined in Opticom2K program or in relation with software variant.

FOLDERS AND FILES

EnerluxM.mpl library has certain types of files associated to it, as follows:

File type Default location Extension Aim

Obser-

vations

Configu-

rations

<Opticom2K installation

directory >\EnerluxM

Files\

cfg

The storage of

the current

configurations

established by

the user

(dlgs.cfg) and

of the meters

options

(enerluxm.cfg)

Program

<Opticom2K installation

directory>\EnerluxM

Files\Program\

pexm

Program files

created by the

user or read

from the meter

Encrypted.

Can be

read and

edited with

Opticom2

K

Data

<Opticom2K installation

directory>\EnerluxM

Files\Data\

dexm

Data files

obtained

following the

meter reading

according to

IEC 1107. The

user can also

create

subfolders for

keeping these

files.

Enrypted.

Can be

read with

Opticom2

K

4

Status

<Opticom2K installation

directory>\EnerluxM

Files\Status\

sexm

Files obtained

following the

meter reading,

comprising in

the main

information

concerning the

controls sent to

the meter

Encrypted.

Can be

read with

Opticom2

K

Report

<Opticom2K installation

directory>\EnerluxM

Files\Report\

rexm

Files obtained

following the

meter reading,

comprising the

cumulated

information of

the types of the

data, program,

and status files.

The user can

also create

subfolders for

keeping these

files.

Encrypted.

Can be

read with

Opticom2

K

Script

<Opticom2K installation

directory>\EnerluxM

Files\Script\

mso

Batch of

communication

jobs

"EnerluxM Files" folder and the associated subfolders will be created (if they do

not exist) every time the library is loaded into Opticom2K program.

METER PROGRAM

Meter programming consists in writing a parameters set that will govern meter

operation in its memory. The meter-operating program can be logically divided in the

following sections:

1. Time program

It is the time program, which establishes the meter operation referring to TOU metered

energy. The meter has 4 tariff energy registers (4 tariffs). The current tariff register is

established as function of the following elements:

1.1 Type of day: There can be defined 8 such types of day. There can be defined up to 12

tariff-switching rules for each type of day (with reference to the 4 possible tariffs), the

switching being made with a resolution of 30 minutes (at hh:00 or hh: 30).

1.2. Type of week: There can be defined up to 8 types of weeks, so that each week day

(SMTWTFS) is allotted a certain type of day.

1.3 Season: There can be defined up to 12 calendar seasons characterized by the

beginning calendar date (day, month). Each season is allotted a certain type of week.

5

2. Special dates

As compared to the usual time program, there can be defined up to 24 days as exceptions

from the tariff program. Each day is characterized by the date and month. In case of non-

repetitive annual dates, the year shall also be specified. Each day is associated a type of

day out of the 8 possible ones and the number of days for which the rule is valid.

3. Summer-winter hour changing rule

The meter uses the European algorithm for the hour change (the last Sunday in March,

and October, respectively). The changing direction and the changing hour shall be

specified. The change of the summer hour in winter can be invalidated.

4. Other parameters

The following quantities are grouped:

4.1The communication speed according to IEC1107, to be selected out of 300, 600, 1200,

2400, 4800, 9600 string of values. Anyway the meter can be forced to communicate at a

speed different from the programmed one.

4.2 Self-reading date. One of the following dates can be chosen: 128

4.3 Number of the displayed decimal figures (2 or 3)

4.4 Display hold time for every displayed item (160) seconds.

4.5 Meter account: 16 decimal figures

4.6 Program identifier: 8 decimal figures

5.Display sequence

The meter display sequence can be displayed out of a maximum set of available

quantities.

The program has certain syntax as concerns the programming lines, as shown in the table

below:

Programmable

quantity

Program line Significance

Type of day 120N(HH:MM-T;HH:MM-

T)

N=number of 0-7 type

HH:MM activating hour=tariff

The two of them characterize the beginning

dates of the respective season

Type of

Week

110N(DDDDDDD) N=number of 0-7 type

D=type of day associated to the week day,

SMTWTFS

Season 10NN(DD.MM-S) N=01-12 season number

DD.MM-beginning date

S-type of week

Summer-winter

hour changing

rule

2000(03.05;10.05;hh;s) Summer: Month 3, Sunday 5

Winter: Month 10, Sunday 5

Change at hh:00 hour

Change direction, in summer: s=+ advance

s=- lagging

Calendar date 2050(DD) DD=0128

Baud speed 2052(xxx) Xxx=300,600,1200,2400,4800,9600

6

Decimals after

point

2053(N) N=nr. Figures following the point

Display time 2054(XX) XX=0160 seconds

ID program 2055(dd) 8 decimal figures

Account 2056(dd) 16 decimal figures

Quantity to be

displayed

00NN(AAABBB) NN=00-31 number of quantity

AAA quantity code sup.

BBB quantity code inf.

If AAA=000 is a simple quantity

The program files properly edited or read from the meter bear pmsp extension. Their

implicit location is <Director instalare Opticom 2K>\EnerluxM Files\ Program\. The

programs editing and writing operations are carried out by means of a properties sheet.

Any time this sheet is activated to create a new file, its contents will be that of a self-

created program file named template.pexm. Since this file is a self-created one during

the program running, do not save your own programs in this file.

Operating program creating, editing and writing

Operating program creating, editing writing is carried out by means of PROGRAM

property sheet.

The property sheet contains the following property pages:

7

Program preview

TOU program

Exclusion dates

Daylight saving time rule

Other parameters

Display sequence

Pressing Exit button will close the property sheet. In case the user has made changes in

the currently loaded program, when pressing the button he will be warned concerning the

possibility of loosing those changes. The property sheet quitting is not possible during the

communication process.

Program preview

This page enables the program files loading and saving, the currently loaded program

view, the specification of the target meter parameters (address and password) as

compared to the current meters list, the specification of what is going to be written in the

meter, as well as the communication process start and control. This page is always

present.

The list control shows the contents of the current program loaded for editing and/or

writing. Description column shows the significance of the program line, as per the

syntax, and Explain column contains a brief explanation of the program line. The non-

defined program lines bear NULL value.

8

Load button enables loading another program file then the current one by means of Open

standard box. If the user has made changes in the previously loaded file, he will be

warned concerning the loss of those changes.

Save button enables saving the current file loaded by means of Save As standard box.

Meter group contains the data of the current meters list, as well as General option

referring to a generic meter, which is not contained in the meters list. In case there is no

current list, only General option is present. Description combo box contains the

descriptions of all the meters in the meters list established in Opticom2K program. The

selection of the target meter is made from this combo box. If All meters check box is

selected, the programming operation will be successively applied to all the meters on the

list. If the current list is null, the combo box is invalidated. This communication option

shall be used when the meters are connected to a communication bus. Serial no and

Password editing fields reflect the contents of the current list as compared to the meter

serial no (used as communication address) and password. As far as General option is

concerned, these fields contain General series and NULL password, or that established in

the reading dialogs behaviour. The alteration of these fields is operational only during the

existence of PROGRAM properties sheet, it not being reflected by the contents of the

list used by the program.

Communication section enables the start and control of the communication operation.

The user may choose writing for TOU Program, Exclusion dates, Daylight saving

time, Display sequence, Parameters, either separately or together. The option is

expressed by selecting the requested check box. It is also permitted to alter only one of

the following parameters: the change of the summer-winter hour rule, the baud speed, or

the number of decimals displayed for monetary units. This can be done by selecting the

requested parameter from the program list and by activating Selection. Selection option

is not active for the display sequence. The use can chose to erase battery functioning

time counter together with the meter parameterisation operation. This can be

accomplished by checking the corresponding checkbox. The option is carried out only for

meters with embedded software version starting with 2.2. The communication operation

begins by pressing Start button. The communication process can be followed in WR

(number of transmitted characters) and RD (number of the read characters) fields. The

process can be stopped by pressing the Stop button. If an error appears during the

communication process, the process ends, and the user is warned by message about the

error. The properties page cannot be changed, and PROGRAM property sheet cannot be

closed during the process.

9

TOU program

Day types table enables specifying the switching moments during a day. It is not

necessary to fill in the whole table. Only the boxes corresponding to the transition

moments shall be filled in. Show rate transitions button pressing enables only tariff

transitions view. The types of days (except the first box) can be deleted by pressing

Delete all day types button.

Week types table enables specifying the type of day for each weekday (SMTWTFS).

Seasons table shall be completed with the day, the month, and the type of week for

maximum 12 seasons. The lines that are not complete will not be taken into account.

10

Exclusion dates

There can be programmed up to 25 special data characterized by date (day and month). If

the day is not repeated the next year, the year shall also be repeated (two digits). If the

day is repeated the next year, the year shall be marked with XX. Each special day is

attached a certain type of day. A special date is taken into account only if all the boxes

are filled in. The whole table can be deleted by pressing Delete table button.

11

Daylight saving time

The meter observes the European algorithm for the summer and winter hour changing

(the last Sunday in March, and the last Sunday in October). The March switching hour

and switching direction can be programmed (then the October switching will take place

in the opposite direction). There can also be selected Disable daylight saving rule

option.

Other parameters

12

This properties sheet contains certain programmable parameters, namely:

FLAG Baud rate as it is defined in IEC1107, C mode. This speed can be ignored

by the program, which forces the communication at other speed as compared to the

programmed one.

Billing date, which is a monthly parameter and can be established between 128

day of every month.

Digits after the decimal point: The metered quantities can be displayed with 0 up

to 3 figures after the decimal point.

Display hold time: The time of displaying a quantity during the display sequence

can be programmed between 1...60 seconds.

Account and Identifier: Two programmable numerical strings of 16 and 8 figures,

which can be displayed and resituated at the meter reading.

Display sequence

The properties page comprises two lists:

Available items: which comprises all the quantities that can be displayed.

Display list: which comprises the quantities selected for displaying.

Each quantity is preceded by a code of 6 figures. The quantities with the first

three digits equal to zero are simple and fill in half of the memory space of the

quantities whose superior half code is different from zero. The memory space available

for the display list is equivalent to 31 simple quantities.

13

In order to add something new to the display list, press Insert item button, or

double click the requested item in the list on the left.

To eliminate a quantity from the display list, press Delete item button, or double

click the requested item in the list on the right.

The display list can be totally deleted by pressing Remove all. If Copy list

button is pressed, the maximum possible number of quantities starting with the first one

from the list of available quantities will be inserted in the display list.

METERS ACCESS

Communication with the meters

The communication with the meters is based on IEC1107 protocol C mode provisions.

The type of transmission is asynchronous, half duplex, with the following format for the

communication word: one start byte, 7 data bytes, para parity, one stop byte.

The communication begins with a foreword at 300 baud speed, initiated by the

computer, which comprises meter selection through its address, meter type reading, and

the negotiation of the communication baud speed, and the type of communication (data

reading, program reading, or programming). Then there follows the reading or writing

operation proper.

The meter address is that which is specified in the current list chosen in

Opticom2K program, and it has to correspond to the meter series + the last two digits of

the manufacturing year. The address shall be specified only for the meters connected to

the same communication bus. In case of meters, which are read through the optical port,

the address is not necessary to be specified, and General address can be used. On the

other hand, the addresses of Pxx cu xx=0039 form are reserved to be used in

conjunction with the multiplexing parallel interface. They shall not be used if this

interface is not present at the previously selected parallel port of the computer.

The communication speed is proposed by the meter, correlated with the

previously programmed one. The communication may continue either with this speed, or

there can be forced another communication speed.

The data-reading mode requires only the knowledge of the communication

protocol. The program-reading mode requires the fulfilment of an automatic safety

algorithm ensured by the program. The programming mode requires the knowledge of the

password previously written in the meter. If no password has been previously

programmed, the specified password shall be void (equivalent also to NULL password).

Certain reading or programming functions are available only when the meter

operates in a special mode, namely the CALIBRATION MODE. This mode is operative

only if a hardware modification is made in the meter after its unsealing.

EnerluxM module accepts only ENERLUX M type meters. The access of any

other type of device, even under the conditions of observing IEC1107 requirements will

be signalled out as error.

Meters reading

The meters reading function refers to the following possibilities:

Reading of the data as supplied by the meter.

Reading of the meter-operating program as it has been previously programmed.

Reading of the meter status data (i.e. clock, display mode, operating mode).

14

Reading of a complete report concerning the contents of the meter memory, which

sums up all the types of the previous readings.

Following the successful reading operations, the read data will be stored in files of

MeterSerial@aallzzhhmmss type names and extensions of dexm, pexm, sexm type, rexm,

respectively (as concerns the program files, @aallzzhhmmss does not appear). Following

every successful reading operation, the corresponding file will be automatically loaded in

Opticom 2K program view zone.

The reading of the meter program and meter status is made by using a safety algorithm,

while the data reading is possible only on the basis of the data reading procedure

according to IEC1107, C mode.

All the reading operations take place by means of Read meter dialog box.

This dialog box appears after launching any of the reading controls.

If Exit button is pressed, the dialog box closes.

Meter group contains the data of the current meters list, as well as General option

referring to a generic meter, which is not contained in the meters list. In case there is no

current list, only General option is present. Description combo box contains the

descriptions of all the meters in the meters list established in Opticom2K program. The

selection of the target meter is made from this combo box. If All meters check box is

selected, the programming operation will be successively applied to all the meters on the

list. If the current list is null, the combo box is invalidated. This communication option

shall be used only when the meters are connected to a communication bus. Serial no

editing field reflects the contents of the current list as compared to the meter series (used

as communication address). As far as General option is concerned, it contains General

series. The alteration of this field is operative only during the existence of the dialog box,

it not being reflected by the contents of the meters list used by the program. Start

automatically check box will start the communication process if checked at the same

time with the dialog box launching, and Close when communication ends combo box

will automatically close the dialog box if checked in case there were no errors in the

communication process. The status of these boxes is memorized in dlgs.cfg. file. The user

may change the status of these boxes during the communication process.

Communication section enables the release and the control of the communication

operation. The communication operation is released by pressing Start button. The

communication process can be watched in WR (no. of transmitted characters) and RD

15

(number of read characters) fields. Pressing Stop button can interrupt the communication

process. If an error appears during the communication process, the process ends and the

user is warned through an error message. The Only current values option, when

checked causes the reading only for current register values (energies and maximum

demand). The dialog box cannot be closed during the communication process.

Reading dialog behaviour

The dialog box enables the configuration of the meter reading dialog boxes through the

selection of the following options: Starts automatically and Close when

communication ends. Default password editing field enables password configuration

for "General" options, as well as quick programming. The user can define new subfolders

for dta and report reading or use existing ones.

Meters programming

Meters programming operation implies knowing the password, which has been

previously entered into the meter (if it exists). The programming operation leads to the

change of the meter-operating mode. The programming refers to the following

operations:

Meter internal clock programming

Operating program writing

Maximum demand reset

Special commands:

Display mode programming

Passwords programming

Optical port LED behaviour programming

Meter initialisation

Meter measuring scheme

Meter internal clock programming

The control can be operated only if a communication port has been previously

selected for the optical probe, and the current is permitted to program the meter clock.

16

The meter internal clock programming is carried out by means of Program meter clock

dialog box.

If Exit button is pressed, the dialog box closes.

Meter group contains the data of the current meters list, as well as General option which

refers to a generic meter not contained in the meters list. In case there is no current list,

only General option is present. Description combo box contains the descriptions of all

the meters from the meters list chosen from Opticom 2K software. The target meter

selection is made from this combo list. If All meters check box is selected, the

programming operation will be successively applied to all the meters on the list. If the

current list is null, the combo box is invalidated. This communication option has to be

used only when the meters are connected to a communication bus. Serial no and

Password editing fields reflect the contents of the current list concerning the meter series

(used as communication address) and the meter password. As far as General option is

concerned, these fields contain General series and NULL password, or the password

established in the reading dialogs behaviour. The alteration of these fields operates only

during the dialog box display, it not being contained in the meters list used by the

program, as well.

Date an time section comprises the following controls:

A time control (date and hour) which enables establishing the date and hour, which will

be written in the meter. Date and hour establishing is carried out by means of up and

down arrows.

Synchronization button: Following the current hour modification, this button is pressed

to update the time control values.

Communication section enables the release and control of the communication operation.

The communication operation is released by pressing Start button. The communication

process can be watched up in WR fields (no. of transmitted characters) and RD (no. of

read characters). The process can be interrupted by pressing Stop button. If an error

occurs during the communication process, the process ends, and the user is warned by

error message. The dialog box cannot be closed during the communication process.

Operating program

17

The operating program writing is carried out by means of Program properties

sheet, Program preview properties page. The operating program writing means writing

into the meter the tariff program and the other parameters, either cumulatively or

selectively.

PROGRAM property sheet can be accessed by means of the meter editing and

programming controls.

Quick programming (meter program, clock)

The command for quick programming enables the transmission to the meter of the

program file loaded in the main window view zone in Opticom 2K program.

The quick clock control enables sending the calculator clock current value to the meter.

If these controls are activated, similar functions dialog boxes will be displayed. If the

operation has been correctly carried out, the communication starts automatically and the

dialog box closes automatically. The communication process can be watched up in WR

(no. of transmitted characters) and RD (no. of read characters) fields. The process can be

stopped by pressing Stop button. The process also stops at the occurrence of an error, and

it can be resumed by pressing Start button, or it can be closed by pressing Exit button.

The password that will be used in the communication process will be that which is

specified at the configuration of the communication dialog boxes.

Special commands

Special commands refer to a number of controls sent to the meter which are not

comprised in the program proper. These controls can be accessed through Special

commands dialog box.

18

Special commands section contains the list of these controls and enables the selection of

the required control. If Exit button is pressed, the dialog box closes.

Meter group contains the data of the current meters list, as well as General option which

refers to a generic meter not contained in the meters list. In case there is no current list,

only General option is present. Description combo box contains the descriptions of all

the meters from the meters list chosen from Opticom 2K software. The target meter

selection is made from this combo list. If All meters check box is selected, the

programming operation will be successively applied to all the meters on the list. If the

current list is null, the combo box is invalidated. This communication option has to be

used only when the meters are connected to a communication bus. Serial no and

Password editing fields reflect the contents of the current list concerning the meter series

(used as communication address) and the meter password. As far as General option is

concerned, these fields contain General series and NULL password, or the password

established in the reading dialogues behaviour. The alteration of these fields operates

only during the dialog box display, it not being contained in the meters list used by the

program, as well.

Communication section enables the release and the control of the communication

operation. The communication operation is released by pressing Start button. The

communication process can be watched in WR (no. of transmitted characters) and RD

(number of read characters) fields. The communication process can be interrupted by

pressing Stop button. If an error appears during the communication process, the process

ends and the user is warned through an error message. The dialog box cannot be closed

during the communication process.

19

The right side of the dialog box contains the controls referring to the control that will be

sent to the meter and depends on the control chosen from Special commands list.

The special controls are as follows:

Display mode: enables the selection of the meter multiplexed display mode or the

energy exclusive display with maximum resolution.

Passwords establishing: Enables writing the password for clock writing and/or meter

programming. The current user shall have editing rights.

The passwords have to be confirmed with the same written sequence and the two

editing fields. The password that exists in the meter can be deleted and the null password

can be written instead. Null password means: void sequence, "General" sequence or

"NULL" sequence.

Optical port LED behaviour: it enables establishing the behaviour of the optical

port transmitter, which can be exclusively meant for communication or can have the

function of energy pulses emitting.

20

Meter erase: it enables the erasing of current registers and/or the events and self-

readings registers. For embedded software versions of the meter starting with 2.2

version, it is possible to reset the battery functioning time counter.

Meter measuring scheme: The meter can be configured as follows:

To add the positive and negative energy

To count the positive energy only

21

Reset maximum demand

The dialog box closes after pressing Exit button.

Meter group contains the data of the current meters list, as well as General option

referring to a generic meter not contained in the meters list. In case there is no current

list, only General option is present. Description combo box contains the descriptions of

all the meters from the meters list chosen from Opticom 2K software. The target meter

selection is made from this combo list. If All meters check box is selected, the

programming operation will be successively applied to all the meters on the list. If the

current list is null, the combo box is invalidated. This communication option has to be

used only when the meters are connected to a communication bus. Serial no and

Password editing fields reflect the contents of the current list concerning the meter series

(used as communication address) and the meter password. As far as General option is

concerned, these fields contain General series and NULL password, or the password

established in the reading dialogues behaviour. The alteration of these fields operates

only during the dialog box display, it not being contained in the meters list used by the

program, as well. Start automatically check box will start the communication process if

checked at the same time with the dialog box launching, and Close when

communication ends combo box will automatically close the dialog box if checked in

case there were no errors in the communication process. The status of these boxes is

memorized in dlgs.cfg. file. The user may change the status of these boxes during the

communication process.

Communication section enables the release and the control of the communication

operation. The communication operation is released by pressing Start button. The

communication process can be watched up in WR (no. of transmitted characters) and RD

(number of read characters) fields. The communication process can be interrupted by

pressing Stop button. If an error appears during the communication process, the process

ends and the user is warned through an error message. The dialog box cannot be closed

during the communication process.

22

One step meter programming

The command can be launched can be operated if a port for the communication with the

optical probe has been previously selected. The commands are released by means of the

One step programming dialog box.

The dialog box closes after pressing Exit button.

Meter group contains the data of the current meters list, as well as General option

referring to a generic meter not contained in the meters list. In case there is no current

list, only General option is present. Description combo box contains the descriptions of

all the meters from the meters list chosen from Opticom 2K software. The target meter

selection is made from this combo list. If All meters checkbox is selected, the

programming operation will be successively applied to all the meters on the list. If the

current list is null, the combo box is invalidated. This communication option has to be

used only when the meters are connected to a communication bus. Serial no and

Password editing fields reflect the contents of the current list concerning the meter series

(used as communication address) and the meter password. As far as General option is

concerned, these fields contain General series and NULL password, or the password

established in the reading dialogues behaviour. The alteration of these fields operates

only during the dialog box display, it not being contained in the meters list used by the

program, as well.

Items to program section comprises the following controls:

Program file ombo box enables the selection of the program file. The attached

option control enables the validation of the operation.

Meter clock time control together with the attached option control enables the

transmission of the current calculator clock to the meter.

Meter account editing control enables the specification of the identifier to be written in

the meter. The attached option control enables the validation of the operation.

23

Display mode combo box enables the meter passing to the normal display mode.

The attached option control enables the validation of the operation.

OP LED combo box enables the optical port passing to the test output duty. The

attached option control enables the validation of the operation.

Delete controls enable deleting the current registers (Reg), the table of events

(Events) and the self-readings (Self-readings). For meters with software version of 2.2

and above, it is possible to reset the battery time counter.

Reset MD control enables specifying the cancelling option of the current power

maximums.

Communication section enables the release and the control of the communication

operation. The communication operation is released by pressing Start button. The

communication process can be watched up in WR (no. of transmitted characters) and RD

(number of read characters) fields. Pressing Stop button can interrupt the communication

process. If an error appears during the communication process, the process ends and the

user is warned through an error message. The dialog box cannot be closed during the

communication process.

Scripts editing and running

The script files contain a succession of reading and writing operations. The script file

editing and / or launching is made trough the Script dialog box. This dialog box can be

invoked either from Opticom software menu or by launching Opticom program having a

valid file name as command line parameter.

24

The Script combo box contains the names of all available script files. Selecting a certain

file, the file is loaded. This is automatically done when the file name appears as a

parameter of the command line. The script file can be saved by pressing the Save as

button. The file is saved with the name taken from the combo box. The mso extension is

mandatory.

The operations that can be launched are enabled by the check boxes next to each

group box. The operations are:

Read the meter; one can choose the data reading, report reading or current

energy registers reading. The export in text format can also be accomplished.

Program the meter; the possible operations are: meter clock adjusting related to

PC clock and meter programming with a program file selected from the combo box

Erase the meter; the user can erase the energy registers, billing values, events

table. The MD can also be reset. ). For meters with software version of 2.2 and above, it

is possible to reset the battery time counter.

Regardless the script file content, the check boxes state corresponds to the rights

of the current user. This is also valid for the Save and Start buttons.

Meter group contains the data of the current meters list, as well as General option

referring to a generic meter not contained in the meters list. In case there is no current

list, only General option is present. Description combo box contains the descriptions of

all the meters from the meters list chosen from Opticom 2K software. The target meter

selection is made from this combo list. If All meters checkbox is selected, the

programming operation will be successively applied to all the meters on the list. If the

current list is null, the combo box is invalidated. This communication option has to be

used only when the meters are connected to a communication bus. Serial no editing

field reflects the contents of the current list as compared to the meter series (used as

communication address). As far as General option is concerned, it contains General

series. The alteration of this field is operative only during the existence of the dialog box,

it not being reflected by the contents of the meters list used by the program.

Communication section enables the release and the control of the communication

operation. Pressing Start button launches the communication operation. The operation is

automatically launched when it is started using the command line argument. The

communication process can be watched up in WR (number of transmitted characters) and

RD (number of read characters) fields. Pressing Stop button can interrupt the

communication process. If an error appears during the communication process, the

process ends and the user is warned through an error message. The dialog box cannot be

closed during the communication process.

Meter calibration (calibration mode)

The calibration mode is a meter special working mode. This operating mode

enables additional commands through the optical port, commands that are required for

the meter testing, initialization and calibration. The checking of the password and of the

safety algorithms cannot be carried out in the calibration mode. The meter-operating

mode can be activated by means of a control through the optical port, but to activate the

calibration mode and make it effective in the meter, a hardware modification, permitted

only by the meter unsealing, is required.

Change of meter operating mode

25

Meter configuration

Testing the meter measuring circuit

Direct access to the meter internal memory

Meter calibration

Change of meter operating mode

The command is given through Set working mode dialog box

If Exit button is pressed, the dialog box closes.

Meter group contains the data of the current meters list, as well as General option, which

refers to a generic meter not contained in the meters list. In case there is no current list,

only General option is present. Description combo list contains the descriptions of all the

meters from the meters list chosen from Opticom 2K software. The target meter selection

is made from this combo list. If All meters check box is selected, the programming

operation will be successively applied to all the meters on the list. If the current list is

null, the combo box is invalidated. This communication option has to be used only

when the meters are connected to a communication bus. Serial no and Password

editing fields reflect the contents of the current list concerning the meter series (used as

communication address) and the meter password. As far as General option is concerned,

these fields contain General series and NULL password, or the password established in

the reading dialogues behaviour. The alteration of these fields operates only during the

dialog box display, it not being contained in the meters list used by the program, as well.

Working mode section comprises Calibration mode and Normal mode radio buttons,

which enable establishing the meter operating duty following the command launching.

Even if the Calibration mode control has been activated, the meter can pass to this

operating mode only if a hardware change has been executed inside the meter. The

passage to the normal operating mode can be executed even after the hardware

modification inside the meter has been completed.

Communication section enables the release and the control of the communication

operation. The communication operation is released by pressing Start button. The

communication process can be watched up in WR (no. of transmitted characters) and RD

(number of read characters) fields. The communication process can be interrupted by

26

pressing Stop button. If an error appears during the communication process, the process

ends and the user is warned through an error message. The dialog box cannot be closed

during the communication process.

The control for the passage to the meter calibration mode shall be password checked as

any meter programming. After the meter passage to the calibrating mode, the meter will

make no password and safety algorithm checkings.

Meter configuration

The meters configuration can be carried out through Meters configuration dialog box.

The meter configuration refers to writing the meter series and a sequence of digital values

for the configuration of the measuring circuit in the meter non-volatile memory. The

identification sequence and the measuring circuits configuration values are taken from

enerlux. cfg. configuration file.

List content table contains on its first line the meter with its generic address (general),

and then each line of the table contains the addresses and the passwords from the

program password current list. The table cells can be edited. The table can be

automatically filled in for the meter configuration by pressing Same ID button, as well as

with the automatically incremented series by pressing ++Serial no button. The reference

is the first line of the table.

27

The options for the series programming are either Selected row or All meters. The

following options: Send serial no and Send config can be selected either separately or

cumulatively.

The writing process begins by pressing Start button. The writing process can be stopped

by pressing Stop button. RD and WR controls enable supervising the communication

process. If an error appears during the communication process, the process ends and the

user is warned through an error message. The box can be quit by pressing Exit button.

The box cannot be quit during the communication process.

Testing the meter measuring circuit

The program enables the direct access to the values of the configuration and metering

registers of the measuring circuit and of the registers corresponding locations in the meter

internal memory.

The box comprises Registers table which besides DSP reg. value and E2 reg. Value

where there can be read/write the locations corresponding to DSP and E2PROM

registers, also comprises information columns referring to register addresses, register

type, its size, and its implicit value.

Meter group contains the data of the current meters list, as well as General option, which

refers to a generic meter not contained in the meters list. In case there is no current list,

only General option is present. Description combo box contains the descriptions of all

the meters from the meters list chosen from Opticom 2K software. The target meter

selection is made from this combo list. If All meters check box is selected, the

programming operation will be successively applied to all the meters on the list. If the

current list is null, the combo box is invalidated. This communication option has to be

28

used only when the meters are connected to a communication bus. Serial no and

Password editing fields reflect the contents of the current list concerning the meter series

(used as communication address) and the meter password. As far as General option is

concerned, these fields contain General series and NULL password, or the password

established in the reading dialogues behaviour. The alteration of these fields operates

only during the dialog box display, it not being contained in the meters list used by the

program, as well.

Communication section enables the release and the control of the communication

operation. The communication operation is released by pressing Start button. The

communication process can be watched up in WR (no. of transmitted characters) and

RD (number of read characters) fields. The communication process can be interrupted by

pressing Stop button. If an error appears during the communication process, the process

ends and the user is warned through an error message. The dialog box cannot be closed

during the communication process.

Moreover, this section enables the selection of the required operation (Write DSP, Read

DSP, Continuous reading), as well as of the way the operation takes place (Read DSP

after interrupt given by DSP at the meter microcontroller and Perform operation also

into E2PROM).

Generator button enables the access to the generator dialog box. This button is valid if a

communication port has been defined for the generator.

Exit button enables quitting the dialog box. Dialog box quitting is not possible during the

communication process.

Meter calibration

Meter calibration implies first of all its proper calibration as concerns the hardware

option. Calibration implies determining a set of four coefficients through calculations

made with the values shown by the meter as compared to the values of the voltages and

currents generator to which the meter is connected. Measurements shall be made after the

measuring circuit has been calibrated. Three measuring points are required for the

coefficients determining:

1. The meter base current for determining the energy pulses division coefficient as

compared to the selected CFDIV meter constant and to the APGAIN measured power

gain coefficient.

2. The minimum current for determining the offset coefficient of the measured power -

APOS.

3. The base and phase displacement current between voltage and 60 degrees current for

determining the displacement coefficient - PHCAL.

The meter calibration is carried out by means of an wizard type dialog. The wizard

comprises the following pages:

Calibration start

Calibration gain

Calibration offset

Calibration phase displacement

Checking and adjustment

Calibration end

29

Calibration start

The dialog enables the configuration of the calibration process conditions and the

initialization of the meters for calibration.

Meter group contains the data of the current meters list, as well as General option which

refers to a generic meter not contained in the meters list. In case there is no current list,

only General option is present. Description combo box contains the descriptions of all

the meters from the meters list chosen from Opticom 2K software. The target meter

selection is made from this combo list. If All meters check box is selected, the

programming operation will be successively applied to all the meters on the list. If the

current list is null, the combo box is invalidated. This communication option has to be

used only when the meters are connected to a communication bus. Serial no and

Password editing fields reflect the contents of the current list concerning the meter series

(used as communication address) and the meter password. As far as General option is

concerned, these fields contain General series and NULL password, or the password

established in the reading dialogues behaviour. The alteration of these fields operates

only during the dialog box display, it not being contained in the meters list used by the

program, as well.

Communication section enables the release and the control of the communication

operation. The communication operation is released by pressing Start button. The

communication process can be watched up in WR (no. of transmitted characters) and RD

(number of read characters) fields. The communication process can be interrupted by

pressing Stop button. If an error appears during the communication process, the process

30

ends and the user is warned through an error message. The page cannot be quit during the

communication process.

Moreover, this section enables the configuration of the meter initialization with the

following options: Meter in calibration mode, DSP in calibration mode, Config.

meter according to the chosen option and Reset meter coefficients.

Meter type and SPE group contains the following controls:

- The combo box which enables the selection of the meter option

- The calibrating option Use SPE and the phases that will be ordered - Phase 1, Phase 2,

Phase 3 and the start/stop button of the generator: SPE ON , SPE OFF. These controls

are validated only when there has been selected a valid port for the communication with

the generator.

Process configuration group enables the elimination of certain properties pages referring

to calibration: Skip gain calib., Skip phase calib., Skip offset calib.

Gain, offset and phase calibration

31

32

The dialogues enable the determination of the following:

1. CFDIV division and APGAIN gain coefficients

2. APOS offset coefficient

3. PHCAL phase displacement coefficient.

Meter group contains the data of the current meters list, as well as General option which

refers to a generic meter not contained in the meters list. In case there is no current list,

only General option is present. Description combo box contains the descriptions of all

the meters from the meters list chosen from Opticom 2K software. The target meter

selection is made from this combo list. If All meters check box is selected, the

programming operation will be successively applied to all the meters on the list. If the

current list is null, the combo box is invalidated. This communication option has to be

used only when the meters are connected to a communication bus. Serial no and

Password editing fields reflect the contents of the current list concerning the meter series

(used as communication address) and the meter password. As far as General option is

concerned, these fields contain General series and NULL password, or the password

established in the reading dialogues behaviour. The alteration of these fields operates

only during the dialog box display, it not being contained in the meters list used by the

program, as well.

Communication section enables the release and the control of the communication

operation. The communication operation is released by pressing Start button. The

communication process can be watched up in WR (no. of transmitted characters) and

RD (number of read characters) fields. The communication process can be interrupted by

pressing Stop button. If an error appears during the communication process, the process

ends and the user is warned through an error message. The page cannot be quit during the

communication process.

Moreover, this section contains SPE OFF button for the urgent stop of the station. This

button is enabled only if a valid port has been specified for the communication with the

generator.

Calibration conditions group contains the editing controls for the specification of the

electric and constructive conditions of the meter on which the calibration depends. These

values are taken from enerlux.cfg. file.

Calibration results group enables the view of the calculations made for the

determination of the coefficient, following the end of the communication process. In case

calibration develops successively for several meters, the selection of the value that is

required to be seen is made from Meter selection combo box.

33

Calibration checking and adjustment

Calibration conditions group contains the editing controls for the specification of the

electric and constructive conditions of the meter. These values are taken from

meters.cfg. file. The electric conditions initially correspond to the base current value.

The error can be correctly calculated if these values are the values really applied to the

meter.

Meter group contains the data of the current meters list, as well as General option which

refers to a generic meter not contained in the meters list. In case there is no current list,

only General option is present. Description combo box contains the descriptions of all

the meters from the meters list chosen from Opticom 2K software. The target meter

selection is made from this combo list. If All meters check box is selected, the

programming operation will be successively applied to all the meters on the list. If the

current list is null, the combo box is invalidated. This communication option has to be

used only when the meters are connected to a communication bus. Serial no and

Password editing fields reflect the contents of the current list concerning the meter series

(used as communication address) and the meter password. As far as General option is

concerned, these fields contain General series and NULL password, or the password

established in the reading dialogues behaviour. The alteration of these fields operates

only during the dialog box display, it not being contained in the meters list used by the

program, as well.

Communication group enables the release and control of the communication operation.

The release of the coefficients reading operation can be made by pressing Read meter

button. The release of the writing operation can be made by pressing Update meter

34

button. This button is validated only when values have been written in the coefficients

editing fields.The communication process can be watched up in WR (no. of transmitted

characters) and RD (number of read characters) fields. The communication process can

be interrupted by pressing Stop button. If an error appears during the communication

process, the process ends and the user is warned through an error message. The page

cannot be quit during the communication process.

Moreover, this section contains SPE OFF button for the urgent stop of the station Set

SPE button which prescribes at the generator the values of electrical quantities from

Calibration conditions group. These buttons are validated only if there has been

specified a valid port for the communication with the generator. The error calculation in

the communication processes with the meters can be made if DSP in calibration mode

option is selected.

Results group contains the editing controls for CFDIV, APGAIN, APOS, PHCAL

coefficients which can be read/written both from/in DSP and from/in E2PROM memory.

Only the coefficients that have their WR option selected will be written. The group also

contains the view fields of the calculation auxiliary quantities AENERGY, kWh/LSB,

Meter power[kWh] and Error in percentages as compared to the values from Calibration

conditions group.

Calibration end

The dialog contains the options for the meter passage to normal operation.

35

Meter group contains the data of the current meters list, as well as General option which

refers to a generic meter not contained in the meters list. In case there is no current list,

only General option is present. Description combo list contains the descriptions of all the

meters from the meters list chosen from Opticom2K software. The target meter selection

is made from this combo list. If All meters combo box is selected, the programming

operation will be successively applied to all the meters on the list. If the current list is

null, the combo box is invalidated. This communication option has to be used only

when the meters are connected to a communication bus. Serial no and Password

editing fields reflect the contents of the current list concerning the meter series (used as

communication address) and the meter password. As far as General option is concerned,

these fields contain General series and NULL password, or the password established in

the reading dialogues behaviour. The alteration of these fields operates only during the

dialog box display, it not being contained in the meters list used by the program, as well.

Communication group enables the release and control of the communication operation.

The release of the communication operation can be made by pressing Start button. The

communication process can be watched up in WR (no. of transmitted characters) and

RD (number of read characters) fields. The communication process can be interrupted by

pressing Stop button. If an error appears during the communication process, the process

ends and the user is warned through an error message. The page cannot be quit during the

communication process.

Moreover, this section enables the meter configuration by means of the following

options: Meter in normal mode, DSP in normal mode.

Você também pode gostar

- Cognos Impromptu by GopiDocumento14 páginasCognos Impromptu by Gopipsaravanan1985Ainda não há avaliações

- Sadp Lab Manual EditedDocumento61 páginasSadp Lab Manual EditedSupriya Kagitha0% (1)

- MCA I Year SyllabusDocumento55 páginasMCA I Year SyllabusKrishna Chandra Sekhar ReddyAinda não há avaliações

- Lab 1 Introduction To MIPS LabDocumento3 páginasLab 1 Introduction To MIPS LabDropMySpaghettiAinda não há avaliações

- Analysis of A High-Potential Business: Sqreen: Application Security Management PlatformDocumento13 páginasAnalysis of A High-Potential Business: Sqreen: Application Security Management Platformhinaya khanAinda não há avaliações

- Mastering Impromptu 7.5Documento195 páginasMastering Impromptu 7.5idaya_cnAinda não há avaliações

- Intelligent Line-Following Robot ProjectDocumento7 páginasIntelligent Line-Following Robot ProjectAmla SingAinda não há avaliações

- 266F Lecture Notes 2017Documento167 páginas266F Lecture Notes 2017ameonnajuAinda não há avaliações

- Get Advanced Reports via APIDocumento13 páginasGet Advanced Reports via APILuca Ele Ale StefiAinda não há avaliações

- BPM and CEP IntegrationDocumento14 páginasBPM and CEP IntegrationManisha_tAinda não há avaliações

- Mock Assessment Informatica - Practitioner & Specialist LevelDocumento5 páginasMock Assessment Informatica - Practitioner & Specialist LevelPavi EceAinda não há avaliações

- Tag and Alarm Export ManualDocumento46 páginasTag and Alarm Export ManualscozansAinda não há avaliações

- Aurora Cidr03Documento12 páginasAurora Cidr03CobWangAinda não há avaliações

- CRM Project Report on Customer Relationship Management SystemDocumento70 páginasCRM Project Report on Customer Relationship Management SystemSubho ChakrabortyAinda não há avaliações

- Ronneby County Library Management System Software Requirements SpecificationDocumento23 páginasRonneby County Library Management System Software Requirements SpecificationRuhul92Ainda não há avaliações

- Next Reports ServerDocumento81 páginasNext Reports ServerRonny IndraAinda não há avaliações

- Cse345p Bi LabDocumento30 páginasCse345p Bi LabkamalAinda não há avaliações

- Com 113 Intro To Computer Programming TheoryDocumento107 páginasCom 113 Intro To Computer Programming TheoryUmar100% (1)

- Wireless Speed Control of DC Motor Using PWM and UARTDocumento3 páginasWireless Speed Control of DC Motor Using PWM and UARTElins Journal100% (1)

- Domain Driven Architecture Technical ReferenceDocumento98 páginasDomain Driven Architecture Technical Referenceyoogi85Ainda não há avaliações

- AlertsDocumento26 páginasAlertsshailajaAinda não há avaliações

- Asternic CCStats PRO Installation GuideDocumento5 páginasAsternic CCStats PRO Installation GuideEdgar A CanizalezAinda não há avaliações

- SQL Tips and Best PracticesDocumento70 páginasSQL Tips and Best PracticesARIZKI0% (1)

- Database Engineering (EC-240) : Lab Manual # 05Documento9 páginasDatabase Engineering (EC-240) : Lab Manual # 05AMINA QADEERAinda não há avaliações

- MDC (8.0) User ManualDocumento114 páginasMDC (8.0) User ManualMauricio SuarezAinda não há avaliações

- STQA Lab Writeup2013Documento83 páginasSTQA Lab Writeup2013Bhakti ShahAinda não há avaliações

- Lab1 - Vlsi EceDocumento19 páginasLab1 - Vlsi EceMichelleCYLAinda não há avaliações

- Function Oriented DesignDocumento10 páginasFunction Oriented DesignKuhoo AgrawalAinda não há avaliações

- Embedded Systems Notes MidtermsDocumento67 páginasEmbedded Systems Notes MidtermsCol. Jerome Carlo Magmanlac, ACP100% (1)

- Real Time Systems NotesDocumento127 páginasReal Time Systems NotesVijay Kumar100% (1)

- 11-5699 Inprocess FAQ - FinalDocumento7 páginas11-5699 Inprocess FAQ - Finalsidiq16Ainda não há avaliações

- Software Metrics & Information Flow MetricsDocumento26 páginasSoftware Metrics & Information Flow MetricsRuchit GuptaAinda não há avaliações

- SDD TemplateDocumento7 páginasSDD TemplateMing HanAinda não há avaliações

- CPU Scheduling Program in C++ - Code With CDocumento4 páginasCPU Scheduling Program in C++ - Code With CAmey SheteAinda não há avaliações

- Build Mamdani Systems (GUI) : On This PageDocumento14 páginasBuild Mamdani Systems (GUI) : On This PageJESWAinda não há avaliações

- BSC ItimDocumento2 páginasBSC ItimUmesh PalakshaiahAinda não há avaliações

- "Routine Management System": Project Report OnDocumento26 páginas"Routine Management System": Project Report OnSonali AnandAinda não há avaliações

- Tutorial of OOS With JavaDocumento5 páginasTutorial of OOS With JavaTiwari AnuragAinda não há avaliações

- Fetch-Decode-Execute-Reset Cycle ExplainedDocumento36 páginasFetch-Decode-Execute-Reset Cycle ExplainedAbhishek Belnekar0% (1)

- DA 9000 Tech SpecDocumento9 páginasDA 9000 Tech SpecJenrri Herhuay Huaman100% (1)

- File Tracking System SRSDocumento16 páginasFile Tracking System SRSParthAinda não há avaliações

- Unit Ii: 2.1 Problem Solving TechniquesDocumento31 páginasUnit Ii: 2.1 Problem Solving TechniquesseravanakumarAinda não há avaliações

- Ssa Report Format (Ooad)Documento4 páginasSsa Report Format (Ooad)bishal0% (1)

- TMS320x28xx, 28xxx DSP Peripheral PDFDocumento22 páginasTMS320x28xx, 28xxx DSP Peripheral PDFHiren MistryAinda não há avaliações

- SMS SRSDocumento5 páginasSMS SRSSameer khanAinda não há avaliações

- Tarteel White PaperDocumento8 páginasTarteel White PaperAbdellatif AbdelfattahAinda não há avaliações

- Revenue Recovery System Report GenerationDocumento40 páginasRevenue Recovery System Report GenerationNarendra PallaAinda não há avaliações

- Installing The Contoso Test DatasetDocumento7 páginasInstalling The Contoso Test DatasetTilak RajuAinda não há avaliações

- TasmDocumento5 páginasTasmRyan RyanAinda não há avaliações

- ModbusDocumento12 páginasModbusCh Moazzam HanjraAinda não há avaliações

- CDT Plug-InDocumento84 páginasCDT Plug-InAitor_Amorrort_8707Ainda não há avaliações

- Servo Drive Systems - Chapter 3 - 2019 PDFDocumento43 páginasServo Drive Systems - Chapter 3 - 2019 PDFcườngAinda não há avaliações

- 98-364 DATABASE ADMINISTRATION FUNDAMENTALS PRACTICE QUIZ KEYDocumento7 páginas98-364 DATABASE ADMINISTRATION FUNDAMENTALS PRACTICE QUIZ KEYCarlos Díaz100% (1)

- CSCE 313-501 Definitions: 1.1 & The Basic ElementsDocumento6 páginasCSCE 313-501 Definitions: 1.1 & The Basic Elementsjcschwartz1Ainda não há avaliações

- Computer Architecture Study Guide (Draft - Pending Final Review) PDFDocumento93 páginasComputer Architecture Study Guide (Draft - Pending Final Review) PDFMuhammad Yaseen OsmanAinda não há avaliações

- Configuring Windows Client with Multiple Partitions, User Groups & PrinterDocumento23 páginasConfiguring Windows Client with Multiple Partitions, User Groups & PrinterRif CAinda não há avaliações

- Unit 1 Front Room ArchitectureDocumento7 páginasUnit 1 Front Room ArchitecturePrathamesh SarafAinda não há avaliações

- Real Time Operating System A Complete Guide - 2020 EditionNo EverandReal Time Operating System A Complete Guide - 2020 EditionAinda não há avaliações

- Enerlux TN Software Module Users' Manual Rev.3: TimisoaraDocumento51 páginasEnerlux TN Software Module Users' Manual Rev.3: TimisoaraMuhammad Faisal KhanAinda não há avaliações

- 07-Relay TechnologyDocumento13 páginas07-Relay Technologyapi-3769988Ainda não há avaliações

- Transforsmer TESTSDocumento40 páginasTransforsmer TESTSMuhammad Faisal KhanAinda não há avaliações

- Pakistan Water and Power Development Authority: Travelling Allowance BillDocumento5 páginasPakistan Water and Power Development Authority: Travelling Allowance BillMuhammad Faisal KhanAinda não há avaliações

- Enerlux M Software Module Users' Manual Rev.3: TimisoaraDocumento35 páginasEnerlux M Software Module Users' Manual Rev.3: TimisoaraMuhammad Faisal KhanAinda não há avaliações

- Budget Manual PDFDocumento147 páginasBudget Manual PDFMuhammad Faisal Khan100% (1)

- Book 1 CDocumento4 páginasBook 1 CMuhammad Faisal KhanAinda não há avaliações

- Mba CoursesDocumento3 páginasMba CoursesMuhammad Faisal KhanAinda não há avaliações

- Mark Eeting 1DDocumento15 páginasMark Eeting 1DMuhammad Faisal KhanAinda não há avaliações

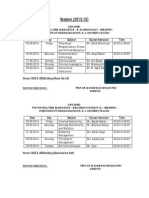

- Session (2013-15) : Date Day Subject Course Instructor TimeDocumento10 páginasSession (2013-15) : Date Day Subject Course Instructor TimeMuhammad Faisal KhanAinda não há avaliações

- What Is Forward Vertical Integration - Docx2Documento2 páginasWhat Is Forward Vertical Integration - Docx2Muhammad Faisal KhanAinda não há avaliações

- Enerlux TN Software Module Users' Manual Rev.3: TimisoaraDocumento51 páginasEnerlux TN Software Module Users' Manual Rev.3: TimisoaraMuhammad Faisal KhanAinda não há avaliações

- What Is Fiscal PolicyDocumento42 páginasWhat Is Fiscal PolicyMuhammad Faisal KhanAinda não há avaliações

- Three Phase Power Calibrator and Power Engineering Devices TesterDocumento4 páginasThree Phase Power Calibrator and Power Engineering Devices TesterMuhammad Faisal KhanAinda não há avaliações

- Enerlux M Software Module Users' Manual Rev.3: TimisoaraDocumento35 páginasEnerlux M Software Module Users' Manual Rev.3: TimisoaraMuhammad Faisal KhanAinda não há avaliações

- Assignment No 1 AccountingDocumento2 páginasAssignment No 1 AccountingMuhammad Faisal KhanAinda não há avaliações

- "Do Marketers Create Need or Satisfy Need": Directorate of Distance LearningDocumento5 páginas"Do Marketers Create Need or Satisfy Need": Directorate of Distance LearningMuhammad Faisal KhanAinda não há avaliações

- Yaqoob CV RevisedzzDocumento3 páginasYaqoob CV RevisedzzMuhammad Faisal Khan100% (1)

- Daewoo VDocumento2 páginasDaewoo VMuhammad Faisal KhanAinda não há avaliações

- Ead Proforma Surty Undertaking1Documento3 páginasEad Proforma Surty Undertaking1Muhammad Faisal KhanAinda não há avaliações

- Sharjeel N Awaz Résumé Automation Engr PDFDocumento1 páginaSharjeel N Awaz Résumé Automation Engr PDFMuhammad Faisal KhanAinda não há avaliações

- Asim New SexfffcDocumento2 páginasAsim New SexfffcMuhammad Faisal KhanAinda não há avaliações

- R.E SB CVDocumento5 páginasR.E SB CVMuhammad Faisal KhanAinda não há avaliações

- R.E SB CVDocumento5 páginasR.E SB CVMuhammad Faisal KhanAinda não há avaliações

- China 2014 Pakistan Training ProgramDocumento4 páginasChina 2014 Pakistan Training ProgramMuhammad Faisal KhanAinda não há avaliações

- New CV Mohsin VDocumento6 páginasNew CV Mohsin VMuhammad Faisal KhanAinda não há avaliações

- Asim New SexfffcDocumento2 páginasAsim New SexfffcMuhammad Faisal KhanAinda não há avaliações

- Serial IO and Data CommunicationDocumento25 páginasSerial IO and Data Communicationapi-3724082100% (8)

- COA - Chapter # 3Documento26 páginasCOA - Chapter # 3Set EmpAinda não há avaliações

- Service Manual Sdv-3540 9188tDocumento36 páginasService Manual Sdv-3540 9188tequus43Ainda não há avaliações

- 1.introduccion A CursoDocumento10 páginas1.introduccion A Cursobelita1Ainda não há avaliações

- VRPP Technical ManualDocumento16 páginasVRPP Technical ManualJegadeshwaran RAinda não há avaliações

- Action Plans and EU Acquis Progress Report 2023 WEBDocumento212 páginasAction Plans and EU Acquis Progress Report 2023 WEBRaza KandicAinda não há avaliações

- Tan Emily Sooy Ee 2012 PDFDocumento323 páginasTan Emily Sooy Ee 2012 PDFMuxudiinAinda não há avaliações

- Azure FundamentalsDocumento5 páginasAzure FundamentalsRamziAinda não há avaliações

- Effective Strategies For Virtual Classroom ParticipationDocumento3 páginasEffective Strategies For Virtual Classroom ParticipationRicha SinghAinda não há avaliações

- Maintain Equipment Request FormDocumento5 páginasMaintain Equipment Request FormDwayne SmithAinda não há avaliações

- Drive TechnologyDocumento352 páginasDrive TechnologyBurak İLHANAinda não há avaliações

- Rpa SheetDocumento5 páginasRpa SheetGaurav PoddarAinda não há avaliações

- Insert Report From - Read Report Into - Delete ReportDocumento2 páginasInsert Report From - Read Report Into - Delete ReportDairo LozanoAinda não há avaliações

- AZ-900T01-A - Microsoft Azure Fundamentals - SkillpipeDocumento1 páginaAZ-900T01-A - Microsoft Azure Fundamentals - SkillpipeAdministrador de SistemasAinda não há avaliações

- Hyperloop ReportDocumento25 páginasHyperloop ReportAVI RAJAinda não há avaliações

- سوالات فصل پنجمDocumento2 páginasسوالات فصل پنجمshadab BenawarAinda não há avaliações

- MS4101 Individual Assignment 2022Documento2 páginasMS4101 Individual Assignment 2022Shauna DeveryAinda não há avaliações

- CV-JM Van StraatenDocumento5 páginasCV-JM Van StraatenJovan Van StraatenAinda não há avaliações

- Social Media Safety TipsDocumento5 páginasSocial Media Safety TipsIthran IthranAinda não há avaliações

- Ingun Ada Catalogue enDocumento80 páginasIngun Ada Catalogue enMichael DoyleAinda não há avaliações

- DevLIVE PresentationDocumento53 páginasDevLIVE PresentationGeneva LozadaAinda não há avaliações

- BSNL Performance ScorecardDocumento1 páginaBSNL Performance ScorecardpokharnapokarAinda não há avaliações

- COMSATS University Islamabad Lab Sessional IDocumento2 páginasCOMSATS University Islamabad Lab Sessional IAdnan AadiAinda não há avaliações

- Prince2 ThemesDocumento3 páginasPrince2 Themesshiva_1912-1Ainda não há avaliações

- SAIC-RTR4 User Manual 20 PagesDocumento20 páginasSAIC-RTR4 User Manual 20 PagesJim ToewsAinda não há avaliações

- InTech-Omnidirectional Mobile Robot Design and ImplementationDocumento18 páginasInTech-Omnidirectional Mobile Robot Design and ImplementationSenthil KumarAinda não há avaliações

- RPA Development Life CycleDocumento22 páginasRPA Development Life CycleDrAnand ShankarAinda não há avaliações

- Brochure Imaxeon Salient DualDocumento4 páginasBrochure Imaxeon Salient DualQuyet LeAinda não há avaliações

- Saes K 402Documento18 páginasSaes K 402drbabithameringeorgemdsorthoAinda não há avaliações

- Turning Aerospace IndustryDocumento12 páginasTurning Aerospace Industryawaism471Ainda não há avaliações