Escolar Documentos

Profissional Documentos

Cultura Documentos

Análise de Fadiga em Vasos de Pressão Na Plataforma Ansys@

Enviado por

Suzi Bugarim0 notas0% acharam este documento útil (0 voto)

77 visualizações7 páginasTítulo original

Análise de Fadiga Em Vasos de Pressão Na Plataforma Ansys@

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

DOCX, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

77 visualizações7 páginasAnálise de Fadiga em Vasos de Pressão Na Plataforma Ansys@

Enviado por

Suzi BugarimDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF, TXT ou leia online no Scribd

Você está na página 1de 7

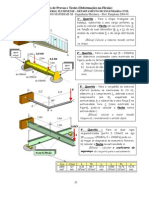

ANLISE DE FADIGA NOS VASOS DE PRESSO: CONSTRUO DO MODELO

NUMRICO DOS CASCOS CILINDRICOS DOS ACUMULADORES DE AR/LEO DO

SISTEMA REGULADOR DE VELOCIDADE ATRAVS DO SOFTWARE ANSYS@

Autora: Suziane Bugarim Meireles

Comandos do programa Ansys@ verso 11.0

1. Titulo da anlise

Utility Menu > File > Change Title [TITLE]:

Acumulador Ar oleo

2. Nome do arquivo

Utility Menu > File > Change Jobname:

Casco VP

3. Etapa de Pr-processamento

3.1 Escolha do Elemento

Ansys Main Menu > Preprocessor> Element type > Add/ Edit/ Delete:

Solid > 8node 183> OK.

Click Options, selecione Axisymmetric for K3 (Element behavior) > OK > Close.

3.2 Propriedades do Material

Ansys Main Menu > Preprocessor > Material Props> Material Models > Structural > Linear > Elastic >

Isotropic:

EX 210e9

PRXY 0.3

OK.

3.3 Criando a Geometria

Ansys Main Menu > Preprocessor > Modeling> Create > Keypoint >In Active CS >

N Keypoint X Y

1 0.85 0 Apply

2 0.85 2.3 Apply

3 0.897 2.3 Apply

4 0.897 0 OK

3.3.1 Formao das linhas atravs dos keypoints

Ansys Main Menu > Preprocessor > Modeling> Create > Lines >Lines >Straight Line>

Click em cada keypoint > OK.

3.3.2 Criando rea

Ansys Main Menu > Preprocessor > Modeling> Create > Areas >Arbitrary >By lines > loop.

3.4 Gerando a Malha

Ansys Main Menu > Preprocessor > Meshing > Mesh Tool >

Size Controls> Areas>

element length 0.01 >Mesh: Areas> Quad, Mapped > Mesh > OK > Close.

4. Etapa de Soluo

Eventos estabelecidos pela variao de presso nos acumuladores de ar/leo.

N do Evento N da Carga Cargas N de Ciclos Passo de Atuao da Carga

1 1 6,8 MPa

900.000

1s

1 2 6,5 MPa 900s

2 1 6,5 MPa 901s

2 2 6,8 MPa 990s

Ansys Main Menu > Solution > Analysis Type > New Analysis > Transient > OK > Full > OK.

Ansys Main Menu > Solution > Sols Controls>Basic Tab>

Time at end of loadstep: 0 >Transient Tab> Stepped Loading > OK.

4.1 Aplicao das Cargas e Condies de Simetria

Define Loads>Apply >Structural>Displacement> Symmetry B.C.>On Lines.

Selecionar a linha 3 no modelo > OK.

Ansys Main Menu >Solution > Define Loads >Apply >Structural > Pressure >OnLines >

Selecionar a linha da parte interna do casco cilndrico do vaso de presso, linha 2 >OK>

Load PRES value: 6.8e6 >OK.

Load Step Opts >Write LS File> Load step file number n: 1> OK

Ansys Main Menu > Solution > Sols Controls >Basic Tab>

Time at end of loadstep: 900 > OK.

Define Loads>Delete>Structural> Pressure > On Line > Pick All > OK.

Define Loads> Apply >Structural>Displacement> Symmetry B.C. >On Lines.

Selecionar a linha 3 no modelo > OK.

Ansys Main Menu > Solution > Define Loads >Apply >Structural > Pressure > On Lines >

Selecionar a linha da parte interna do casco cilndrico do vaso de presso, linha 2 >OK>

Load PRES value: 6.5e6 >OK.

Load Step Opts >Write LS File> Load step file number n: 2 > OK

Ansys Main Menu > Solution > Sols Controls >Basic Tab>

Time at end of loadstep: 900 > OK.

Define Loads>Delete>Structural> Pressure > On Line > Pick All > OK.

Define Loads> Apply >Structural>Displacement> Symmetry B.C. >On Lines.

Selecionar a linha 3 no modelo > OK.

Ansys Main Menu > Solution > Define Loads >Apply >Structural > Pressure > On Lines >

Selecionar a linha da parte interna do casco cilndrico do vaso de presso, linha 2 >OK>

Load PRES value: 6.5e6 >OK.

Load Step Opts >Write LS File> Load step file number n: 3 > OK

Ansys Main Menu > Solution > Sols Controls >Basic Tab>

Time at end of loadstep: 990 > OK.

Define Loads>Delete>Structural> Pressure > On Line > Pick All > OK.

Define Loads> Apply >Structural>Displacement> Symmetry B.C. >On Lines.

Selecionar a linha 3 no modelo > OK.

Ansys Main Menu > Solution > Define Loads >Apply >Structural > Pressure > On Lines >

Selecionar a linha da parte interna do casco cilndrico do vaso de presso, linha 2 >OK>

Load PRES value: 6.8e6 >OK.

Load Step Opts >Write LS File> Load step file number n: 4 > OK

4.2 Obtendo a Soluo

Ansys Main Menu > Solution >Solve>From LS Files>

Starting LS file number: 1

Ending LS file number: 4

File number increment: 1 > OK

Ansys Main Menu > General Postproc>Read Results>By Pick>

Select Set: 1 > Read > Close.

5. Anlise de Tenso

Ansys Main Menu >GeneralPostproc> Plot Results > Contour Plot >

Selecione: Stress > 1st Principal stress > OK.

Utility Menu >PlotCtrls> Style >Symmetry Expansion >2-D Axi-Symmetric >

Selecione: 3/4 expansion >OK.

6. Procedimento da Anlise de Fadiga

Ansys Main Menu > General Postproc>Fatigue>Property Table>S-N Table.

Ansys Main Menu > General Postproc>Fatigue>Stress Locations>

NLOC = 1

NODE = 4 (n localizado na extremidade superior da geometria).

TITLE = EX. SUPERIOR> Apply.

Ansys Main Menu > General Postproc>Fatigue>Store Stresses>

From rst File>

NODE: 4

Event: 1

Loading: 1 > Apply.

Ansys Main Menu > General Postproc>Read Results>By Pick>

Select Set: 2 > Read > Close.

Ansys Main Menu > General Postproc>Fatigue >Store Stresses>

From rst File

NODE: 4

Event: 1

Loading: 2 >Apply.

Ansys Main Menu >GeneralPostproc>Read Results>By Pick>

Select Set: 3> Read > Close.

Ansys Main Menu >GeneralPostproc> Fatigue >Store Stresses>

From rst File

NODE: 4

Event: 2

Loading: 1>Apply.

Ansys Main Menu > General Postproc>Read Results>By Pick>

Select Set: 4> Read > Close.

Ansys Main Menu > General Postproc> Fatigue >Store Stresses>

From rst File

NODE: 4

Event: 2

Loading: 2 >Apply.

Ansys Main Menu > General Postproc> Fatigue >Assign Events>

NEV = 1

CYCLE = 900000

TITLE = FATIGUE >Apply.

Ansys Main Menu > General Postproc> Fatigue >Assign Events>

NEV = 2

CYCLE = 900000

TITLE = FATIGUE >Apply.

Ansys Main Menu > GeneralPostproc> Fatigue >Calculate Fatig> OK.

7. Resultados

A intensidade da tenso alternada produzida de 2,939 MPa decorrente da combinao dos 2 eventos com

suas respectivas cargas. Para o estudo, foi considerado que o vaso de presso estar submetido a 900.000

ciclos em 50 anos, tendo 50 ciclos dirios. A partir da Tabela S-N, o mximo nmero de ciclos permitidos

para esta intensidade de tenso 10

6

ciclos. O valor de uso parcial, 0,900 corresponde ao nmero de

ciclos utilizados / ciclos permitidos. O valor de uso acumulado de Fadiga a soma dos fatores de uso

parcial.

Você também pode gostar

- Memorial de Cálculo Andaime Tipo GavetasDocumento6 páginasMemorial de Cálculo Andaime Tipo GavetasSuzi BugarimAinda não há avaliações

- Seminário de Biologia Slide (Biomas Terrestres)Documento28 páginasSeminário de Biologia Slide (Biomas Terrestres)Breno José Alves PedrozaAinda não há avaliações

- Nova Dieta Da UspDocumento2 páginasNova Dieta Da UspLuciane Lorra0% (1)

- Dimensionamento de Um Chassi Do Tipo Spaceframe Através de Análise Numérica Estática e DinâmicaDocumento80 páginasDimensionamento de Um Chassi Do Tipo Spaceframe Através de Análise Numérica Estática e DinâmicaGabriel Ramires Peixoto ReisAinda não há avaliações

- PEF2602-2016-Aula-7 - Estruturas Hiperestaticas - 2 Slides Por Pagina PDFDocumento11 páginasPEF2602-2016-Aula-7 - Estruturas Hiperestaticas - 2 Slides Por Pagina PDFBianca Oliveira100% (1)

- Cálculo de barras comprimidas com flambagemDocumento38 páginasCálculo de barras comprimidas com flambagemHallyson CarvalhoAinda não há avaliações

- Memorial de CalculoDocumento9 páginasMemorial de CalculoThaisa Gonçalves da SilvaAinda não há avaliações

- Resumo AndaimesDocumento34 páginasResumo Andaimes084250Ainda não há avaliações

- Projeto de guindaste telescópicoDocumento22 páginasProjeto de guindaste telescópicoBrenno Flávio100% (2)

- Introdução ANSYSDocumento116 páginasIntrodução ANSYSRoberto AbreuAinda não há avaliações

- Plano de RiggingDocumento2 páginasPlano de RiggingNilsonAinda não há avaliações

- Enunciado Da Avaliação 2 - Cálculo Elementar (IL10009)Documento2 páginasEnunciado Da Avaliação 2 - Cálculo Elementar (IL10009)Passei DiretoAinda não há avaliações

- Dimensionamento de freios para veículo de passageiros (M1Documento42 páginasDimensionamento de freios para veículo de passageiros (M1VQuadrosAinda não há avaliações

- Manual Do Balancim Pneumático BPDDocumento15 páginasManual Do Balancim Pneumático BPDSandro NadineAinda não há avaliações

- Medição de Espessura Por UltrassomDocumento15 páginasMedição de Espessura Por UltrassomThiagoDosSantosCangussuAinda não há avaliações

- Barra N29/N30 perfil W150x37.1Documento8 páginasBarra N29/N30 perfil W150x37.1Bruno FernandesAinda não há avaliações

- TCC 2 - Matheus Felizardo Torchia PDFDocumento61 páginasTCC 2 - Matheus Felizardo Torchia PDFMatheus TorchiaAinda não há avaliações

- Teorias de FalhaDocumento40 páginasTeorias de FalhaPermutante BMAinda não há avaliações

- Cap. 3 - Introdução Ao Método Dos Elementos FinitosDocumento44 páginasCap. 3 - Introdução Ao Método Dos Elementos FinitosJean PazaAinda não há avaliações

- Translação Do CarroDocumento37 páginasTranslação Do Carrorobson leoniAinda não há avaliações

- Resistencia Materiais VIÇOSADocumento46 páginasResistencia Materiais VIÇOSAMarcio NunesAinda não há avaliações

- Viga V1 projetoDocumento9 páginasViga V1 projetoosmar.portela8926Ainda não há avaliações

- Projeto suporte linha vida caminhão validado FEMDocumento15 páginasProjeto suporte linha vida caminhão validado FEMLeonardo GalbiatiAinda não há avaliações

- Porta Paletes 187594 MECALUX PDFDocumento44 páginasPorta Paletes 187594 MECALUX PDFrmrodrig2005-mail3134Ainda não há avaliações

- Laudo Teste de CargaDocumento67 páginasLaudo Teste de CargaPatrick SilvaAinda não há avaliações

- Orifício e sela da boca de lobo projetoDocumento2 páginasOrifício e sela da boca de lobo projetoSergio Charcape100% (1)

- Calculo de Vibração Longitudinal VirabrequimDocumento118 páginasCalculo de Vibração Longitudinal VirabrequimJoão Vitor MeiraAinda não há avaliações

- Topology Optimization of a Lower A-Arm for an Off-Road Vehicle SuspensionDocumento89 páginasTopology Optimization of a Lower A-Arm for an Off-Road Vehicle SuspensionFelintoNetoAinda não há avaliações

- Especificações Técnicas Peneira Vibratória M.I Modulares - ZL Equipamentos.Documento5 páginasEspecificações Técnicas Peneira Vibratória M.I Modulares - ZL Equipamentos.Antônio MiguelAinda não há avaliações

- Univiga Ponte Rolante 12 ToneladasDocumento61 páginasUniviga Ponte Rolante 12 ToneladasCleiton Jose NevesAinda não há avaliações

- Elementos de Máquinas PDFDocumento7 páginasElementos de Máquinas PDFrasrodrigo23Ainda não há avaliações

- Projeto de Ponte Rolante de Elemaq 2Documento31 páginasProjeto de Ponte Rolante de Elemaq 2Matheus Alves CostaAinda não há avaliações

- Dispositivo de ancoragem SkyORBTM para caminhõesDocumento8 páginasDispositivo de ancoragem SkyORBTM para caminhõesJoão BispoAinda não há avaliações

- Apostila Mopntagem de Andaimes PDFDocumento15 páginasApostila Mopntagem de Andaimes PDFLindemberg TrindadeAinda não há avaliações

- NBR 09968 - 1987 - Talhas Com Acionamento Manual PDFDocumento4 páginasNBR 09968 - 1987 - Talhas Com Acionamento Manual PDFfernandonascime7325Ainda não há avaliações

- Análise de tensão MEF do evaporador EVP-16Documento18 páginasAnálise de tensão MEF do evaporador EVP-16Wellisson Felipe BarbosaAinda não há avaliações

- Questões de Provas e TestesDocumento10 páginasQuestões de Provas e TestesJorlandoAinda não há avaliações

- Resistência dos Materiais: Estudo dos EsforçosDocumento59 páginasResistência dos Materiais: Estudo dos EsforçosSavio fonseca ufosAinda não há avaliações

- Memorial cálculo estrutura linha vidaDocumento8 páginasMemorial cálculo estrutura linha vidabruno531Ainda não há avaliações

- Inspeção veicular completaDocumento9 páginasInspeção veicular completawcojrAinda não há avaliações

- Lajes Maciças Exemplo NuméricoDocumento21 páginasLajes Maciças Exemplo NuméricoAnonymous Byopfd100% (2)

- Curso Arquitetura Desenho TécnicoDocumento5 páginasCurso Arquitetura Desenho TécnicoM. IsabelAinda não há avaliações

- Estudo do desgaste de rodas de pontes rolantes na siderurgiaDocumento87 páginasEstudo do desgaste de rodas de pontes rolantes na siderurgiaeducrocoAinda não há avaliações

- Análise de tensões em estrutura navalDocumento20 páginasAnálise de tensões em estrutura navalAnonymous swEs7SEgAinda não há avaliações

- Aula 08 - Ensaio de EmbutimentoDocumento25 páginasAula 08 - Ensaio de Embutimentopaulo1americoAinda não há avaliações

- Relatório Ensaio de TraçãoDocumento6 páginasRelatório Ensaio de Traçãofaeljose100% (1)

- Treliças planas resistênciaDocumento13 páginasTreliças planas resistênciaAlefe De SouzaAinda não há avaliações

- Dimensionamento de Transportador de Roletes Sem AcionamentoDocumento7 páginasDimensionamento de Transportador de Roletes Sem AcionamentoMatheusJoseDalleMolleAinda não há avaliações

- Trabalho de DelineamentoDocumento22 páginasTrabalho de DelineamentoDaniel RêgoAinda não há avaliações

- Escada: projeto e dimensionamentoDocumento97 páginasEscada: projeto e dimensionamentoRafael AlvesAinda não há avaliações

- Visualventos-Tutorial PDFDocumento5 páginasVisualventos-Tutorial PDFNablaFi100% (1)

- Curso Estrutura Metálica-002Documento55 páginasCurso Estrutura Metálica-002Lima Rocha100% (1)

- Folder Inspecao Corrente RudDocumento1 páginaFolder Inspecao Corrente RudCJCONSTANTEAinda não há avaliações

- TCC - Projeto de Uma Suspensão de Um Fórmula SAE - Do Conceito Ao Cálculo de Fadiga - Mauricio Slovinscki MotterDocumento83 páginasTCC - Projeto de Uma Suspensão de Um Fórmula SAE - Do Conceito Ao Cálculo de Fadiga - Mauricio Slovinscki MotterAnonymous ZC1ld1CLmAinda não há avaliações

- Artigo Galpões em Pórticos de AçoDocumento4 páginasArtigo Galpões em Pórticos de AçoEduardo SiqueiraAinda não há avaliações

- AncoragemDocumento121 páginasAncoragemThiago BenevidesAinda não há avaliações

- Lista01 Hiperestatica Metodocargaunitariagab 141019202042 Conversion Gate01Documento13 páginasLista01 Hiperestatica Metodocargaunitariagab 141019202042 Conversion Gate01172026Ainda não há avaliações

- Exemplo Sap 2000-Modelagem Computacional de Uma Viga Com Abertura Na Alma Utilizando o Sap 2000Documento10 páginasExemplo Sap 2000-Modelagem Computacional de Uma Viga Com Abertura Na Alma Utilizando o Sap 2000Wesley MachadoAinda não há avaliações

- Exemplo Simples de Viga No AnsysDocumento16 páginasExemplo Simples de Viga No Ansysfuturista666Ainda não há avaliações

- Apresentação - Abaqus (Cont.)Documento46 páginasApresentação - Abaqus (Cont.)Denini FernandesAinda não há avaliações

- Roberto Luiz KrugerDocumento127 páginasRoberto Luiz KrugerVitória MarcenariaAinda não há avaliações

- Calibração de ManômetrosDocumento9 páginasCalibração de ManômetrosGustavo SantosAinda não há avaliações

- Projetos Com Arm Programado Em Arduino Com Base No Modelo Stm32f103c8 Parte XiNo EverandProjetos Com Arm Programado Em Arduino Com Base No Modelo Stm32f103c8 Parte XiAinda não há avaliações

- Cap 7 PDFDocumento6 páginasCap 7 PDFSuzi BugarimAinda não há avaliações

- Manual de ARTDocumento21 páginasManual de ARTcristianesilvaferrAinda não há avaliações

- Epm Apostila Capc3adtulo09 Ensaios ModDocumento110 páginasEpm Apostila Capc3adtulo09 Ensaios ModSuzi BugarimAinda não há avaliações

- Processos de Fundição UERJDocumento49 páginasProcessos de Fundição UERJRaphael MatAinda não há avaliações

- EG-M-402 EG Trat Superf Pintura Protecao Acabamento Rev 11Documento70 páginasEG-M-402 EG Trat Superf Pintura Protecao Acabamento Rev 11Lucas MoraesAinda não há avaliações

- Fundição Por Centrifugação PDFDocumento22 páginasFundição Por Centrifugação PDFSuzi BugarimAinda não há avaliações

- FourierDocumento11 páginasFourierSuzi BugarimAinda não há avaliações

- Riscos do teste hidrostático em equipamentosDocumento2 páginasRiscos do teste hidrostático em equipamentosSuzi BugarimAinda não há avaliações

- Divisão Celular 2017.2Documento33 páginasDivisão Celular 2017.2Edmar Nascimento100% (1)

- Manual de Produção de Pólen e Propolis PDFDocumento24 páginasManual de Produção de Pólen e Propolis PDFdaniel_velez702543100% (2)

- O PinheirinhoDocumento12 páginasO PinheirinhoceuvazAinda não há avaliações

- Farmacotécnica BatomDocumento4 páginasFarmacotécnica Batomchagas_83Ainda não há avaliações

- Exposição Universal ParisDocumento343 páginasExposição Universal ParismariajulianafaAinda não há avaliações

- Solo, suporte de vida - Síntese sobre a formação e importância do soloDocumento2 páginasSolo, suporte de vida - Síntese sobre a formação e importância do soloElisabete BarbosaAinda não há avaliações

- Projeto de Controladores Digitais Pid e I-Pd Via RST: Uma Análise de DesempenhoDocumento6 páginasProjeto de Controladores Digitais Pid e I-Pd Via RST: Uma Análise de DesempenhoTarcisio CarlosAinda não há avaliações

- Receita de Guioza ou GyozaDocumento9 páginasReceita de Guioza ou Gyozactaima100% (1)

- Importância dos microorganismos do solo e ameaça ao tatu bolaDocumento5 páginasImportância dos microorganismos do solo e ameaça ao tatu bolapizzaiolloucoAinda não há avaliações

- Endodontia Contemporânea: Anatomia da Cavidade PulparDocumento14 páginasEndodontia Contemporânea: Anatomia da Cavidade PulparRebeka Thiara Nascimento dos SantosAinda não há avaliações

- Dieta de Ganho de Massa MagraDocumento2 páginasDieta de Ganho de Massa MagraAguiarDaSilvaGuimarães100% (2)

- 01 - Deus Fez Todas As CoisasDocumento26 páginas01 - Deus Fez Todas As CoisasDepartamento Intantil Batista Shallom IdealAinda não há avaliações

- AS Folhas Completa Possui LimboDocumento16 páginasAS Folhas Completa Possui LimboAline Silvestre PereiraAinda não há avaliações

- Ementa BercárioDocumento4 páginasEmenta BercárioOlga Pérez MarquesAinda não há avaliações

- Genética e Herança: Conceitos BásicosDocumento19 páginasGenética e Herança: Conceitos BásicosSimone Caires50% (2)

- Produção do vinho passo a passoDocumento4 páginasProdução do vinho passo a passoRodrigo PominiAinda não há avaliações

- Estrutura e pigmentos dos vegetaisDocumento14 páginasEstrutura e pigmentos dos vegetaisMamudo SadamoAinda não há avaliações

- Pragas Do Pimentão e Da Pimenta: Caracterlstlcas e Métodos de ControleDocumento7 páginasPragas Do Pimentão e Da Pimenta: Caracterlstlcas e Métodos de ControleGUILHERME GIRALDIAinda não há avaliações

- 713 Instrucoes Protecao Ambiental PDFDocumento165 páginas713 Instrucoes Protecao Ambiental PDFMaria Da Conceição PatricioAinda não há avaliações

- A Célula Como Unidade BiodiversidadeDocumento19 páginasA Célula Como Unidade BiodiversidadeGonçaloAinda não há avaliações

- Guia 101 Projetos Paisagismo - Ed. 01 - 2016Documento116 páginasGuia 101 Projetos Paisagismo - Ed. 01 - 2016Impacto ConsultoriaAinda não há avaliações

- 7 Reprodução AssexuadaDocumento45 páginas7 Reprodução Assexuadaalexa100% (1)

- Autism Spectrum QuotientDocumento4 páginasAutism Spectrum QuotientTaize de OliveiraAinda não há avaliações

- Podas de Inverno Parte Tres - Bagas GojiDocumento3 páginasPodas de Inverno Parte Tres - Bagas GojiAdriana GonçalvesAinda não há avaliações

- Microrganismos em ambientes naturaisDocumento48 páginasMicrorganismos em ambientes naturaisVanessa DuzAinda não há avaliações

- Sopa milagrosa com frango e legumesDocumento16 páginasSopa milagrosa com frango e legumesVAICAVALOAinda não há avaliações

- A história do grande rabaneteDocumento20 páginasA história do grande rabanetejulianagsramosAinda não há avaliações

- Morfologia vegetal: raízes e caulesDocumento20 páginasMorfologia vegetal: raízes e caulesRobson Almeida Da Silva100% (1)