Escolar Documentos

Profissional Documentos

Cultura Documentos

Esr Meter Dick Smith Kit k7204 by Bob Parker Assembly

Enviado por

psapwellDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Esr Meter Dick Smith Kit k7204 by Bob Parker Assembly

Enviado por

psapwellDireitos autorais:

Formatos disponíveis

Text and illustrations courtesy of Electronics Australia

S

ome wise person once said, The

reliability of any piece of electronic

equipment is inversely proportional to

the number of electrolytic capacitors in

it, and I doubt that many service techni-

cians would disagree!

Especially now that switch-mode

power supplies (SMPSs) have been

commonly used in domestic VCRs and

TVs, etc for a decade or so, one of the

most likely components to fail is the

humble electrolytic. The symptoms can

be as diverse as a VCRs playback pic-

ture swimming in tiny dots, up to SMPSs

mysteriously self-destructing.

As a service technician myself (though

Id prefer to be a full-time designer!), I

was just about tearing my hair out

because of the difficulty in determining

which electros were faulty and which

ones were still OK, in SMPSs and other

equipment. I wanted to be able to check

electros in circuit, with the power safely

disconnected.

Why not use a readily-available capac-

itance meter? Because when electros go

faulty, they normally dont lose their

capacitance significantly (as many tech-

nicians assume they do). Rather their

equivalent series resistance (ESR) goes

through the roof. Capacitance meters

dont tell you this; about the best they

can do is give a low reading if the elec-

tro is nearly open circuit.

About ESR...

So what exactly is an electrolytics

equivalent series resistance?

Electrolytics depend on a water-based

electrolyte, soaked into a strip of porous

material between the aluminium foil

plates, to complete the outer electrical

connection to the aluminium oxide

dielectric coating on the anode foil.

The electrolyte has electrical resist-

ance which, along with the (negligible)

resistance of the connecting leads and

aluminium foil plates, forms the capaci-

tors equivalent series resistance.

Normally the ESR has a very low

value, which stays that way for many

years unless the rubber seal is defective.

Then the electrolytes water component

gradually dries out and the ESR creeps

up with time. The electro gradually acts

more and more like a capacitor with its

own internal series resistor...

Heat makes it worse

If an electro is subjected to high tem-

peratures, especially from heat generat-

ed internally as a result of large ripple

currents, the electrolyte will start to

decompose and the dielectric may dete-

riorate - and the ESR will increase far

more rapidly.

To make things worse, as the ESR

increases, so does the internal heating

caused by ripple current. This can lead to

Assembly Manual

ACN 000 908 716

K T

Reproduced in part by arrangement

with Electronics Australia, from their

January 1996 edition.

ESR & Low Ohms

Meter

K 7204

Please read Disclaimer carefully as we

can only guarantee parts and not the

labour content you provide.

by Bob Parker

Cat No.

If you repair switch-mode power supplies, TV receivers, computer monitors, vintage radios,

or similar equipment, and/or if you need to measure very low values of resistance, this proj-

ect can save you lots of time and aggravation - as it has for me. It measures an aspect of

electrolytic capacitor performance which is very important, but normally very difficult to

check: the equivalent series resistance, or ESR.

an upward spiral in the capacitors core

temperature, followed by complete fail-

ure - sometimes even explosive!

The service life of electros is approxi-

mately halved for every 10

0

C increase in

temperature and, surprisingly, many are

designed for a reliable operating life of

only a few thousand hours at their max-

imum rated temperature and ripple cur-

rent. (A year is only 8766 hours!)

Switch-mode power supplies place

quite severe stresses on filter capacitors.

Because of their compact construction,

temperatures are high (thats why your

PCs power supply is equipped with a

fan), and the capacitors have to endure

large ripple currents.

Micro-based ESR meter

Necessity is supposed to be the moth-

er of invention, but desperation works

even better and I designed this ESR

meter from scratch. Its based on a ver-

satile Zilog Z86E0408 or Z86E0412

microcontroller - which already has two

voltage comparators and two flexible

counter/timers built in, greatly simplify-

ing the rest of the circuit. A micro also

allows the easy incorporation of some

user-friendly features...

This instrument has three ESR ranges,

with full-scale readings to 0.99, 9.9

and 99 respectively. The range is auto-

matically selected by the micro, so your

hands are free to hold the test leads. The

accuracy of the prototypes was better

than +/-5% of displaying reading, +/-1

digit. A single - on the left-hand dis-

play indicates a reading above 99.

The readout is on two 0.5 (13mm)

seven-segment LED displays, plus two

3mm decimal point LEDs which are

needed because the display decimal

points are on the wrong side for this

application.

If you forget to turn the power off, the

micro will do it for you when the dis-

played reading has remained the same

for two minutes. This feature can be dis-

abled for uninterrupted operation from a

9V optional plugpack.

When the battery voltage is nearly too

low for the circuits 5V regulator to

function correctly, the Z86 reduces the

power to the LED displays and flashes a

b on the right-hand one in the off-

scale condition, to warn you to look for

a new battery.

Meter operation

Theres a single pushbutton, which has

three functions: one press turns the

power on, and another press will switch

it off again if the measured resistance is

1 or more.

A push of the button with the leads

shorted together will cause their resist-

ance value to be subtracted from all sub-

sequent readings, as long as its less than

1.

Before making a measurement on an

electrolytic, first discharge it. I find a

100 5W does this well. Then connect

the test leads - either way around. If your

capacitor is still in circuit (with the

power OFF!), youre likely to get quite

an accurate reading, because it should be

Text and illustrations courtesy of Electronics Australia

Page 2

A close up view of the ESR meter

PCB, showing the position and orien-

tation of all the parts - except the test

leads jacks, push button and battery.

Note that the LED displays and deci-

mal point LEDs are mounted via a 28-

pin IC socket.

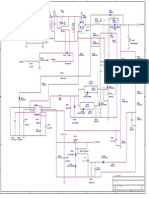

The schematic may look a little complicated, but the circuit is actually quite elegant. Everything is under the control of

IC2, a low cost microcontroller. As well as auto ranging, it also compensates for test lead resistance.

the component with by far the lowest

high-frequency impedance.

The circuits test signal has a peak

open-circuit voltage of 600mV (maxi-

mum 100mV peak at full-scale reading),

so it wont make diodes or transistors

conduct and cause measurement errors.

Compare the reading you get with the

front-panel table, to get an idea of

whether the electros ESR is about nor-

mal or significantly above it.

The tables approximate worst ESR

figures were taken from the Nippon

Chemi-Con Aluminium Electrolytic

Capacitors Catalog Number 4, as

100kHz impedance figures for their

SXE, SXG and LXA capacitor

series. They agree pretty closely with

my own measurements of many new

electros of assorted brands, styles, sizes

and ages.

From my actual faultfinding experi-

ence with the prototypes, an electros

ESR needs to be many times the table

value before its likely to cause trouble.

Low ohms uses

The instrument is very handy for

measuring low values of resistance, too.

But note that because it makes an AC

measurement, it cant give a sensible

indication of the DC resistance of induc-

tive components, such as transformer

windings or chokes.

Ive used it to roll my own low value

resistors, by measuring off the required

number of (milli) ohms of DSE catalog

number W-3200 resistance wire, which

I then formed into a spiral by wrapping

it around a drill shank.

It can also locate short circuits on PC

boards, by measuring actual track resist-

ances. If the reading increases as you

probe further along the track, you know

youre going in the wrong direction!

You could also use it to confirm solid

continuity of mains lead earth conduc-

tors, etc, etc...

What NOT to do

There are a few minor points to keep

in mind, when using the meter. First, it

cant identify leaky or short-circuited

capacitors - thats what the resistance

ranges of normal multimeters are for!

Also, avoid using self-retracting curly

test leads, because their inductance can

cause small measurement errors.

Lastly, dont use the meter right next

to an operating TV set or computer

monitor - the high amplitude pulses

radiated by the horizontal output stage

can be picked up by the test leads and

cause unstable readings.

The circuit

Now lets have a brief look at how it

all works, by reference to the schematic.

A push of the button switches on Q1,

supplying +9V to IC1, the 5V regulator.

Once the Z86E0408 or Z86E0412

microcontroller (Z86 for short) starts

up, it forward biases Q2. This holds Q1

on, maintaining the 5V supply after you

release the button.

The displays are driven by IC3, an

eight bit serial-in parallel-out shift regis-

ter. IC3s outputs are connected to both

seven segment displays and the decimal

point LEDs in parallel. Cathode driver

transistors Q12 and Q13 are configured

so that only one display and its decimal

point LED can illuminate at a time,

under control to the Z86s pin 18.

Every 5ms the Z86 serially updates the

segment and decimal point data in IC3,

and swaps displays; at this speed it

appears both displays are continuously

illuminated.

The Z86 starts a measurement by

grounding its pin 4, switching on current

mirror transistors Q9 and Q10 and caus-

ing C10 to begin charging at a constant

rate. Under control of its firmware, the

Z86 drives Q3, 4 or 5 to apply short cur-

rent pulses of 0.5, 5 or 50mA, via C5/6,

to the capacitor being tested. The result-

ing voltage pulses, proportional to the

electros ESR, are amplified by Q7 and

Q8 (no relation to the one in the Persian

Gulf!), and compared with C10s volt-

age. Q6 functions as a ground reference

Text and illustrations courtesy of Electronics Australia Page 3

Capacitors

C1 100uF 16/25 VW RB

electrolytic

C2,4,5,13 0.1uF/100n/104 50VW

disc/monolithic

C3,9 220uF 16/25VW RB

electrolytic

C6 47uF 50VW bipolar RB

electrolytic

C7 33nF/0.033uF/333 63/100VW

C8 22uF 16/25 VW RB

electrolytic

C10 0.47uF/470n/474

63/100VW MKT

C11,12 27pF 50V NPO disc ceramic

Semiconductors

D1,2,5,6 1N4148/1N914 etc signal

diode

D3,4 1N4002/4 etc power diode

Q1,3,4,5 BC328 PNP transistor

Q2,6,11,

12,13 BC338 NPN transistor

Q7 BC548 NPN transistor

Q8,9,10 BC558 PNP transistor

IC1 78L05 voltage regulator

IC2 Z86E0408/Z86E0412

microcontroller

(with custom firmware)

IC3 4094 CMOS shift register

DIS1,2 Seven-segment LED

displays LTS 5503AE

(see text)

LED1,2 3mm LEDs (see text)

Miscellaneous

Resistor 82R 1% & resistor 5.6R 5% (used

for calibration); XTAL-1 3.58MHz crystal,

HC-49/U case; One each 16, 18 28-pin IC

sockets; 216 type battery snap lead; plas-

tic utility box, type UB3; PC board; 95 x

57mm, code ZA1245 (96ESR1); push-on

momentary pushbutton switch; two x 4mm

banana sockets; pre-punched silk-

screened front panel; 4 x 15mm spacers;

2 x 4mm banana plugs; 2 x mini alligator

clips; PCB pins; piece of foam; red per-

spex display filter; hookup wire; solder; 8 x

washers; test leads.

Parts List

Resistors

(All 0.25W 5% unless noted) 4-band 5% 5-band 1%

R1,19,20,21,23,24 10k brn-blk-org-gld brn-blk-blk-red-brn

R2,27,28 4.7k yel-vio-red-gld yel-vio-blk-brn-brn

R3,26 15k brn-grn-org-gld brn-grn-blk-red-brn

R4,25 47k yel-vio-org-gld yel-vio-blk-red-brn

R5,7,9,15 2.2k red-red-red-gld red-red-blk-brn-brn

R6 10k 1% M/F brn-blk-org-brn brn-blk-blk-red-brn

R8 1k 1% M/F brn-blk-red-brn brn-blk-blk-brn-brn

R10 100 1% M/F brn-blk-brn-brn brn-blk-blk-blk-brn

R11 220 red-red-brn-brn red-red-blk-blk-brn

R12 1k brn-blk-red-gld brn-blk-blk-brn-brn

R13 100k brn-blk-yel-gld brn-blk-blk-org-brn

R14 220k red-red-yel-gld red-red-blk-org-brn

R16 180 brn-gry-brn-gld brn-gry-blk-blk-brn

R17 6.8k blu-gry-red-gld blu-gry-blk-brn-brn

R18 680 blu-gry-brn-gld blu-gry-blk-blk-brn

R22 470k 1% M/F yel-vio-yel-brn yel-vio-blk-org-brn

R29 2.7k red-vio-red-gld red-vio-blk-brn-brn

VR1 10k hor. trimpot

VR2 200 hor. trimpot

plays the value.

Now for the frills...

Battery voltage check: The Z86 regu-

larly allows C10 to charge to 2V. If the

battery voltage sample on VR1s wiper

(fed in via pin 9) drops below this 2V

level, the battery low warning condi-

tion is triggered.

Protection: Sooner or later this meter

will find itself connected to an unexpect-

edly charged capacitor (or worse), so

some protection has been built in. D3,

D4, D5 and D6 are strategically placed

to prevent destructive voltages from

finding their way back to the microcon-

troller; D4 also limits the test voltage to

0.6V peak.

The rest: When the Z86 detects the

button is pushed while measuring a

resistance of one ohm or more, it switch-

es off Q2 and displays questions marks

until your finger leaves the button. Then

Q1 switches off the battery supply.

Crystal XTAL1, C11 and C12 com-

plete the Z86s clock oscillator, which

provides the timing for all the meters

operations.

Construction

As the photos show, every component

except the pushbutton is mounted on a

57 x 95mm PC board, coded ZA1245

(96ESR1).

Before fitting any components to the

switch.

A simple time measurement allows

the Z86 to determine the amplitude of

the voltage pulses and so the capacitors

ESR. At the end of each measurement,

Q11 is used to discharge C10.

Then the Z86 subtracts the test lead

resistance (if its been zeroed), and dis-

Text and illustrations courtesy of Electronics Australia

Page 4

Here is the PCB diagram showing where everything goes. Use it in conjunction

with the photo when you are assembling your own board, to ensure that you get

everything in the right place.

The display window (perspex) is inserted into the panel cut-out from inside the flush with the front panel.

Fig.1: Shows how the

front panel is mounted to

the PCB using 15mm

insulated tapped spacers.

Note, if more clearance is

needed between the LED

display and perspex win-

dow we suggest to insert

one or two flat washers

beneath each spacer as

shown in the diagram.

PCB, first illuminate its component side

with a bright light, and examine the cop-

per side carefully for fine track breaks

and especially whiskers or bridges - par-

ticularly where tracks pass between IC

socket pads.

If youre planning to run the ESR &

Low Ohm Meter from an optional (not

supplied) 9V plugpack, leave R25

(47k) off the PCB. This will dis-

able the two minute automatic

switchoff function, and also the

low battery warning...

When youre soldering the com-

ponents to the PCB, using the

overlay diagram as a guide, bear in

mind that the PCB is tightly

packed and the solder pads are

small. The last thing this circuit

needs is solder bridges and bad

joints.

Begin installing the compo-

nents, starting with the lowest-

height ones (resistors and diodes),

and working your way up to the

tall ones. Note that the displays

and LEDs are mounted on a 28-pin

IC socket, not soldered directly to

the PCB!

Its a good idea to double-check,

especially at the beginning, that

youre putting each components

leads into its correct holes.

Theyre rather closely-spaced...

Take care with the orientation of

the polarised components, and

make sure the different transistors

types and IC1 all go in their correct

places. Dont install the socketed parts

just yet, though.

When everythings on the PCB, once

again illuminate it from the top, and

check for and correct any solder bridges

or other problems.

Making a display

Next study the display area in the

photo of the PCB. Then, keeping the

cathode (short) leads of the decimal

point LEDs to the right, cut the leads

down to about 9mm long. Use long-nose

pliers to dog-leg the leads about 3mm

from the ends, so the LEDs will be about

level with the bottom of the seven-seg-

ment displays when installed.

Push the LEDs into their places in the

28-pin socket, followed by the seven-

segment displays themselves, ensuring

their decimal points are at the bottom,

and they are properly seated.

First test

Solder the battery snap leads to their

pads, making certain their polarity is

correct, and solder long component lead

offcuts to the capacitor and button

pads. Temporarily solder the pushbutton

to the ends of its leads, then turn VR1

fully clockwise, and set VR2 to mid-

range.

Using alligator clip leads or similar,

connect a variable DC power supply set

for 9V (and preferably with about 50mA

current limiting) to the battery snap ter-

minals. Make sure the positive lead goes

to the clip, and the negative to the stud.

You can use another battery snap to

make a connection, but remember that its

black lead will be the positive one!

Hold the button down and check that

pin 5 of IC2s socket and pin 16 of IC3s

socket have +5V on them, relative to the

power supply negative. If they have, dis-

charge any static electricity by touching

something earthed, then install IC2 and

IC3 in their sockets and double-check

their orientation.

Push the button for a second or so, and

you should see EA flash on the displays

for a moment, followed by a single - on

the left-hand one. If not, carefully

recheck the PCB and its soldering and

component placement, until you find the

problem.

Now short the capacitor leads, and

the display should indicate a resistance

of around .03 ohms. Push the button

again and this should change to .00,

possibly with the least significant digit

hesitating between 0 and 1.

Calibration

Connect a resistor of known accuracy

of around 68 to 82 ohms to the capaci-

tor leads, and adjust VR2 for a correct

reading. Now try a resistor in the range

of 1 to 9 ohms, and check that the meter

reads close to the correct value.

Battery Warning: Skip this bit if you

disabled the automatic switchoff func-

tion by leaving R25 off the PCB.

Leaving the capacitor leads separat-

ed, turn the power supply voltage down

to 7.0V, preferably confirmed by a digi-

tal voltmeter. Slowly turn VR1 anti-

clockwise until the display brightness

suddenly drops noticeably, and a b

begins flashing on the right-hand dis-

play.

Push the button again and displays

should switch off. Wind the power sup-

ply back up to 9V, switch the ESR meter

back on by pushing the button, and

recheck that the battery warning triggers

when you drop the supply to 7.0V.

General assembly

Now you only need to install the com-

pleted electronics in the box. The front

panel is supplied pre-punched and silk-

Text and illustrations courtesy of Electronics Australia Page 5

Above is a component overlay showing

component designations that can be used

in a servicing or assembly situation to

cross-reference between the circuit dia-

gram and board overlay.

The milled perspex window should

be of snug fit inside the front panel

cut-out. At times, paint over-spray

on the inner edge of the front panel

cut-out could make mounting diffi-

cult whereby a little filing may be

needed.

We suggest to file smooth the verti-

cal milled edge of the perspex win-

dow as shown above until perfect

snug fit is formed. Now a small drop

of glue at each corner can be used to

secure the window in place.

Fitting Perspex Window

ACN 000 908 716

CNR Lane Cove & Waterloo Roads

North Ryde NSW 2113

PH: (02) (lnt 612) 9937 3200 Fax: (02) 9888 3631

Assembly Notes

Text and illustrations courtesy of Electronics Australia

Dick Smith Electronics ZA8667- 4

screened. So mount the button and

banana sockets as shown in the photos,

then position a milled edge red filter per-

spex under the display window - holding

it in place with a small drop of contact

adhesive or similar on each corner. Be

careful not to get any glue onto the view-

ing section of the window.

Now bolt the PCB to the lid, using four

15mm spacers (or a similar scheme).

Finally solder the capacitor and

pushbutton leads in place and connect a

9V alkaline battery (not supplied), which

can be held snugly against the bottom of

the box by the PCB via a piece of foam

strip provided, trim foam if necessary.

The cardboard piece is to protect the bot-

tom of the PCB from shorting out against

the battery.

Alternatively, you can bring the lead

from an optional 9V plugpack into the

box via a suitable grommeted hole.

Now screw the lid down, plug in some

probe (or clip) leads, and prepare for a

future of easy identification of faulty

electrolytics, and low resistance meas-

urements!

Você também pode gostar

- Final Research SHSDocumento30 páginasFinal Research SHSEuniceCareLanaja91% (76)

- Service: ManualDocumento155 páginasService: Manualdennischauvin3973Ainda não há avaliações

- Samsung Ue32-37-40-46d55xxr d57xxrs Ue40d5500 Chassis U66a Ue32-37-40-46d50xxpw U57a Ue19-22-27d40xxnw U57bDocumento218 páginasSamsung Ue32-37-40-46d55xxr d57xxrs Ue40d5500 Chassis U66a Ue32-37-40-46d50xxpw U57a Ue19-22-27d40xxnw U57bZoran Prokic100% (3)

- Iphone5 PCB Layout Vietmobile - VNDocumento1 páginaIphone5 PCB Layout Vietmobile - VNtyros567% (3)

- 1998 Motorola TVS Zener Device DataDocumento409 páginas1998 Motorola TVS Zener Device DataPelotaDeTrapoAinda não há avaliações

- Capacitor ESR MeterDocumento7 páginasCapacitor ESR MeterrubemllAinda não há avaliações

- Samsung UN50EH5000FXZA Fast Track Troubleshooting ManualDocumento7 páginasSamsung UN50EH5000FXZA Fast Track Troubleshooting ManualMarcosRomanoAinda não há avaliações

- Mosfet PDFDocumento13 páginasMosfet PDFTad-electronics TadelectronicsAinda não há avaliações

- Iphone 5SE Schematic PDFDocumento61 páginasIphone 5SE Schematic PDFPentti Hevosaho43% (7)

- Introduction To Capacitors Inductors andDocumento68 páginasIntroduction To Capacitors Inductors andIlavarasan Tamizh100% (1)

- Codes SMD Rs PDFDocumento2 páginasCodes SMD Rs PDFsiile100% (1)

- 100w FM AmplifierDocumento4 páginas100w FM AmplifierAntonio José Montaña Pérez de CristoAinda não há avaliações

- Assembly, Use & Troubleshooting Manual: ESR Meter KitDocumento12 páginasAssembly, Use & Troubleshooting Manual: ESR Meter KitUfuk AkgülAinda não há avaliações

- Workshop EquipmentDocumento14 páginasWorkshop EquipmentFenny Fitrianti BudiAinda não há avaliações

- ESR Capacitor Meter ProjectDocumento22 páginasESR Capacitor Meter ProjectTonyandAnthony100% (1)

- Electronic Load PDFDocumento73 páginasElectronic Load PDFserviciobsasAinda não há avaliações

- 12V 4A Solar ChargerDocumento2 páginas12V 4A Solar Chargerdoraemon007Ainda não há avaliações

- Linear Power Supply Design:: T1 J1 F1 D1Documento5 páginasLinear Power Supply Design:: T1 J1 F1 D1VromAinda não há avaliações

- 0-30 V DC Stabilized Power Supply With Current Control 0.002-3 ADocumento8 páginas0-30 V DC Stabilized Power Supply With Current Control 0.002-3 AWaseem AhmadAinda não há avaliações

- Kit 60. 3 Pin Regulated Power Supply: ComponentsDocumento1 páginaKit 60. 3 Pin Regulated Power Supply: ComponentsHenry SaputraAinda não há avaliações

- Tube Grid Dip MeterDocumento4 páginasTube Grid Dip MeterDiego García Medina100% (1)

- Sanyo Integrated Circuits For TV-VCR UseDocumento34 páginasSanyo Integrated Circuits For TV-VCR UseИгорь КремковAinda não há avaliações

- HDMI Industrial CameraDocumento17 páginasHDMI Industrial CameraIvan CvasniucAinda não há avaliações

- A Simple Regen Radio For Beginner NotesDocumento3 páginasA Simple Regen Radio For Beginner NotesMR X100% (1)

- Power Supply Unit (PSU) : Oakley Sound SystemsDocumento15 páginasPower Supply Unit (PSU) : Oakley Sound Systemskarimi-15100% (1)

- Idoc - Pub - LCD Monitor Repair PDFDocumento26 páginasIdoc - Pub - LCD Monitor Repair PDFElektroNiAinda não há avaliações

- Triacs and DiacsDocumento4 páginasTriacs and Diacsssami670Ainda não há avaliações

- Turn Your Mic Jack Into A Headphone JackDocumento25 páginasTurn Your Mic Jack Into A Headphone JackIndianOcean77Ainda não há avaliações

- 12 Volt Smps Circuit DiagramDocumento7 páginas12 Volt Smps Circuit DiagramAnura MaddumageAinda não há avaliações

- 023 Tubes and Sockets PDFDocumento14 páginas023 Tubes and Sockets PDFJozo Ćurčić100% (1)

- AC Current Monitor by LM358Documento14 páginasAC Current Monitor by LM358wlen2012Ainda não há avaliações

- Iphone Charger Schematic PDFDocumento13 páginasIphone Charger Schematic PDFilliliAinda não há avaliações

- Scintillation Counter PDFDocumento11 páginasScintillation Counter PDFAndrew GatesAinda não há avaliações

- Thanks Sir YouDocumento40 páginasThanks Sir YouHamza Abbasi AbbasiAinda não há avaliações

- Philips 40pfl3505df7 Chassis Pl10 5Documento87 páginasPhilips 40pfl3505df7 Chassis Pl10 5latino52Ainda não há avaliações

- Service Manual: KLV-26L500A KLV-26L500A KLV-32L500A KLV-32L500A KLV-37L500A KLV-37L500ADocumento87 páginasService Manual: KLV-26L500A KLV-26L500A KLV-32L500A KLV-32L500A KLV-37L500A KLV-37L500Apaelocom855050% (2)

- LG W4320S Service ManualDocumento24 páginasLG W4320S Service ManualeleandrorobertoAinda não há avaliações

- Wire Size and Length DeterminationDocumento11 páginasWire Size and Length Determinationxeron7126Ainda não há avaliações

- TransistorsDocumento3 páginasTransistorsSohaib AhmedAinda não há avaliações

- VK3QM Reflex Regen EA88Documento8 páginasVK3QM Reflex Regen EA88max_orwellAinda não há avaliações

- Samsung UN32D4000ND UN32D4010ND Chasis U59A PDFDocumento26 páginasSamsung UN32D4000ND UN32D4010ND Chasis U59A PDFczarbrrj0% (1)

- BK-Precision Dynascan 470 CRT Tester Rejuvenator 1986 SMDocumento23 páginasBK-Precision Dynascan 470 CRT Tester Rejuvenator 1986 SMMariela ContrerasAinda não há avaliações

- Troubleshooting Linear Power Supply Was Quite EasyDocumento2 páginasTroubleshooting Linear Power Supply Was Quite EasyNAYEEMAinda não há avaliações

- DatasheetDocumento1 páginaDatasheetjakob278313Ainda não há avaliações

- LD 7537 - Controlador PWMDocumento16 páginasLD 7537 - Controlador PWMTiago LeonhardtAinda não há avaliações

- Discrete and Integrated Electronics Volume Two Analysis and Design For Engineers and Engineering Technologists. 2 (2020)Documento495 páginasDiscrete and Integrated Electronics Volume Two Analysis and Design For Engineers and Engineering Technologists. 2 (2020)Charlie DiazAinda não há avaliações

- Troubleshooting and Repairing LCD TvsDocumento100 páginasTroubleshooting and Repairing LCD TvsMohamed HadjiAinda não há avaliações

- Lab 1 Power SupplyDocumento7 páginasLab 1 Power SupplyKatherine YenAinda não há avaliações

- Automatic 12V Lead Acid Battery ChargerDocumento10 páginasAutomatic 12V Lead Acid Battery ChargerRajib ChatterjeeAinda não há avaliações

- Microwave Oven E BookDocumento23 páginasMicrowave Oven E BookgkavosAinda não há avaliações

- Slim TV Service Manual - Sy33 ChassisDocumento45 páginasSlim TV Service Manual - Sy33 ChassisUmar MajeedAinda não há avaliações

- Three Phase Ac Winding CalculationDocumento1 páginaThree Phase Ac Winding CalculationNARENDRA BABU RAinda não há avaliações

- Talking Electronics Led TorchDocumento27 páginasTalking Electronics Led TorchKalFowleAinda não há avaliações

- TV Haier 32 Led LE32F2220a PDFDocumento54 páginasTV Haier 32 Led LE32F2220a PDFJuan Jose100% (1)

- Practical ElectronicsDocumento107 páginasPractical ElectronicsSaeed Ali Shahani100% (2)

- SM-G570M: Samsung Confidential Samsung ConfidentialDocumento9 páginasSM-G570M: Samsung Confidential Samsung Confidentialvinh tuanAinda não há avaliações

- LG 60LB5800 ZM 60LB580V ZM LD46B.Documento85 páginasLG 60LB5800 ZM 60LB580V ZM LD46B.Cristea Gabriel100% (1)

- The Electrolytic Cap ESR Problem, and This MeterDocumento5 páginasThe Electrolytic Cap ESR Problem, and This Meterrichardp3Ainda não há avaliações

- Your Test Bench: Build An ESR Meter ForDocumento6 páginasYour Test Bench: Build An ESR Meter ForRafael SuarezAinda não há avaliações

- K 7214Documento14 páginasK 7214Kevin BenjaminAinda não há avaliações

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaNo EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaAinda não há avaliações

- Vinafix - VN - Quanta I5 U81Documento37 páginasVinafix - VN - Quanta I5 U81psapwellAinda não há avaliações

- Samsung R60 PDFDocumento48 páginasSamsung R60 PDFBojfiński StafańskiAinda não há avaliações

- Ipad3 DiagramDocumento48 páginasIpad3 Diagrampsapwell100% (1)

- Compal La-6901p r2.0 SchematicsDocumento62 páginasCompal La-6901p r2.0 SchematicspsapwellAinda não há avaliações

- 32LC2DU ServiceDocumento40 páginas32LC2DU ServiceborlasAinda não há avaliações

- Pioneer - Avic n1 - Avic x1r crt3423Documento312 páginasPioneer - Avic n1 - Avic x1r crt3423psapwell100% (1)

- Avr265 Om enDocumento62 páginasAvr265 Om enpsapwellAinda não há avaliações

- Smps - TFT - Eer35 - Res TR810: 17PW26 REV:02Documento1 páginaSmps - TFT - Eer35 - Res TR810: 17PW26 REV:02frankie35Ainda não há avaliações

- Samsung BN44 - 00134ADocumento3 páginasSamsung BN44 - 00134APablo Acapulco GuerreroAinda não há avaliações

- Panasonic TX-26led8f Fs TX-26lxd8 CH Glp23Documento60 páginasPanasonic TX-26led8f Fs TX-26lxd8 CH Glp23psapwellAinda não há avaliações

- 17mb35 Hotelmode SpecificationDocumento8 páginas17mb35 Hotelmode SpecificationpsapwellAinda não há avaliações

- 17mb35 Service ManualDocumento91 páginas17mb35 Service ManualpsapwellAinda não há avaliações

- 17MB29Documento11 páginas17MB29psapwellAinda não há avaliações

- 17mb35 Hotelmode SpecificationDocumento8 páginas17mb35 Hotelmode SpecificationpsapwellAinda não há avaliações

- 17MB25Documento11 páginas17MB25tavitaraAinda não há avaliações

- 17mb35 Service ManualDocumento91 páginas17mb35 Service ManualpsapwellAinda não há avaliações

- Samsung BN44 - 00134ADocumento3 páginasSamsung BN44 - 00134APablo Acapulco GuerreroAinda não há avaliações

- Wind Turbine Modelling Approaches For Dynamic Power System SimulationsDocumento7 páginasWind Turbine Modelling Approaches For Dynamic Power System SimulationsYounes AdnaniAinda não há avaliações

- Ac DistributionDocumento19 páginasAc Distributionsrinimeha@gmail.comAinda não há avaliações

- Cross Polarization Interference Cancellation (XPIC)Documento18 páginasCross Polarization Interference Cancellation (XPIC)David Chandy PesantezAinda não há avaliações

- LENOVO ThinkCentre M70a and M90a AiO - Hardware Maintenance Manual (M70a - M90a - HMM - En)Documento144 páginasLENOVO ThinkCentre M70a and M90a AiO - Hardware Maintenance Manual (M70a - M90a - HMM - En)JohnnyAinda não há avaliações

- Manual Técnico ACE6000Documento95 páginasManual Técnico ACE6000AlexandreRodrigues50% (2)

- RFQ - TransformersDocumento6 páginasRFQ - Transformersasim469Ainda não há avaliações

- Price List 2014Documento18 páginasPrice List 2014João Carlos OliveiraAinda não há avaliações

- E7 2users Manual CDocumento291 páginasE7 2users Manual CAleksandar StankovićAinda não há avaliações

- A Guide To IR - PIR Sensor Set-Up and Testing (2009)Documento10 páginasA Guide To IR - PIR Sensor Set-Up and Testing (2009)FarhanaAinda não há avaliações

- Rane Fpm44 Mixer ManualDocumento4 páginasRane Fpm44 Mixer ManualtubegeekAinda não há avaliações

- Ba 14741Documento5 páginasBa 14741Nicck GarcíaAinda não há avaliações

- Buy Clamp Meter Online - GeM PDFDocumento7 páginasBuy Clamp Meter Online - GeM PDFsunilkumarmeenaAinda não há avaliações

- Investigatory Project On LDRDocumento17 páginasInvestigatory Project On LDRAnima ThakurAinda não há avaliações

- Sulfation Pulse Treatment SurpriseDocumento67 páginasSulfation Pulse Treatment SurpriseLeonel RodriguezAinda não há avaliações

- Ra 930ax TMDocumento8 páginasRa 930ax TMAuconly LinAinda não há avaliações

- 1TTS900001M0203 ABB MNS - Service Manual ENDocumento64 páginas1TTS900001M0203 ABB MNS - Service Manual ENCalum MartinAinda não há avaliações

- Encoder TbifDocumento1 páginaEncoder TbifHanns JorgAinda não há avaliações

- Motor Bus Transfer Considerations and MethodsDocumento10 páginasMotor Bus Transfer Considerations and MethodsmoisesramosAinda não há avaliações

- Ree 4 Speed ControlDocumento2 páginasRee 4 Speed ControlJurisĶigursAinda não há avaliações

- Controlling Speed of DC Motor Using 555 Timer!: Elp ProjectDocumento13 páginasControlling Speed of DC Motor Using 555 Timer!: Elp ProjectAntriksh SaranAinda não há avaliações

- Manual CarretillaDocumento158 páginasManual Carretillaroboperrin89% (9)

- Mechatronics Model Exam - 2Documento1 páginaMechatronics Model Exam - 2Kaleab AndualemAinda não há avaliações

- Beol - CL 636 (2) (10759)Documento37 páginasBeol - CL 636 (2) (10759)shubhamAinda não há avaliações

- Bds en 50122 2 2010Documento29 páginasBds en 50122 2 2010Ginanjar Kurnia Haadi100% (1)

- Transformers NotesDocumento5 páginasTransformers NotessauravAinda não há avaliações

- The Best Electronics and Marine Electrics TroubleshootingDocumento136 páginasThe Best Electronics and Marine Electrics Troubleshootingtesfaye alebachewAinda não há avaliações

- Sun Tracking Solar Panel Project Using MicrocontrollerDocumento5 páginasSun Tracking Solar Panel Project Using MicrocontrollerVeeraPavanVasireddiAinda não há avaliações

- EDMS 08-201-1 Dry TRANSFORMERS 22-0.4 KVDocumento22 páginasEDMS 08-201-1 Dry TRANSFORMERS 22-0.4 KVAmr El-ghannamAinda não há avaliações

- Siemens Micromaster Vector Manual PDFDocumento79 páginasSiemens Micromaster Vector Manual PDFCarlosAinda não há avaliações