Escolar Documentos

Profissional Documentos

Cultura Documentos

4140

Enviado por

Cristopher CastroDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

4140

Enviado por

Cristopher CastroDireitos autorais:

Formatos disponíveis

Alloy Steel/319

4140, 4140H

Chemical Composition. 4140. AISI and UNS: 0.38 to 0.43 C, 0.75

to 1.00 Mn, 0.035 P max, 0.040 S max, 0.15 to 0.30 Si, 0.80 to 1.10 Cr, 0.15

to 0.25 Mo. 4140H. AISI and UNS: 0.37 to 0.44 C, 0.65 to 1.10 Mn, 0.035

P max, 0.040 S max, 0.15 to 0.30 si, 0.75 to 1.20 Cr, 0.15 to 0.25 Mo

Similar Steels (U.S. and/or Foreign). 4140. UNSG41400;AMS

6381,6382,6390,6395; ASTM A322, A331, A505, A519, A547, A646;

MIL SPEC MIL-S-16974; SAE J404, J412, 1770; (Ger.) DIN 1.7225; (Fr.)

AFNOR 40 CD 4, 42 CD 4; (ltal.) UNI 40 CrMo 4, G 40 CrMo 4, 38 CrMo

4 KB; (Jap.) rrs SCM 4 H, SCM 4; (Swed.) SS14 2244; (UK) B.S. 708 A

42,708 M 40, 709 M 40. 4140H. UNS H41400; ASTM A304; SAE J407;

(Ger.) DIN 1.7225; (Fr.) AFNOR40 CD 4, 42 CD 4; (ltal.) UN! G 40 CrMo

4,40 CrMo 4, 38 CrMo 4 KB; (Jap.) 1IS SCM 4 H, SCM 4; (Swed.) SS14

2244; (UK) B.S. 708 A42, 708 M 40,709 M 40

Characteristics. Among the most widely used medium-carbon alloy

steels. Relatively inexpensive considering the relatively high hardenability

4140H offers. Fully hardened 4140H ranges from about 54 to 59 HRC,

depending upon the exact carbon content. Forgeability is very good, but

machinability is only fair and weldability is poor, because of susceptibility

to weld cracking

Forging. Heat to 1230 C (2250 OF). Do not forge after temperature of

forging stock below approximately 870C (1600 oF)

Recommended Heat Treating Practice

Normalizing. Heat to 870 C (1600 oF). Cool in air

Annealing. For a predominately pearlitic structure, heat to 845C (1555

"F), cool fairly rapidly to 755 C (1390 OF), then cool from 755C (1390

"F) to 665 C (1230 "F), at a rate not to exceed 14C (25 "F) per h; or heat

to 845C (1555 "F), cool rapidly to 675C (1245 OF), and hold for 5 h. For

a predominately spheroidized structure, heat to 750C (1380 OF), cool to

665 C (1230 "F) at a rate not to exceed 6 C (10 OF) per h; or heat to 750

C (1380 OF), cool fairly rapidly to 675C (1245 "F), and hold for 9 h

Hardening. Austenitize at 855C (1570 OF), and quench in oil

Tempering. Reheat after quenching to obtain the required hardness

Nitriding. 4140H responds to the ammonia gas nitriding process, result-

ing in a thin, file hard case, the outer portion of which is composed of

epsilon nitride. This constituent not only provides an abrasion-resistant

surface, but also increases fatigue strength of components such as shafts by

as much as 30%. However, if nitriding is considered, the steel must be

pretreated (hardened and tempered), and nitriding must be done on fmished

parts because any fmishing operation will remove the most useful portion

of the case. A typical processing cycle that includes nitriding is:

Rough machine

Austenitize at 845C (1555 OF)

Oil quench

Temper at 620 C (1150 OF)

Finish machine

Nitride at 525C (975 OF) for 24 h, using an ammonia dissociation of

30%; or nitride at 525C (975 OF) for 5 h with an ammonia dissociation

of25%, then at 565C (1050 "F) for 20 h with an ammonia dissociation

of75 to 80%

Certain proprietary salt bath nitridingprocesses are also applicable for surface

hardening of 4140H

Recommended Processing Sequence

Forge

Normalize

Anneal

Rough machine

Austenitize

Quench

Temper

Finish machine

Nitride (optional)

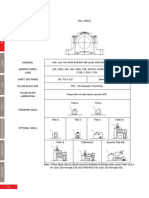

4140: Isothermal Transformation Diagram. Composition: 0.37 C, 0.77 Mn, 0.98 Cr, 0.21 Mo. Austenitized at 845C (1555 OF) Grain size:

7to 8

29

29

29

20

61

44

37

10

S 102 2 S 103 2

Time, sec

10

LtenL

-

-

A"

=

--

- As - - -

V

V

I--'/ r;...

-

/ I

V

!

(

r.....

'-

I"- ...... I'---r-.

I

Austenite

+ ferrite

....... r-

.........

-

V Austenite +ferrite + I'-....

- -A

1.0-

carbide

V

(,/

I- .-

V Ferrite +carbide

-

-

\ /

1

60%\ (

-

_.

--f-

1-- M

s-

___L

-- -

\:

.- -

I--t-- M

so

,

I--I-- MgO

"

E1000

8-

E

t!

800

1200

600

400

10-

1

u.

o

1400

1600

Previous Page

LIVE GRAPH

Click here to view

320 I Heat Treater's Guide

4140H: End-Quench Hardenability

Distance from Distance from

10

quenched Hardness, quenched Hardness,

surface HRC surface HRC

%6 in. mm max min %6 in. mm max min 60

---

o

r---

1 1.58 60 53 13 20.54 55 38

a:

r---

I

--

I--- 2 3.16 60 53 14 22.12 54 37

50

........

3 4.74 60 52 15 23.70 54 36

c:

<,

--

r---

4 6.32 59 51 16 25.28 53 35

<,

r-- I

5 7.90 59 51 18 28.44 52 34

6 9.48 58 50 20 31.60 51 33

40

'-- 7 11.06 58 48 22 34.76 49 33

--

8 12.64 57 47 24 37.92 48 32

9 14.22 57 44 26 41.08 47 32

30

8 12 16 20 24 28 32

0 4

10 15.80 56 42 28 44.24 46 31

Distance from quenched surface, 1/16 in.

u 17.38 56 40 30 47.40 45 31

12 18.96 55 39 32 50.56 44 30

4140: Cooling Transformation Diagram. Composition: 0.44 C, 1.04 Mn, 0.29 Si, 1.13 Cr, 0.15 Mo. Austenitized at 845C (1555 OF). Grain

size: 9. Ac

a

, 795C (1460 OF); AC

ll

750C (1380 OF). A: austenite, F: ferrite, P: pearlite, B: bainite, M: martensite. Source: Bethlehem Steel

1600,------.-------,------,---.--------,,------.-----,-------,-----,

300

200

600

LL. 1000

!? 0

,;

i

Z

:J

"

0. 0.

E

I-

800

200L-__--L -':-__-----' -7- 100

2

10

Cooling time, sec

LIVE GRAPH

Click here to view

LIVE GRAPH

Click here to view

Alloy Steel I 321

4140: Effect of Microstructure on Tool Life

Feed was 0.010 in./rev (0.25 mm/rev) for all specimens; depth of cut was 0.100 in. (2.5 mm).

Microstructure constituent, %

Tempered Cutting speed

Steel condition Hardness, HB Pearlite Ferrite martensite ft/min mmls

Normalized 192 90 10 300 1520

Annealed 180 65 35 360 1830

Quenched. tempered 300 100 300 1520

4140: Hardness vs Tempering Temperature. Normalized at 870

C (1600 OF). Quenched from 845C (1555 OF) in oil and tem-

pered in 56C (100 OF) intervals in 13.716 mm (0.540 in.) rounds.

Tested in 12.827 mm (0.505 in.) rounds. Source: Republic Steel

1200

600

1000

500 400

Tempering temperature, c

Tempering temperature, OF

600 800

300

I I I I

-.

0

'"

0

1\

'\

-.

0 20

400

500

30

600

'" J:

40

<:

J:

4140: Effect of Mass. Composition: 0.38 to 0.43 C, 0.75 to 1.00

Mn, 0.040 P max, 0.040 S max, 0.20 to 0.35 Si, 0.80 to 1.10 Cr.

0.15 to 0.25 Mo. Approximate critical points: Ac

l

, 730C (1350 OF);

Ac

a

, 805C (1480 OF); Ar

a

745C (1370 OF); Ar

l

, 680C (1255 OF).

Recommended thermal treatment: forge at 1205 C (2200 OF)

maximum. anneal at 815 to 870C (1500 to 1600 OF) for a maxi-

mum hardness of 197 HB, normalize at 845 to 900C (1555 to

1650 OF) for an approximate hardness of 311 HB; quench from

830 to 855C (1525 to 1570 OF) in oil. Test specimens were nor-

malized at 870 C (1600 OF) in over-sized rounds, quenched from

845C (1555 OF) in oil in sizes shown, tempered at 540 C (1000

OF), tested on 12.827 mm (0.505 in.) rounds. Tests from 38.1 mm

(1.5 in.) diam bars and over are taken at half radius position.

Source: Republic Steel

Size round Hardness, HRC

in. mm Surface %radius Center

1;2 13 57 56 55

1 25 55 55 50

2 51 49 43 38

4 102 36 34.5 34

Source: Bethlehem Steel

4140: As-Quenched Hardness

Specimens quenched in oil

[T-

i--;

I I I

---

'-

30

'" 300

J:

i3 280

s:

260

J:

Diameter, mm

60 90 120 150

240

1 4

Diameter, in.

4140: Gas Nitriding. Oil quenched from 845C (1555 OF), tem-

pered at 595 C (1105 OF), and nitrided at 550C (1020 OF)

0.10 ,------.------.-----,--_______,,, 2.5

0.081-----t----t-----r--------=t 2.0

80 20 40

Duration of nitriding, hr

0.02 1--r-"7''''-i----;-------r-------=t 0.5

E

E

O.061-------t-----""do-=----r-------=-i 1 5 oi

D .

o 0

E. 0.04 1.0 E-

o 0

.s

0

00

<Dei

4140: Depth of Hardness. 31.75 mm (1.25 ln.) diam bars,

through hardened by induction

0

6

a:

J: 58

Ii

1! 56

"E

54

o 3 4 6 7 9 10

Distance below surface, 1116 in.

LIVE GRAPH

Click here to view

LIVE GRAPH

Click here to view

LIVE GRAPH

Click here to view

LIVE GRAPH

Click here to view

322/ Heat Treater's Guide

I I I

I

t.....

--

t--

-

4140: Effect of Mass. Composition: 0.38 to 0.43 C, 0.75 to 1.00

Mn, 0.040 P max, 0.040 S max, 0.20 to 0.35 Si, 0.80 to 1.10 Cr,

0.15 to 0.25 Mo. Approximate critical points: Ac

1

, 730C (1350 OF);

Ac

3

, 805C (1480 OF); Ar

3

, 745C(1370 OF); Ar

ll

680 DC (1255 OF).

Recommended thermal treatment: forge at 1205 DC (2200 OF)

maximum, anneal at 815 to 870 DC (1500 to 1600 OF) for a maxi-

mum hardness of 197 HB, normalize at 845 to 900 DC (1555 to

1650 OF) for an approximate hardness of 311 HB; quench from

830 to 855 DC (1525 to 1570 OF) in oil. Test specimens were nor-

malized at 870 DC (1600 OF) in over-sized rounds, quenched from

845 DC (1555 OF) in sizes shown, tempered at 650 DC (1200 OF),

tested on 12.827 mm (0.505 in.) rounds. Tests from 38.1 mm (1.5

in.) diam bars and over are taken at half radius position. Source:

Republic Steel

4140: Variations in Hardness after Production Tempering. (a)

76.2 mm (3 in.) diam valve bonnets. Steel from one mill heat. Parts

heated at 870 DC (1600 OF), oil quenched, and tempered at 605 DC

(1125 OF) to a hardness of 255 to 302 HB. (b) Valve segments,

12.7t025.4 mm (0.5to 1 in.) section thickness. Steel from one mill

heat. Parts heated at 870 DC (1600 OF), oil quenched, and tem-

pered at 580C (1075 OF) to a hardness of 321 to 363 HB

10 5

Batchnumber

I

""'specification range

I I

260

240

o 1

Cal

320

300

eo

I

i 280

c

I

150 120 90

Diameter, in.

Diameter, mm

60 30

co 280

I

.; 260

c 240

I 220

200

1

10

Batch number

0

..

I

0

0

.1 I

............. Specification range I

..

380

32

o 1

34

Cb)

m 36

I

c

I

E

E

"

0.5 _

o

s:

o

o

80 20 40 60

Duration of nitriding, hr

4

20

V

2

o

o

0.0

'"

c

0.0

'0

-s

0

4140: Depth of Case vs Duration of Nitriding. Double stage ni-

trided at 525 DC (975 OF). Numbers indicate hours of nitriding at 15

to 25% dissociation. Remainder of cycle at 83 to 85% dissociation

1.0

Cutting speed Metal removed

between grinds

Steel

condition Itlmin mls in.

3

m

3

Normalized ...... 300 1.5 165 2.3 x 10-

3

Annealed ....... 360 1.8 190 3.1 x 10 3

Annealed ....... 300 1.5 260 4.3 x 10-

3

Quenched and .... 300 1.5 115 1.9 x 10-

3

tempered

4140: Effect of Microstructure on Tool Life

20 40 60 80

Tool life between grinds, min

LIVE GRAPH

Click here to view

LIVE GRAPH

Click here to view

Alloy Steel I 323

4140: Gas Nitriding. (a) 7 h, 2 suppliers, 20 to 30% dissociation; (b) 9 h, 2 heats, 25 to 30% dissociation; (c) 24 h, 2 suppliers, 20 to 30%

dissociation; (d) 40 h, 5 heats, 25 to 30% dissociation; (e) 90 h, 9 heats, 25 to 35% dissociation; (f) 25 h, 20 to 30% dissociation; (9) 35 h, 20

to 30% dissociation; (h) 50 h, 20 to 30% dissociation. For (f), (9), (h), 1: 21 to 23 HRC; 2: 26 to 28 HRC; 3: 33 to 35 HRC; 4: 36 to 37 HRC

core hardness

0.030 0.035

07

0.025 0.020 0.015

Distance below surface, mm

03 05

0.010 0.005

01

-

"'"

300

o

600

400

700

>l

J:

::i

1! 500

l'

..

J:

0.015 0.010 0.005

700,------..------rr-----,

600

Distance below surface, mm

0.125 0.250

(a) Distance below surface, in. (b) Distance belowsurface, in.

Distance below surface, mm

0.040

0.9

0.035 0.030

0.7

0.025

0.5

0.020 0.015

0.3

0.010 0.005

Distance belowsurface, in.

300'-----'----<------'------'----'-------'----'-------'

o

4001---1-----11-----1-----"1""""""'-

(dl

>l

J:

5001---+----P......

J:

0.020

Distance below surface, mm

0.1 0.3 0.5

>l

J:

c

l'

..

J:

Distance below surface, mm

o 0.5 1.0 1.5 2.0 2.5

-6 400

:-

J: 300

o 0.02 0.04 0.06 0.08 0.10

Dlstanea balowsurface, In.

0.020 0.016 0.010 0.006

Dlstance balowsurfaea, mm

0.1 0.2 0.3 0.4

70

0

L..__--'-__--'-__--'-__....J

z

a:

J:

D'

" l'

761---t-

Distance below surface, in.

Distance below surface, in.

(el

(e)

Distancebelowsurface, mm

0.1 0.2 0.3 0.4 0.5

z

a:

J:

80

" l'

751---+--- '---t-----==""i_;;;;;:;:=""i

Z

ltI

a:

J:

J:

761----t---+--+"""'o;;;::-i

0.020 0.015 0.010 0.005

70'--_--J'--_--J'--_----'__----'

o 0.015 0.020 0.010 0.005

70'::-0_---:-,':-,---:_--'-__--'--__....J

(g) Distancebelowsurface, in.

(h)

Distanea balowsurface, In.

LIVE GRAPH

Click here to view

LIVE GRAPH

Click here to view

LIVE GRAPH

Click here to view

LIVE GRAPH

Click here to view

LIVE GRAPH

Click here to view

LIVE GRAPH

Click here to view

LIVE GRAPH

Click here to view LIVE GRAPH

Click here to view

324/ Heat Treater's Guide

4140: Microstructures. (a) 2% nital, 825x. Resulfurized forging normalized by austenitizing at 900C (1650 OF) %h, air cooling; annealed

by heating at 815C (1500 OF) 1 h, furnace cooling to 540C (1000 OF), air cooling. Blocky ferrite and fine-to-coarse lamellar pearlite. Black

dots are sulfide. (b) Nital, 500x. 25.4 mm (1 in.) diam, austenitized at 845C (1555 OF) 1 h, cooled to 650C (1200 OF), and held 1 h for iso-

thermal transformation, then air cooled to room temperature. White areas, ferrite; gray and black areas, pearlite with fine and coarse lamellar

spacing. (c) 2% nital, 500x. Hot rolled steel round bar. 25.4 mm (1 in.) diam, austenitized at 845C (1555 OF) for 1 h and water quenched.

Fine, homogeneous, untempered martensite. Tempering at 150C (300 OF) would result in a darker etching structure. (d) 2% nital, 500x.

Same as (c), except the steel was quenched in oil rather than water, resulting in the presence of bainite (black constituent) along with the

martensite (light). (e) 2% nital, 750x. Steel bar austenitized at 845C (1555 OF), oil quenched to 66C (150 OF), and tempered 2 h at 620C

(1150 OF). Martensite-ferrite-carbide aggregate. (f) As polished (not etched), 200x. Oxide inclusions (stringers) in a steel bar, 25.4 mm (1 in.)

diam. Stringers parallel to the direction of rolling on the as-polished surface of the bar. (g) Not polished, not etched, 8600x. Replica electron

fractograph showing the dimpled structure typical of the overstress mode of failure. (h) 2% nital, 400x. Oil quenched from 845C (1555 OF),

tempered for 2 h at 620C (1150 OF), surface activated in manganese phosphate, gas nitrided for 24 h at 525C (975 OF), 20 to 30% disso-

ciation. 0.0050 to 0.0076 mm (0.0002 to 0.0003 in.) white surface layer Fe

2N,

iron nitride, and tempered martensite. (j) 2% nital, 400x. Same

steel and prenitriding conditions as (h), except double stage gas nitrided: 5 h at 525C (975 OF), 20 to 30% dissociation; 20 h at 565C (1050

OF), 75 to 80% dissociation. High second-stage dissociation caused absence of white layer. Diffused nitride layer and a matrix of tempered

martensite

Alloy Steel/325

4140H: HardenabilityCurves. Heat-treating temperatures recommended by SAE. Normalize (for forged or rolled specimens only): 870C

(1600 OF). Austenitize: 845C (1555 OF)

Hardness limits for specification

Approximate diameters of rounds with

purposes

same as-quenched hardness (HRC), mm

Location in round Quench

J distance, Hardness, HRC 5075 Surface

Mild

mm Maximum Minimum 2030 60 90 3/4 radius from center water

20 30 40 50 60 80 100 Center

quench

1.5 60 53

3 60 52

20 40 60 80 100 Surface

Mild

5 60 52 15 30 45 60 75 90 3/4 radius from center oil

7 59 51 10 20 30 40 50 60 75 Center

quench

9 59 50

65

11 58 48

13 57 46

15 57 43

60

t-

I--

20 55 38

t--

I--

r--

25 53 35

55

------

30 51 33

r-

r-

-......

----

35 49 32 50

I'...

-

--

40 48 32

0

r-,

--

a:

-

45 46 31

I

45

<,

50 45 30

u>

en

<,

Q)

c;

"E 40

<,

'"

I

-------

35

--

I-

30

25

20

0 3 5 7 9 11 13 15 20 25 30 35 40 45 50

Distance from quenched end, mm

Hardness limits for specification

Diameters of rounds with

Location in round Quench

purposes same as-quenched hardness (HRC), in.

2 4 Surface

Mild

J distance, Hardness, HRC

1 2 3 4 3/4 radius from center water

11t6in. Maximum Minimum

0.5 1 1.5 2 2.5 3 3.5 4 Center

quench

1 60 53

1 2 3 4 Surface

Mild

2 60 53

0.5 1 1.5 2 2.5 3 3.5 4 3/4 radius from center oil

3 60 52

0.5 1 1.5 2 2.5 3 3.5 Center

quench

4 59 51

5 59 51 65

6 58 50

7 58 48 60

-

8 57 47 r--

r---

9 57 44

r--..

55

-

10 56 42 l-

I--

I--

r--

11 56 40

50

r-----.-.. ;---

12 55 39

r-.

I-- 0

I--

r-- 13 55 38

a:

:-- I

14 54 37 u>

45

<, en

15 54 36

Q)

r-,

c;

16 53 35

"E 40

r-.

'" 18 52 34

I

r----

20 51 33 35

-

22 49 33

r--t---

24 48 32

30

26 47 32

28 46 31

25

30 45 31

32 44 30

20

20 22 24 26 28 30 32 0 2 4 6 8 10 12 14 16 18

Distance from quenched end, 1/16 in.

Next Page

LIVE GRAPH

Click here to view

Você também pode gostar

- Fatigue Design Procedures: Proceedings of the 4th Symposium of the International Committee on Aeronautical Fatigue held in Munich, 16–18 June 1965No EverandFatigue Design Procedures: Proceedings of the 4th Symposium of the International Committee on Aeronautical Fatigue held in Munich, 16–18 June 1965E. GassnerAinda não há avaliações

- A1018 Hslas GR 50Documento1 páginaA1018 Hslas GR 50Claudio SampaioAinda não há avaliações

- Steel Bars, Carbon, Hot-Wrought, Special Quality: Standard Specification ForDocumento6 páginasSteel Bars, Carbon, Hot-Wrought, Special Quality: Standard Specification ForIngrid Tatiana RojasAinda não há avaliações

- Weldlok 43 Data SheetDocumento2 páginasWeldlok 43 Data Sheetjhon jairo arangoAinda não há avaliações

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNo EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceAinda não há avaliações

- En 353Documento93 páginasEn 353kumarsathish2009Ainda não há avaliações

- AISI 4130 Alloy Steel (UNS G41300) 1Documento4 páginasAISI 4130 Alloy Steel (UNS G41300) 1shubham soni100% (1)

- Winches and Reels Tension in Line and Pressure On The Drum and Flanges PDFDocumento18 páginasWinches and Reels Tension in Line and Pressure On The Drum and Flanges PDFjosebernal_mzaAinda não há avaliações

- SKF Pillow Block HousingsDocumento64 páginasSKF Pillow Block HousingsJulio Deyvis Ayala Gutierrez100% (1)

- High Tensile Steel 4140Documento2 páginasHigh Tensile Steel 4140Lazzarus Az GunawanAinda não há avaliações

- Oring Sizes BS1806 PDFDocumento6 páginasOring Sizes BS1806 PDFSivaAinda não há avaliações

- DSI Underground Systems Mechanical Rock Bolts Extension Bolts Stelpipe Bolts US 01Documento16 páginasDSI Underground Systems Mechanical Rock Bolts Extension Bolts Stelpipe Bolts US 01Tato Del AguilaAinda não há avaliações

- Fatigue Analysis Problem Solution: Basquin's LawDocumento13 páginasFatigue Analysis Problem Solution: Basquin's LawAnonymous pmPNWGpAinda não há avaliações

- Modelling of Frictional Joints in Dynamically LoadDocumento26 páginasModelling of Frictional Joints in Dynamically LoadAaron GalvezAinda não há avaliações

- Astm 666Documento7 páginasAstm 666JOSEPH REFUERZOAinda não há avaliações

- En 13445 Parte 4Documento8 páginasEn 13445 Parte 4rovergammaAinda não há avaliações

- Fracture Mechanics: Theory and ApplicationsDocumento137 páginasFracture Mechanics: Theory and ApplicationsSunilkumar ReddyAinda não há avaliações

- Tools Threading MachineDocumento20 páginasTools Threading MachinedayglisAinda não há avaliações

- GBT 17107Documento23 páginasGBT 17107Luis100% (1)

- 8510 1181TeflonBack UpRings PDFDocumento23 páginas8510 1181TeflonBack UpRings PDFAmir Hooshang Ghadymi MahaniAinda não há avaliações

- Socket Head Cap Screws Alloy SteelDocumento5 páginasSocket Head Cap Screws Alloy SteelChris MedeirosAinda não há avaliações

- Worm and Worm Wheel NomenclatureDocumento1 páginaWorm and Worm Wheel NomenclaturemuhdqasimAinda não há avaliações

- Alloy Structure Steel ComparisionDocumento3 páginasAlloy Structure Steel ComparisionNenad TabandzelicAinda não há avaliações

- Specialty Materials Hastelloy C-276 ALLOY: Certified To Iso 9001Documento3 páginasSpecialty Materials Hastelloy C-276 ALLOY: Certified To Iso 9001Jarbas MoraesAinda não há avaliações

- Suhm Spring Works-Spring Materials Issue 9a en US v1Documento37 páginasSuhm Spring Works-Spring Materials Issue 9a en US v1DizzixxAinda não há avaliações

- Crankshaft: Page NoDocumento13 páginasCrankshaft: Page NoAmit GauravAinda não há avaliações

- En 10025 - 2004Documento11 páginasEn 10025 - 2004Abhishek GoelAinda não há avaliações

- Hi Force CatalogDocumento68 páginasHi Force CatalogmjscarAinda não há avaliações

- Ms 16142Documento2 páginasMs 16142Bryan MartinezAinda não há avaliações

- Stephens Adamson Hoods Tech - BulletinDocumento4 páginasStephens Adamson Hoods Tech - BulletinJC AlemanAinda não há avaliações

- Specification of Phosphor Bronze StripDocumento3 páginasSpecification of Phosphor Bronze Stripsaleemnel100% (1)

- Guidelinesfor Fabricating&Processing Plate SteelDocumento97 páginasGuidelinesfor Fabricating&Processing Plate SteelFIM SA100% (1)

- Vector International Techlok Data SheetDocumento11 páginasVector International Techlok Data SheetHarry NielsenAinda não há avaliações

- 1.4 - Precipitation HardeningSteelDocumento1 página1.4 - Precipitation HardeningSteelMuhammad Khizer KhanAinda não há avaliações

- Hot Working Guide: A Compendium of Processing MapsDocumento10 páginasHot Working Guide: A Compendium of Processing MapsAnket DeshmukhAinda não há avaliações

- Alodine 6105Documento3 páginasAlodine 6105Sivalingam GovindarajanAinda não há avaliações

- Atmospheric Corrosivity in New ZealandDocumento7 páginasAtmospheric Corrosivity in New ZealandjeccoAinda não há avaliações

- Steel Bars, Alloy, Standard GradesDocumento5 páginasSteel Bars, Alloy, Standard GradesSamuel PeterAinda não há avaliações

- B16.15 Fittings BMI CanadaDocumento9 páginasB16.15 Fittings BMI CanadaSagar KadamAinda não há avaliações

- Sae 6000 PsiDocumento41 páginasSae 6000 PsiEricAinda não há avaliações

- Grades of Steel ChartDocumento3 páginasGrades of Steel ChartKimAinda não há avaliações

- Desain Wave Spring WasherDocumento7 páginasDesain Wave Spring WasheragungAinda não há avaliações

- CFD Analysis of Pressure Variation Inside Iron Ore Slurry PipelinesDocumento41 páginasCFD Analysis of Pressure Variation Inside Iron Ore Slurry PipelinesIJRASETPublicationsAinda não há avaliações

- Structural Steel - S235, S275, S355 Chemical Composition, Mechanical Properties and Common ApplicationsDocumento14 páginasStructural Steel - S235, S275, S355 Chemical Composition, Mechanical Properties and Common Applicationsnaveenbaskaran1989Ainda não há avaliações

- IS 14962 Part 5.2001 PDFDocumento12 páginasIS 14962 Part 5.2001 PDFGurdeep SinghAinda não há avaliações

- Ufc 3 340 02Documento1.943 páginasUfc 3 340 02mirko huaranccaAinda não há avaliações

- TurnbucklesDocumento6 páginasTurnbucklesRonny Andalas100% (1)

- Vulcraft Steel DeckDocumento116 páginasVulcraft Steel DeckJeff GarnettAinda não há avaliações

- Ultra BoltsDocumento4 páginasUltra BoltsmirosekAinda não há avaliações

- Spiral Wound GasketsDocumento7 páginasSpiral Wound GasketsPrem NautiyalAinda não há avaliações

- Military Handbook: Materials and Processes For Corrosion Prevention and Control in Aerospace Weapons SystemsDocumento26 páginasMilitary Handbook: Materials and Processes For Corrosion Prevention and Control in Aerospace Weapons Systemsalang126100% (1)

- Chaplin 1995Documento13 páginasChaplin 1995Rodrigo Alejandro Flores ZuñigaAinda não há avaliações

- Fatigue Curve - S235JR ExperimantalDocumento9 páginasFatigue Curve - S235JR ExperimantalPrabath MadusankaAinda não há avaliações

- Scanned From A Xerox Multifunction Printer5Documento1 páginaScanned From A Xerox Multifunction Printer5Dennis RangwetsiAinda não há avaliações

- Maintenance and Inspection of BTH LiftersDocumento8 páginasMaintenance and Inspection of BTH Liftersrpatel12Ainda não há avaliações

- Aisi Type 403 (Chemical Composition)Documento7 páginasAisi Type 403 (Chemical Composition)MiguelPacheecoAgamezAinda não há avaliações

- 15-7 Mo Data BulletinDocumento16 páginas15-7 Mo Data BulletinmsdoharAinda não há avaliações

- 100Cr6 PropertiesDocumento1 página100Cr6 PropertiesRudrendu ShekharAinda não há avaliações

- 1.3343 HS6-5-2CDocumento3 páginas1.3343 HS6-5-2CmustafabodurAinda não há avaliações

- Specification: EN9 - 070M55: Hollowbar - Co.zaDocumento3 páginasSpecification: EN9 - 070M55: Hollowbar - Co.zaAnantha RamanAinda não há avaliações

- 1999 Xu and GoswamiDocumento13 páginas1999 Xu and Goswamilucena_thiagoAinda não há avaliações

- XSteam Excel v2.6Documento12 páginasXSteam Excel v2.6Jorge GuillermoAinda não há avaliações

- Machine Symbols & Surface FinishDocumento40 páginasMachine Symbols & Surface Finishadn1987100% (1)

- Phy-1 Mod 3 (Elasticity)Documento11 páginasPhy-1 Mod 3 (Elasticity)Ässæilèd BönhîAinda não há avaliações

- Assignment #2 2018Documento2 páginasAssignment #2 2018Rima ChinnasamyAinda não há avaliações

- LS DYNA Aerospace Working Group Modeling Guidelines Document Version 19 1 Dated June 28, 2019 PDFDocumento252 páginasLS DYNA Aerospace Working Group Modeling Guidelines Document Version 19 1 Dated June 28, 2019 PDFЮрий НовожиловAinda não há avaliações

- CE6501 Structural Analysis I Unit 2Documento12 páginasCE6501 Structural Analysis I Unit 2Sri DAinda não há avaliações

- Filament Winding of aramid/PA6 Commingled Yarns With in Situ ConsolidationDocumento18 páginasFilament Winding of aramid/PA6 Commingled Yarns With in Situ ConsolidationEduardo SantosAinda não há avaliações

- 3.0 Strength of MaterialsDocumento21 páginas3.0 Strength of Materialsronnie oraleAinda não há avaliações

- CREEP AND FATIGUE FAILURE ANALYSIS OF TURBINE BLADE REPORT-2 (Final)Documento28 páginasCREEP AND FATIGUE FAILURE ANALYSIS OF TURBINE BLADE REPORT-2 (Final)akshithaAinda não há avaliações

- Canal Trough DesignDocumento18 páginasCanal Trough DesignmukhleshAinda não há avaliações

- Journal Bearing Analysis PDFDocumento56 páginasJournal Bearing Analysis PDFVivek Singh100% (1)

- Lampiran Astm E10 BrinellDocumento3 páginasLampiran Astm E10 Brinellanaba jioAinda não há avaliações

- E8. Sbs Styrene-Butadiene Rubber and Crumb Rubber PDFDocumento15 páginasE8. Sbs Styrene-Butadiene Rubber and Crumb Rubber PDFMohammed QaderAinda não há avaliações

- Numerical Simulation of Sheet Stamping Process Using Flexible PunchDocumento13 páginasNumerical Simulation of Sheet Stamping Process Using Flexible PunchRui MatiasAinda não há avaliações

- Bolted Joint DesignDocumento5 páginasBolted Joint Designperdhana2000Ainda não há avaliações

- CS6306Documento9 páginasCS6306reddyprasadAinda não há avaliações

- Pressure Sensor COMSOLDocumento13 páginasPressure Sensor COMSOLRipan DeuriAinda não há avaliações

- PPE-STD-CAL-ME-006 Rectangular Tank Thickness CalculationDocumento4 páginasPPE-STD-CAL-ME-006 Rectangular Tank Thickness CalculationNadya Askar100% (1)

- Synthesis and Characterization of Mgo-Doped Srtio3 CeramicsDocumento8 páginasSynthesis and Characterization of Mgo-Doped Srtio3 CeramicsthrowawayAinda não há avaliações

- Plagiarism AmerDocumento31 páginasPlagiarism Amernelly hammoudaAinda não há avaliações

- Sustamid PA6GOLDocumento1 páginaSustamid PA6GOLPatrick BaridonAinda não há avaliações

- 11.mechanical Properties of MaterialsDocumento22 páginas11.mechanical Properties of MaterialsHarish LakshminarayananAinda não há avaliações

- 67 31085 IM515E 2016 1 2 2 MaterialSelection 06Documento21 páginas67 31085 IM515E 2016 1 2 2 MaterialSelection 06GiovannaPachecoAinda não há avaliações

- Design of A SILODocumento21 páginasDesign of A SILOAkhilprasad Sadige100% (1)

- Electrical Properties 1Documento80 páginasElectrical Properties 1SarumathiAinda não há avaliações

- Axial Load Capacity of Columns: (Short) : N ST G ST G ST STDocumento9 páginasAxial Load Capacity of Columns: (Short) : N ST G ST G ST STAurora VillalunaAinda não há avaliações

- Conversion Chart For HardnessDocumento5 páginasConversion Chart For HardnessIshmael WoolooAinda não há avaliações

- Analisis StrukturDocumento21 páginasAnalisis StrukturAngga Fajar SetiawanAinda não há avaliações

- HASCO Mat 1 2767 ENDocumento1 páginaHASCO Mat 1 2767 ENspazzastura showAinda não há avaliações