Escolar Documentos

Profissional Documentos

Cultura Documentos

Controls Switches-217763 PDF

Enviado por

Luis Fernando Garcia STítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Controls Switches-217763 PDF

Enviado por

Luis Fernando Garcia SDireitos autorais:

Formatos disponíveis

80 Ohmite Mfg. Co. 1-866-9-OHMITE Intl 1-847-258-0300 Fax 1-847-574-7522 www.ohmite.com info@ohmite.com Ohmite Mfg. Co.

0300 Fax 1-847-574-7522 www.ohmite.com info@ohmite.com Ohmite Mfg. Co. 1600 Golf Rd., Rolling Meadows, IL 60008 1-866-9-OHMITE Intl 1-847-258-0300 Fax 1-847-574-7522 www.ohmite.com info@ohmite.com 81

S TA N D A R D PA R T N U MB E R S F O R P O WE R TA P S WI T C H E S

Ohmite power Tap Switches

(high power rotary switches)

are constructed to provide

dependable, convenient

operation.

All Ohmite tap switches,

from 15 to 100 amps, have

ceramic arc-proof bodies and

metal alloy contacts. Their

all-soldered and all-riveted

construction assures mechani-

cal and operational integrity.

Even the smallest Ohmite Tap

Power Tap Switches

High-current, Non-shorting Type

Overall

Rating Rating Max. no. Diameter Depth behind panel (in./mm) Shaft

Model (AC) (DC)* of taps (max., in./mm) single 2 in tandem 3 in tandem Torque

711 7A 125V 7A 20V 11 1.56 / 39.6

13

/16 / 20.6 1

25

/32 / 45.2 2

15

/32 / 62.7 7-12 oz.-in.

111 15A 125V 15A 20V 11 2.19 / 56 1

1

/8 / 28.7 2

3

/4 / 69.9 1.5-3.8 in.-lbs.

212 20A 150V 20A 20V 12 2.25 / 57 1

3

/4 / 44.5 4

3

/16 / 106.4 6

3

/16 / 157.2 3-7 in.-lbs.

312 30A 300V 30A 20V 12 3.31 / 84 2

1

/4 / 57.2 4

5

/8 / 117.5 7 / 177.8 3-7 in.-lbs.

412 50A 300V 50A 20V 12 4.25 / 108 2

7

/16 / 61.9 5

1

/32 / 127.8 7

5

/8 / 193.7 3-8 in.-lbs.

608 100A 300V 100A 20V 8 6.25 / 159 3

5

/16 / 84.1 6

13

/16 / 173.0 10

5

/16 / 261.9 25-35 in.-lbs.

*non-inductive load

All dimensions for reference only; consult factory for details.

Switch, rated at 7 amps, has

a reinforced non-metal body

and solid metal alloy contacts.

These units feature high cur-

rent handling capability in a

small package.

F E A T U R E S

Slow-breaking, Quick-make

action proved best for switching

AC current.

Non-shorting type disconnects

previous circuit before establish-

ing contact for succeeding tap.

Ceramic and metal construction

provides resistance to arcing,

burning and charring.

Tandem assemblies available as

standard models.

UL listed for models 111, 212,

312 and 412

RoHS compliant product avail-

able Jan. 2006 Add E suffix to

part number to specify.

S P E C I F I C A T I O N S

Material

Body: Ceramic, arc-proof

(models 212, 312, 412, 608).

Compression Molded Polyester

(model 111). Melamine Phenolic

(model 711)

Contacts: Silver alloy. Common

contact is rounded for assured

seating. Self-cleaning with built

in wiping action.

Terminals: Soldering. 711 also

accepts quick connectors; 412,

#10 screws; 608, 0.25 bolts.

Mounting

Model 711: Using

3

/8-32 bushing

for

1

/8 thick maximum panel.

Four non-turn lug positions are

possible on the single, unen-

closed switch. Recesses in body

of switch permit positioning of

non-turn washer at 12, 3, 6 and

9 oclock.

3

/16 hole for non-turn

washer. Shaft

1

/4

Model 111: For

1

/4 panel, maxi-

mum, using

3

/8-32 bushing and

hex nut. A

3

/16 hole is required

for the non-turn washer. Shaft

1

/4

Model 212: Using

3

/8-32 threaded

bushing and hex nut. A

5

/32 hole

is required for the non-turn pin.

Shaft

1

/4

Model 312: For

1

/4 panel, maxi-

mum, use three 10-32 flat-head

machine screws

3

/8 long. Shaft

1

/4

Model 412: For

1

/4 panel, maxi-

mum, use three 10-32 flat-head

machine screws

3

/8 long. A

5

/16 hole in panel is required for

shaft.

Model 608: For 1 panel, maxi-

mum, three flat-head machining

screws

1

/4-20, 1

1

/4 long. Drill

a

7

/16 hole in panel for shaft.

Shaft

3

/8

NOTE: Since all tap switches are

electro-mechanical devices, they

are subject to wear and, there-

fore, have a finite life.

Typical

tandem model

Model 711

Typical

ceramic style

See page 82 for knobs,

dials, and other hardware

3 60

4 90

5 120

6 150

7 180

8 210

9 240

10 270

11 300

12 330

N

u

m

b

e

r

o

f

t

a

p

s

*

7

1

1

-

*

S

i

n

g

l

e

u

n

i

t

T

o

t

a

l

r

o

t

a

t

i

o

n

7

1

1

-

*

-

T

2

2

i

n

t

a

n

d

e

m

7

1

1

-

*

-

T

3

3

i

n

t

a

n

d

e

m

1

1

1

-

*

S

i

n

g

l

e

u

n

i

t

1

1

1

-

*

-

T

2

2

i

n

t

a

n

d

e

m

2

1

2

-

*

S

i

n

g

l

e

u

n

i

t

2

1

2

-

*

-

T

2

2

i

n

t

a

n

d

e

m

2

1

2

-

*

-

T

3

3

i

n

t

a

n

d

e

m

3

1

2

-

*

S

i

n

g

l

e

u

n

i

t

3

1

2

-

*

-

T

2

2

i

n

t

a

n

d

e

m

3

1

2

-

*

-

T

3

3

i

n

t

a

n

d

e

m

4

1

2

-

*

S

i

n

g

l

e

u

n

i

t

4

1

2

-

*

-

T

2

2

i

n

t

a

n

d

e

m

4

1

2

-

*

-

T

3

3

i

n

t

a

n

d

e

m

Model 711

7A - 125V

Model 111

15A - 125V

Model 212

20A - 150V

Model 312

30A - 300V

Model 412

50A - 300V

3 80

4 120

5 160

6 200

7 240

8 280

6

0

8

-

*

S

i

n

g

l

e

u

n

i

t

6

0

8

-

*

-

T

2

2

i

n

t

a

n

d

e

m

6

0

8

-

*

-

T

3

3

i

n

t

a

n

d

e

m

Model 608

100A - 300V

= Non-standard values subject to minimum handling charge per item

* Insert number of taps at asterisk for complete part number (e.g. 111-3-T2)

N

u

m

b

e

r

o

f

t

a

p

s

*

T

o

t

a

l

r

o

t

a

t

i

o

n

Check product availability at www.ohmite.com

80 Ohmite Mfg. Co. 1600 Golf Rd., Rolling Meadows, IL 60008 1-866-9-OHMITE Intl 1-847-258-0300 Fax 1-847-574-7522 www.ohmite.com info@ohmite.com Ohmite Mfg. Co. 1-866-9-OHMITE Intl 1-847-258-0300 Fax 1-847-574-7522 www.ohmite.com info@ohmite.com 81

Power Tap Switches

High-current, Non-shorting Type

Model 212 Model 111

Model 412 Model 312

Model 608

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Ohmite:

412-12E 212-12E 111-7E 212-8E 212-6E 111-3E 111-5E 111-6E 111-4E 312-6E 312-8E 312-12E 312-12

Você também pode gostar

- QB CatalogDocumento281 páginasQB CatalogFreddy Ferrer100% (1)

- En Operation Instructions PaxScan 4336R RevA 2017-06Documento46 páginasEn Operation Instructions PaxScan 4336R RevA 2017-06Luis Fernando Garcia S50% (2)

- Digital Radiography System Image Quality Adjustment ManualDocumento64 páginasDigital Radiography System Image Quality Adjustment ManualLuis Fernando Garcia SAinda não há avaliações

- AT520CT Users ManualDocumento14 páginasAT520CT Users ManualAlbert SomendraAinda não há avaliações

- Dynamometer: Theory and Application to Engine TestingNo EverandDynamometer: Theory and Application to Engine TestingAinda não há avaliações

- Steel SAE O-Rings AdaptersDocumento3 páginasSteel SAE O-Rings Adaptersgeav25653855Ainda não há avaliações

- Shimadzu Radspeed ManualDocumento1 páginaShimadzu Radspeed ManualLuis Fernando Garcia S33% (3)

- Evil Detonator: Owner'S ManualDocumento5 páginasEvil Detonator: Owner'S ManualMichael BrownAinda não há avaliações

- En User Manual Provario HF VD 2016-05Documento65 páginasEn User Manual Provario HF VD 2016-05Luis Fernando Garcia S100% (1)

- Siemens Polymobil 3 - Trouble Shooting GuideDocumento104 páginasSiemens Polymobil 3 - Trouble Shooting GuideDemsey Euceda Ramos86% (7)

- Introduction To Fuel CellsDocumento16 páginasIntroduction To Fuel CellsJess9girlAinda não há avaliações

- BOSS Slow Gear SG-1 Attack DelayDocumento1 páginaBOSS Slow Gear SG-1 Attack Delay大石 真義Ainda não há avaliações

- Manual MyLab 5Documento80 páginasManual MyLab 5Luis Fernando Garcia S100% (4)

- Mobile Art Evolution IngDocumento12 páginasMobile Art Evolution IngLuis Fernando Garcia SAinda não há avaliações

- Hygk307 ManualDocumento16 páginasHygk307 Manualkenlavie1Ainda não há avaliações

- Endos Ac / Acp: Service Manual Service Manual Service Manual Service ManualDocumento122 páginasEndos Ac / Acp: Service Manual Service Manual Service Manual Service ManualLuis Fernando Garcia SAinda não há avaliações

- Mil-C-22992 RTIDocumento16 páginasMil-C-22992 RTIchak1729Ainda não há avaliações

- 3) Catalogue - Convex CouplingDocumento8 páginas3) Catalogue - Convex CouplingmarcusAinda não há avaliações

- 6.75in Hemidril MotorDocumento2 páginas6.75in Hemidril Motorerdal aydinAinda não há avaliações

- 2NKX6 1Documento24 páginas2NKX6 1Ana Gabriela Gómez PeraltaAinda não há avaliações

- CI2400 BS2400 Product DataDocumento6 páginasCI2400 BS2400 Product DataDaniel BrownAinda não há avaliações

- Namco Limit SwitchDocumento4 páginasNamco Limit SwitchprabumunishAinda não há avaliações

- DC Spec Sheet v1 0 3 LR 2016Documento13 páginasDC Spec Sheet v1 0 3 LR 2016MohamadHuntashAinda não há avaliações

- Axenbr1001 PDFDocumento12 páginasAxenbr1001 PDFrizky efrinaldoAinda não há avaliações

- WSP22G Ola1 - 400 P 120601 e 01Documento4 páginasWSP22G Ola1 - 400 P 120601 e 01Eng-Mohammed SalemAinda não há avaliações

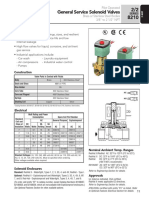

- General Service Solenoid Valves: ConstructionDocumento3 páginasGeneral Service Solenoid Valves: ConstructionAditya B. RyantoAinda não há avaliações

- Catalog SBDocumento40 páginasCatalog SBNicho WijayaAinda não há avaliações

- Legrand IsolatorsDocumento4 páginasLegrand IsolatorsHein Thu AungAinda não há avaliações

- 720 Sealed Cage Level Control: SeriesDocumento2 páginas720 Sealed Cage Level Control: SeriesAndroid RockAinda não há avaliações

- Dayton Integral and Fractional HP Motors: Motor Installation and Maintenance InformationDocumento28 páginasDayton Integral and Fractional HP Motors: Motor Installation and Maintenance Informationjaime appletonAinda não há avaliações

- STT Series-Tubular Flooded Batteries: SpecificationsDocumento1 páginaSTT Series-Tubular Flooded Batteries: SpecificationsPedro A Ocanto BAinda não há avaliações

- Installation and Testing: 8.1 Receiving, Handling and StorageDocumento29 páginasInstallation and Testing: 8.1 Receiving, Handling and StorageGerardo Muñoz UrbinaAinda não há avaliações

- Inoxpa 6400 Ball Vave enDocumento2 páginasInoxpa 6400 Ball Vave enRizky edytyaAinda não há avaliações

- OGi Mono Block N6 US0123Documento2 páginasOGi Mono Block N6 US0123Nguyễn Anh DanhAinda não há avaliações

- Western Valve Double Block and Bleed Valve (DBB Valve) Dual Expanding Plug ValveDocumento5 páginasWestern Valve Double Block and Bleed Valve (DBB Valve) Dual Expanding Plug ValveEdisson SanabriaAinda não há avaliações

- Sentrol 2700 Series ManualDocumento2 páginasSentrol 2700 Series ManualCarlosEstupiñanAinda não há avaliações

- Series 1000 Hinged ClosureDocumento3 páginasSeries 1000 Hinged ClosureKavan PatelAinda não há avaliações

- DS-1201 - W60 - W80 - W90 Series LR 10 2014 - tcm11-10502Documento28 páginasDS-1201 - W60 - W80 - W90 Series LR 10 2014 - tcm11-10502ChemicalProgrammerAinda não há avaliações

- Instruction Manual G-550: Vertex Standard Co., Ltd. Vertex StandardDocumento12 páginasInstruction Manual G-550: Vertex Standard Co., Ltd. Vertex Standardsdelpi5146Ainda não há avaliações

- Keeping The World Flowing: IW Quarter-Turn Gear SeriesDocumento6 páginasKeeping The World Flowing: IW Quarter-Turn Gear SeriesGourav SharmaAinda não há avaliações

- S&S Cycle, Inc.: Installation Instructions For S&S Cams For Pan, Shovel, and V /evo EnginesDocumento4 páginasS&S Cycle, Inc.: Installation Instructions For S&S Cams For Pan, Shovel, and V /evo EnginesSean SvatosAinda não há avaliações

- Electroctraft VR PM Stepper CatalogDocumento4 páginasElectroctraft VR PM Stepper CatalogElectromateAinda não há avaliações

- 4G63 Turbo Eclipse & Talon - Twin Cam: Accessories Engineered Component KitsDocumento4 páginas4G63 Turbo Eclipse & Talon - Twin Cam: Accessories Engineered Component KitsWolim HonAinda não há avaliações

- F 401 IeDocumento12 páginasF 401 IeMatt EbrahimiAinda não há avaliações

- Series EA Electric Actuators Low Torque, Medium Torque, and Spring Return Manual 1321-In-003!0!13Documento16 páginasSeries EA Electric Actuators Low Torque, Medium Torque, and Spring Return Manual 1321-In-003!0!13Isaac MonterreyAinda não há avaliações

- Specifications: Model 311 NPT Valve: Horizontal FlowDocumento2 páginasSpecifications: Model 311 NPT Valve: Horizontal FlowBrayan CJAinda não há avaliações

- Sunco: SO-100 SO-400 SeriesDocumento2 páginasSunco: SO-100 SO-400 SeriesJBHSBAinda não há avaliações

- Interruptor de Presion - AscoDocumento9 páginasInterruptor de Presion - AscoJosephGutierrezAinda não há avaliações

- 02 Isolators - HRDocumento4 páginas02 Isolators - HRSan Lin KyawAinda não há avaliações

- Microswitches Subminiature v4ncDocumento4 páginasMicroswitches Subminiature v4ncAlecu ElenaAinda não há avaliações

- SB SL HeatersDocumento4 páginasSB SL HeatersAndré AlfacinhaAinda não há avaliações

- V RingDocumento8 páginasV RingCALVINAinda não há avaliações

- Series 92 Electric Actuator: Standard FeaturesDocumento2 páginasSeries 92 Electric Actuator: Standard FeaturesSreekanthAinda não há avaliações

- WW 450 65 2023Documento4 páginasWW 450 65 2023Marcel TatebeAinda não há avaliações

- 21Documento4 páginas21Cao LanAinda não há avaliações

- Series 08 81 Probe Style DS - F 08 81 001Documento3 páginasSeries 08 81 Probe Style DS - F 08 81 001Pedro LuisAinda não há avaliações

- Assembly and Operating Instructions: Inverter Welding MachineDocumento14 páginasAssembly and Operating Instructions: Inverter Welding MachineTom PleysierAinda não há avaliações

- GE Tetra PowerGridDocumento2 páginasGE Tetra PowerGridPatrick MorcosAinda não há avaliações

- General Service Solenoid Valves: FeaturesDocumento6 páginasGeneral Service Solenoid Valves: FeaturesIgnacio FranAinda não há avaliações

- 8210R9 PDFDocumento6 páginas8210R9 PDFarturoncAinda não há avaliações

- General Service Solenoid Valves: FeaturesDocumento6 páginasGeneral Service Solenoid Valves: FeaturesMohamed RaafatAinda não há avaliações

- Selenoid eDocumento9 páginasSelenoid ejlfyAinda não há avaliações

- Liquid Refrigerant Receivers: Vertical, ULDocumento17 páginasLiquid Refrigerant Receivers: Vertical, ULDianaAinda não há avaliações

- Catalogo Ced Aprile19-EngDocumento22 páginasCatalogo Ced Aprile19-EngmedAinda não há avaliações

- GIW Technical Series: Pipe Flange BoltsDocumento4 páginasGIW Technical Series: Pipe Flange BoltsTravis SkinnerAinda não há avaliações

- Atwoods Waterheater Parts ModelsDocumento8 páginasAtwoods Waterheater Parts ModelsJohn LarsonAinda não há avaliações

- KSB Sicca Forged ValvesDocumento8 páginasKSB Sicca Forged ValvesKumarAinda não há avaliações

- Astronomical Instruments and AccessoriesNo EverandAstronomical Instruments and AccessoriesAinda não há avaliações

- DAC0854 Quad 8-Bit Voltage-Output Serial D/A Converter With ReadbackDocumento14 páginasDAC0854 Quad 8-Bit Voltage-Output Serial D/A Converter With ReadbackLuis Fernando Garcia SAinda não há avaliações

- ADC1001 10-Bit P Compatible A/D Converter: General Description FeaturesDocumento9 páginasADC1001 10-Bit P Compatible A/D Converter: General Description FeaturesLuis Fernando Garcia SAinda não há avaliações

- Aws4.7 Install ManualDocumento395 páginasAws4.7 Install ManualBashir AhmedAinda não há avaliações

- RTM101 HS 0.6 - 1.2 1Documento17 páginasRTM101 HS 0.6 - 1.2 1Luis Fernando Garcia SAinda não há avaliações

- Advantx-E Operator Console Schematics SM 2123272-100 8Documento62 páginasAdvantx-E Operator Console Schematics SM 2123272-100 8Luis Fernando Garcia S100% (1)

- GAL16V8: Features Functional Block DiagramDocumento22 páginasGAL16V8: Features Functional Block DiagramLuis Fernando Garcia SAinda não há avaliações

- ADC0800 8-Bit A/D Converter: General Description FeaturesDocumento10 páginasADC0800 8-Bit A/D Converter: General Description FeaturesLuis Fernando Garcia SAinda não há avaliações

- Mux 100 B. Diagram StarterDocumento1 páginaMux 100 B. Diagram StarterLuis Fernando Garcia S100% (1)

- Reciprocating Bucky: Model No. J500 Installation and Service Manual 01495-000 Rev. BtsDocumento29 páginasReciprocating Bucky: Model No. J500 Installation and Service Manual 01495-000 Rev. BtsLuis Fernando Garcia SAinda não há avaliações

- sg2524 PDFDocumento29 páginassg2524 PDFLuis Fernando Garcia SAinda não há avaliações

- Cares. DV5700 Dicom PDFDocumento40 páginasCares. DV5700 Dicom PDFLuis Fernando Garcia SAinda não há avaliações

- Hcmi DCX PDFDocumento2 páginasHcmi DCX PDFLuis Fernando Garcia SAinda não há avaliações

- Acr DMR 500t 600tDocumento7 páginasAcr DMR 500t 600tLuis Fernando Garcia SAinda não há avaliações

- 2 N 3053Documento3 páginas2 N 3053sas999333Ainda não há avaliações

- 8Kv 400ma High Voltage Diode: FeaturesDocumento1 página8Kv 400ma High Voltage Diode: FeaturesLuis Fernando Garcia SAinda não há avaliações

- Brivo Essential BrochureDocumento12 páginasBrivo Essential BrochureLuis Fernando Garcia SAinda não há avaliações

- Vari An WirelessDocumento4 páginasVari An WirelessLuis Fernando Garcia SAinda não há avaliações

- Experiences Using A Mobile X-Ray System With A Thin, Large-Field-of-View FPDDocumento4 páginasExperiences Using A Mobile X-Ray System With A Thin, Large-Field-of-View FPDLuis Fernando Garcia SAinda não há avaliações

- Selectivity Catalog Domestic 291015Documento12 páginasSelectivity Catalog Domestic 291015Samarendu BaulAinda não há avaliações

- Week 1 Part I Capacitors June 05Documento41 páginasWeek 1 Part I Capacitors June 05Marty J. SmithAinda não há avaliações

- Ma1 PDFDocumento316 páginasMa1 PDFRMK BrothersAinda não há avaliações

- TDS 5450 Soft EN 20091127Documento2 páginasTDS 5450 Soft EN 20091127Tim LeclerAinda não há avaliações

- Akai Dv-p4785kdsm DVD PlayerDocumento50 páginasAkai Dv-p4785kdsm DVD PlayerhussainArifAinda não há avaliações

- Audio Spotlighting - ECE Seminar TopicsDocumento3 páginasAudio Spotlighting - ECE Seminar Topicsuday kumarAinda não há avaliações

- Wireless World 1995 09 S OCRDocumento100 páginasWireless World 1995 09 S OCRMilton NastAinda não há avaliações

- Weidmuller PT100 TransducersDocumento3 páginasWeidmuller PT100 TransducersF Sisniegas GCAinda não há avaliações

- Ieee Base CT PT Sizing For Substation Excel Sheet - Google SearchDocumento2 páginasIeee Base CT PT Sizing For Substation Excel Sheet - Google SearchUjjal ChakmaAinda não há avaliações

- AccuLoad III-D Operator Reference ManualDocumento120 páginasAccuLoad III-D Operator Reference Manualpablobs100% (1)

- 1SDA074678R1 xt1s 125 TMF 125 1250 3p F F Ul CsaDocumento3 páginas1SDA074678R1 xt1s 125 TMF 125 1250 3p F F Ul CsaJose FloresAinda não há avaliações

- KSW-230 (Water Flow Switch)Documento2 páginasKSW-230 (Water Flow Switch)Anonymous XYAPaxjbYAinda não há avaliações

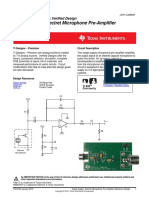

- Transimpedance Amplifier With Mic PDFDocumento23 páginasTransimpedance Amplifier With Mic PDFChanderKishoreJoshiAinda não há avaliações

- ABB - TechNotes - 2.2 - Overvoltages - Protective Distance 1HC0138872 EN AADocumento11 páginasABB - TechNotes - 2.2 - Overvoltages - Protective Distance 1HC0138872 EN AADeoudrafAinda não há avaliações

- Mathcad - UCC3817 Design Procedure 7 29 08Documento10 páginasMathcad - UCC3817 Design Procedure 7 29 08servetAinda não há avaliações

- Prac. Summer 2014Documento19 páginasPrac. Summer 2014Praful KakdeAinda não há avaliações

- Velomitor CT Transducer 125389-01 REV CDocumento57 páginasVelomitor CT Transducer 125389-01 REV CHamid HannitAinda não há avaliações

- F5 Physics Chapter 4 Alfred NotesDocumento28 páginasF5 Physics Chapter 4 Alfred NotesseezhanrholAinda não há avaliações

- NTSB Panhandle Train Onboard Image Recorder ReportDocumento11 páginasNTSB Panhandle Train Onboard Image Recorder ReportRicky TreonAinda não há avaliações

- LM380 Power Audio AmplifierDocumento8 páginasLM380 Power Audio AmplifierYonatan José Roche AndradeAinda não há avaliações

- Unit-2, Electrical Power Quality 4-1, June 2019Documento55 páginasUnit-2, Electrical Power Quality 4-1, June 2019Naga AnanthAinda não há avaliações

- Prime Mover Synchronous Generator Electrical GridDocumento12 páginasPrime Mover Synchronous Generator Electrical GridReymart ManablugAinda não há avaliações

- Ami Bios RecoveryDocumento4 páginasAmi Bios RecoveryphilAinda não há avaliações

- Course Outline: Mercer County Community CollegeDocumento4 páginasCourse Outline: Mercer County Community CollegeJeremy CokeleyAinda não há avaliações

- Inverters & Utility Grid ConfigurationDocumento1 páginaInverters & Utility Grid ConfigurationLanz ValdezAinda não há avaliações

- Performance Tuning Guide: DB2 UDB V7.1Documento418 páginasPerformance Tuning Guide: DB2 UDB V7.1karthika.subramanianAinda não há avaliações