Escolar Documentos

Profissional Documentos

Cultura Documentos

Adsorption of Oil From Waste Water by Coal PDF

Enviado por

Paola Olivares SanchezDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Adsorption of Oil From Waste Water by Coal PDF

Enviado por

Paola Olivares SanchezDireitos autorais:

Formatos disponíveis

Received 07 December 2009; accepted 08 March 2010

*Corresponding author. Tel: 86 516 83885878

E-mail address: cumtlxb@126.com.

doi: 10.1016/S1674-5264(09)60280-5

Adsorption of oil from waste water by coal:

characteristics and mechanism

LI Xiaobing

*

, ZHANG Chunjuan, LIU Jiongtian

School of Chemical Engineering and Technology, China University of Mining & Technology, Xuzhou 221116, China

Abstract: The work described here was focused on exploring the potential application of coal to purification of oily waste water.

Coal was added to oily waste water as an adsorbent and then removed through a flotation process. This allowed economical and

highly efficient separation of oil from the waste water. The absorption time, coal type, coal particle size distribution, pH value and

oil concentration were investigated. The results indicate that oil absorption by a coal increases for a period of 1.5 h and then gradu-

ally tends toward an equilibrium value. It appears that the absorption capacity of anthracite is more than that of lean coal or lignite,

given the same coal particle size distribution. The absorption capacity of a coarse coal fraction is less than that of finer coal, given

the same of coal type. The absorption capacity of anthracite decreases slightly as the pH increases from 4 to 9. The adsorption of oil

on anthracite follows the Freundlich isothermal adsorption law: given initial oil concentrations of 160.5 or 1023.6 mg/L the absorp-

tion capacity was 23.8 or 840.0 mg/g. The absorption mechanism consists of two kinds of absorption, a physical process assisted by

a chemical one.

Keywords: oily wastewater; waste water; separation; coal; oil; adsorption; mechanism

1 Introduction

Oily waste water is one of the most serious envi-

ronmental issues created by production in oil fields.

The treatment of oily waste water is important not

only from an economic view point but also in terms

of ending the pollution of water resources. Com-

monly used technologies for treating oily waste water

include physical treatment, physical chemistry,

chemical de-emulsifying, biochemistry and electro-

chemistry

[1-4]

. However, application of these tech-

niques has been limited for both technical and eco-

nomic reasons. A flotation process has been attracting

much recent attention from scholars because of its

high separation efficiency, low capital investment and

operational costs. Some new types of flotation de-

vices and some new methods for quick and highly

efficient separation of oily waste water have been

developed

[5-9]

.

Currently, many oil fields in China have entered a

medium-high water-cut stage during their mid to late

phase of oil extraction. The development and applica-

tion of the polymer-flooding technology in oil fields

has resulted in the production of water containing a

large amount of high molecular weigh polymer that is

highly emulsified and has a high water-phase viscos-

ity. This makes treatment of the polymer-flooding

waste water considerably more difficult.

Hao Z T et al. used fly ash as an adsorbent to ad-

sorb oil from oily waste water

[10]

. Oil removal effi-

ciencies reached 70%~80% in that scheme and the

adsorption process fit an S-shaped isothermal adsorp-

tion law. Yan L H et al. reported that the adsorption

process follows the Freundlich isothermal adsorption

law when fly ash was used as an adsorbent for sepa-

ration of oil from oily waste water at room tempera-

ture

[11]

. The results showed that the residual oil con-

centration in the waste water would not be too high

when the adsorption process was helped by stirring.

However, the recovered oil can not be recycled effec-

tively when fly ash is used as the adsorbent.

The objective of this study was to explore the po-

tential application of using coal to treat oily waste

water. The oil can first be separated from the waste

water with a novel method where the coal is used as

an oil adsorbent and then the coal-oil mixture is

separated from the waste water by flotation eco-

nomically and with high efficiently. As a result, oil

removal from waste water was successfully per-

formed and the recycled oil could then be used as fuel,

namely a coal-oil-water multiphase fuel. The adsorp-

tion of oil droplets onto a coal particle surface from

oily waste water was also studied.

Mining Science and Technology 20 (2010) 07780781

MINI NG

SCIENCE AND

TECHNOLOGY

www.elsevier.com/locate/jcumt

LI Xiaobing et al Adsorption of oil from waste water by coal 779

2 Experimental

2.1 Materials

The oily waste water was polymer-flooding water.

Samples were obtained from the Shengli Gudao Oil

Field, China. The initial oil mean concentration in the

water was 246.40 mg/L. The oil droplet size distribu-

tion was analyzed with a laser particle size analyzer

(LS-100Q). About 13.4% of the oil droplets were 1

m in diameter or smaller and about 99.1% were 10

m or smaller. The oily waste water is very difficult

to separate because of the small mean size of the

droplets that consist of emulsified oil and polymer.

The coals used as sorbent in the experiments were

Yongcheng anthracite from Henan province, China,

Anyang lean coal from Henan province, China and

Wuhai lignite from Inner Mongolia province, China.

These coal samples were ground into fine particles

for 8 minutes using a XMB-67 ball mill. Then they

were screened with a bushing screen into fractions of

particle size +0.51.0, +0.1250.5, +0.0740.125,

+0.0460.074 and 0.046 mm.

2.2 Methods

2.2.1 Oil concentration measurement and the

absorption capacity calculation

The oil concentration of the waste water was de-

termined by UV spectrophotometry (UV2602).

The adsorption capacity for crude oil was calcu-

lated using Eq.(1)

0

( ) /

e

C C v m = (1)

where is the superficial adsorption capacity; C

0

the

initial concentration of crude oil in the oily waste wa-

ter; C

e

the equilibrium concentration of crude oil in the

waste water; and m the quantity of coal added to the

sample.

2.2.2 Equilibrium absorption time

In a typical experiment 0.25 g of anthracite, the

lean coal or the lignite was used for each trial. The

coal was first added to a 250 mL conical flask along

with 50 mL of oily waste water. The mixture was then

mixed with a thermostatically controlled oscillator at

(251) C. The mixing time was programmed from 0

to 3.0 h. Finally, the oil concentration of these sam-

ples was measured after absorption by the coal. The

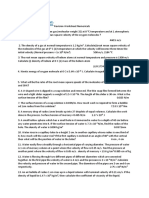

results are presented in Fig. 1.

Fig. 1 Absorption as a function of time

Fig. 1 shows that absorption equilibrium occurs

later than 1.5 hours after initial contact. Thus, a 3.0 h

contact time was chosen as being most suitable by

experiment. The absorption process of each of the

three coals may be divided into two stages, a quick

and a slow absorption stage. The absorption capacity

during the quick absorption stage is more than 90%

of the total absorption capacity. The absorption

gradually comes to equilibrium during the slow, final

absorption stage.

2.2.3 Selection of coal type and particles size

0.25 g samples of anthracite, the lean coal or the

lignite were used. The particle sizes of the samples

were 0.046, 0.074 +0.046, 0.125+0.074, 0.5+

0.125 or 1.0+0.5 mm. The coal sample was put into

a 250 mL conical flask along with 50 mL of oily

waste water. Then the mixture was mixed in a ther-

mostatically controlled oscillating bath at (251) C

for 3.0 h. The results are shown in Fig. 2.

2.2.4 pH value

0.25 g anthracite samples with a particles size of

0.074+0.046 mm were used for this part of the work.

The coal sample was added to a 250 mL conical flask

along with 50 mL of oily waste water. Then the pH of

the mixture was adjusted by adding either NH

3

H

2

O

or HCl to it. The flask was mixed in a thermostati-

cally controlled oscillating mixer at (251) C for 3.0

h. The results are shown in Fig. 3.

2.2.5 Oil concentrations

Samples with different oil concentrations in the

water were prepared at a pH value of 7.0. Again, 0.25

g of anthracite, particle size +0.0460.074 mm, were

placed in a 250 mL conical flask along with 50 mL of

oily waste water. This mixture was mixed in the

thermostatically controlled oscillating mixer at (251)

C for 3.0 h. The results from this trial are shown in

Fig. 4.

3 Results and discussion

3.1 Effect of coal type and particles size on the

absorption capacity

Fig. 2 shows that the absorption capacity of an-

thracite exceeds that of the lean coal and the lignite

for each particle size. The equilibrium adsorption

capacities of anthracite, lean coal and lignite were

24.4, 18.6 and 20.7 mg/g, respectively, when the par-

ticle size was 0.046 mm.

The coarser lean coal had greater absorption capac-

ity than the coarser lignite. For example, the equilib-

rium adsorption capacities of lean coal and lignite

were 11.3 and 9.3 mg/g respectively when the particle

size was 1.0+0.5 mm. However, the absorption ca-

pacity of the lean coal is less than the lignite when the

particle size was smaller. For example, the adsorption

capacities of the lean coal and the lignite were 14.1

and 17.8 mg/g respectively when the particle size was

Mining Science and Technology Vol.20 No.5 780

0.125+0.074 mm.

1.0

0.5

0.5

0.125

0.125

0.074

0.074

0.046

0.046

0

4

8

12

16

20

24

Particle size (mm)

Anthracite

Lean coal

Lignite

Fig. 2 Effect of coal type and particles size on the

absorption capacity

The quantity of oil absorbed increased as the parti-

cle size decreased. This was true for all coals and oc-

curs because the specific surface area of coal particles

increases as their size decreases. It is difficult for the

suspended solids to be removed completely, however,

if the particle size is too fine. Under these conditions

the amount of suspended solids in the waste water

might increase. This experiment shows that the parti-

cle size of anthracite should be kept within the range

of 0.074+0.046 mm.

3.2 Effect of pH on absorption by anthracite

Fig. 3 shows that the absorption capacity of an-

thracite decreases as the pH value increases. The ad-

sorption capacity under acidic condition is clearly

greater than for alkaline condition. However, on the

whole, the effect pH is rather small and the adsorp-

tion capacity of the anthracite ranges from 22.0 to

25.0 mg/g over the pH range examined. Therefore,

the pH of the oily waste water need not be adjusted

when anthracite is used as the sorbent.

(

m

g

/

g

)

Fig. 3 Effect of pH value on absorption capacity

3.3 Effect of oil concentration on the absorption

capacity of anthracite

Fig. 4 shows the absorption as a function of oil

concentration with anthracite as the absorbent. Oil

concentrations of 42.2, 160.5, 523.6 or 1023.6 mg/L

resulted in adsorption capacities of 9.5, 23.8, 499.9 or

840.0 mg/g, respectively. The results shown in Fig. 4

indicate that the adsorption capacity of anthracite fits

the Freundlich isothermal adsorption law. Initially the

adsorption capacity is small, which indicates that the

absorption of oil is affected by other substances in the

waste water. A single terminal group of the crude oil

molecules is targeted for adsorption on the coal sur-

face. Increasing the oil concentration results in im-

proved adsorption capacity, especially at high con-

centrations, which may result from oil molecules

saturating the coal surface and then providing a ther-

modynamically more stable site for further adsorp-

tion.

(

m

g

/

g

)

Fig. 4 Effect of oil concentration on the absorption

capacity of anthracite

4 Mechanism of oil absorption onto coal

particles

Coal is a solid material consisting of crevices and

growth holes. It has a double porosity and contains

both micro- and macro-pores: it has a large surface

area and included volume

[12-14]

. Coal particles ab-

sorbed oil droplets from the waste water, especially

the smaller sized droplets and the emulsified oil. Oil

is absorbed to the coal particles and then separated

from the water through flotation.

The adsorption of oil depends on three processes:

diffusion of oil molecules into the substrate; capillary

action of the oil at the fiber structure/substrate inter-

face; and, aggregation of oil in cavities such as pores,

microcracks and uncovered interfaces. The pores and

surface microcracks are the main locations for ab-

sorption of oil by coal (Fig. 5).

Fig. 5 Adsorption of oil on coal particles

FTIR spectra can demonstrate the adsorption

mechanism. The FTIR spectra of anthracite and an-

thracite with oil adsorbed on it are shown in Fig. 6.

LI Xiaobing et al Adsorption of oil from waste water by coal 781

4000 3500 3000 2500 2000 1500 1000 500

10

20

30

40

50

1100~1200

C-H

730~770

690~710

Wavenumber (cm

1

)

OH3300~3450

Anthracite

Anthracite adsorbed oil

C-O

CO, CC 1600~1650

C-H

Fig. 6 FTIR spectra of anthracite and anthracite plus oil

Referring to Fig. 6, the peak at 3450~3300 cm

1

is

attributed to the absorption of hydroxyl. Hydroxyls in

coal-based compounds are generally hydrogen

bonded, therefore the peak moves from 3300 to 3450

cm

1

becomes broad and strong along with the shift to

shorter wavelengths. Most of the oil in the waste wa-

ter consists of hydrocarbons, which contribute to the

methyl and methylene absorptions. The vibrations at

1650 to 1600 cm

1

arise from three types of covalent

bonds including stretching vibrations of >C=O and

the stretching vibrations of C=C in alkenes or arenes.

This absorption in the untreated anthracite may be

attributed to C=C stretching in alkenes or arenes. As

to another aspect, compared to another weak peak at

2750 cm

1

, it may be inferred that >C=O is contained

in the molecular structure of the coal as arene is one

of the main components in crude oil. So the absorp-

tion here is slightly stronger after oil treatment than

before.

The absorption at 1200~1100 cm

1

results from the

bending vibrations of C-O in alcohols and may con-

firm the presence of hydrogen bonded hydroxyl along

with the absorption peak at 3450~3300 cm

1

. The

other peak at 900~700 cm

1

reflects the bending vi-

bration of aromatic and alkene moieties and grows

with increased of coalification.

The FTIR spectra reveal small differences in ab-

sorption frequency and intensity before and after

treatment. While there was no new characteristic ab-

sorption detected we can infer that the oil absorption

mechanism consists of two kinds: a physical process

assisted by chemical one.

5 Conclusions

1) The results of this work show that coal type and

particles size are important factors that significantly

affect the absorption of oil from waste water. The

absorption capacity of anthracite is larger than that of

the lean coal or the lignite for all particle sizes tested.

For each kind of coal, the absorption capacity of the

fine fractions is larger than that of the coarse frac-

tions.

2) The time to reach equilibrium absorption is

longer for lean coal and lignite than for anthracite.

The absorption capacity of anthracite decreases gra-

dually as the pH value of the mixture increases. In

practical terms the effect of pH is negligible. Oil ad-

sorption on anthracite follows the Freundlich iso-

thermal adsorption law.

Acknowledgements

The authors are grateful to the Science and Tech-

nology Fund of China University of Mining & Tech-

nology (No.2006A019) and the National Natural

Science Foundation of China (No.50974119) for their

support of this project.

References

[1] Kong J, Li K. Oil removal from oil-in-water emulsions

using PVDF membranes. Separation and Purification

Technology, 1999, 16(1): 83-93.

[2] Han H J. Treatment of oil-containing wastewater by

micro cell filter bed process. Environmental Protection

of Chemical Industry, 2000, 20(5): 19-22. (In Chinese)

[3] Auflem I H, Kallevik H, Westvik A, Sjblom J. Influ-

ence of pressure and solvency on the separation of wa-

ter-in-crude-oil emulsions from the North Sea. Journal

of Petroleum Science and Engineering, 2001, 31(1):

1-12.

[4] Chen G H, He G H. Separation of water and oil from

water-in-oil emulsion by freeze/thaw method. Separation

and Purification Technology, 2003, 31(1): 83-89.

[5] Rubio J, Souza M L, Smith R W. Overview of flotation

as a wastewater treatment technique. Minerals Engi-

neering, 2002, 15(3): 139-155.

[6] Yan J, Ding S B. Utilization of the new type JHX flota-

tion cell in oil-bearing wastewater treatment. Environ-

ment Protection in Petrochemical Industry, 2002, 25(1):

16-19. (In Chinese)

[7] Li X B, Liu J T, Wang YT, Wang C Y, Zhou X H. Sepa-

ration of oil from wastewater by column flotation. Jour-

nal of China University of Mining & Technology, 2007,

17(4): 546-577.

[8] Zhang J W, Zhang Q, Wang H J. Progress of flotation

technique and its application on treatment of oily

wastewater. Environment Protection in Petrochemical

Industry, 2003, 26(1): 12-16. (In Chinese)

[9] Gu X Q, Chiang S H. A novel flotation column for oily

water cleanup. Separation Purification Technology, 1999,

16(3): 193-203

[10] Yan L H, Zhao D F. Application of the fly ash absorption

to dispose of petroleum in oil refining wastewater. Arid

Environmental Monitoring, 1998, 12(3): 139-144. (In

Chinese)

[11] Hao Z T, Wu J, Lu Z Y, Yan Y X, Wang Z Q. Study on

the adsorption of pollutants in oily wastewater with the

fly ash. Environmental Protection of Chemical Industry,

2004, 24(supp): 341-344. (In Chinese)

[12] Zhang S Q. Coal Chemistry. Xuzhou: China University

of Mining & Technology Press, 2004. (In Chinese)

[13] Qin Z H, Hou C L, Chen J, Zhang L Y, Ma J Q. Group

separation of coal components and new ideas of coal

utilization as petroleum. Mining Science and Technology,

2009, 19(5): 636-641.

[14] Zhang Y J, Wu G G, Xu H F, Meng X L, Wang G Y.

Prediction of oxygen concentration and temperature dis-

tribution in loose coal based on BP neural network.

Mining Science and Technology, 2009, 19(2): 216-219.

Você também pode gostar

- Dynamic HPHT System - FANNDocumento3 páginasDynamic HPHT System - FANNPaola Olivares SanchezAinda não há avaliações

- 2nd Year Engineering DegreeDocumento1 página2nd Year Engineering DegreePaola Olivares SanchezAinda não há avaliações

- Rye Celda de Difusion Conway de Polipropileno Pdeterminacion Co2 Pk3Documento1 páginaRye Celda de Difusion Conway de Polipropileno Pdeterminacion Co2 Pk3Paola Olivares SanchezAinda não há avaliações

- PIP PNSM0001 - Piping Line Class Design at or SystemDocumento20 páginasPIP PNSM0001 - Piping Line Class Design at or SystemKusnadi100% (1)

- 1966 Tridiagonal Matrix For DistillationDocumento9 páginas1966 Tridiagonal Matrix For DistillationPaola Olivares SanchezAinda não há avaliações

- Taller 2 .Transformada de Laplace.g5Documento1 páginaTaller 2 .Transformada de Laplace.g5Paola Olivares SanchezAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- 3 CombustionDocumento30 páginas3 CombustionCllyan ReyesAinda não há avaliações

- DTK-120HW, DTK-MRJ11, DTK-2LVLP: Surge ProtectorsDocumento1 páginaDTK-120HW, DTK-MRJ11, DTK-2LVLP: Surge Protectorsethan8888Ainda não há avaliações

- Sizing and Cost Estimation Methodology For Stand Alone Residential PV Power SystemDocumento20 páginasSizing and Cost Estimation Methodology For Stand Alone Residential PV Power SystemvenvettyAinda não há avaliações

- Shibaura Diesel Engine S773L - Tier4 XXDocumento28 páginasShibaura Diesel Engine S773L - Tier4 XXMihai PopaAinda não há avaliações

- klx250 h6fh7f Parts List PDFDocumento91 páginasklx250 h6fh7f Parts List PDFOliverAinda não há avaliações

- Ambitious Science Lesson PlanDocumento10 páginasAmbitious Science Lesson Planapi-605820842Ainda não há avaliações

- R ChidambaramDocumento2 páginasR Chidambaramshridhar sutarAinda não há avaliações

- COMPRO Bintang AuroraDocumento26 páginasCOMPRO Bintang AurorabintangAinda não há avaliações

- Samba™PLC+HMI Installation Guide: General DescriptionDocumento12 páginasSamba™PLC+HMI Installation Guide: General DescriptionDragisa DjukicAinda não há avaliações

- Auma - Electric ActuatosDocumento44 páginasAuma - Electric ActuatosRakesh Karan Singh100% (1)

- Indian Minerals Yearbook 2019: 58 EditionDocumento32 páginasIndian Minerals Yearbook 2019: 58 EditionmohitAinda não há avaliações

- Meralco AnalysisDocumento7 páginasMeralco AnalysisjemAinda não há avaliações

- Revision Worksheet Numericals SA2Documento2 páginasRevision Worksheet Numericals SA2Chinmaya NagpalAinda não há avaliações

- WPIC Platinum Essentials January 2024Documento17 páginasWPIC Platinum Essentials January 2024Никита МузафаровAinda não há avaliações

- Mass Air Flow Sensor Diagnostics For Adaptive Fueling Control ofDocumento6 páginasMass Air Flow Sensor Diagnostics For Adaptive Fueling Control ofSinAnime ConAnimeAinda não há avaliações

- Grade 7 LPDocumento5 páginasGrade 7 LPMelfe John CerezoAinda não há avaliações

- Republic v. Pilipinas Shell, GR 173918Documento10 páginasRepublic v. Pilipinas Shell, GR 173918Glenn FortesAinda não há avaliações

- Tech Spec For Plate Heat ExchangersDocumento37 páginasTech Spec For Plate Heat ExchangersSHIVAJI CHOUDHURY50% (2)

- Chemistry Project: Saturated Solutions: Measuring SolubilityDocumento8 páginasChemistry Project: Saturated Solutions: Measuring SolubilityAbhay Kumar NayakAinda não há avaliações

- JD 624h Loader Tc62h Operator Sec WatDocumento20 páginasJD 624h Loader Tc62h Operator Sec Watalbert100% (51)

- MCQ For Midsem - Ind - Inst.Documento5 páginasMCQ For Midsem - Ind - Inst.Nirav ChauhanAinda não há avaliações

- Symmetric Bending of Beams: Learning ObjectivesDocumento0 páginaSymmetric Bending of Beams: Learning ObjectivesWijayanto BekasiAinda não há avaliações

- Maintenance and Safety of Stationary Lead Acid BatteriesDocumento20 páginasMaintenance and Safety of Stationary Lead Acid BatteriessaikatkhanAinda não há avaliações

- How Air Compressor WorksDocumento3 páginasHow Air Compressor WorksPinak ParkhiAinda não há avaliações

- Peb Fabrication Project WorkDocumento16 páginasPeb Fabrication Project Workmadhu krishnaAinda não há avaliações

- Applications of 8086Documento38 páginasApplications of 8086Ajay PeterAinda não há avaliações

- GC-1F Operators ManualDocumento9 páginasGC-1F Operators Manualnhocti007Ainda não há avaliações

- Design of High Heat Release Slinger Combustor With Rapid Acceleration RequirementDocumento18 páginasDesign of High Heat Release Slinger Combustor With Rapid Acceleration RequirementFernando TaleroAinda não há avaliações

- Component Maintenance Manual With Illustrated Parts ListDocumento62 páginasComponent Maintenance Manual With Illustrated Parts ListRaymond Zamora100% (7)