Escolar Documentos

Profissional Documentos

Cultura Documentos

3A Maintenance M050733 - 06E

Enviado por

Liya MahagamaTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

3A Maintenance M050733 - 06E

Enviado por

Liya MahagamaDireitos autorais:

Formatos disponíveis

Maintenance Schedule

Diesel Engine

V 4000 G43

V 4000 G63, G63L

V 4000 G83, G83L

Application Group 3A

M050733/06E

12V4000G43 99 kW/cyl.

12V4000G63 109 kW/cyl.

12V4000G83 118 kW/cyl.

16V4000G43 103 kW/cyl.

16V4000G63 102 kW/cyl.

16V4000G83 122 kW/cyl.

20V4000G43 95 kW/cyl.

20V4000G63 100 kW/cyl.

20V4000G63L 109 kW/cyl.

20V4000G83 112 kW/cyl.

20V4000G83L 125 kW/cyl.

Table 1: Valid for ...

Printed in Germany

2013 Copyright MTU Friedrichshafen GmbH

This Publication is protected by copyright and may not be used in any way whether in whole or in part without the prior

written permission of MTU Friedrichshafen GmbH. This restriction also applies to copyright, distribution, translation, mi-

crofilming and storage or processing on electronic systems including data bases and online services.

This handbook is provided for use by maintenance and operating personnel in order to avoid malfunctions or damage

during operation.

Subject to alterations and amendments.

1 Maintenance Schedule

1.1 Preface

MTU maintenance concept

The maintenance system for MTU products is based on a preventive maintenance concept. Preventive

maintenance facilitates advance planning and ensures a high level of equipment availability.

The maintenance schedule is based on the load profile / load factor specified below. The time intervals

at which the maintenance work is to be carried out and the relevant checks and tasks involved are aver-

age values based on operational experience and are therefore to be regarded as guidelines only. Spe-

cial operating conditions and technical requirements may require additional maintenance work and/or

modification of the maintenance intervals. The intervals according to which the maintenance tasks have

to be carried out are specified as operating hours and time limits. The limit which occurs first is applica-

ble. In order to be authorized to carry out the individual maintenance jobs, maintenance personnel must

have achieved a level of training and qualification appropriate to the complexity of the task in hand. The

various Qualification Levels QL1 to QL4 reflect the levels of training offered in MTU courses and the

contents of the tool kits required:

QL1: Operational monitoring and maintenance which can be carried out during a break in operation

without disassembling the engine.

QL2: Component exchange (corrective only).

QL3: Maintenance work which requires partial disassembly of the engine.

QL4: Maintenance work which requires complete disassembly of the engine.

The maintenance schedule matrix normally finishes with extended component maintenance. Following

this, maintenance work is to be continued at the intervals indicated.

The numbers stated in the list of jobs provide a reference to the scope of parts required.

Notes on maintenance

Specifications for fluids and lubricants, guideline values for their maintenance and change intervals and

lists of recommended fluids and lubricants are contained in the MTU Fluids and Lubricants Specifica-

tions A001061 and in the fluids and lubricants specifications produced by the component manufactur-

ers. They are therefore not included in the maintenance schedule (exception: deviations from the Fluids

and Lubricants Specifications). All fluids and lubricants used must meet MTU specifications and be ap-

proved by the relevant component manufacturer.

Amongst other items, the operator/customer must carry out the following additional maintenance

work:

Protect components made of rubber or synthetic material from oil. Never treat them with organic

detergents. Wipe with a dry cloth only.

Fuel prefilter:The maintenance interval depends on how dirty the fuel is. The paper inserts in fuel pre-

filters must be changed every two years at the latest (Task 9998).

Battery:Battery maintenance depends on the level of use and the ambient conditions. The battery

manufacturer's instructions must be obeyed.

The relevant manufacturer's instructions apply with respect to the maintenance of any components

which do not appear in this maintenance schedule.

This Maintenance Schedule may include components which are not included in the MTU supply scope;

these may be disregarded.

Out-of-service periods

If the engine is to remain out of service for more than 1 month, carry out engine preservation proce-

dures in accordance with the Fluids and Lubricants Specifications, MTU Publication No. A001061.

M050733/06E 2013-02 | Maintenance Schedule | 3

T

I

M

-

I

D

:

0

0

0

0

0

2

0

0

1

8

-

0

0

4

Application Group

3A Continuous operation, unrestricted

4 | Maintenance Schedule | M050733/06E 2013-02

T

I

M

-

I

D

:

0

0

0

0

0

2

0

0

1

8

-

0

0

4

Load profile

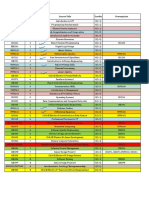

1.2 Maintenance schedule matrix

0-10,000 Operating hours

Item

L

i

m

i

t

Operating hours [h]

D

a

i

l

y

5

0

0

1

,

0

0

0

1

,

5

0

0

2

,

0

0

0

2

,

5

0

0

3

,

0

0

0

3

,

5

0

0

4

,

0

0

0

4

,

5

0

0

5

,

0

0

0

5

,

2

5

0

5

,

5

0

0

6

,

0

0

0

6

,

5

0

0

7

,

0

0

0

7

,

5

0

0

8

,

0

0

0

8

,

5

0

0

9

,

0

0

0

9

,

5

0

0

1

0

,

0

0

0

Engine operation 1 m

Engine oil filter 2 a

Engine operation - X

Oil indicator filter 6 m X X X X X X X X X X X X X X X X X X X X

Centrifugal oil filter 2 a X X X X X X X X X X X X X X X X X X X X

Fuel filter 2 a X X X X X X X X X X

Engine mounts 1 a X X X X X X X X X X

Belt drive 2 a X X X X X X

Valve gear 2 a X X X

Air filters 3 a X X X

Fuel injectors 9 a X

Engine governor 9 a X

Combustion chambers 4 a X

Crankcase breathers 2 a X

Turbochargers 18 a

Component maintenance 9 a

Engine mounts 5 a

Fuel delivery pump 9 a

HP fuel pump 9 a

Cylinder heads 9 a

Rubber sleeves 6 a

Hose lines 6 a

Automatic engine oil filter 6 a

Extended component maintenance 18 a

Turbochargers 18 a

w = weeks

m = months

a = years

10,500-20,500 Operating hours

Item

L

i

m

i

t

Operating hours [h]

1

0

,

5

0

0

1

1

,

0

0

0

1

1

,

5

0

0

1

2

,

0

0

0

1

2

,

5

0

0

1

3

,

0

0

0

1

3

,

5

0

0

1

4

,

0

0

0

1

4

,

5

0

0

1

5

,

0

0

0

1

5

,

5

0

0

1

5

,

7

5

0

1

6

,

0

0

0

1

6

,

5

0

0

1

7

,

0

0

0

1

7

,

5

0

0

1

8

,

0

0

0

1

8

,

5

0

0

1

9

,

0

0

0

1

9

,

5

0

0

2

0

,

0

0

0

2

0

,

5

0

0

Engine operation 1 m

Engine oil filter 2 a

Engine operation -

Oil indicator filter 6 m X X X X X X X X X X X X X X X X X X X X X

Centrifugal oil filter 2 a X X X X X X X X X X X X X X X X X X X X X

Fuel filter 2 a X X X X X X X X X X

Engine mounts 1 a X X X X X X X X X X

Belt drive 2 a X X X X X X X

Valve gear 2 a X X X

Air filters 3 a X X X

w = weeks

m = months

a = years

M050733/06E 2013-02 | Maintenance Schedule | 5

T

I

M

-

I

D

:

0

0

0

0

0

2

0

0

1

9

-

0

0

3

Item

L

i

m

i

t

Operating hours [h]

1

0

,

5

0

0

1

1

,

0

0

0

1

1

,

5

0

0

1

2

,

0

0

0

1

2

,

5

0

0

1

3

,

0

0

0

1

3

,

5

0

0

1

4

,

0

0

0

1

4

,

5

0

0

1

5

,

0

0

0

1

5

,

5

0

0

1

5

,

7

5

0

1

6

,

0

0

0

1

6

,

5

0

0

1

7

,

0

0

0

1

7

,

5

0

0

1

8

,

0

0

0

1

8

,

5

0

0

1

9

,

0

0

0

1

9

,

5

0

0

2

0

,

0

0

0

2

0

,

5

0

0

Fuel injectors 9 a X X

Engine governor 9 a X X

Combustion chambers 4 a X X

Crankcase breathers 2 a X X

Turbochargers 18 a X

Component maintenance 9 a X

Engine mounts 5 a X

Fuel delivery pump 9 a X

HP fuel pump 9 a X

Cylinder heads 9 a X

Rubber sleeves 6 a X

Hose lines 6 a

Automatic engine oil filter 6 a

Extended component maintenance 18 a

Turbochargers 18 a

w = weeks

m = months

a = years

21,000-31,000 Operating hours

Item

L

i

m

i

t

Operating hours [h]

2

1

,

0

0

0

2

1

,

5

0

0

2

2

,

0

0

0

2

2

,

5

0

0

2

3

,

0

0

0

2

3

,

5

0

0

2

4

,

0

0

0

2

4

,

5

0

0

2

5

,

0

0

0

2

5

,

5

0

0

2

6

,

0

0

0

2

6

,

2

5

0

2

6

,

5

0

0

2

7

,

0

0

0

2

7

,

5

0

0

2

8

,

0

0

0

2

8

,

5

0

0

2

9

,

0

0

0

2

9

,

5

0

0

3

0

,

0

0

0

3

0

,

5

0

0

3

1

,

0

0

0

Engine operation 1 m

Engine oil filter 2 a

Engine operation -

Oil indicator filter 6 m X X X X X X X X X X X X X X X X X X X X X

Centrifugal oil filter 2 a X X X X X X X X X X X X X X X X X X X X X

Fuel filter 2 a X X X X X X X X X X X

Engine mounts 1 a X X X X X X X X X X X

Belt drive 2 a X X X X X X X

Valve gear 2 a X X X X

Air filters 3 a X X X X

Fuel injectors 9 a X X

Engine governor 9 a X X

Combustion chambers 4 a X X

Crankcase breathers 2 a X X

Turbochargers 18 a X

Component maintenance 9 a X

Engine mounts 5 a X

Fuel delivery pump 9 a X

HP fuel pump 9 a X

Cylinder heads 9 a X

Rubber sleeves 6 a X

Hose lines 6 a X

Automatic engine oil filter 6 a X

w = weeks

m = months

a = years

6 | Maintenance Schedule | M050733/06E 2013-02

T

I

M

-

I

D

:

0

0

0

0

0

2

0

0

1

9

-

0

0

3

Item

L

i

m

i

t

Operating hours [h]

2

1

,

0

0

0

2

1

,

5

0

0

2

2

,

0

0

0

2

2

,

5

0

0

2

3

,

0

0

0

2

3

,

5

0

0

2

4

,

0

0

0

2

4

,

5

0

0

2

5

,

0

0

0

2

5

,

5

0

0

2

6

,

0

0

0

2

6

,

2

5

0

2

6

,

5

0

0

2

7

,

0

0

0

2

7

,

5

0

0

2

8

,

0

0

0

2

8

,

5

0

0

2

9

,

0

0

0

2

9

,

5

0

0

3

0

,

0

0

0

3

0

,

5

0

0

3

1

,

0

0

0

Extended component maintenance 18 a X

Turbochargers 18 a

w = weeks

m = months

a = years

31,500-41,500 Operating hours

Item

L

i

m

i

t

Operating hours [h]

3

1

,

5

0

0

3

2

,

0

0

0

3

2

,

5

0

0

3

3

,

0

0

0

3

3

,

5

0

0

3

4

,

0

0

0

3

4

,

5

0

0

3

5

,

0

0

0

3

5

,

5

0

0

3

6

,

0

0

0

3

6

,

5

0

0

3

6

,

7

5

0

3

7

,

0

0

0

3

7

,

5

0

0

3

8

,

0

0

0

3

8

,

5

0

0

3

9

,

0

0

0

3

9

,

5

0

0

4

0

,

0

0

0

4

0

,

5

0

0

4

1

,

0

0

0

4

1

,

5

0

0

Engine operation 1 m

Engine oil filter 2 a

Engine operation -

Oil indicator filter 6 m X X X X X X X X X X X X X X X X X X X X X

Centrifugal oil filter 2 a X X X X X X X X X X X X X X X X X X X X X

Fuel filter 2 a X X X X X X X X X X

Engine mounts 1 a X X X X X X X X X X

Belt drive 2 a X X X X X X X

Valve gear 2 a X X X

Air filters 3 a X X X

Fuel injectors 9 a X X

Engine governor 9 a X X

Combustion chambers 4 a X X

Crankcase breathers 2 a X X

Turbochargers 18 a X

Component maintenance 9 a X

Engine mounts 5 a X

Fuel delivery pump 9 a X

HP fuel pump 9 a X

Cylinder heads 9 a X

Rubber sleeves 6 a X

Hose lines 6 a

Automatic engine oil filter 6 a

Extended component maintenance 18 a

Turbochargers 18 a

w = weeks

m = months

a = years

42,000-42,000 Operating hours

Item

L

i

m

i

t

Operating hours [h]

4

2

,

0

0

0

Engine operation 1 m

Engine oil filter 2 a

Engine operation -

Oil indicator filter 6 m X

w = weeks

m = months

a = years

M050733/06E 2013-02 | Maintenance Schedule | 7

T

I

M

-

I

D

:

0

0

0

0

0

2

0

0

1

9

-

0

0

3

Item

L

i

m

i

t

Operating hours [h]

4

2

,

0

0

0

Centrifugal oil filter 2 a X

Fuel filter 2 a X

Engine mounts 1 a X

Belt drive 2 a X

Valve gear 2 a X

Air filters 3 a X

Fuel injectors 9 a X

Engine governor 9 a X

Combustion chambers 4 a X

Crankcase breathers 2 a X

Turbochargers 18 a X

Component maintenance 9 a X

Engine mounts 5 a X

Fuel delivery pump 9 a X

HP fuel pump 9 a X

Cylinder heads 9 a X

Rubber sleeves 6 a X

Hose lines 6 a X

Automatic engine oil filter 6 a X

Extended component maintenance 18 a X

Turbochargers 18 a X

w = weeks

m = months

a = years

8 | Maintenance Schedule | M050733/06E 2013-02

T

I

M

-

I

D

:

0

0

0

0

0

2

0

0

1

9

-

0

0

3

1.3 Maintenance tasks

Qualifi-

cation

level

Interval Limit Item Maintenance tasks

O

p

t

i

o

n

Task

[h]

QL1 - 1 m Engine operation Test run at not below 1/3 load and at least until steady-state tempera-

ture is reached (monthly).

W0534

QL1 - 2 a Engine oil filter Fit new engine oil filters each time the engine oil is changed or, at the

latest, on expiry of the time limit (given in years).

W1008

QL1 Daily - Engine operation Check engine oil level. W0500

Carry out visual inspection of engine for general condition and leaks. W0501

Inspect intercooler drain system. X W0502

Inspect service indicator of air filter. W0503

Check relief bores of coolant pump(s). W0505

Check for abnormal running noises, exhaust gas color and vibration. W0506

Drain off water and contamination from fuel prefilter. X W0507

Check differential pressure gauge of fuel prefilter. X W0508

QL1 500 6 m Oil indicator filter Check and clean oil indicator filter. X W1714

QL1 500 2 a Centrifugal oil filter Check thickness of oil residue layer. Clean. Fit new sleeve, at the lat-

est, each time the engine oil is changed.

X W1009

QL1 1000 2 a Fuel filter Fit new fuel filter or new fuel filter insert. W1001

QL1 1000 1 a Engine mounts Carry out visual inspection of engine mounts for general condition. W1463

QL1 1500 2 a Belt drive Inspect condition of drive belts and fit new ones if necessary. Adjust

tension.

W1241

QL1 3000 2 a Valve gear Check valve clearance, adjust if required. ATTENTION! First adjustment

after 1,000 hours.

W1207

QL1 3000 3 a Air filters Fit new air filters. W1005

QL1 5250 9 a Fuel injectors Replace fuel injectors. W1006

QL1 5250 9 a Engine governor Injector: reset drift compensation parameters (CDC). W1713

QL1 5250 4 a Combustion chambers Inspect cylinder chambers using endoscope. W1011

QL1 5250 2 a Crankcase breathers Crankcase breathers: Fit new filters or filter inserts. W1046

QL3 10500 18 a Turbochargers Overhaul turbocharger (MTU-ZR-turbocharger) If Garrett turbocharger,

fit new.

W1388

QL3 10500 9 a Component maintenance Before starting maintenance work, drain the coolant and flush the

cooling systems.

W2000

Inspect rocker arms and valve bridge for wear. Insert an endoscope

through the pushrod bore to visually inspect swing followers and cam-

shaft running surfaces.

W2001

Clean air ducting. W2002

Clean intercooler and inspect for leakage. W2003

Fit new high-pressure fuel sensor. W2004

Check engine coolant thermostat and fit new thermal actuator. W2006

Check charge-air coolant thermostat and fit new thermal actuator. W2007

Overhaul engine coolant preheating system. X W2008

Inspect centrifugal oil filter for wear. X W2009

Overhaul starter. W2010

Fit new seals/sealing materials for all disassembled components. W2062

Overhaul charge-air coolant pump. W2070

Overhaul engine coolant pump. W2110

QL3 10500 5 a Engine mounts Check buffer clearance of resilient mounts Check proper seating of se-

curing screws.

W1026

Check for cracks. Measure cracks if necessary. Measure height of rub-

ber elements.

W1462

w = weeks

m = months

a = years

M050733/06E 2013-02 | Maintenance Schedule | 9

T

I

M

-

I

D

:

0

0

0

0

0

2

0

0

2

0

-

0

0

4

Qualifi-

cation

level

Interval Limit Item Maintenance tasks

O

p

t

i

o

n

Task

[h]

QL3 10500 9 a Fuel delivery pump Fit new fuel delivery pump. W1051

QL3 10500 9 a HP fuel pump Fit new high-pressure fuel pump. W1058

QL3 10500 9 a Cylinder heads Overhaul cylinder heads. W1134

QL3 10500 6 a Rubber sleeves Replace all rubber sleeves. W1250

QL3 21000 6 a Hose lines Replace all hose lines. W1251

QL4 21000 6 a Automatic engine oil filter Remove filter housing and clean. Fit new filter candles. X W1478

QL4 21000 18 a Vibration damper Remove free-end vibration damper, inspect, repair if necessary. W1129

QL4 21000 18 a Extended component mainte-

nance

Completely disassemble the engine. Inspect engine components as

per assembly instructions and repair or fit new components as re-

quired.

W3000

QL4 21000 18 a Extended component mainte-

nance

Replace all elastomeric parts and seals with new ones. W3001

Fit new piston rings. W3002

Fit new conrod bearings. W3003

Fit new crankshaft bearings. W3004

Fit new cylinder liners. W3005

Fit new camshaft bearings and camshaft thrust bearings. W3018

Check gear train for cracks, replace bushings, check axles and replace

if necessary.

W3063

Fit new engine oil pump. W3073

Replace wiring harnesses. W3083

Fit new rubber elements of engine mounts. W3100

Replace turbine wheels of exhaust turbochargers (MTU ZR turbocharg-

er).

W3101

Replace swing followers and swing-follower shafts. W3103

Replace insulated flywheel. X W3140

QL4 42000 18 a Turbochargers Replace compressor wheels of exhaust turbochargers (MTU ZR turbo-

charger).

W1472

w = weeks

m = months

a = years

10 | Maintenance Schedule | M050733/06E 2013-02

T

I

M

-

I

D

:

0

0

0

0

0

2

0

0

2

0

-

0

0

4

Você também pode gostar

- Мануал L33 - new - MS50199 - 01EDocumento16 páginasМануал L33 - new - MS50199 - 01EAleksey100% (1)

- MS15018 01eDocumento162 páginasMS15018 01eاشرينكيل مسونكيلAinda não há avaliações

- Mtu Diesel Engine MS150068 - 01eDocumento287 páginasMtu Diesel Engine MS150068 - 01eM Nuraga Lazuardy Ramadhan100% (1)

- Manual de Operaciones 4000G03Documento217 páginasManual de Operaciones 4000G03Victorina's Delicateses100% (1)

- Mtu 12v4000 Spec Sheet PDFDocumento6 páginasMtu 12v4000 Spec Sheet PDFSomadbsiAinda não há avaliações

- 4016TRG Feature and Benefits - Rev3Documento8 páginas4016TRG Feature and Benefits - Rev3bagusAinda não há avaliações

- Voltage Regulator vr6 - 2Documento20 páginasVoltage Regulator vr6 - 2Manuel Otero0% (1)

- Parts Catalog: EngineDocumento84 páginasParts Catalog: EngineVivek AwasthiAinda não há avaliações

- KTA 19 Parts Catalogue PDFDocumento58 páginasKTA 19 Parts Catalogue PDFArgee PadauanAinda não há avaliações

- QSK60G4Documento4 páginasQSK60G4Mohamed Hamdallah100% (1)

- QSK60 G6 PDFDocumento2 páginasQSK60 G6 PDFShahzad Ali100% (2)

- QSK19G PerformanceDocumento5 páginasQSK19G PerformancetroyAinda não há avaliações

- CURSOR TIER 3 SERIES Industrial Application C87 CURSOR 87 TE XDocumento24 páginasCURSOR TIER 3 SERIES Industrial Application C87 CURSOR 87 TE XAminadavAinda não há avaliações

- 99 MTU 4000 SeriesDocumento6 páginas99 MTU 4000 SeriesMohamed Naser100% (6)

- 4016T 61TRG32250kVA For 50Hz PDFDocumento13 páginas4016T 61TRG32250kVA For 50Hz PDFParinya100% (1)

- AGC-4 Data SheetDocumento30 páginasAGC-4 Data SheetTimAinda não há avaliações

- Dse8610 DiagramDocumento2 páginasDse8610 DiagramEbied Yousif Aly100% (1)

- Technical - Info MTU 20V4000L62Documento7 páginasTechnical - Info MTU 20V4000L62Marvin Tejerina Garfias100% (1)

- Series: 973 - 1327 KWM (Gross) at 1500 RPMDocumento18 páginasSeries: 973 - 1327 KWM (Gross) at 1500 RPMlahcen boudaoudAinda não há avaliações

- Gas Engine TCG 2032 - en PDFDocumento8 páginasGas Engine TCG 2032 - en PDFPankaj Kamble0% (1)

- STC Oil Control Valve (Mechanical) - 5Documento2 páginasSTC Oil Control Valve (Mechanical) - 5Parveen KashyapAinda não há avaliações

- Installation RecommendationsDocumento64 páginasInstallation RecommendationsMdava0% (1)

- PMG PDFDocumento6 páginasPMG PDFrajan_2002eeeAinda não há avaliações

- 1800reozm Specification KohlerDocumento4 páginas1800reozm Specification KohlerTrần Quang TuyênAinda não há avaliações

- Magnetic Pickups and Proximity Switches For Electronic ControlsDocumento18 páginasMagnetic Pickups and Proximity Switches For Electronic ControlsRicardo CalmonAinda não há avaliações

- Installation Conditions: Gas Engine-Generator Sets With Series 400, Series 500, and Series 4000 EnginesDocumento62 páginasInstallation Conditions: Gas Engine-Generator Sets With Series 400, Series 500, and Series 4000 EnginesBen ZithaAinda não há avaliações

- QSV91G Containerized SpecificationDocumento26 páginasQSV91G Containerized SpecificationmackyyoAinda não há avaliações

- KTA50Documento7 páginasKTA50Claudesson Nascimento RodriguesAinda não há avaliações

- Kta50 Gs8 (Advantage)Documento4 páginasKta50 Gs8 (Advantage)Ursula Johnson100% (1)

- 4006-23TRS1&2 Gas EngineDocumento16 páginas4006-23TRS1&2 Gas Enginenanocycle100% (1)

- MarelliGenerator MJB TypeDocumento16 páginasMarelliGenerator MJB Typeสงกรานต์ คันทะเนตรAinda não há avaliações

- C15 Genset SchematicDocumento8 páginasC15 Genset SchematicdubimouAinda não há avaliações

- QSK60 Over Head Valve Setting PerformaDocumento2 páginasQSK60 Over Head Valve Setting PerformaMuhammad Ishfaq100% (1)

- Engine Interface ModuleDocumento3 páginasEngine Interface ModuleAziz ArrahalAinda não há avaliações

- Partsmanual Onan K38-G3 PDFDocumento165 páginasPartsmanual Onan K38-G3 PDFnachoAinda não há avaliações

- Presentation Diesel EngineDocumento29 páginasPresentation Diesel Enginefaizan997Ainda não há avaliações

- Specsheet 3516 1825 kVA PrimeDocumento6 páginasSpecsheet 3516 1825 kVA PrimeYusman EkaAinda não há avaliações

- Operation Maintenance Manual 2206-E13 SEBU8337-00 May 08Documento88 páginasOperation Maintenance Manual 2206-E13 SEBU8337-00 May 08Kornelius David Pattiselanno100% (1)

- Cat Emcp2Documento2 páginasCat Emcp2mahdi100% (2)

- Operating Instructions: Diesel Engine 12 V 4000 T94, T94LDocumento197 páginasOperating Instructions: Diesel Engine 12 V 4000 T94, T94LCristian A.Ainda não há avaliações

- Mitsubishi S6R Lubcation SystemDocumento19 páginasMitsubishi S6R Lubcation SystemHai VanAinda não há avaliações

- MTU White Paper Electronic Engine ManagementDocumento4 páginasMTU White Paper Electronic Engine ManagementDeepak ChachraAinda não há avaliações

- TP 6834Documento48 páginasTP 6834Brandon AtzAinda não há avaliações

- N39453 Issue 7 WebDocumento124 páginasN39453 Issue 7 WebClarence Clar100% (2)

- InteliVision 5 Reference GuideDocumento45 páginasInteliVision 5 Reference Guidexuyen tranAinda não há avaliações

- Product Information: Reference OnlyDocumento4 páginasProduct Information: Reference Onlyjesus silvaAinda não há avaliações

- D110E2Documento2 páginasD110E2Ahmad El KhatibAinda não há avaliações

- IB-NT-1.0 - ManualDocumento34 páginasIB-NT-1.0 - ManualDiego Costa67% (3)

- Operating Instructions: Diesel Engine 12 V 4000 M93 X 16 V 4000 M93 XDocumento223 páginasOperating Instructions: Diesel Engine 12 V 4000 M93 X 16 V 4000 M93 XNaftal MassingueAinda não há avaliações

- STC Oil Control Valve (Mechanical) - 3Documento2 páginasSTC Oil Control Valve (Mechanical) - 3Parveen KashyapAinda não há avaliações

- Mtu 16v4000g63Documento196 páginasMtu 16v4000g63Manuel Perez0% (1)

- 2 G3600 A3 System OperationDocumento67 páginas2 G3600 A3 System Operation巴啦啦Ainda não há avaliações

- 3306 164-200KW PRDocumento4 páginas3306 164-200KW PRvanaselvan vpAinda não há avaliações

- 1600 Series Parts and OverviewDocumento94 páginas1600 Series Parts and OverviewJorge Eraldo Albarran PoleoAinda não há avaliações

- MTU 4000 Maintenance ScheduleDocumento35 páginasMTU 4000 Maintenance Schedulenereomad100% (8)

- 12-16V4000 Gx3 3B Maintenance Schedule MS50005 - 00EDocumento5 páginas12-16V4000 Gx3 3B Maintenance Schedule MS50005 - 00EJuan Carlos Mino Eneque100% (2)

- Plan de Manteniemiento m53 MtuDocumento9 páginasPlan de Manteniemiento m53 MtuNippur de LagashAinda não há avaliações

- Mtu - Technical Documentation: ServiceDocumento7 páginasMtu - Technical Documentation: Servicekarbaran1391Ainda não há avaliações

- Maint Sched 12 or 8 V183 TE93Documento4 páginasMaint Sched 12 or 8 V183 TE93dieseldogwillie100% (2)

- Maintenance ScheduleDocumento12 páginasMaintenance ScheduleVanHoangAinda não há avaliações

- 3B Maintenance MS50005 - 04EDocumento12 páginas3B Maintenance MS50005 - 04ELiya Mahagama100% (2)

- Fuel System DrawingDocumento1 páginaFuel System DrawingLiya MahagamaAinda não há avaliações

- Ad693 RTD A 4-20maDocumento13 páginasAd693 RTD A 4-20maLuis MadrigalAinda não há avaliações

- Avr Newage mx321 PDFDocumento4 páginasAvr Newage mx321 PDFLiya MahagamaAinda não há avaliações

- Current Source ConceptualDocumento3 páginasCurrent Source ConceptualLiya MahagamaAinda não há avaliações

- Current Source ConceptualDocumento3 páginasCurrent Source ConceptualLiya MahagamaAinda não há avaliações

- Ad693 RTD A 4-20maDocumento13 páginasAd693 RTD A 4-20maLuis MadrigalAinda não há avaliações

- Innovator PDFDocumento89 páginasInnovator PDFLiya MahagamaAinda não há avaliações

- SpehroLoopProtect2 PDFDocumento2 páginasSpehroLoopProtect2 PDFLiya MahagamaAinda não há avaliações

- Open Source Whitebox Router PDFDocumento13 páginasOpen Source Whitebox Router PDFtobecaAinda não há avaliações

- Shell Case StudyDocumento9 páginasShell Case StudyAnslem MirandaAinda não há avaliações

- 1 2 3 4 Bro Smart TC Eng PDFDocumento4 páginas1 2 3 4 Bro Smart TC Eng PDFnguyenAinda não há avaliações

- Next Generation Network Addressing SolutionsDocumento318 páginasNext Generation Network Addressing SolutionspvsairamAinda não há avaliações

- V.K FITNESS J SERIES PDFDocumento4 páginasV.K FITNESS J SERIES PDFavik mukherjeeAinda não há avaliações

- BSE SoSDocumento2 páginasBSE SoSALI AHMADAinda não há avaliações

- Fundamentals of Data Structures in C - , 2 - Ellis Horowitz, Sahni, Dinesh MehtaDocumento521 páginasFundamentals of Data Structures in C - , 2 - Ellis Horowitz, Sahni, Dinesh Mehtajely thakkarAinda não há avaliações

- Setting Financial Goals - AssignmentDocumento10 páginasSetting Financial Goals - Assignmentharshita khadayteAinda não há avaliações

- TACCP Risk Assessment Template Checklist - SafetyCultureDocumento4 páginasTACCP Risk Assessment Template Checklist - SafetyCultureNaeemaAinda não há avaliações

- Variabile: Atribuire - Greeting "Hello" Echo $greetingDocumento8 páginasVariabile: Atribuire - Greeting "Hello" Echo $greetingTina CondracheAinda não há avaliações

- TFS Installation GuideDocumento131 páginasTFS Installation GuideSudhakar RaiAinda não há avaliações

- 3FB7Documento7 páginas3FB7fauzan datasheetAinda não há avaliações

- DENON AVR11 Tech Tips Version 2Documento44 páginasDENON AVR11 Tech Tips Version 2Laurentiu ApostolAinda não há avaliações

- Nav1 Eplan2Documento2 páginasNav1 Eplan2Jemar lucidoAinda não há avaliações

- Trango DatasheetDocumento2 páginasTrango Datasheetkhurana1982Ainda não há avaliações

- What Is A Public Information System?Documento19 páginasWhat Is A Public Information System?My SunshineAinda não há avaliações

- Chapter 2. Information Seekers and Electronic EnvironmentsDocumento17 páginasChapter 2. Information Seekers and Electronic EnvironmentsCatalina Echeverri GalloAinda não há avaliações

- History of Electronic SpreadsheetDocumento7 páginasHistory of Electronic SpreadsheetJVAinda não há avaliações

- Wheeled Loader L958FDocumento3 páginasWheeled Loader L958FWidiMufantoAinda não há avaliações

- Action Technological PlanDocumento22 páginasAction Technological PlanMarvin AbaoAinda não há avaliações

- Software For PP / PPK Study Results: Spring Bracket Centre 2171 3240 3304Documento5 páginasSoftware For PP / PPK Study Results: Spring Bracket Centre 2171 3240 3304Gurjeet SinghAinda não há avaliações

- CESGA DTN User Guide: Release 1.0.1Documento25 páginasCESGA DTN User Guide: Release 1.0.1Pop ExpangeaAinda não há avaliações

- Virtualinstrumentation2 150506100543 Conversion Gate01Documento177 páginasVirtualinstrumentation2 150506100543 Conversion Gate01vvipmembersAinda não há avaliações

- Radius: Remote Authentication Dial in User Service (RADIUS) Is A NetworkingDocumento6 páginasRadius: Remote Authentication Dial in User Service (RADIUS) Is A NetworkingVandana SharmaAinda não há avaliações

- Implementing DR Demings Quality PhilosophyDocumento45 páginasImplementing DR Demings Quality PhilosophyDavid del CampoAinda não há avaliações

- CNET324 Fall2010 Exam ReviewDocumento11 páginasCNET324 Fall2010 Exam Reviewmad maranAinda não há avaliações

- Detroit Diesel 50 Engine Tech ManualDocumento2 páginasDetroit Diesel 50 Engine Tech Manualayman akrabAinda não há avaliações

- Internet Access Via Cable TV NetworkDocumento15 páginasInternet Access Via Cable TV Networkankur_desai100% (1)

- Prima Efficiency Across BoundariesDocumento9 páginasPrima Efficiency Across Boundariescosty_transAinda não há avaliações

- Datasheet PDFDocumento2 páginasDatasheet PDFJosemiguel TavarezAinda não há avaliações