Escolar Documentos

Profissional Documentos

Cultura Documentos

SCADA As Heart of Distribution Management System PDF

Enviado por

omar_skt_gnrDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

SCADA As Heart of Distribution Management System PDF

Enviado por

omar_skt_gnrDireitos autorais:

Formatos disponíveis

elect rical-engineering-port al.

com

http://electrical-engineering-portal.com/scada-as-heart-of-distribution-management-system

SCADA The Heart Of Di stri buti on Management System (DMS) - On photo: Fi ma UAB - Dedi cated control systems and

SCADA (Supervi sory Control and Data Acqui si ti on) as wel l as DMS (Di stri buti on Management System) type of systems are

offered for el ectri ci ty, water and gas suppl y compani es, as wel l as tel ecommuni cati on operators and manufacturi ng

compani es.

Edvard

SCADA As Heart Of Distribution Management System

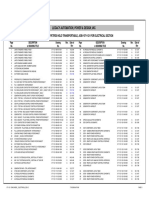

SCADA System Elements

At a high level, the elements of a distribution automation system can be divided into three main areas:

1. SCADA application and server(s)

2. DMS applications and server(s)

3. Trouble management applications and server(s)

Dist ribut ion SCADA

As was stated in the title, the Supervisory Control And Data Acquisition (SCADA) system is the heart of

Distribution Management System (DMS) architecture.

Fi gure 1 - DA system archi tecture

A SCADA system should have all of the inf rastructure elements to support the multif aceted nature of

distribution automation and the higher level applications of a DMS. A Distribution SCADA systems primary

f unction is in support of distribution operations telemetry, alarming, event recording, and remote control of

f ield equipment.

Historically, SCADA systems have been notorious for their lack of support for the import, and more

importantly, the export of power system data values.

A modern SCADA system should support the engineering budgeting and planning f unctions by providing access

to power system data without having to have possession of an operational workstation.

The main elements of a SCADA system are:

1. Host equipment

2. Communication inf rastructure (network and serial communications)

3. Field devices (in sufficient quantity to support operations and telemetry requirements of a DMS platform)

Host

Equipment

The essential elements of a distribution SCADA host are:

1. Host servers (redundant servers with backup/failover capability).

2. Communication f ront-end nodes (network based).

3. Full graphics user interf aces.

4. Relational database server (for archival of historical power system values) and data server/Web server (for

access to near real time values and events).

The elements and components of the typical distribution automation system are illustrated in Figure 1 above.

Host Comput er Syst em

SCADA Servers

As SCADA has proven its value in operation during inclement weather conditions, service restoration, and daily

operations, the dependency on SCADA has created a requirement f or highly available and high performance

systems. Redundant server hardware operating in a live backup/f ailover mode is required to meet the high

availability criteria.

High-perf ormance servers with abundant physical memory, RAID hard disk systems, and interconnected by

10/100 baseT switched Ethernet are typical of todays SCADA servers.

Communicat ion Front -End (CFE) Processors

The current state of host to field device communications still depends heavily on serial communications.

This requirement is f illed by the CFE. The CFE can come in several f orms based on bus architecture (e.g., VME

or PCI) and operating system. Location of the CFE in relation to the SCADA server can vary based on

requirement. In some conf igurations the CFE is located on the LAN with the SCADA server. In other cases,

existing communications hubs may dictate that the CFE reside at the communication hub.

The incorporation of the WAN into the architecture requires a more robust CFE application to compensate f or

less reliable communications (in comparison to LAN).

In general the CFE will include three functional devices:

1. A network/CPU board,

2. Serial cards, and

3. Possibly a time code receiver.

Functionality should include the ability to download conf iguration and scan tables. The CFE should also

support the ability to dead band values (i.e., report only those analog values that have changed by a user-

defined amount).

CFE, network, and SCADA servers should be capable of supporting worst-case conditions (i.e., all points

changing outside of the dead band limits), which typically occur during severe system disturbances.

Full Graphics User Int erf ace

The current trend in the user interface (UI) is toward a full graphics (FG) user interface. While character

graphics consoles are still in use by many utilities today, SCADA vendors are aggressively moving their

platf orms to a f ull graphics UI.

Quite of ten the SCADA vendors have implemented their new f ull graphics user interf ace on low-cost NT

workstations using third-party applications to emulate the X11 window system.

SCADA - Ful l graphi c di spl ay usi ng Vi deo Wal l

Full

graphic

displays

provide

the

ability

to

display

power

system

data

along

with the

electric

distribution f acilities in a geographical (or semigeographical) perspective.

The advantage of using a f ull graphics interf ace becomes evident (particularly for distribution utilities) as SCADA

is deployed beyond the substation f ence where f eeder diagrams become critical to distribution operations.

Relat ional Dat abases, Dat a Servers, and Web Servers

The traditional SCADA systems were poor providers of data to anyone not connected to the SCADA system

by an operational console.

This occurred due to the proprietary nature of the perf ormance (in memory) database and its design

optimization f or putting scanned data in and pushing display values out. Power system quantities such as:

bank and f eeder loading (MW, MWH, MQH, and ampere loading), and bus volts provide valuable inf ormation to

the distribution planning engineer.

The availability of event (log) data is important in postmortem analysis. The use of relational databases, data

servers, and Web servers by the corporate and engineering f unctions provides access to power system

inf ormation and data while isolating the SCADA server f rom nonoperations personnel.

Host t o Field Communicat ions

Serial communications to field devices can occur over several mediums: copper wire, fiber, radio, and even

satellite. Telephone circuits, f iber, and satellites have a relatively high cost. New radio technologies of f er good

communications value.

One such technology is the Multiple Address Radio System (MAS).

The MAS operates in the 900 MHz range and is omnidirectional, providing radio coverage in an area with radius

up to 2025 miles depending on terrain. A single MAS master radio can communicate with many remote sites.

Protocol and bandwidth limit the number of remote terminal units that can be communicated with by a master

radio. The protocol limit is simply the address range supported by the protocol.

Bandwidth limitations can be of f set by the use of ef f icient protocols, or slowing down the scan rate to

include more remote units. Spread-spectrum and point-to-point radio (in combination with MAS) of f ers an

opportunity to address specif ic communication problems.

At the present time MAS radio is pref erred to packet radio (another new radio technology); MAS radio

communications tend to be more deterministic providing f or smaller timeout values on communication

noresponses and controls.

Field Devices

Distribution Automation (DA) field devices are multi-f eatured installations meeting a broad range of control,

operations, planning, and system perf ormance issues f or the utility personnel.

Each device provides specif ic f unctionality, supports system operations, includes f ault detection, captures

planning data and records power quality inf ormation. These devices are f ound in the distribution substation

and at selected locations along the distribution line. The multi-f eatured capability of the DA device increases its

ability to be integrated into the electric distribution system.

The f unctionality and operations capabilities complement each other with regard to the control and

operation of the electric distribution system.

The f ault detection f eature is the eyes and ears f or the operating personnel. The f ault detection capability

becomes increasingly more usef ul with the penetration of DA devices on the distribution line.

The real-time data collected by the SCADA system is provided to the planning engineers f or inclusion in the

radial distribution line studies. As the distribution system continues to grow, the utility makes annual

investments to improve the electric distribution system to maintain adequate f acilities to meet the increasing

load requirements.

The use of the real-time data permits the planning engineers to optimize the annual capital expenditures

required to meet the growing needs of the electric distribution system.

The power quality inf ormation includes capturing harmonic content to the 15th harmonic and recording Percent

Total Harmonic Distortion (%THD). This inf ormation is used to monitor the perf ormance of the distribution

electric system.

Modern RTU

Todays modern RTU is modular in construction with advanced capabilities to support f unctions that

heretof ore were not included in the RTU design.

The modular design supports installation conf igurations ranging f rom the small point count required f or the

distribution line pole-mounted units to the very large point count required f or large bulk-power substations and

power plant switchyard installations.

Modern RTU Scada

The

modern

RTU

modules include analog units with 9 points, control units with 4 control pair points, status units with 16

points, and communication units with power supply.

The RTU installation requirements are met by accumulating the necessary number of modern RTU modules to

support the analog, control, status, and communication requirements f or the site to be automated. Packaging

of the minimum point count RTUs is available f or the distribution line requirement.

The substation automation requirement has the option of installing the traditional RTU in one cabinet with

connections to the substation devices or distributing the RTU modules at the devices within the substation

with f iberoptic communications between the modules.

The distributed RTU modules are connected to a data concentrating unit which in turn communicates with the

host SCADA computer system.

The modern RTU accepts direct AC inputs f rom a variety of measurement devices including line-post

sensors, current transf ormers, potential transf ormers, station service transf ormers, and transducers. Direct

AC inputs with the processing capability in the modern RTU supports f ault current detection and harmonic

content measurements. The modern RTU has the capability to report the magnitude, direction, and duration of

f ault current with time tagging of the f ault event to 1-millisecond resolution. Monitoring and reporting of

harmonic content in the distribution electric circuit are capabilities that are included in the modern RTU.

The digital signal processing capability of the modern RTU supports the necessary calculations to report

%THD f or each voltage and current measurement at the automated distribution line or substation site.

The modern RTU includes logic capability to support the creation of algorithms to meet specif ic operating

needs.

Automatic transfer schemes have been built using automated switches and modern RTUs with the logic

capability. This capability provides another option to the distribution line engineer when developing the method

of service and addressing critical load concerns.

The logic capability in the modern RTU has been used to create the algorithm to control distribution line

switched capacitors f or operation on a per phase basis. The capacitors are switched on at zero voltage

crossing and switched of f at zero current crossing.

The algorithm can be designed to switch the capacitors f or various system parameters, such as voltage,

reactive load, time, etc. The remote control capability of the modern RTU then allows the system operator to

take control of the capacitors to meet system reactive load needs.

The modern RTU has become a dynamic device with increased capabilities. The new logic and input capabilities

are being exploited to expand the uses and applications of the modern RTU.

PLCs and IEDs

Programmable Logic Controller (PLC) and Intelligent Electronic Device (IED) are components of the

distribution automation system, which meet specif ic operating and data gathering requirements.

PLC SCADA Panel

While

there is

some

overlap

in

capability with the modern RTU, the authors are f amiliar with the use of PLCs f or automatic isolation of the

f aulted power transf ormer in a two-bank substation and automatic transf er of load to the unf aulted power

transf ormer to maintain an increased degree of reliability.

The PLC communicates with the modern RTU in the substation to facilitate the remote operation of

the substation facility.

The typical PLC can support serial communications to a SCADA server. The modern RTU has the capability to

communicate via an RS-232 interf ace with the PLC.

IEDs include electronic meters, electronic relays, and controls on specific substation equipment, such as

breakers, regulators, LTC on power transformers, etc.

The IEDs also have the capability to support serial communications to a SCADA server. However, the authors

experience indicates that the IEDs are typically reporting to the modern RTU via an RS-232 interface or via

status output contact points.

As its communicating capability improves and achieves equal status with the f unctionality capability, the IED has

the potential to become an equal player in the automation communication environment.

However, in the opinion of the authors, the limited processing capability f or supporting the

communication requirement, in addition to its f unctional requirements (i.e., relays, meters, etc.), hampers

the widespread use of the IEDs in the distribution automation system.

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- TC3 Kinetmatic TransformationDocumento122 páginasTC3 Kinetmatic TransformationTruong NguyenAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Digital and Industrial ElectronicsDocumento43 páginasDigital and Industrial ElectronicsF. FaiqAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- COUNTERS IN PLC - Portal PDFDocumento88 páginasCOUNTERS IN PLC - Portal PDFAhwangg xGAMINGAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Curriculum Vitae Sample From NTTFDocumento2 páginasCurriculum Vitae Sample From NTTFshaileswor100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- FC Series Add-On Instruction For VLT® EtherNetIP MCA 121 MG92M102Documento14 páginasFC Series Add-On Instruction For VLT® EtherNetIP MCA 121 MG92M102Lisias MouraAinda não há avaliações

- Manual XBC+EconomicStandard+Unit English V1.5 130120 PDFDocumento383 páginasManual XBC+EconomicStandard+Unit English V1.5 130120 PDFSergiu PataAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Agni College of Technology: Office of Examcell Model ExamDocumento3 páginasAgni College of Technology: Office of Examcell Model ExamohmshankarAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- 723 Plus MANUALE INSTALLAZIONE PDFDocumento176 páginas723 Plus MANUALE INSTALLAZIONE PDFMormor OmertaAinda não há avaliações

- Ts-Lng-Lcng-Fuelling StationDocumento19 páginasTs-Lng-Lcng-Fuelling StationAnant RubadeAinda não há avaliações

- DFL Trainees Week 13 ReportDocumento36 páginasDFL Trainees Week 13 ReportMuhammad Bello BabaAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Technical Specifications Wilbur PM2.5Documento2 páginasTechnical Specifications Wilbur PM2.5OscarAinda não há avaliações

- Automated Water Distribution System For Smart City Using PLC and ScadaDocumento4 páginasAutomated Water Distribution System For Smart City Using PLC and ScadaijeteeditorAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Chapter One o Me Dad PLCDocumento38 páginasChapter One o Me Dad PLCHaftamu HailuAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Connect To Any PLC: Approximate TimeDocumento12 páginasConnect To Any PLC: Approximate Timeiosmaris2331Ainda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- 3.1 Factory Acceptance TestingDocumento6 páginas3.1 Factory Acceptance TestingJean-Pierre AwuAinda não há avaliações

- S7-1500 DENSO CommandSlave v12 enDocumento64 páginasS7-1500 DENSO CommandSlave v12 enSaneruAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- SigmaLogic7 Compact HW ManualDocumento46 páginasSigmaLogic7 Compact HW ManualAdamAinda não há avaliações

- CX Programer-Help-Instruction Sets - C-SeriesDocumento8 páginasCX Programer-Help-Instruction Sets - C-SeriesddadaraAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Examples of Mechatronics SystemsDocumento109 páginasExamples of Mechatronics SystemsBettyAinda não há avaliações

- IC-T27 Training Attachment Application (Student Applicant)Documento4 páginasIC-T27 Training Attachment Application (Student Applicant)Lee Ka HoAinda não há avaliações

- 07-1121 DWG Index - Electrical - Rev.cDocumento3 páginas07-1121 DWG Index - Electrical - Rev.cJUAN JOSE VESGA RUEDAAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Md-512-5300-Cn-In-Mst-2003 A01 For Instrument Interlock TestDocumento9 páginasMd-512-5300-Cn-In-Mst-2003 A01 For Instrument Interlock Testsarsan nedumkuzhi maniAinda não há avaliações

- DocumentDocumento38 páginasDocumentprabhu rachutiAinda não há avaliações

- Sequential Function ChartDocumento26 páginasSequential Function ChartOswaldo Rojas GoveaAinda não há avaliações

- Training Institute ScheduleDocumento1 páginaTraining Institute ScheduleAminul Hoque MamunAinda não há avaliações

- GEH-6721 Vol IDocumento202 páginasGEH-6721 Vol Ivishnu ramkaran100% (1)

- Hardware Manual: JY997D53401FDocumento4 páginasHardware Manual: JY997D53401FJose LunaAinda não há avaliações

- Solidworks Product Matrix 2018Documento6 páginasSolidworks Product Matrix 2018Shishir DwivediAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- 9276 K IF INS651 00001 - Rev A04Documento98 páginas9276 K IF INS651 00001 - Rev A04Sandip SurAinda não há avaliações

- 1766 rm001 - en PDocumento668 páginas1766 rm001 - en PtestnotificationAinda não há avaliações