Escolar Documentos

Profissional Documentos

Cultura Documentos

Data 3863 CR Motores PDF

Enviado por

Raul CruzTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Data 3863 CR Motores PDF

Enviado por

Raul CruzDireitos autorais:

Formatos disponíveis

Edition 2012 May 10

DC-Micromotors

Graphite Commutation

150 mNm

For combination with

Gearheads:

38/1(S), 38/2(S), 38A, 44/1

Encoders:

HEDL 5540, HEDM 5500, HEDS 5500, HEDS 5540,

IE2-1024, IE2-16, IE3-1024(L)

Series 3863 ... CR

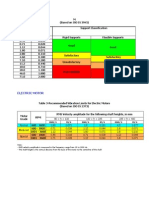

3863 H 012 CR 018 CR 024 CR 036 CR 048 CR

1 Nominal voltage UN 12 18 24 36 48 V

2 Terminal resistance R 0,16 0,36 0,64 1,55 2,58

3 Output power P2 max. 205 211 214 201 217 W

4 Efciency, max. h max. 83 84 85 86 86 %

5 No-load speed n0 5 600 5 900 5 800 5 800 5 800 rpm

6 No-load current (with shaft 6 mm) I0 0,335 0,232 0,168 0,112 0,084 A

7 Stall torque MH 1 424 1 394 1 455 1 363 1 461 mNm

8 Friction torque MR 6,5 6,5 6,5 6,5 6,5 mNm

9 Speed constant kn 480 332 240 160 120 rpm/V

10 Back-EMF constant kE 2,08 3,01 4,17 6,25 8,33 mV/rpm

11 Torque constant kM 19,9 28,8 39,8 59,8 79,7 mNm/A

12 Current constant kI 0,05 0,035 0,025 0,017 0,013 A/mNm

13 Slope of n-M curve Dn/DM 3,9 4,1 3,9 4,1 3,9 rpm/mNm

14 Rotor inductance L 45 90 180 400 700 H

15 Mechanical time constant t m 4,8 4,8 4,8 4,8 4,7 ms

16 Rotor inertia J 120 110 120 110 115 gcm

17 Angular acceleration a max. 119 127 121 124 127 10rad/s

18 Thermal resistance Rth 1 / Rth 2 2,5 / 6 K/W

19 Thermal time constant t w1 / t w2 50 / 900 s

20 Operating temperature range:

motor -30 ... +125 C

rotor, max. permissible +155 C

21 Shaft bearings ball bearings, preloaded

22 Shaft load max.:

with shaft diameter 6 mm

radial at 3 000 rpm (3 mm from bearing) 60 N

axial at 3 000 rpm 6 N

axial at standstill 50 N

23 Shaft play

radial 0,015 mm

axial = 0 mm

24 Housing material steel, black coated

25 Weight 390 g

26 Direction of rotation clockwise, viewed from the front face

Recommended values - mathematically independent of each other

27 Speed up to ne max. 8 000 8 000 8 000 8 000 8 000 rpm

28 Torque up to

1)

Me max. 120 150 157 153 159 mNm

3863 H ... CR 3863 A ... CR

A

0,02

0,04 A

6x

3

0,3 A

M3

3 x 2,75 2,8

64

1

38

1,1

14,8

22,8 2,2

250,3 17,50,5

16

-0,004

-0,010 6 15

22

6

-0,004

-0,010

7

11,50,5

2,8

3,5

90,4

1,5

60 6x

-0,025

0

-0,1

0

-0,02

0 -0,03

-0,11 11,6

0,04

0,07 A

DIN 58400

m=0,5

z=21

5

27,5

0,5

deep

Orientation with respect to motor

terminals not dened

Scale reduced

deep

for Faston connector

2,8 x 0,5

25 for screw M3 DIN 7500

1)

thermal resistance Rth 2 by 55% reduced

For notes on technical data and lifetime performance

refer to Technical Information.

DR. FRITZ FAULHABER GMBH & CO. KG

Specications subject to change without notice.

Page 1/2 www.faulhaber.com

Edition 2012 May 10

For notes on technical data and lifetime performance

refer to Technical Information.

DR. FRITZ FAULHABER GMBH & CO. KG

Specications subject to change without notice.

Page 2/2

Note:

The left portion of the diagram indicates the

recommended area of motor operation for continuous

duty in a thermally insulated condition (not mounted)

at room temperature 22C.

The right portion of the diagram indicates the possible

area of operation if the motor is cooled (ex. R

th2

-55%)

by mounting or ambient air ow conditions.

The diagram indicates the area of continuous operation

for maximum lifetime performance of the motor.

The motor can be driven intermittently outside of the

recommended area of operation. Please consult your

local product representative for more information.

The nominal voltage curve (U

N

) shows the operating

points at nominal voltage. Any points of operation

above the curve will require a higher operating voltage,

points below will require less voltage.

Recommended areas for continuous operation

U

N

M [mNm]

n [rpm]

140 160 120 100 80 60 40 20 0

Watt

120 90 60 30

1 000

0

3 000

2 000

4 000

5 000

6 000

7 000

8 000

9 000

3863 ... CR

3863 ... CR (Rth2 -55%)

www.faulhaber.com

Você também pode gostar

- VIBDI skriptaEN PDFDocumento114 páginasVIBDI skriptaEN PDFЖивко ОрешковAinda não há avaliações

- 121a45 PDFDocumento51 páginas121a45 PDFImran AhmadAinda não há avaliações

- Result Vibration Analysis: Picture MachineDocumento2 páginasResult Vibration Analysis: Picture Machinefelix haryokoAinda não há avaliações

- Principle of Acceleration SensorsDocumento7 páginasPrinciple of Acceleration SensorsEr Vijay MamoriaAinda não há avaliações

- ABB Nema MotorDocumento44 páginasABB Nema MotorAlejandroInostrozaAinda não há avaliações

- Standard VibrationsDocumento1 páginaStandard VibrationsSeto M. PramonoAinda não há avaliações

- Cirkan ZsDocumento1 páginaCirkan ZsbilalAinda não há avaliações

- Dacnis SH 68 TdsDocumento1 páginaDacnis SH 68 TdsMedo MedooAinda não há avaliações

- Electrical Diagnostic Check ListDocumento1 páginaElectrical Diagnostic Check ListSergiSerranoAinda não há avaliações

- Vibration Severity - IsO 2372 ChartDocumento4 páginasVibration Severity - IsO 2372 ChartJagga RaoAinda não há avaliações

- Spike Sorting TutorialDocumento25 páginasSpike Sorting Tutorialtiger05Ainda não há avaliações

- AzimaDLI Severity Chart 2013 PDFDocumento1 páginaAzimaDLI Severity Chart 2013 PDFEswin Paico de la CruzAinda não há avaliações

- Nevada Reports 1992 (108 Nev.) PDFDocumento1.028 páginasNevada Reports 1992 (108 Nev.) PDFthadzigsAinda não há avaliações

- Carter EpDocumento1 páginaCarter EpNguyễn Quang HưngAinda não há avaliações

- DatasheetDocumento7 páginasDatasheetTrọng Vỹ TrươngAinda não há avaliações

- Catalog - Rotating Electrical MachinesDocumento24 páginasCatalog - Rotating Electrical MachinesAshhAlexAinda não há avaliações

- Engr. Simon Mills Developing An ISO For Gearbox Vibration MonitoringDocumento27 páginasEngr. Simon Mills Developing An ISO For Gearbox Vibration MonitoringKaradiasAinda não há avaliações

- Anomalert Motor Anomaly Detector Datasheet-286754k WWW - Ihi.clDocumento12 páginasAnomalert Motor Anomaly Detector Datasheet-286754k WWW - Ihi.clBraian GomezAinda não há avaliações

- Vibration Application DataDocumento44 páginasVibration Application DataSaurabh PanditAinda não há avaliações

- Thatta Cement Company Limited: Daily Vibration / Temperature Report of Main EquipmentDocumento4 páginasThatta Cement Company Limited: Daily Vibration / Temperature Report of Main Equipmentzain140Ainda não há avaliações

- Vibration Question PapersDocumento21 páginasVibration Question PapersÀbhí Sàráf100% (1)

- Visga 68Documento2 páginasVisga 68cajascAinda não há avaliações

- SCOUT140EX Vibration Data Collector Datasheet 323330 PDFDocumento9 páginasSCOUT140EX Vibration Data Collector Datasheet 323330 PDFShouqi ErmanAinda não há avaliações

- SKF 6402 EN 11 10 19 GB High TCM 12-55843Documento60 páginasSKF 6402 EN 11 10 19 GB High TCM 12-55843AlvaroAinda não há avaliações

- vb8 DatasheetDocumento9 páginasvb8 DatasheetPedro Gabriel González GarcíaAinda não há avaliações

- Makes and ModelsDocumento14 páginasMakes and ModelsJuan Pablo Chavez IxtepanAinda não há avaliações

- Detailed of Power Calculation of RBS and Other EquipmentDocumento7 páginasDetailed of Power Calculation of RBS and Other EquipmentWasisAinda não há avaliações

- Catalog New Motor 1LG0Documento40 páginasCatalog New Motor 1LG0bajricaAinda não há avaliações

- Screw CompressorDocumento2 páginasScrew CompressorRiti AdhikariAinda não há avaliações

- Compressor - 101Documento66 páginasCompressor - 101Juan Pablo Chavez IxtepanAinda não há avaliações

- Especificación Técnica: Espesador de RelavesDocumento17 páginasEspecificación Técnica: Espesador de RelavesAlexis GodoyAinda não há avaliações

- Motor Analysis Techniques: 2 November 2017Documento48 páginasMotor Analysis Techniques: 2 November 2017Anonymous PVXBGg9TAinda não há avaliações

- Size Reduction EquipmentDocumento7 páginasSize Reduction Equipmentcimbom_cimbomAinda não há avaliações

- Turbo Gears of G SeriesDocumento4 páginasTurbo Gears of G SeriesrisegraAinda não há avaliações

- System 1: Optimization and Diagnostics SoftwareDocumento14 páginasSystem 1: Optimization and Diagnostics SoftwareAndy Kong KingAinda não há avaliações

- Vibration Formula ScribDocumento2 páginasVibration Formula ScribiulianstoicaAinda não há avaliações

- Ac Induction Motor Data Sheet: General Specification Performance DataDocumento2 páginasAc Induction Motor Data Sheet: General Specification Performance DataBhavik PrajapatiAinda não há avaliações

- Vibration Monitoring Rev.Documento42 páginasVibration Monitoring Rev.Abdurrhman AlzhraniAinda não há avaliações

- Laser Alignment Systems For Shafts, Turbines, and MachinesDocumento16 páginasLaser Alignment Systems For Shafts, Turbines, and MachinesMarcosAinda não há avaliações

- EM 81 - Pump Vibrations Part IIDocumento2 páginasEM 81 - Pump Vibrations Part IIΡαφαηλ Καμ.100% (1)

- Model 3741E1210G DC Response Accelerometer Installation and Operating ManualDocumento16 páginasModel 3741E1210G DC Response Accelerometer Installation and Operating ManualfazzlieAinda não há avaliações

- AS 4171-1994 Rolling Bearings - Static Load Ratings PDFDocumento5 páginasAS 4171-1994 Rolling Bearings - Static Load Ratings PDFSAI Global - APACAinda não há avaliações

- Test Equipment Buyers GuideDocumento29 páginasTest Equipment Buyers GuideMojoshe MonasheAinda não há avaliações

- IS-9178 Part1 PDFDocumento29 páginasIS-9178 Part1 PDFShamik ChowdhuryAinda não há avaliações

- Bently Nevada Services Support Fact SheetDocumento2 páginasBently Nevada Services Support Fact SheetFaruk IbisevicAinda não há avaliações

- Software Operational Manual: Hybrid Servo Drive HBS57/86/86HDocumento25 páginasSoftware Operational Manual: Hybrid Servo Drive HBS57/86/86Hhuutan12345Ainda não há avaliações

- Dm200 CatalogDocumento6 páginasDm200 CatalogAS_865025438Ainda não há avaliações

- Product: Torsional Vibration Meter - Type 2523Documento4 páginasProduct: Torsional Vibration Meter - Type 2523jhon vargas100% (1)

- 96-vfd Torsional - Turbo 2008 PDFDocumento12 páginas96-vfd Torsional - Turbo 2008 PDFwaj1Ainda não há avaliações

- EIT IDC Machinery Vibration Rev5Documento26 páginasEIT IDC Machinery Vibration Rev5nabil160874Ainda não há avaliações

- (Dd0eff91 8517 432e A0db D39ed010873e) - Data Sheet Id FanDocumento16 páginas(Dd0eff91 8517 432e A0db D39ed010873e) - Data Sheet Id FanRajendra NinganuriAinda não há avaliações

- Vibration Test Engineer Resume ExampleDocumento2 páginasVibration Test Engineer Resume ExampleJavier BarreraAinda não há avaliações

- Ac Motor Data SheetDocumento2 páginasAc Motor Data SheetelakiyaAinda não há avaliações

- Centrifugal Pump ImpellerDocumento1 páginaCentrifugal Pump ImpellerksAinda não há avaliações

- Electric Motor: Satisfactory UnsatisfactoryDocumento2 páginasElectric Motor: Satisfactory UnsatisfactoryZuli HarismanAinda não há avaliações

- Field Alignment Kit: Hardware ManualDocumento12 páginasField Alignment Kit: Hardware ManualAnonymous dPyHoLAinda não há avaliações

- T19101 118Documento18 páginasT19101 118Chintan Raval100% (1)

- Nico International: Hazards Identification & Risk AssessmentDocumento4 páginasNico International: Hazards Identification & Risk AssessmentkazishahAinda não há avaliações

- 19-3995 Rev2 SPX - Mixer Quotation For Ramani Investment LTD TanzaniaDocumento8 páginas19-3995 Rev2 SPX - Mixer Quotation For Ramani Investment LTD TanzaniaPhillip PhiriAinda não há avaliações

- En 3274 BP4 DFFDocumento2 páginasEn 3274 BP4 DFFBruteforcea BruteforcebAinda não há avaliações

- MotorDocumento48 páginasMotorHernan CuevasAinda não há avaliações

- UntitledDocumento6 páginasUntitledMohamed ShukryAinda não há avaliações

- Ball Bearing Nom PDFDocumento1 páginaBall Bearing Nom PDFramanshriAinda não há avaliações

- Constant Mesh Manual Transmission Gear BoxDocumento33 páginasConstant Mesh Manual Transmission Gear BoxBirhanu AsfawAinda não há avaliações

- Carga Recomendada RodamientosDocumento4 páginasCarga Recomendada RodamientosFrancisco TorresAinda não há avaliações

- Project Report On NBCDocumento49 páginasProject Report On NBCamaramar511Ainda não há avaliações

- SMD Axially Split Casing, Double Suction PumpDocumento8 páginasSMD Axially Split Casing, Double Suction PumpdonestebAinda não há avaliações

- C0319 Frame 3 Rolling Element Bearing Replacement-MARUMADocumento8 páginasC0319 Frame 3 Rolling Element Bearing Replacement-MARUMAANGEL MURILLOAinda não há avaliações

- Lab Experiments (Report)Documento110 páginasLab Experiments (Report)Mahmoud Kassab100% (1)

- Z5150ADocumento83 páginasZ5150AmkpqAinda não há avaliações

- LM THKDocumento32 páginasLM THKSachin ChalkeAinda não há avaliações

- Bearing LayoutDocumento30 páginasBearing LayoutmayasfaresAinda não há avaliações

- Tesla Turbine TechnicalsDocumento947 páginasTesla Turbine TechnicalsRubens Stuginski Jr100% (2)

- Rodajes Miniatura NSKDocumento41 páginasRodajes Miniatura NSKenicolas2Ainda não há avaliações

- IBC Precision LocknutsDocumento12 páginasIBC Precision LocknutsTUĞÇE ÖZGEN GENÇAinda não há avaliações

- Dunlop Catalog SimulationDocumento24 páginasDunlop Catalog SimulationhouseAinda não há avaliações

- Machine Design Ball Screw Vol 1 e BookDocumento22 páginasMachine Design Ball Screw Vol 1 e Bookविशाल पुडासैनीAinda não há avaliações

- Catb2001e C PDFDocumento33 páginasCatb2001e C PDFCarlos De OrnelasAinda não há avaliações

- Bearing NotesDocumento132 páginasBearing NotesSarvagnaMNAinda não há avaliações

- Bishamon UniLift Exploded View Parts ListDocumento14 páginasBishamon UniLift Exploded View Parts Listarun vk100% (1)

- Internal Freewheels FZ : With Ball Bearing PropertiesDocumento6 páginasInternal Freewheels FZ : With Ball Bearing Propertiesmohammed kareemAinda não há avaliações

- Workshop Manual Triumph Speed Triple 1050-3-2005Documento379 páginasWorkshop Manual Triumph Speed Triple 1050-3-2005Thunderbird390% (21)

- Alternator (Bus) Mercedes OM 926 LA: (Europa) (Engine)Documento12 páginasAlternator (Bus) Mercedes OM 926 LA: (Europa) (Engine)Karthii AjuAinda não há avaliações

- Turbine Gas Meter Series iMTM-Q: Fit For Purpose, Fit For Future by InnovationDocumento4 páginasTurbine Gas Meter Series iMTM-Q: Fit For Purpose, Fit For Future by InnovationaliAinda não há avaliações

- Bearing Tolerances Bearing TolerancesDocumento11 páginasBearing Tolerances Bearing TolerancesAndrew LiebermannAinda não há avaliações

- E728g PDFDocumento155 páginasE728g PDFMai Thế ToanAinda não há avaliações

- Automatic Stair Climbing WheelchairDocumento48 páginasAutomatic Stair Climbing WheelchairInternational Journal of Innovative Science and Research TechnologyAinda não há avaliações

- Pumps-Yantai Gemsun Import and Export Co,.LtdDocumento21 páginasPumps-Yantai Gemsun Import and Export Co,.LtdZahid LatifAinda não há avaliações